Patents

Literature

106results about How to "Improve binding quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gluing and binding machine

InactiveCN1370689AThe whole machine is in stepSimple structureBook making processesBookbinding adhesiveSprayerEngineering

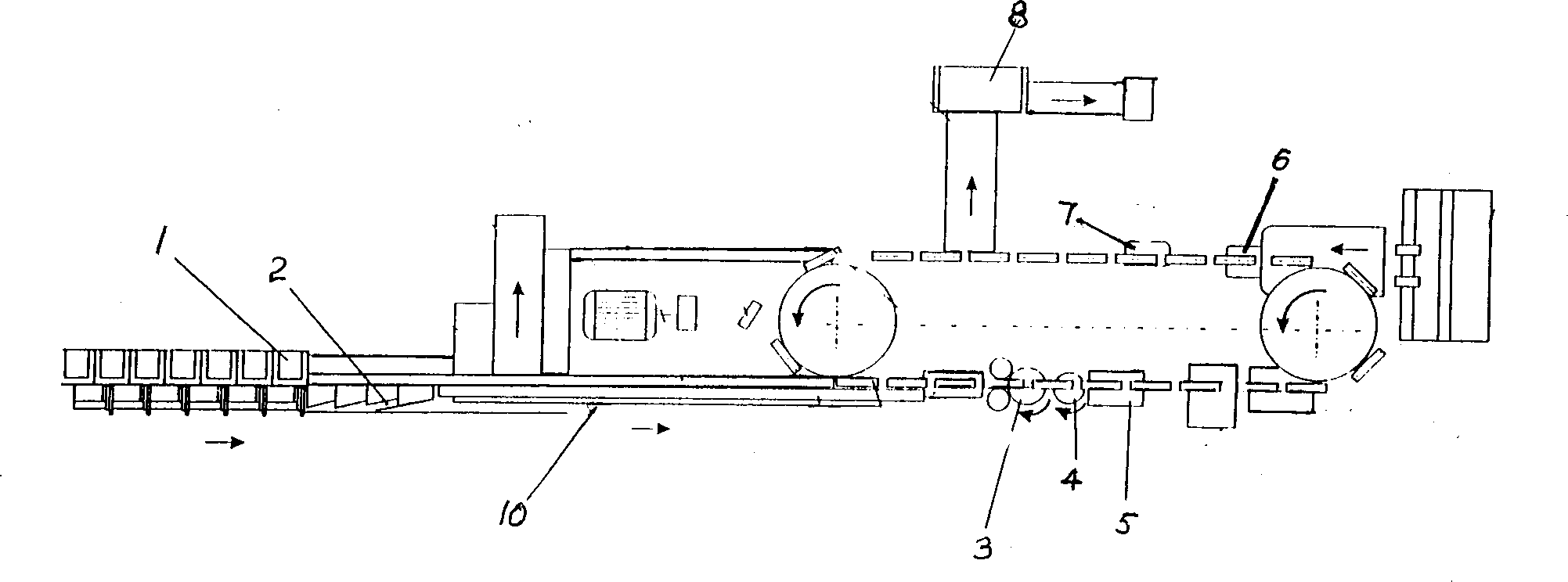

The present invention relates to the field of printing equipment technodlogy. The gluing and binding machine includes page distributing mechanism, cover page conveying mechanism, vibrating and tidying mechanism and gluing and binding formation mechanism combined by a conveying belt into an integral and controlled by a programmed controller. The page distributing mechanism comsists of one or more page distributing conveying belts and several paper suckers; the cover page conveying mechanism consists of paper sucking and impressing wheel; the vibrating and tidying mechanism consists of vibrating cylinder driven paper sucking disc; and the gluing and binding formation mechanism consists of chain driven by chain wheel, support board, paper preheater, glue sprayer and setter.

Owner:贾永康

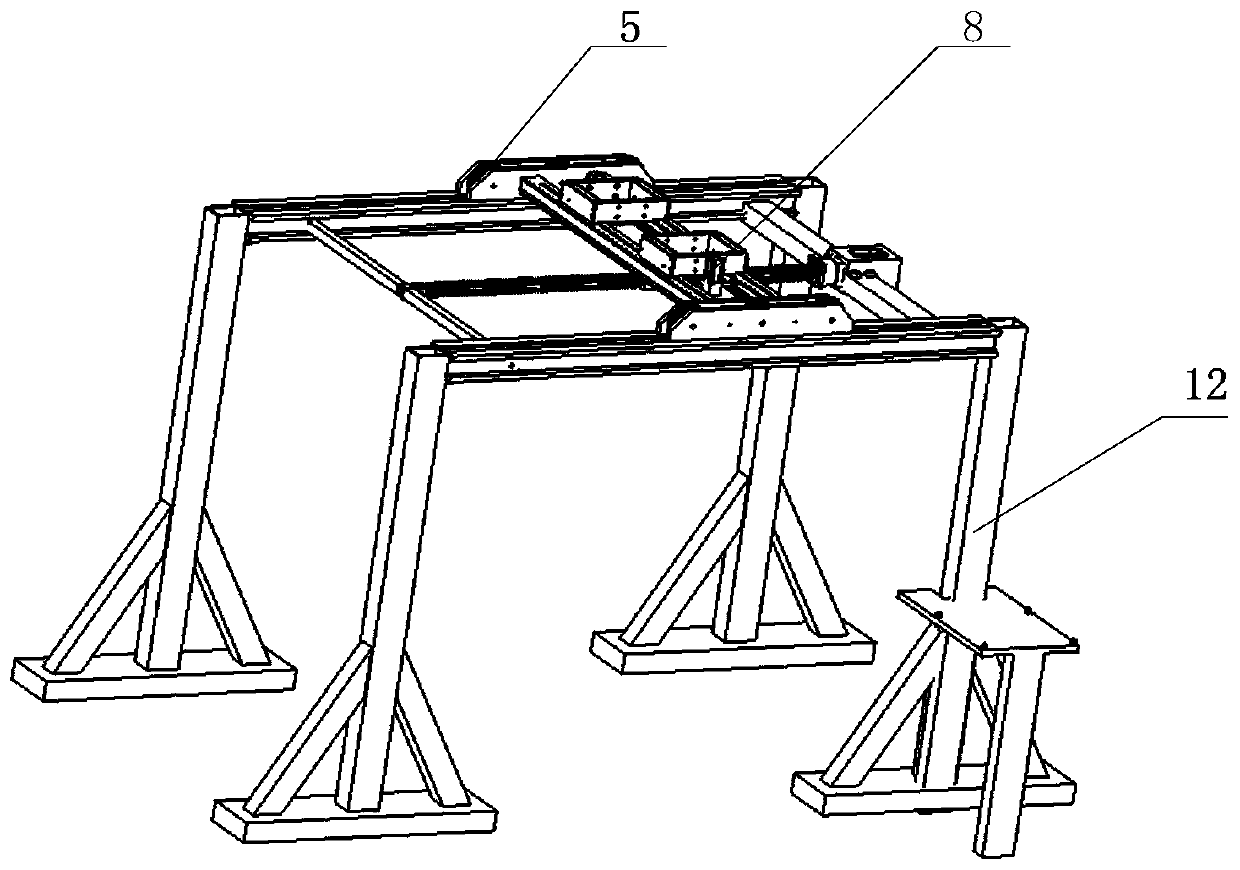

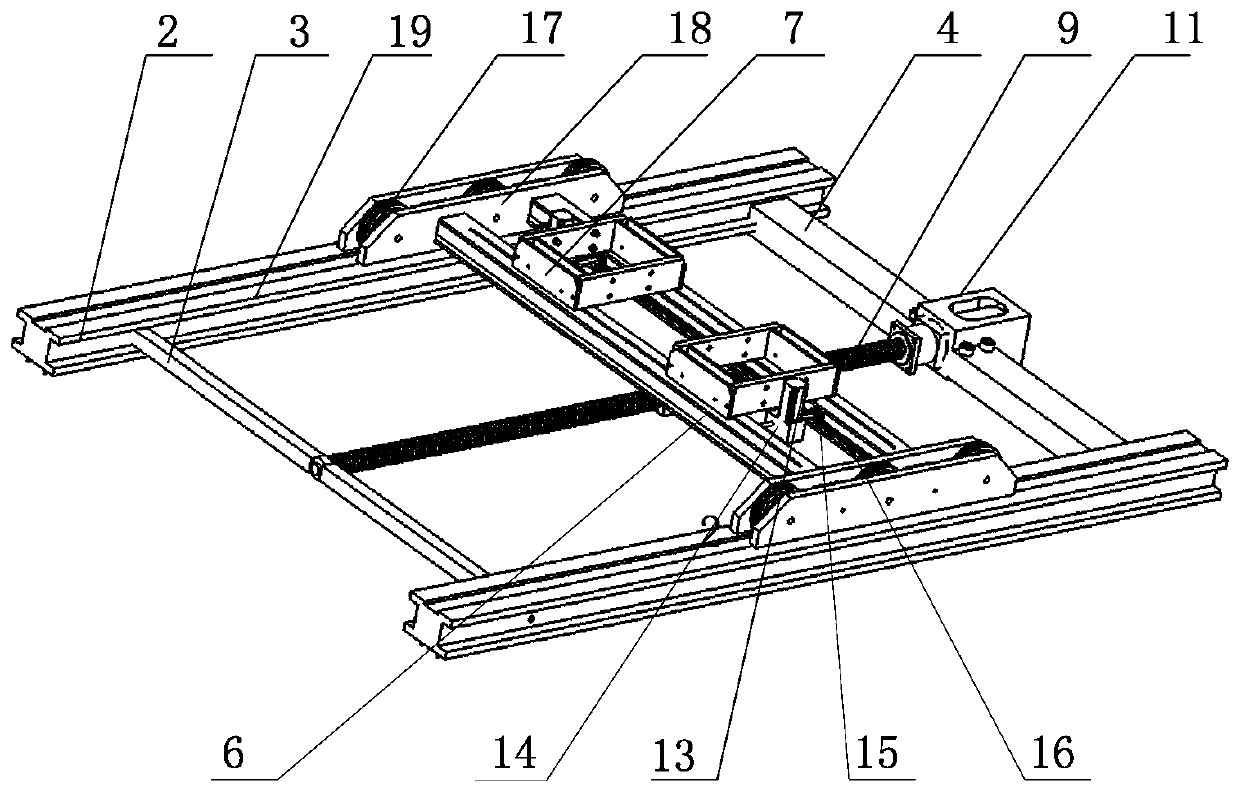

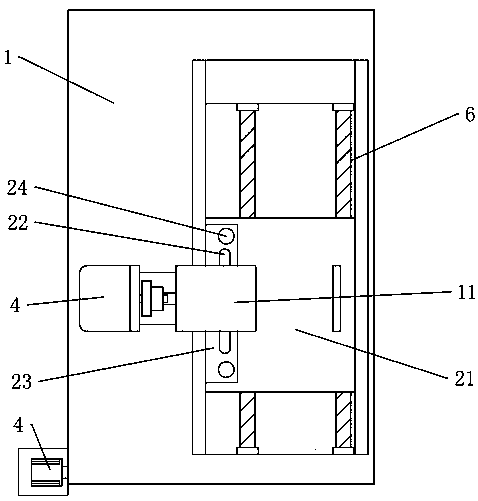

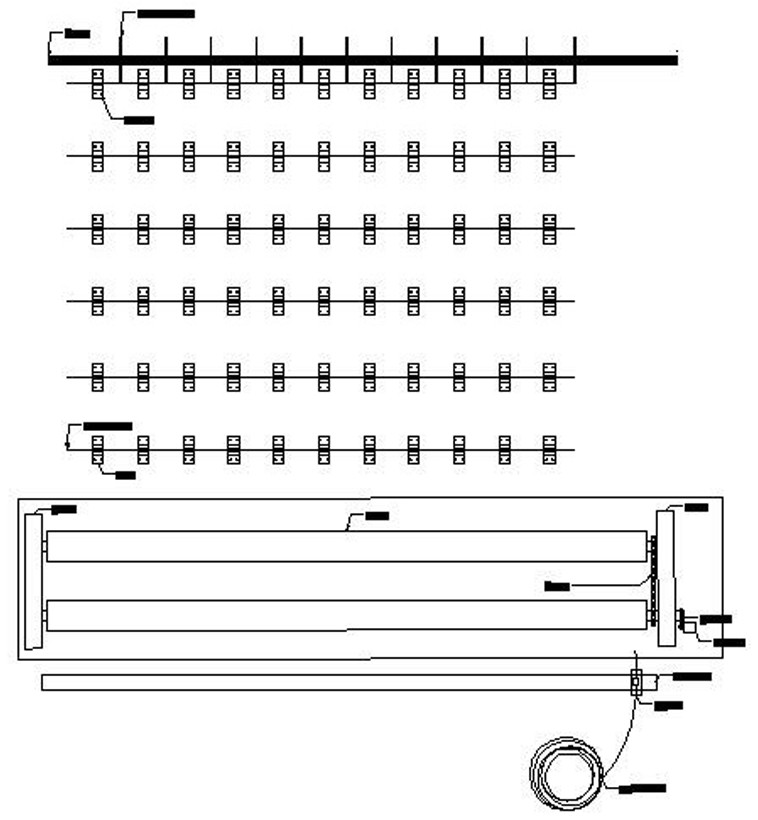

Precast concrete unit reinforcing steel bar binding machine

PendingCN110815544AHigh degree of automationReduce labor intensityCeramic shaping apparatusMesh reinforcementArchitectural engineering

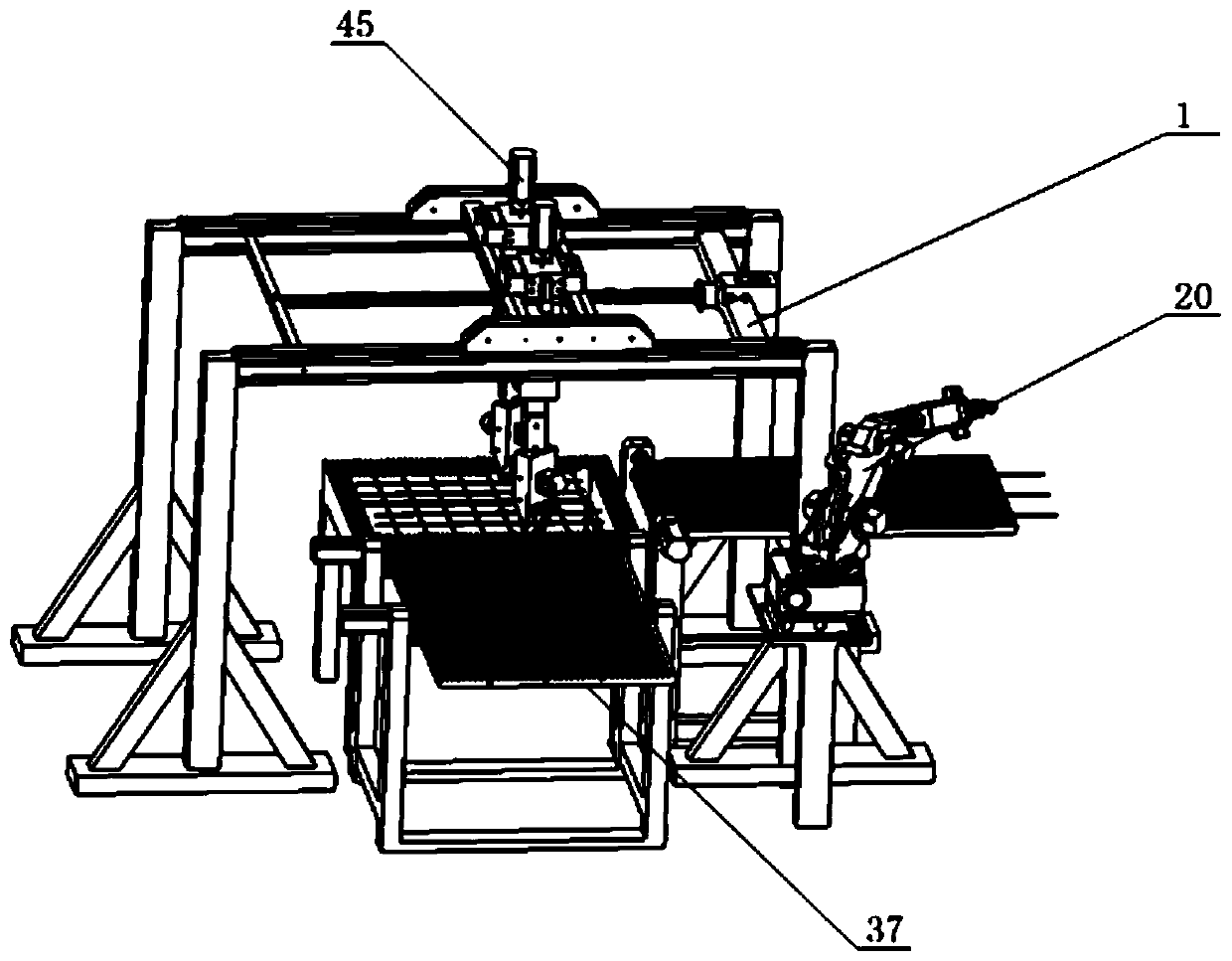

The invention belongs to the technical field of construction machinery equipment, and particularly relates to a precast concrete unit reinforcing steel bar binding machine which comprises a body framemechanism, a reinforcing steel bar grabbing mechanism, a reinforcing steel bar conveying mechanism and a full-automatic binding mechanism. The body frame mechanism comprises transverse beams, a thinrod, a thick rod, transverse beam auxiliary wheel parts, longitudinal beams, longitudinal beam connecting plates, longitudinal beam driving parts, a transverse beam lead screw, a screw nut, a transverse beam lead screw motor and supporting rods. The reinforcing steel bar grabbing mechanism comprises a mechanical arm base, a worm gear case, a worm motor, a mechanical arm, a driving cylinder and a mechanical claw. The reinforcing steel bar conveying mechanism comprises a reinforcing mesh binding platform, conveying supporting frames, long reinforcing steel bar conveying rails, short reinforcingsteel bar conveying rails, long wheel motors and long wheels. The precast concrete unit reinforcing steel bar binding machine is high in automation degree and binding quality.

Owner:TIANJIN CHENGJIAN UNIV

Full-automatic stapler

The invention discloses a full-automatic stapler which comprises a first base. The upper surface of the first base is connected with the lower ends of four guide rods which are symmetrically arranged at the four corners of the first base; a nail box is arranged on the upper portion of the first base; side plates are arranged on the left side and the right side of the nail box; a nail pressing plate is arranged on the upper portion of the nail box; a top plate is arranged on the upper portion of the nail pressing plate; the upper ends of the guide rods sequentially penetrate through the side plates and the nail pressing plate and are connected with the lower surface of the top plate; the side plates and the nail pressing plate are all slidably connected with the guide rods; first springs are arranged between the lower surfaces of the side plates and the upper surface of the first base; and the first springs are wound on the surfaces of the guide rods. According to the full-automatic stapler, using is convenient, the bookbinding speed is increased, double hands of a stapler user are free, hand fatigue caused by long-time use is effectively avoided, the situation that due to insufficient pressing force, stapling nails cannot completely penetrate through paper is avoided, the pressing force is uniform, and the bookbinding quality is improved.

Owner:金可欣

Material binding device for industrial design

InactiveCN109693465AReasonable structureInnovative designSheet bindingIndustrial engineeringBinding process

The invention discloses a material binding device for industrial design, and belongs to the technical field of industrial design. The material binding device for the industrial design comprises supporting legs and a supporting platform fixed at the upper ends of the supporting legs, a rotating shaft is installed between the supporting legs, a driving gear is installed in the middle of the rotatingshaft, a crank is installed in the middle of the left end of the rotating shaft, a sliding sleeve is installed in the middle of the crank, the sliding sleeve is connected with a pedal through a connecting rod, a fixing barrel is installed in the middle of the supporting platform, a lead screw is installed in the fixing barrel, a lifting mechanism is installed in the middle of the lead screw through an inner threaded hole, rotating rods are connected to the two ends of the lifting mechanism through pulling rods, pressing blocks are fixed to the top ends of the rotating rods, the bottom ends ofthe rotating rods are connected with fixing blocks in a hinged mode, the fixing blocks are fixed to the two sides of the upper end of the supporting platform, and the bottom end of the lead screw penetrates through the fixing barrel and is connected with the driving gear. According to the material binding device for industrial design, efficient fixing to the industrial design material is realized, protrusion or sinking in the binding process are avoided, the binding quality is increased, only hand and foot force is needed in the binding process, and the operation is easy.

Owner:李瑞

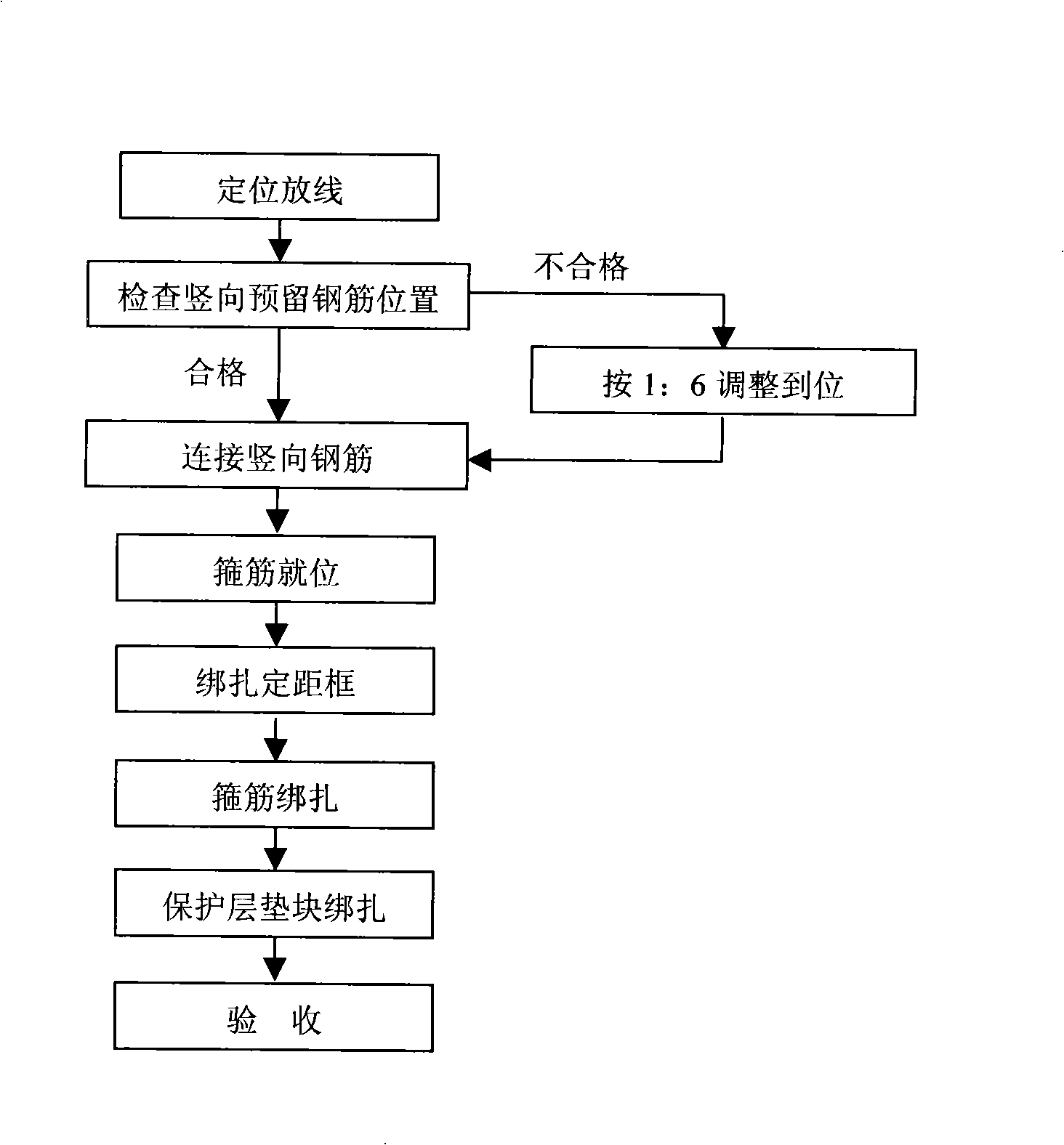

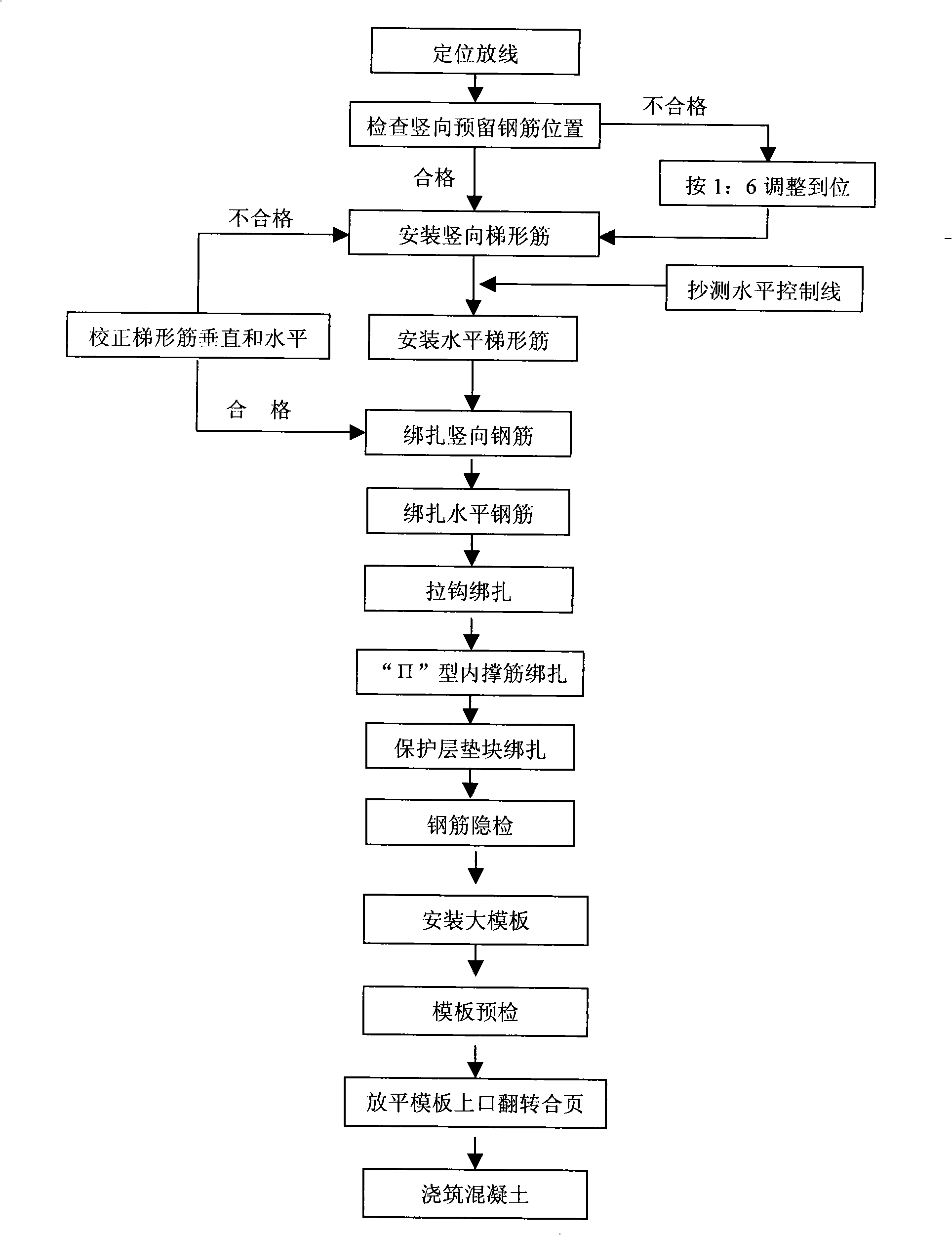

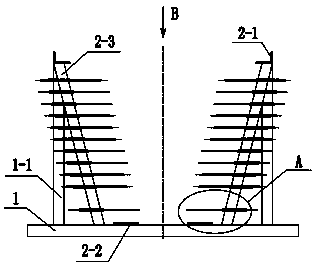

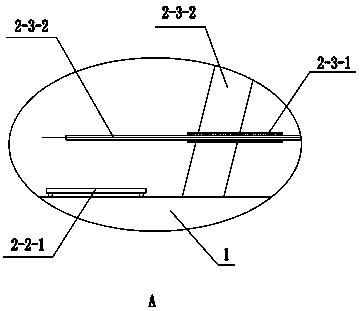

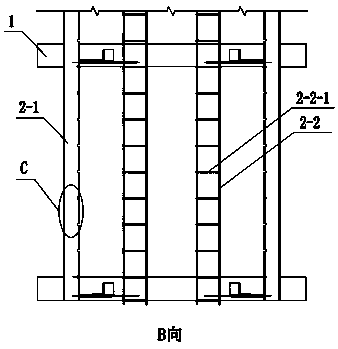

Method for binding high-layer shear force wall reinforcing steel bar

InactiveCN101353920AReduce the ratioImprove protectionBuilding reinforcementsReinforced concreteSteel bar

The invention discloses a steel bar bonding method of a shearing wall of a high-rise building, which relates to the technical filed of building engineering, in particular to the technical field of steel bar bonding in the construction of the shearing wall of the high-rise building. The method comprises ordinal steps of bonding a vertical ladder steel bar, bonding a horizontal ladder steel bar, bonding the vertical steel bars of a wall body and boding the horizontal steel bars of the wall body; the vertical ladder steel bar consists of two vertical steel bars and a plurality of horizontal steel bars; the horizontal ladder steel bar consists of two vertical steel bars and a plurality of horizontal steel bars; and the horizontal ladder steel bar is disassembled after concrete is poured. The method has easy operation and promotion, reduces the proportion of skillful workers, raises assembly speed, improves labor productivity, can effectively control the interval between the steel bars of walls and columns in reinforced concrete structure and the accuracy of the protective layer, and ensure the quality of assembly location of steel bar engineering.

Owner:JIANGSU JIANGDU CONSTR GRP

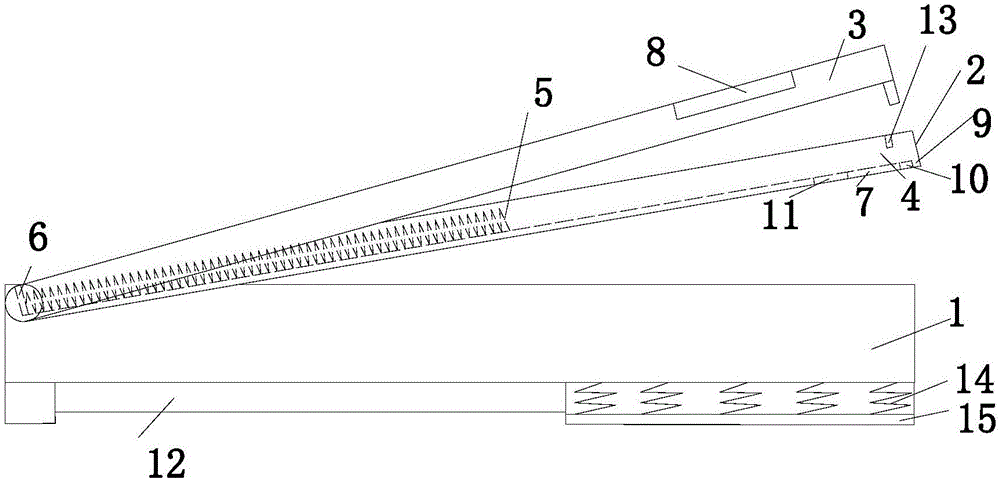

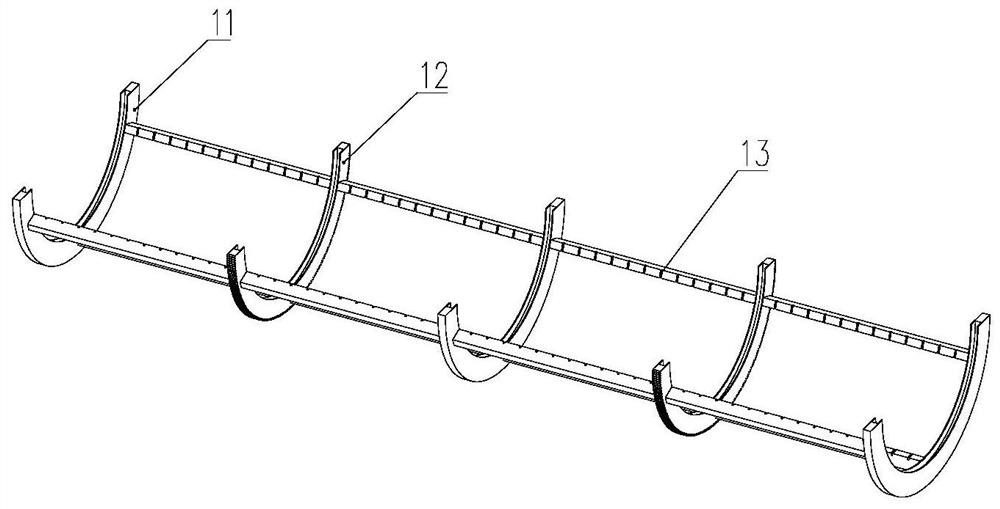

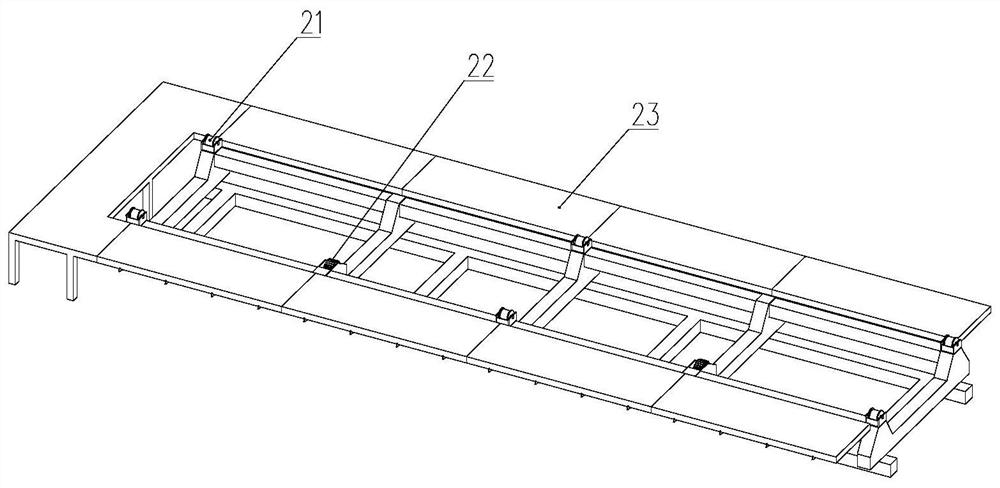

Precast box beam reinforcement binding mold and installation method thereof

ActiveCN108381752AImprove appearance qualityAvoid pollutionCeramic shaping apparatusEngineeringRebar

The invention discloses a precast box beam reinforcement binding mold. The precast box beam reinforcement binding mold comprises a base plate,extension rods, pulleys, a frame, a groove, T-shaped plates, reinforcement placing grooves, a middle plate, triangular plates and a traction block, and is characterized in that the frame and the T-shaped plates form a top plate reinforcement skeleton; the T-shaped plates are fixedly mounted at the two ends of the frame; the T-shaped plates are provided with multiple reinforcement placing grooves arranged in an arithmetic progression manner; the middle plate is fixedly mounted on the frame; the top plate reinforcement skeleton is fixedly mounted on the base plate; the base is provided with the groove; chutes are formed in the two sides of the groove;the triangular plates are mounted in the two chutes; the traction block is fixedly mounted on the base plate; the extension rods are fixedly mounted at four corners of the lower top surface of the base plate; and the pulleys are mounted on the four extension rods. The precast box beam reinforcement binding mold prevents direct machining of reinforcements on a rack to cause pollution of a base plate demolding agent, improves the appearance quality, realizes accurate positioning of reinforcements, is low in workload and high in precision, and controls the pass percent of reinforcement protectionlayers of precast box beams.

Owner:ZHEJIANG BADA TUNNEL ENG CO LTD

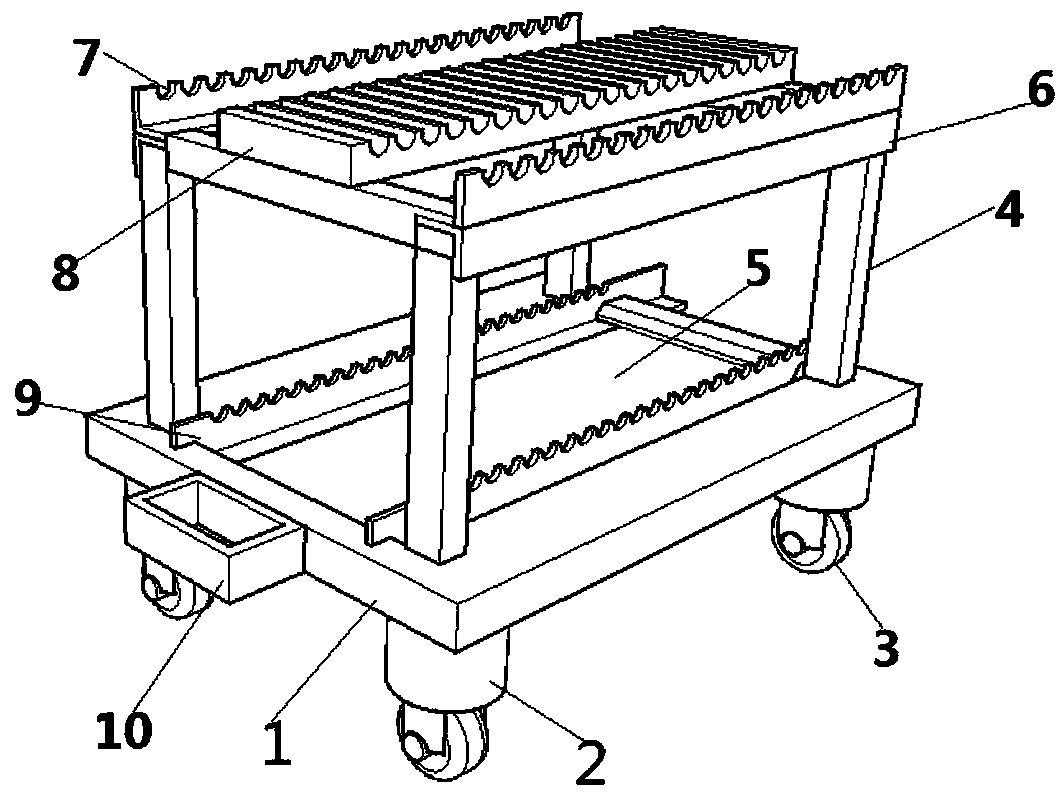

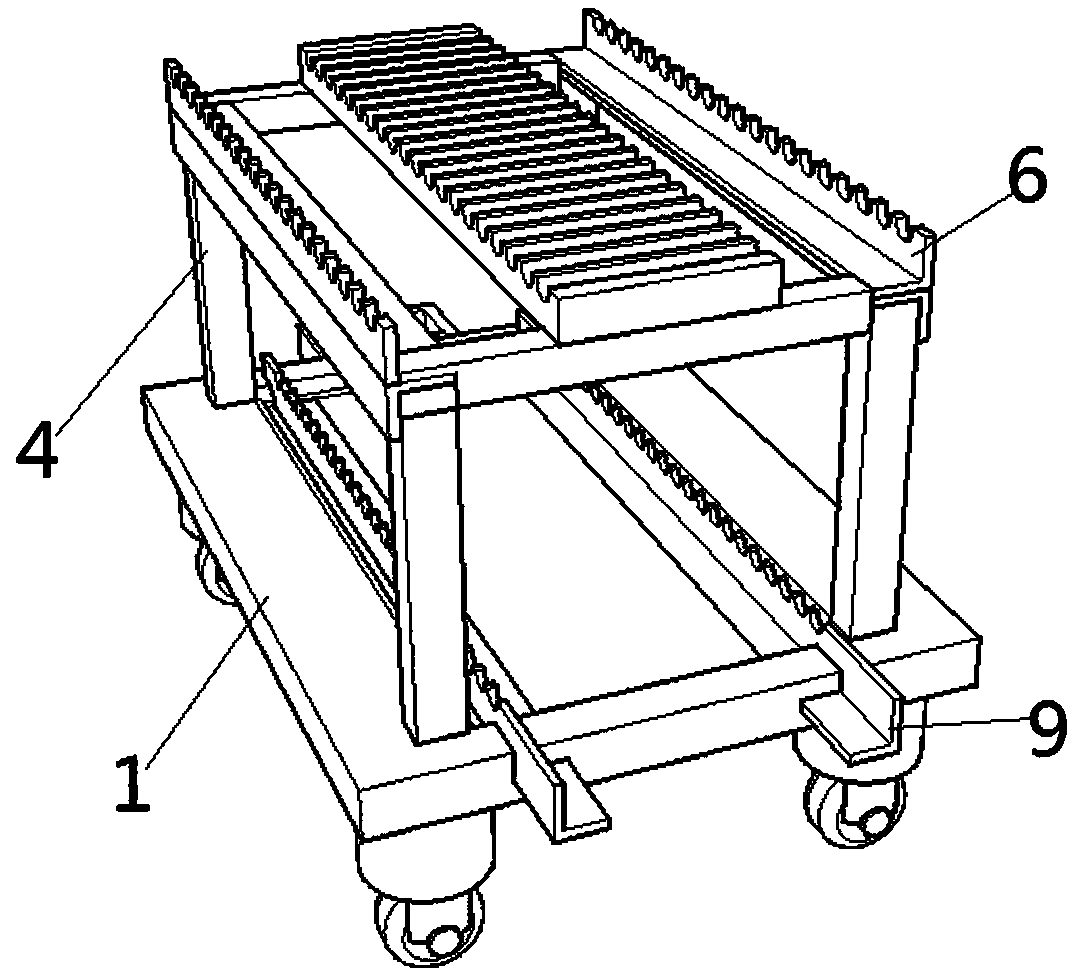

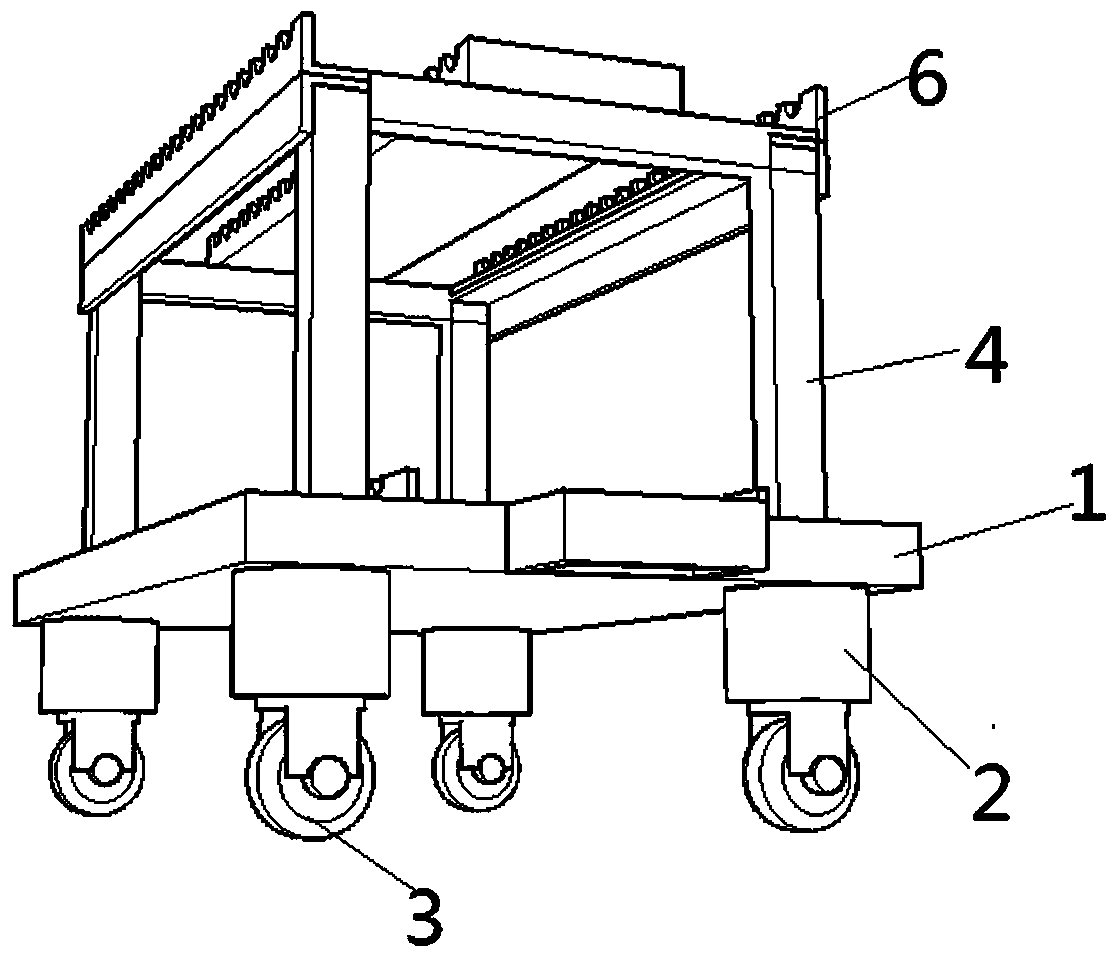

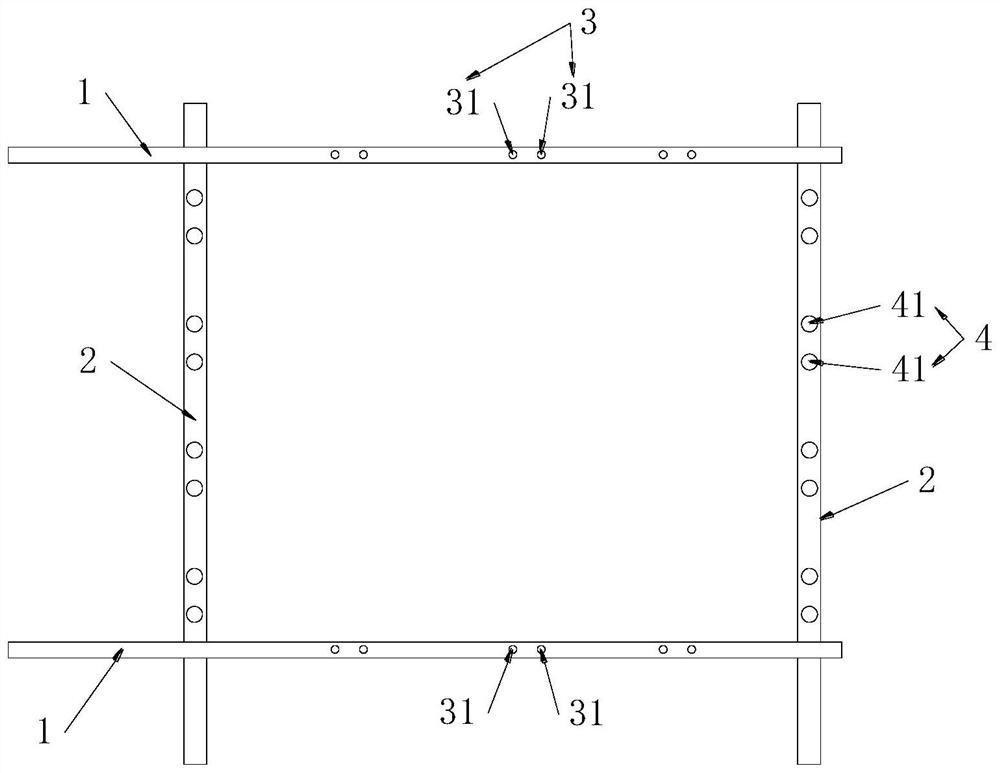

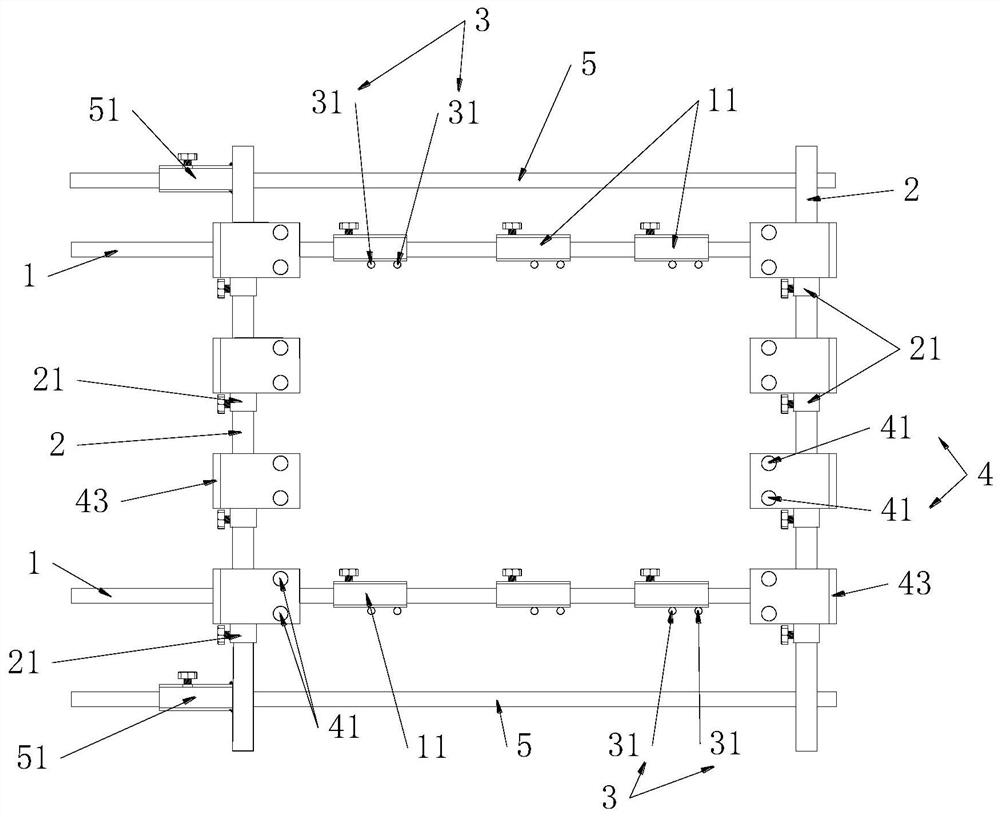

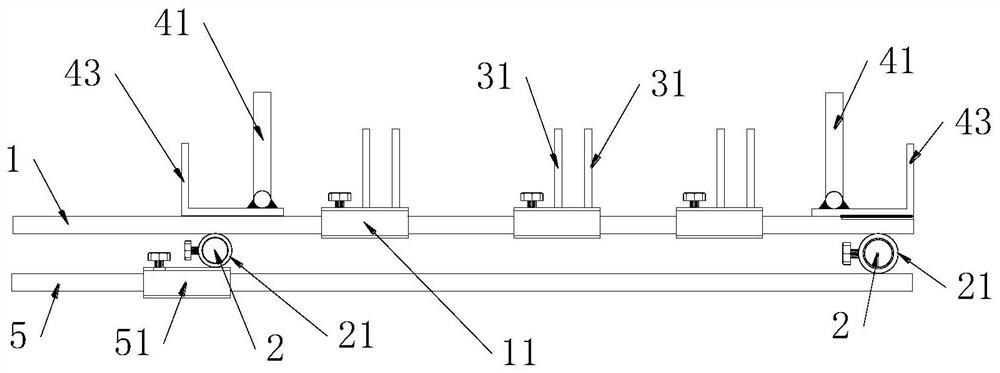

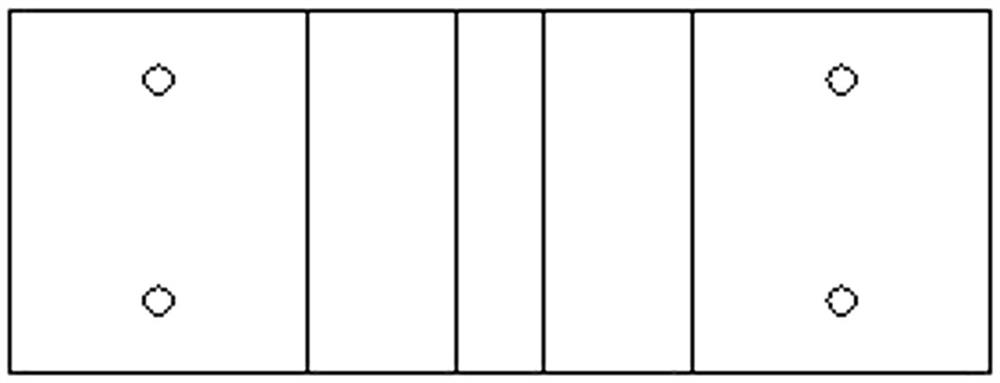

Steel bar binding jig frame for component prefabrication

ActiveCN112847775ABind firmlyImprove binding efficiencyClimate change adaptationCeramic shaping apparatusRebarMechanical engineering

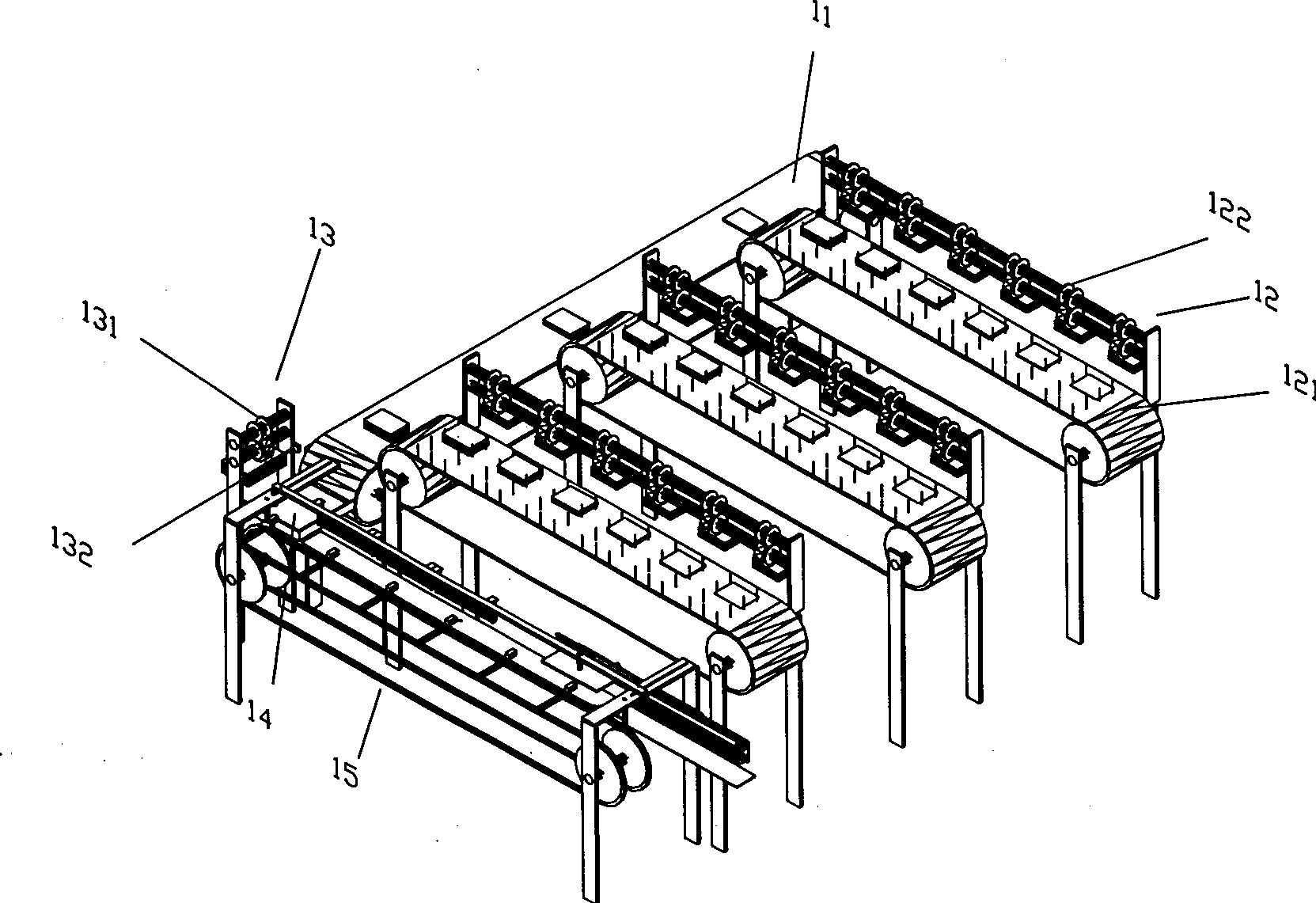

The invention provides a steel bar binding jig frame for component prefabrication. The steel bar binding jig frame for component prefabrication comprises two transverse supports and two longitudinal supports, wherein a plurality of first positioning pieces are arranged on the transverse supports; and a plurality of second positioning pieces are arranged on the longitudinal supports. The transverse supports, the longitudinal supports, the first positioning pieces and the second positioning pieces are correspondingly arranged according to the position relation of transverse steel bars and longitudinal steel bars of the a rectangular steel bar framework, so that the two corresponding first positioning pieces can position the two ends of the transverse steel bars, the two corresponding second positioning pieces can position the two ends of the longitudinal steel bars, the positioning is more accurate, and the steel bar binding process is more stable. Before the transverse steel bars and the longitudinal steel bars are bound, the transverse steel bars and the longitudinal steel bars are placed through the steel bar binding jig frame for component prefabrication and then bound, so that the placing efficiency is high, the accuracy is high, the binding efficiency of the rectangular steel bar framework is effectively improved, the quality of the rectangular steel bar framework can be improved, and engineering construction is facilitated.

Owner:中铁二十三局集团第四工程有限公司 +1

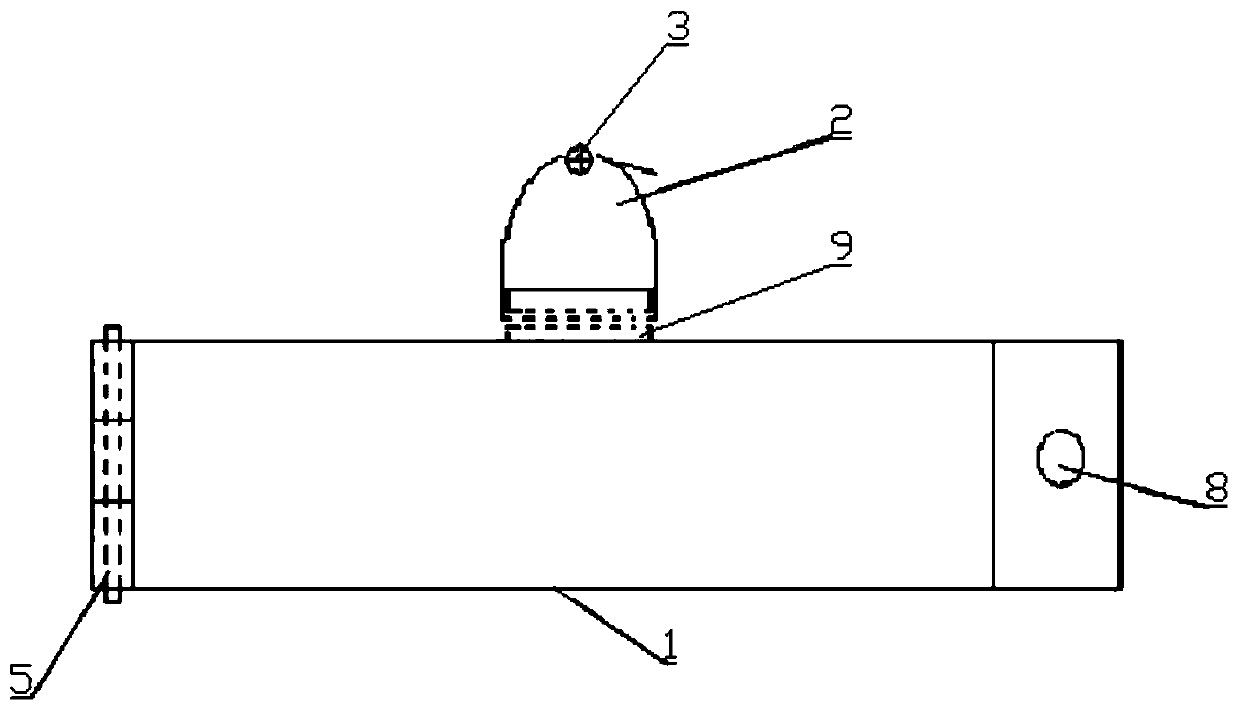

Stapler having counting function

InactiveCN106142006AImprove buffering effectGuaranteed continuityStapling toolsNailing toolsEngineeringContact type

The invention discloses a stapler having the counting function. The stapler comprises a base (1). A staple storage chamber (2) and a staple pressing portion (3) are hinged to the end of the base (1). A bookbinding groove (4) is formed inside the staple storage chamber (2). A conveying spring (5) is arranged inside the bookbinding groove (4). A pressure sensor (6) is arranged at the end of the conveying spring (5) and connected with a controller (7). The controller (7) is connected with a display screen (8). The display screen (8) is located on the surface of the staple pressing portion (3). A staple passing opening (9) is formed in the end of the bookbinding groove (4) and provided with a non-contact type counter (10). The non-contact type counter (10) is connected with the controller (7). The controller (7) is connected with a buzzer alarm device (11) located inside the staple storage chamber (2). The stapler has the beneficial effects that the condition of remaining staples can be displayed; bookbinding quality is improved; and buffering capacity of the base is improved.

Owner:HUZHOU JIANING PRINTING

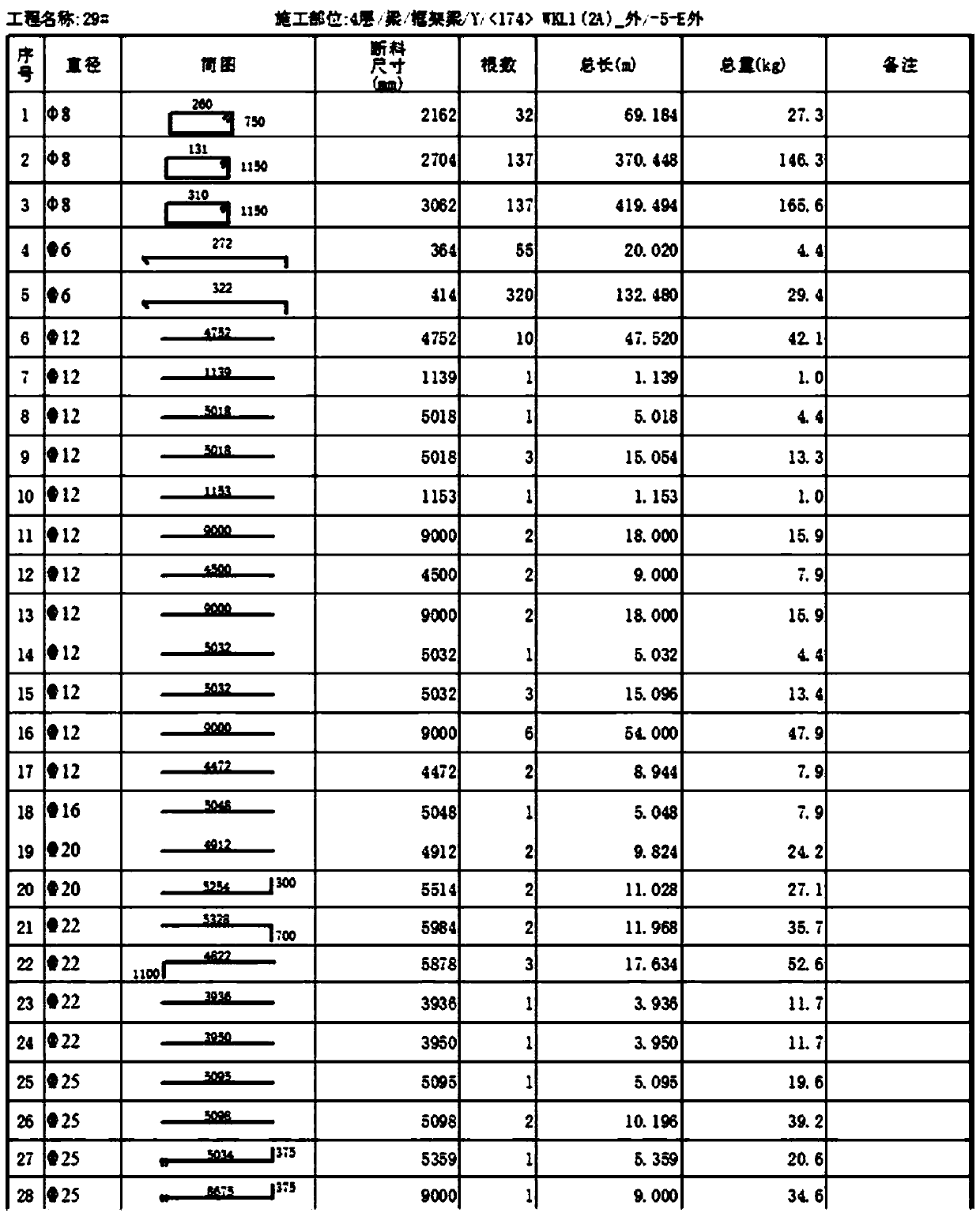

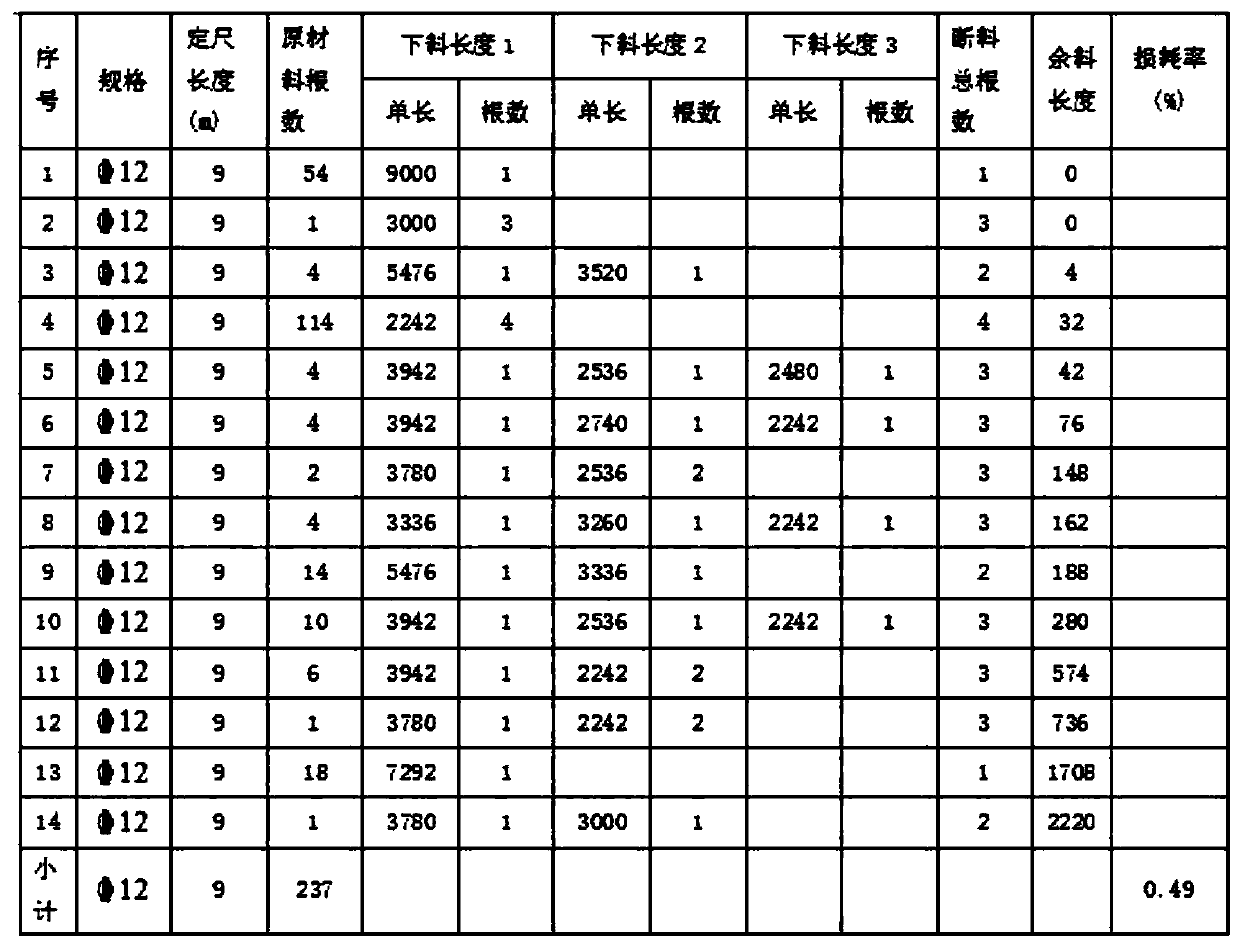

A steel bar construction management method based on a BIM technology

PendingCN109726499APrevent random arrangementPrevent layout irregularitiesSpecial data processing applications3D modellingConstruction managementRebar

The invention discloses a steel bar construction management method based on a BIM technology. The steel bar construction management method includes: Erecting BIM cloud platform, establishing a steel bar model and inputting information; inquirying steel bar models and information of all areas; generating a steel bar blanking table of a single component or a specified area through the steel bar model; machining the steel bars according to the discharging table, generating a remaining material statistical table before machining, then matching and combining the next discharging table and the remaining material statistical table, naming, numbering and pasting the remaining materials to the steel bars, storing all the matched remaining materials independently, utilizing the remaining materialswhen the next steel bar is machined, exporting a steel bar framework diagram, and carrying out construction according to the framework diagram. According to the method, the sample overturning accuracy is ensured, the efficiency is improved, the material loss rate is reduced, and the binding efficiency and quality are improved.

Owner:WUHAN YIYE CONSTR ENG

Novel stapler

InactiveCN107283367AReduce distanceIncrease distanceStapling toolsNailing toolsEngineeringInternal cavity

The invention discloses a novel stapler which comprises a base. A cavity is formed in the base which is internally provided with a rotating rod, two second connecting blocks are connected to the rotating rod in a sleeving mode, a first rotating rod and a second rotating rod are connected to each second connecting block, a first opening communicated with the cavity is formed in the upper end of the base, a connecting block is arranged at the upper end of the base, first connecting blocks are arranged on the lower end side wall of the connecting block and the bottom side wall inside the cavity respectively, the ends, far away from the second connecting blocks, of the first rotating rods and the second rotating rods are connected with the first connecting blocks, the connecting block penetrates through the first opening and is internally provided with a hollow groove, the upper end of the connecting block is provided with a second opening communicated with the hollow groove, and the hollow groove is internally provided with a staple containing box. The novel stapler is high in book binding efficiency, and the binding quality of books is improved.

Owner:肇庆高新区异星科技有限公司

Binding device for ancient volume imitating Chinese language and literature

ActiveCN112810348AImprove binding efficiencyImprove binding qualitySheet bindingBookbinding pressesPunchingPaper sheet

The invention relates to the technical field of literature scroll binding, and discloses a binding device for an ancient volume imitating Chinese language and literature, comprising a base, wherein the rear side of the upper end of the base is fixedly connected with a fixing frame of an inverted L-shaped structure, the upper end of the horizontal part of the fixing frame is slidably sleeved with an ejector rod through a round hole, and the lower end of the ejector rod penetrates through the round hole and is fixedly connected with a mounting plate; a punching mechanism is connected to the front side of the upper end of the mounting plate, a pressing plate is arranged at the lower end of the mounting plate, elastic steel plates are fixedly connected to the left end and the right end of the pressing plate, a positioning mechanism is connected to the upper end of the pressing plate and connected with the side wall of the mounting plate, and a plurality of notches matched with the punching mechanism are formed in the front side of the pressing plate. According to the binding device for the ancient volume imitating the Chinese language and literature, the punching efficiency and quality of paper of an ancient volume book can be improved, the safety is high in the punching process, the ancient volume book can be fixed in the punching process, a binding line can be conveniently threaded to bind the book, and the ancient volume paper cannot be scattered during tightening.

Owner:HEBEI VOCATIONAL & TECHN COLLEGE OF BUILDING MATERIALS

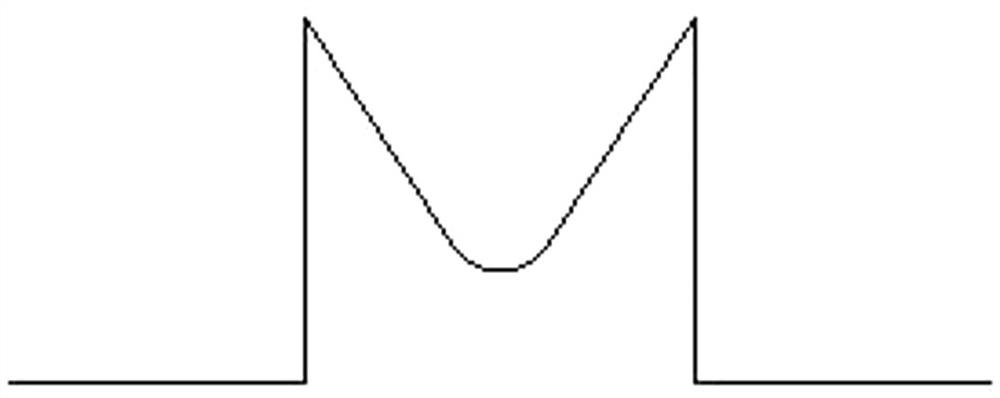

Box girder casting method and forming die frame for box girder steel reinforcement framework

PendingCN110202687ARealize turnover utilizationIncrease profitWire networkCeramic shaping apparatusShaped beamEngineering

The invention discloses a box girder casting method and a forming die frame for a box girder steel reinforcement framework, and aims to overcome the defects that in the prior art, the utilization rateof a box girder prefabricated pedestal is not high, the construction efficiency of the box girder is not high, the steel reinforcement binding quality of the box girder steel reinforcement frameworkcannot be guaranteed, and the construction operation difficulty is high. According to the box girder casting method, the steel reinforcement framework is installed, and the specific steps are as follows: prefabricating a steel reinforcement; setting a steel reinforcement binding area; binding the steel reinforcement framework; installing a corrugated pipe and a steel reinforcement cushion block; and hoisting the steel reinforcement framework. The forming die frame for the box girder steel reinforcement framework comprises a base and web steel reinforcement positioning devices symmetrically arranged on the base. According to the box girder casting method and the forming die frame for the box girder steel reinforcement framework, the utilization rate of a prefabricated pedestal is improved,and streamlining operation of prefabricated box girder construction is achieved; and the steel reinforcement framework is bound with the aid of the forming die frame, the position and the spacing of steel reinforcements are accurately positioned, the construction efficiency and quality of the binding of the steel reinforcements are effectively improved, and the method and the forming die frame aresuitable for pouring construction of box girders or T-shaped beams.

Owner:SHENZHEN CONSTR GRP

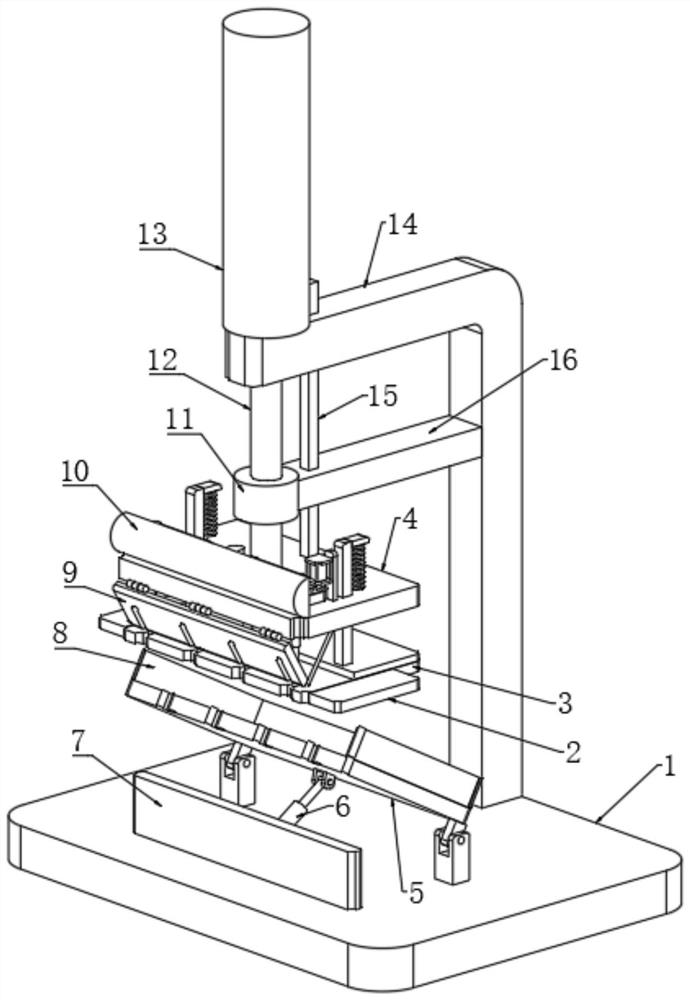

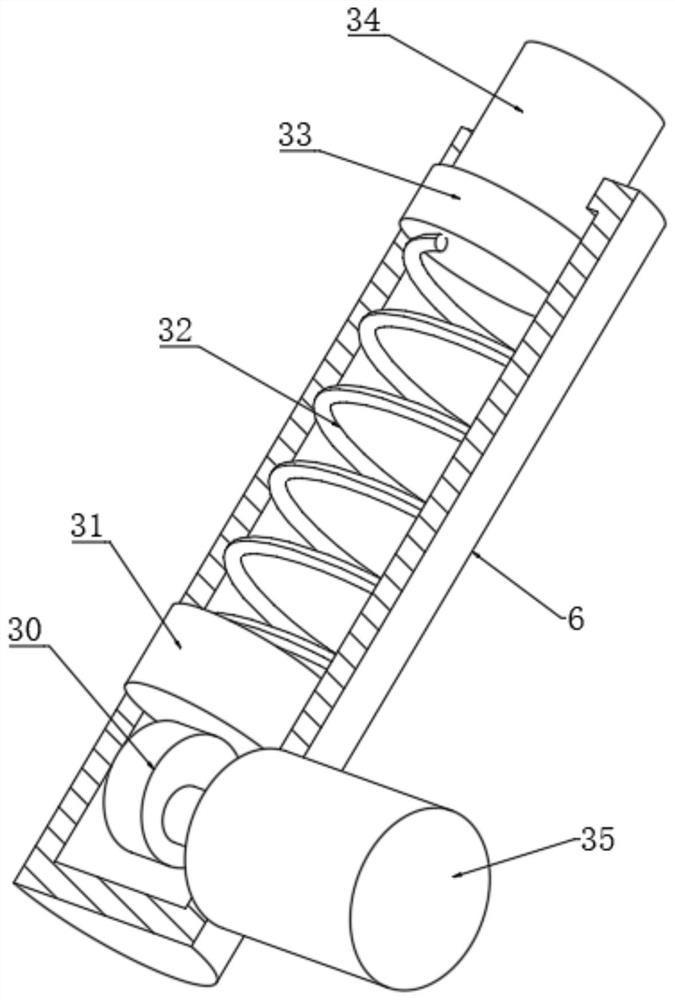

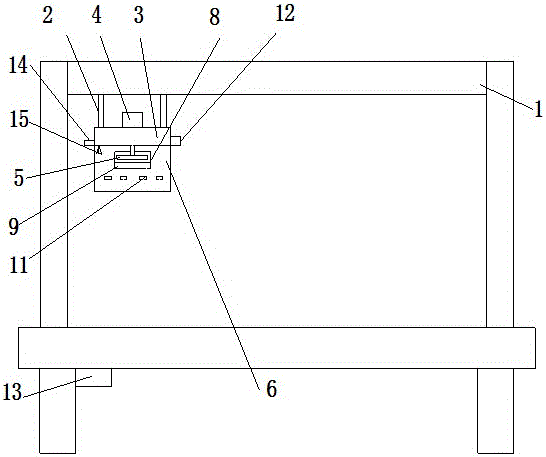

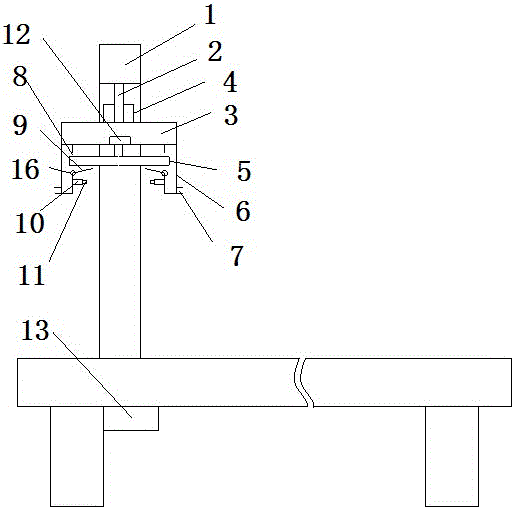

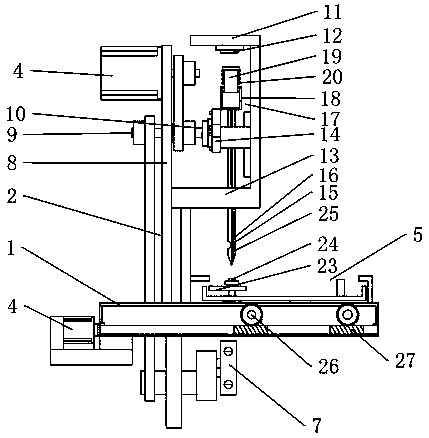

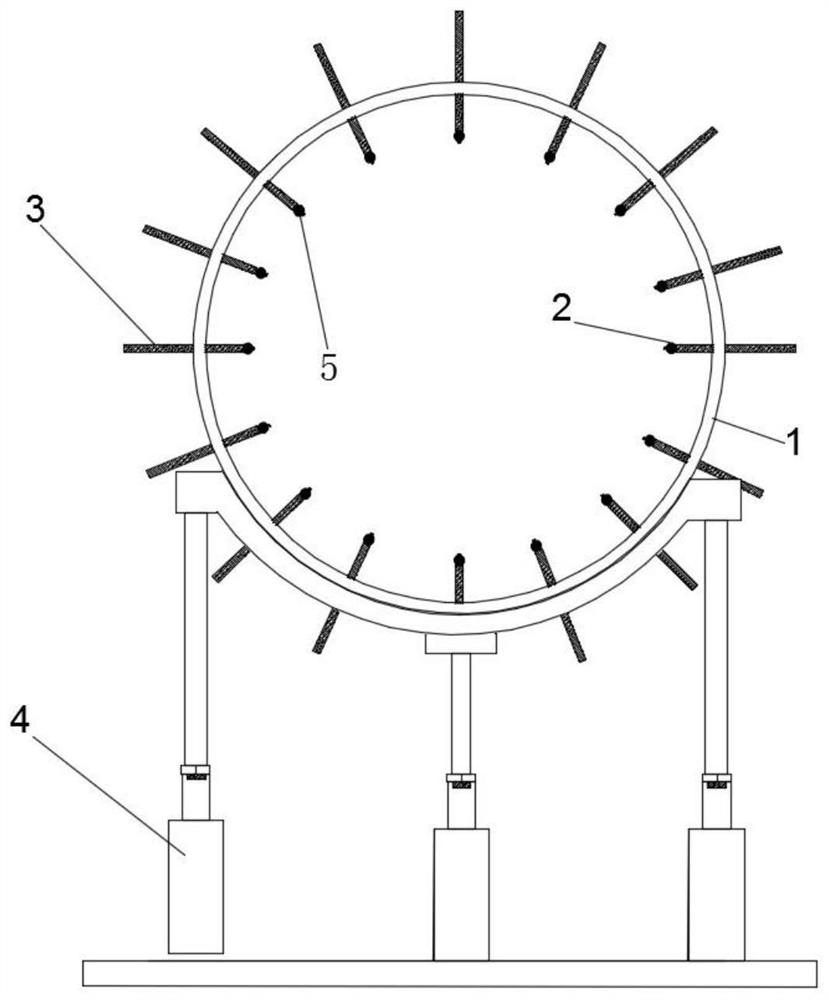

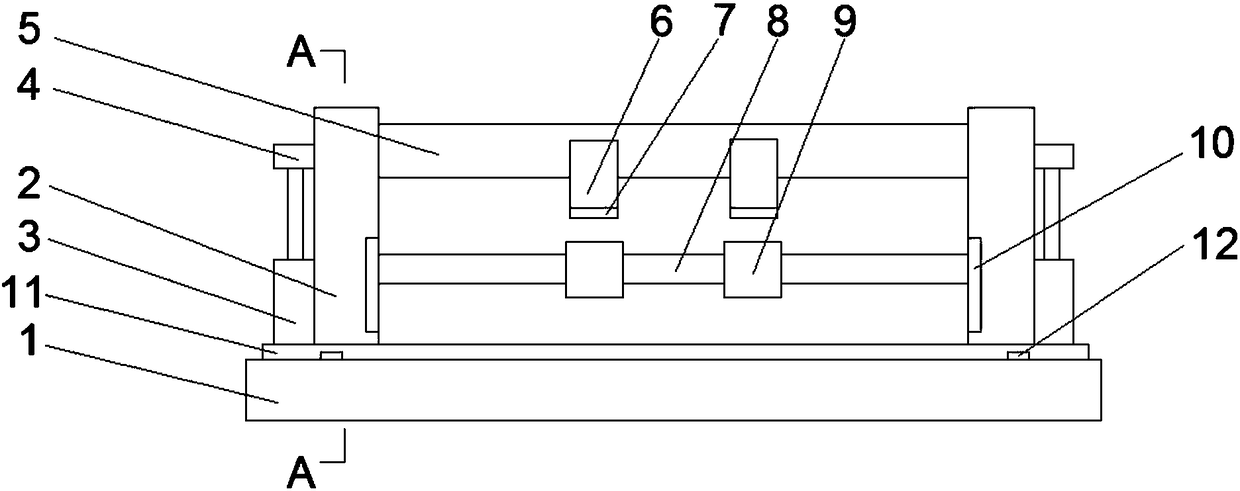

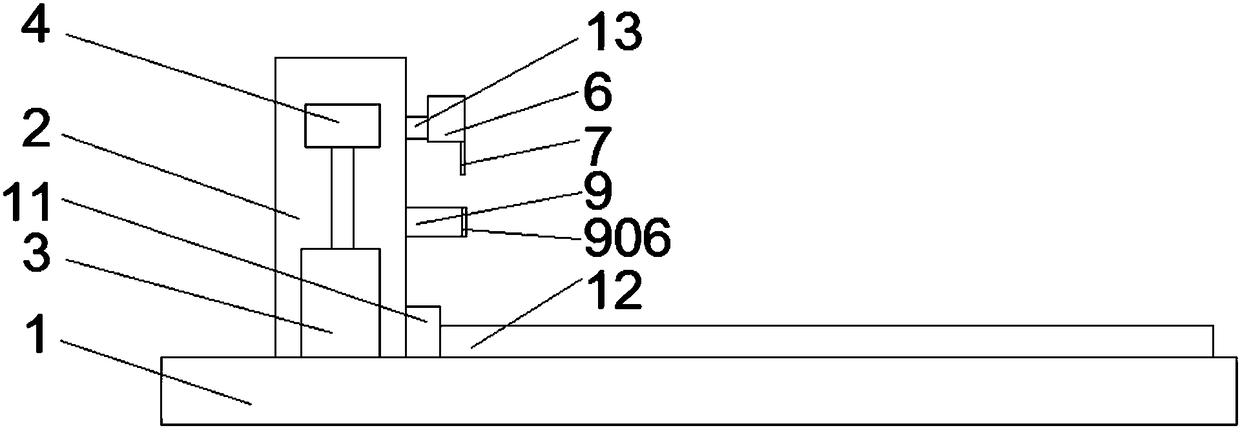

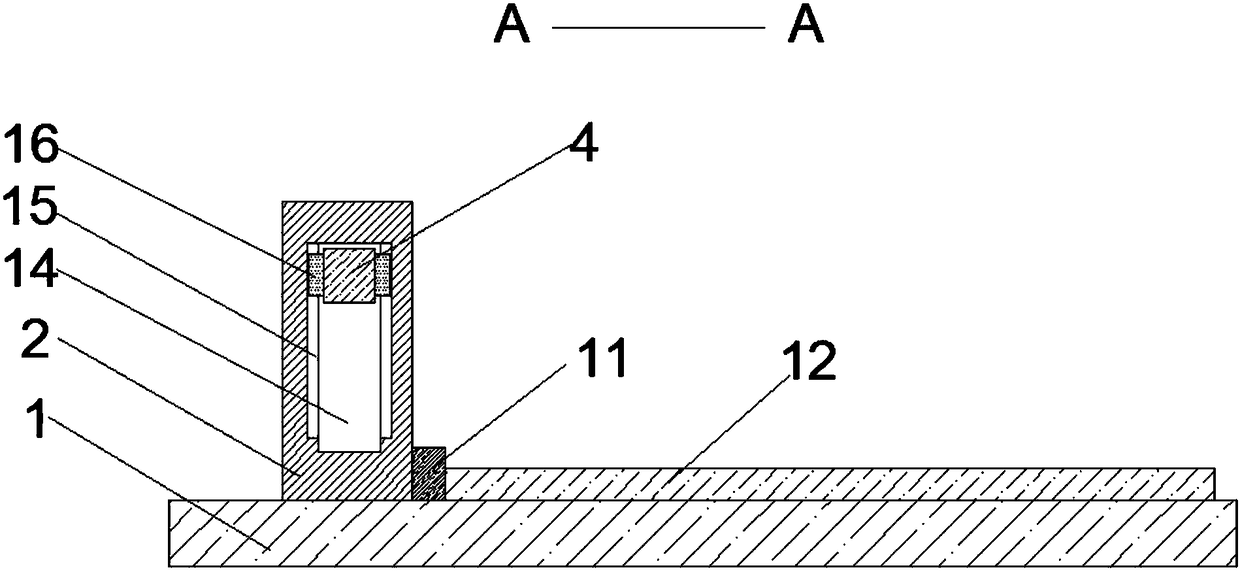

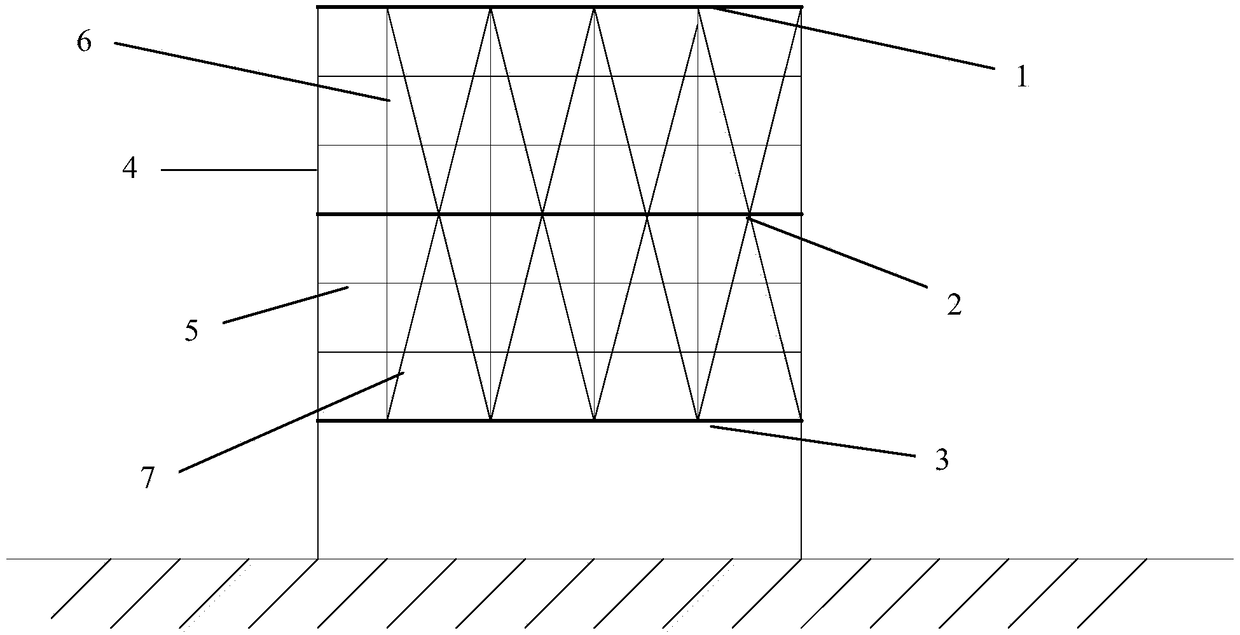

Milling device of perfect binding machine for tabletop

ActiveCN106392158ARealize automatic millingClean up in timeWorkpiecesMilling equipment detailsMilling cutterPulp and paper industry

The invention discloses a milling device of a perfect binding machine for a tabletop, comprising a hydraulic rod (2); the end of the hydraulic rod (2) is provided with a fixed plate (3), and a motor (4) is arranged above the fixed plate (3) and is connected with a milling cutter (5); a dust suction shell (6) is arranged below the fixed plate (3), the bottom of the dust suction shell (6) is provided with a dust suction pipeline (7), a dust suction opening (8) is formed in the inner side of the dust suction shell (6), and the lower end of the dust suction opening (8) is provided with a baffle (9); the inner side of the dust suction shell (6) is provided with a pressing wheel (11); and one end of the fixed plate (3) is provided with an infrared sensor (12) connected with a controller (13), and the controller is connected with the hydraulic rod and a sliding rail (1). The milling device is relatively high in milling precision, convenient to operate and capable of clearing paper scraps in time, reducing influences to the environment, improving the binding quality and reducing the damage rate of paper sheets.

Owner:HUZHOU JIANING PRINTING

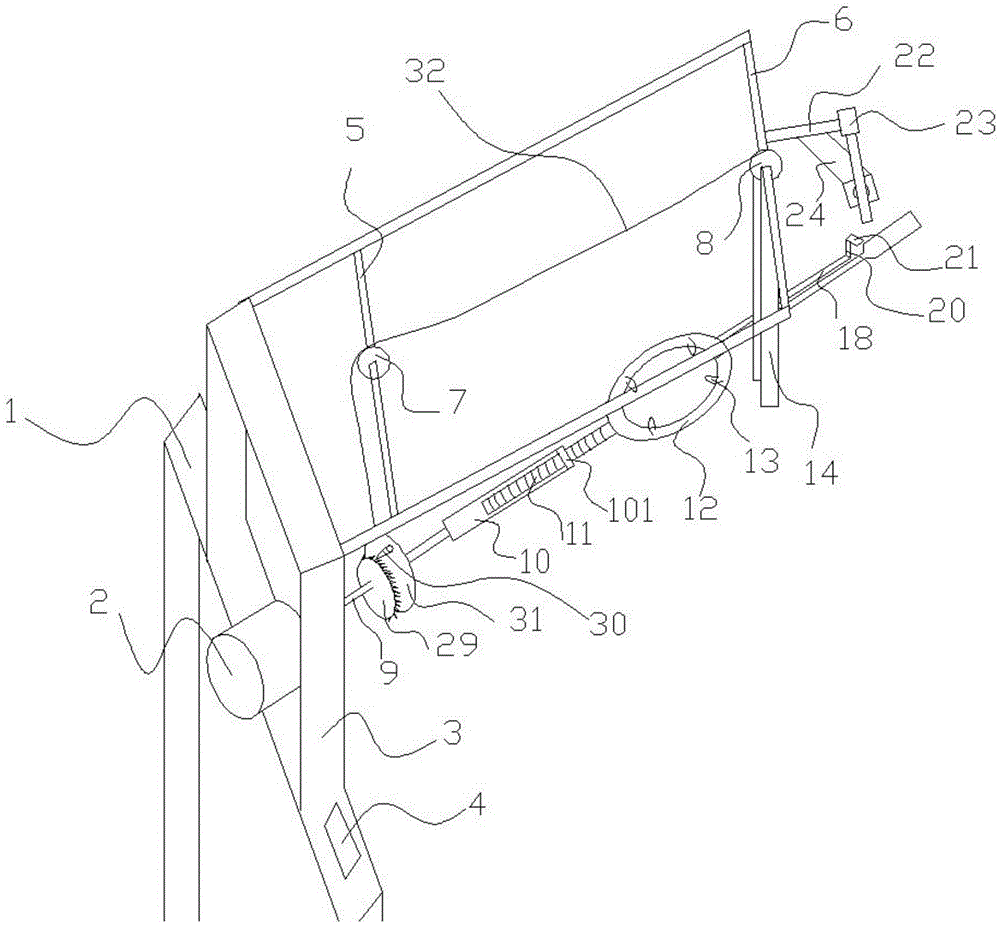

Full-automatic racket sweatband binding device

ActiveCN105599958AImprove adhesionImprove binding qualityBinding material applicationBundling machine detailsDrive shaftMicro motor

A full-automatic racket sweatband binding device comprises a base. A motor, a control panel and a first support are arranged on the base, the first support is provided with a second support rod which is fixedly connected with a fourth support rod, and a micro motor used for driving a sweatband is arranged on the fourth support rod; a rotating shaft of the motor is fixedly connected with a driving shaft, the driving shaft is movably connected with a driven shaft, and the driving shaft can drive the driven shaft to do translational motion and can rotate along the axis of the driven shaft; the driven shaft is fixedly connected with a fixing plate which is provided with fixing clamps; the rotating speed of the micro motor is smaller than that of the motor, and the control panel controls the motor and the micro motor. By means of the full-automatic racket sweatband binding device, automatic binding of the racket sweatband can be achieved, the strength is uniform, and the quality is high.

Owner:RES INST OF ECONOMICS & TECH STATE GRID SHANDONG ELECTRIC POWER +1

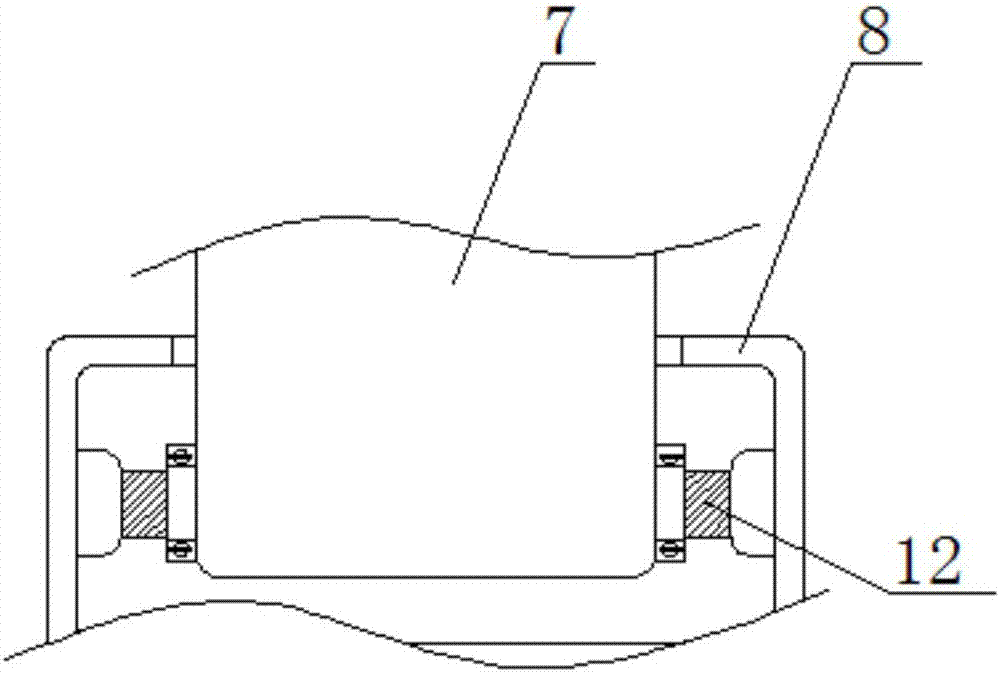

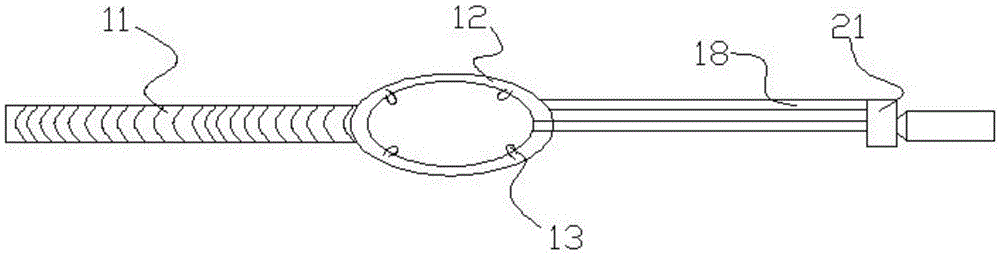

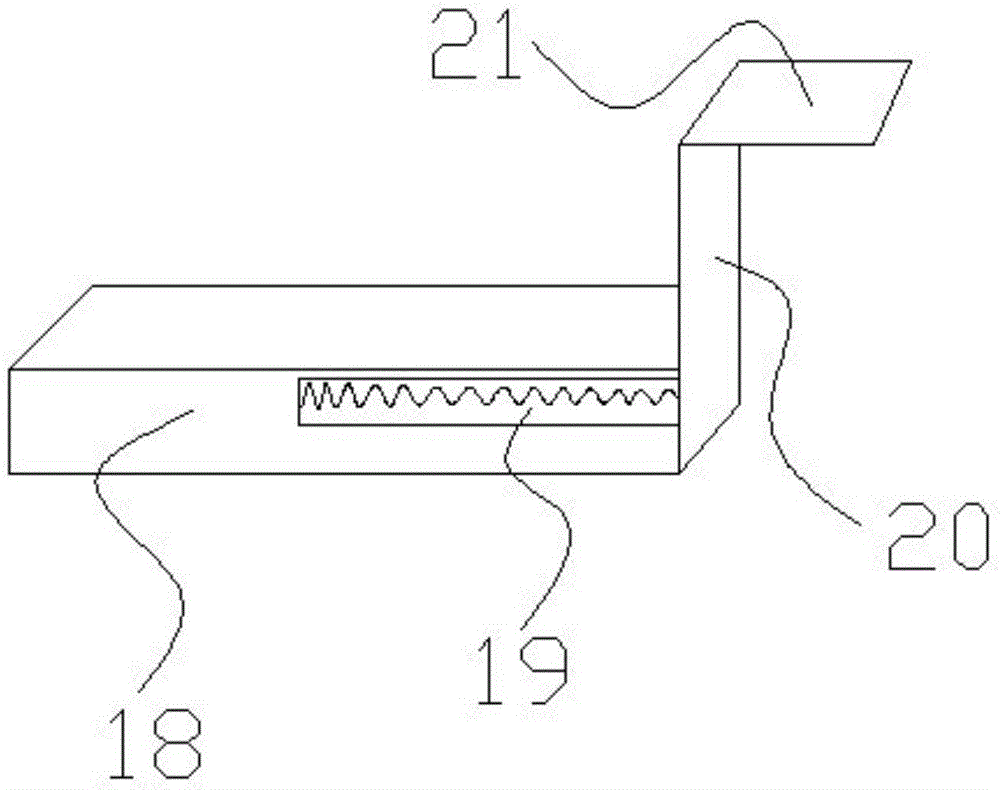

Quick fixing device for low-voltage conducting wire, and using method

PendingCN111463735AImprove binding efficiencyImprove the level of safe operationSuspension arrangements for electric cablesEngineeringSafe operation

The invention provides a quick fixing device for a low-voltage conducting wire, and a using method. The device comprises an insulator hoop, which is fixed on an insulator, fastening assemblies are arranged on the two opposite sides of the insulator hoop respectively, each fastening assembly comprises a circular-ring-shaped steel clamp with an opening in one end, the center line of each circular-ring-shaped steel clamp is perpendicular to the center line of the insulator hoop, an electric wire penetrates through the containing cavity of each circular-ring-shaped steel clamp, and the fastening assembly further comprises a fastener arranged on the circular-ring-shaped steel clamp and used for fastening the electric wire. According to the device, the conducting wire binding efficiency is improved, the binding quality is improved, and the safe operation level of the conducting wire is greatly improved while the construction time is shortened.

Owner:国网山东省电力公司滨州市沾化区供电公司

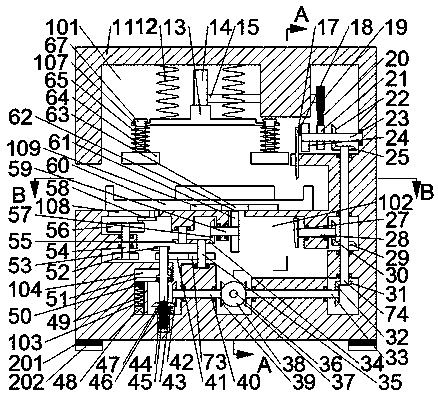

Control device of efficient binding machine

The invention discloses a control device of an efficient binding machine. The control device comprises a machine body, a first cavity and a second cavity, wherein the first cavity and the second cavity are formed inside the machine body; third cavities which are opened downwards are symmetrically formed left and right in the top wall of the first cavity; a first sliding block is arranged inside the first cavity in an up and down sliding manner; through holes corresponding to the third cavities are symmetrically formed left and right inside the first sliding block; second sliding blocks are arranged inside the third cavities in a sliding manner; first threaded holes are formed inside the second sliding blocks in a left and right through manner. The control device disclosed by the inventionis simple in structure and convenient to operate, a paper limiting plate is driven by a same power source to move to clamp paper and drive a paper cutter rod to move up and down, and meanwhile, switching of the functions is achieved while the paper is compressed; the paper is positioned by using the paper limiting plate, meanwhile, the paper is compressed and positioned through paper pressing blocks, then the paper can be bound tidily, the paper binding quality and attractiveness can be improved, different procedures are mutually matched without influence, and the practicability of the deviceis improved.

Owner:童良英

Special three-hole and double-thread punching and threading all-in-one machine for archives room

The invention discloses a special three-hole and double-thread punching and threading all-in-one machine for an archives room. The special three-hole and double-thread punching and threading all-in-one machine comprises a rack, and a stand column is arranged on the rack. A punching mechanism moving up and down is movably arranged on the stand column, and a driving device dynamically connected withthe punching mechanism is arranged on the stand column. A movable positioning clamping plate moving back and forth is correspondingly arranged at the lower part of the punching mechanism, and a powermechanism dynamically connected with the movable positioning clamping plate is arranged on a rack. A switch of the power mechanism is arranged at the upper part of the punching mechanism, and the switch is turned on along with the rising of the punching mechanism and is turned off along with the falling of the punching mechanism. A rotating shuttle forming a lock stitch with the punching mechanism is arranged at the lower part of the rack, and the rotating shuttle is dynamically connected with the driving device. The special three-hole and double-thread punching and threading all-in-one machine is convenient in use, reduces the difficulty of operation, and achieves the technical effects of realizing punching and threading at one time and improving the binding quality.

Owner:LINQU POWER SUPPLY CO OF STATE GRID SHANDONG ELECTRIC POWER CO +1

Thread binding tool

InactiveCN108909235AReduce manual operationsSave operating timeSheet bindingEngineeringOperating time

The invention discloses a thread binding tool. The thread binding tool comprises a machine body and a first cavity formed in the machine body. A second cavity is arranged below the first cavity. A first rotary shaft extending front and back is rotatably arranged in the second cavity. The tail end of the front side of the first rotary shaft is in power connection with a motor fixedly arranged in the end wall of the front side of the second cavity. The tail end of the rear side of the first rotary shaft is provided with a first bevel gear. The second cavity is internally provided with a second rotary shaft extending left and right. The tail end of the right side of the second rotary shaft is fixedly provided with a second bevel gear engaged with the first bevel gear. The thread binding toolcan automatically conduct binding on paper sheets to be bound through an electric driving mechanical structure, manual operation is reduced, the operating time is shortened, and the binding quality and the binding efficiency are improved. Meanwhile, the thread binding tool is simple in structure, reliable and stability in transmission and high in integration level and has good practicality.

Owner:方倩

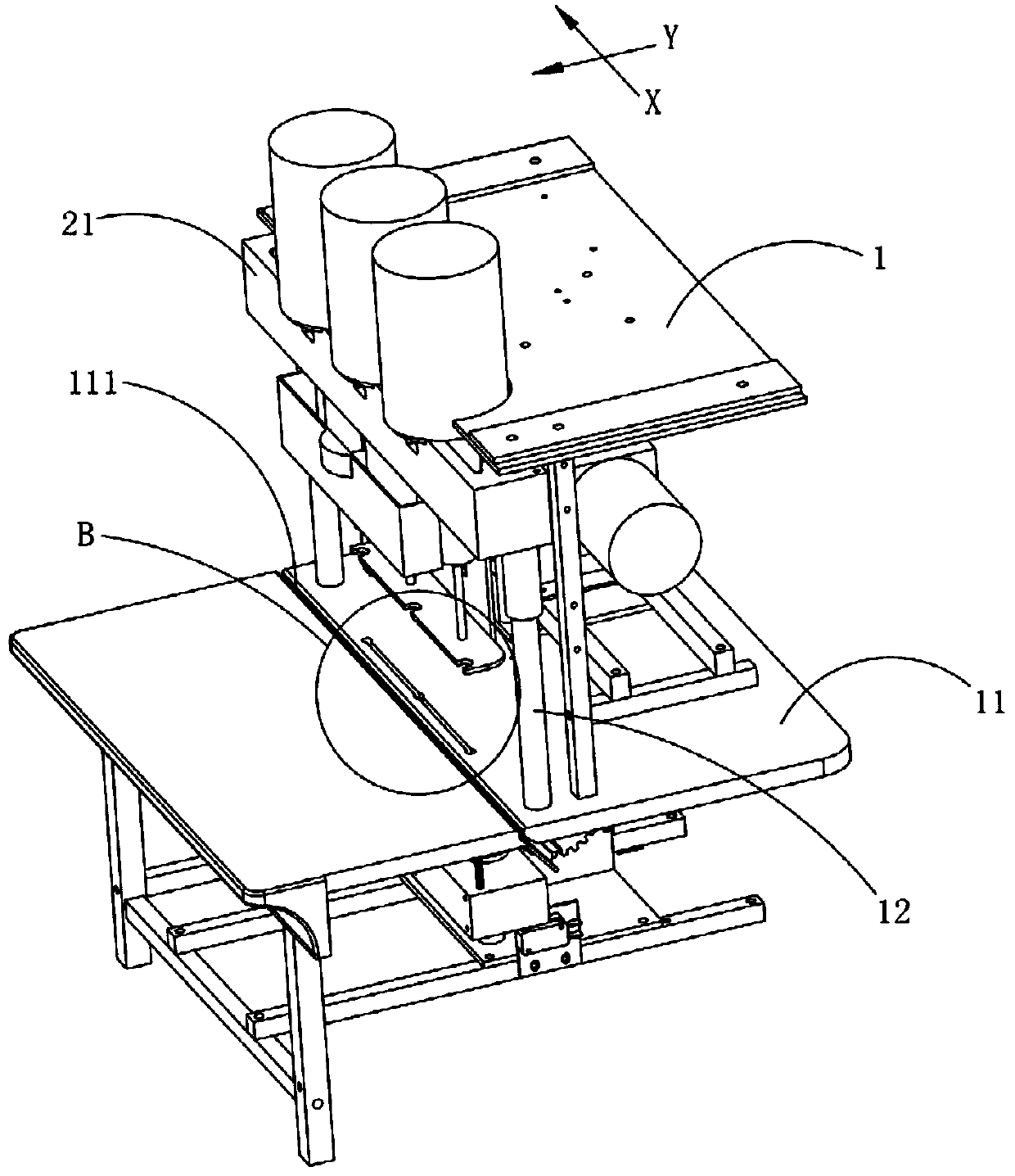

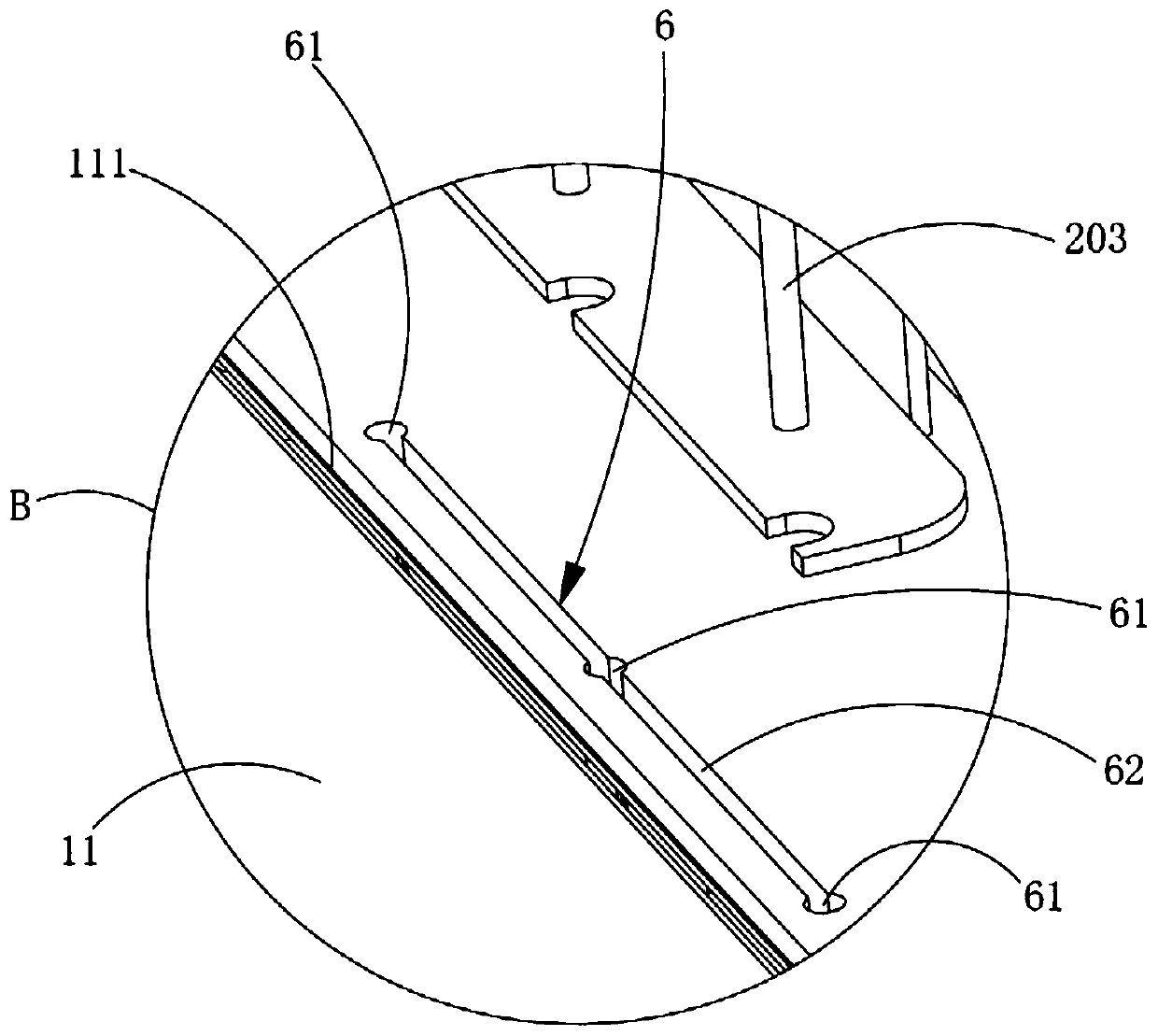

Improved porous wire type binding machine

The invention discloses an improved porous wire type binding machine. The improved porous wire type binding machine comprises a machine frame, a control circuit, a binding platform, a drilling mechanism and a wire feeding mechanism, wherein the binding platform is arranged in the middle of the machine frame; the drilling mechanism is arranged above the binding platform, and the drilling mechanismis provided with three drilling cutters; the wire feeding mechanism is positioned below the binding platform, the wire feeding mechanism is provided with three machine needles, each machine needle isaligned with the corresponding drilling cutter in parallel, a receding groove opening is formed in the binding platform, the binding platform is used for receding the drilling cutters and the machineneedles, the receding groove opening penetrates through the binding platform up and down, the receding groove opening transversely penetrates each drilling cutter and each machine needle, and the width of the receding groove opening is larger than the outer diameter of the drilling cutters and the outer diameter of the machine needles. Compared with the prior art, the binding machine can be used for receding the use of a conductive rubber pad and a rubber pad translation mechanism, receding the drill cutters in the downward drilling process, so that a binding line can be conveyed to penetratethrough the binding platform and a binding hole, and the whole machine is low in cost and good in stability.

Owner:周添星

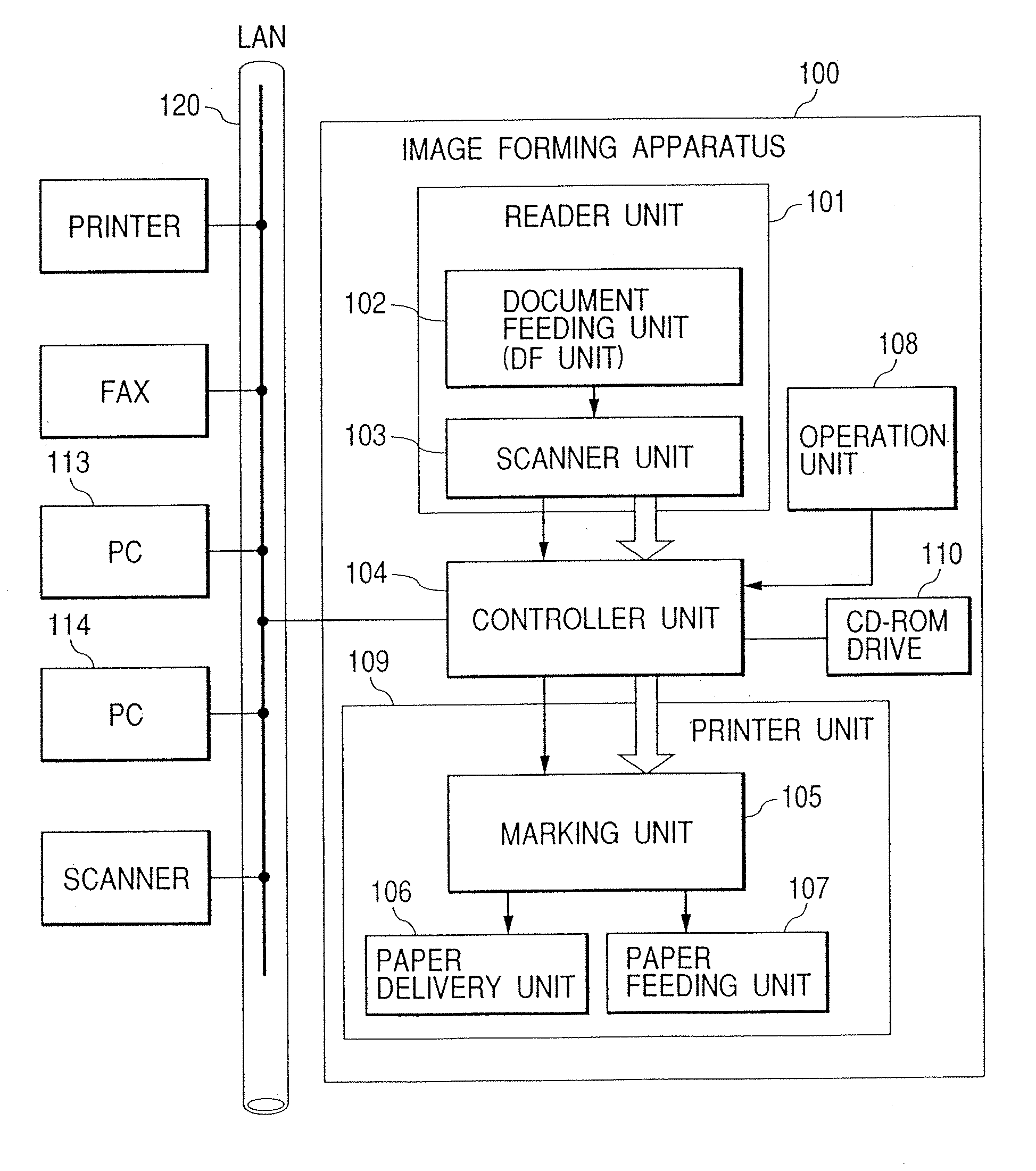

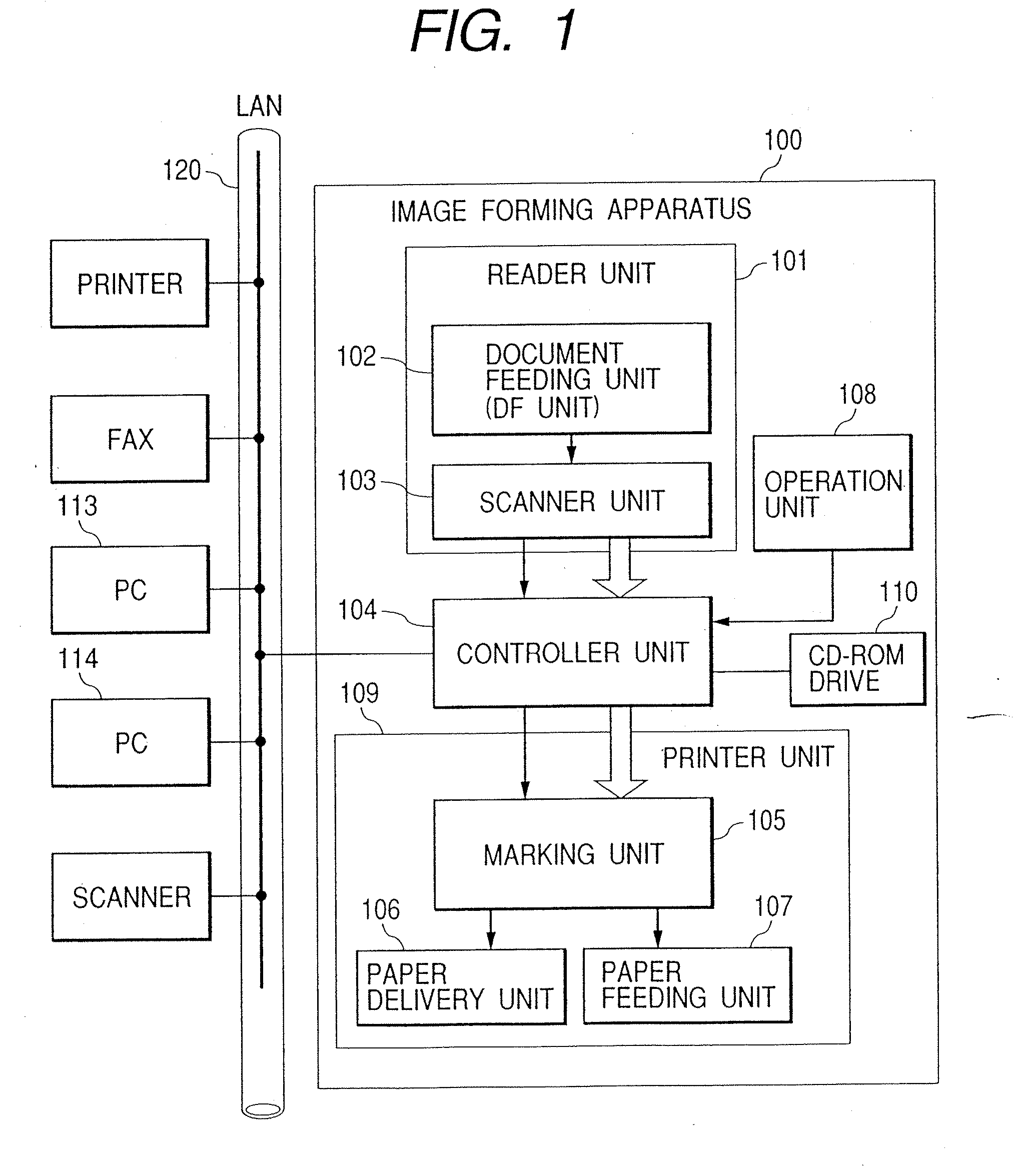

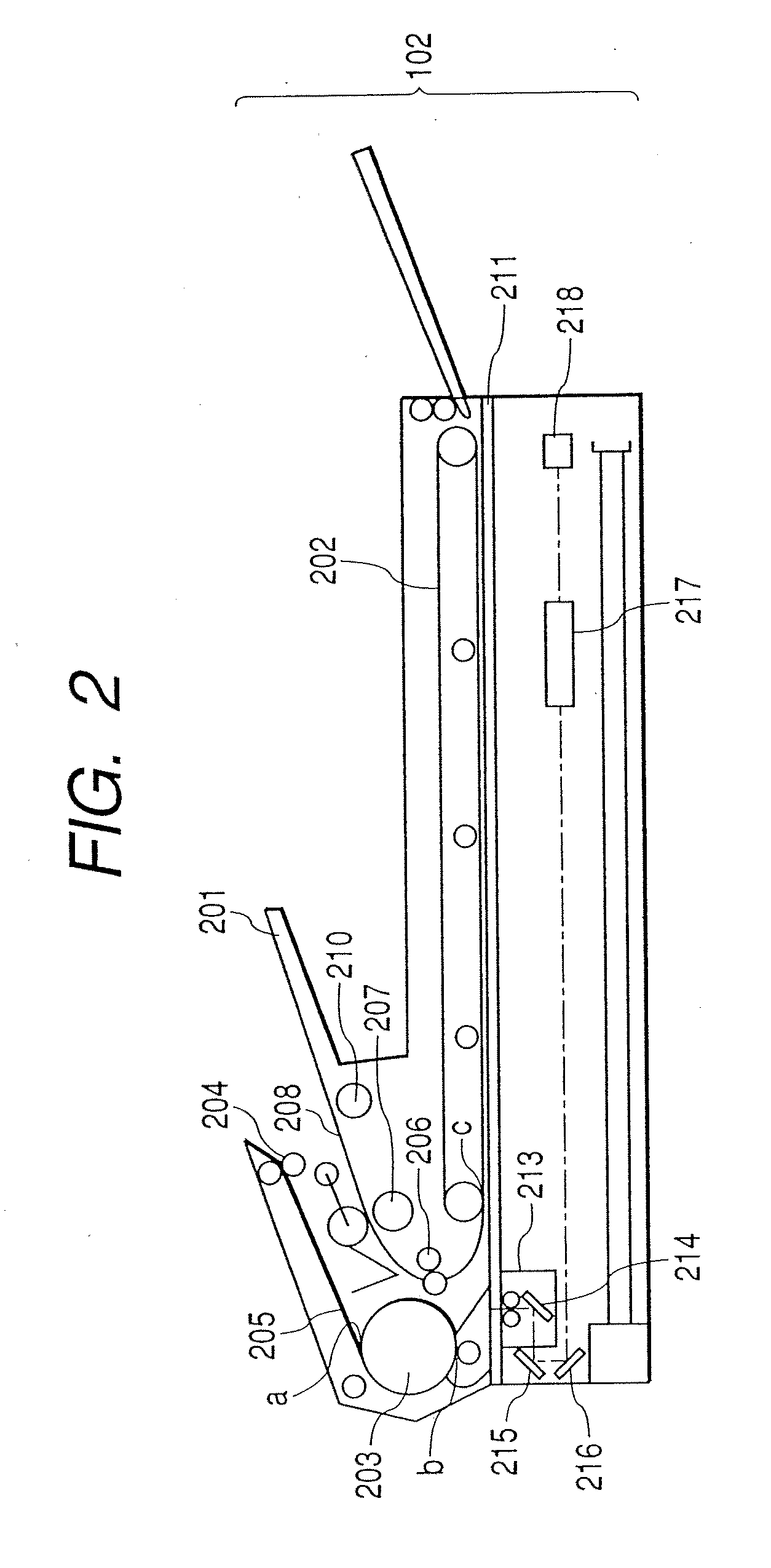

Image Forming Apparatus and Image Forming Method

InactiveUS20080013973A1Improve binding qualityGeometric image transformationElectrographic process apparatusImage formationData visualization

An image forming apparatus having: image forming means for visualizing image data read out by image reading means and forming it onto transfer materials; post-processing means for executing a post-process including a stapling process, a folding process, and / or a sorting process in order to execute a book-binding process to the transfer materials on which the image data has been formed; and a trimmer for executing a trimming process to a bundle of the transfer materials subjected to the binding process by the post-processing means, wherein when the trimming process by the trimmer is executed, the image forming means sets a non-image forming area including a processing portion to which the trimming process is executed and a valid image forming area excluding the non-image forming area onto the transfer material and forms the image data read out by the image reading means into the valid image forming area of the transfer material.

Owner:CANON KK

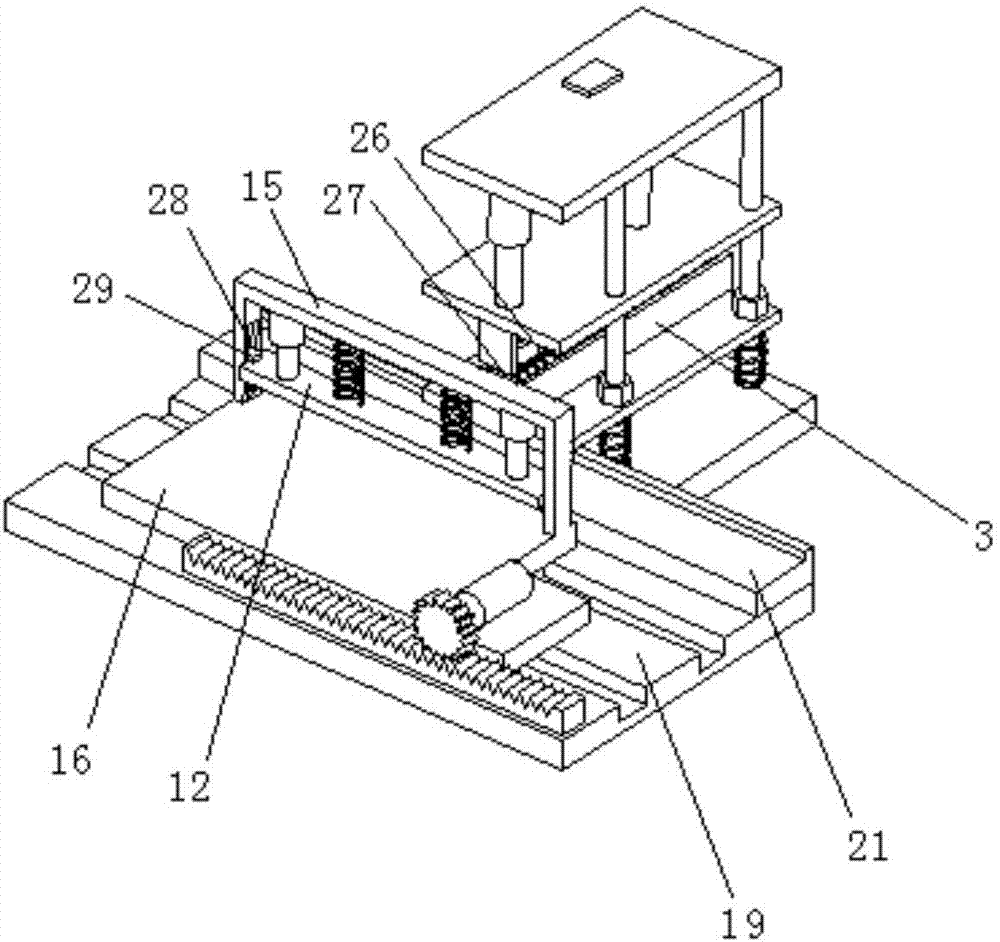

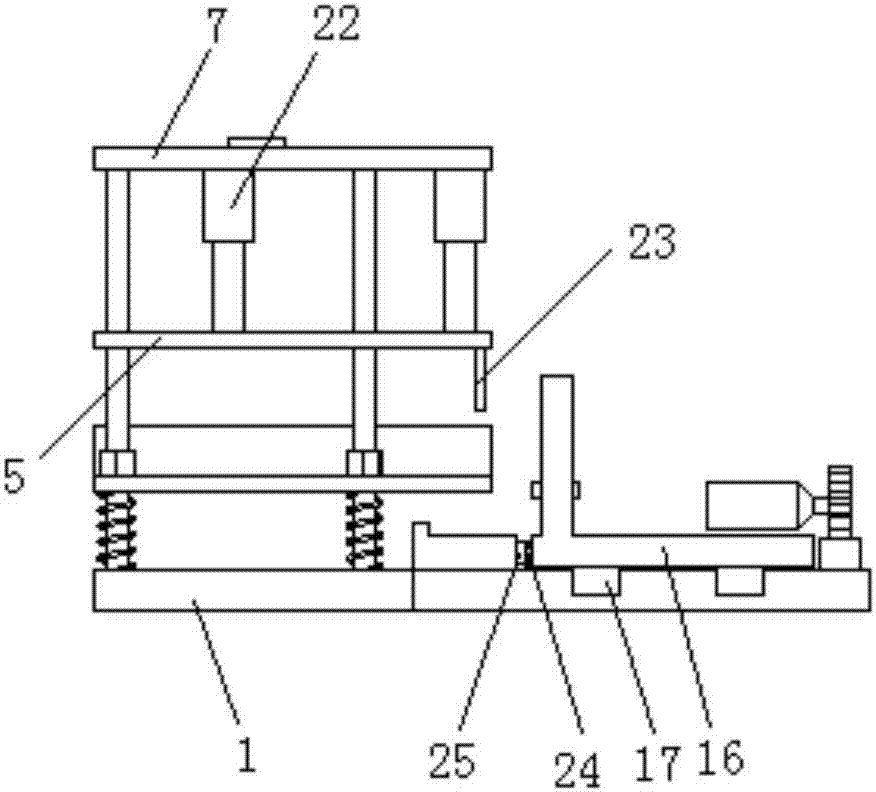

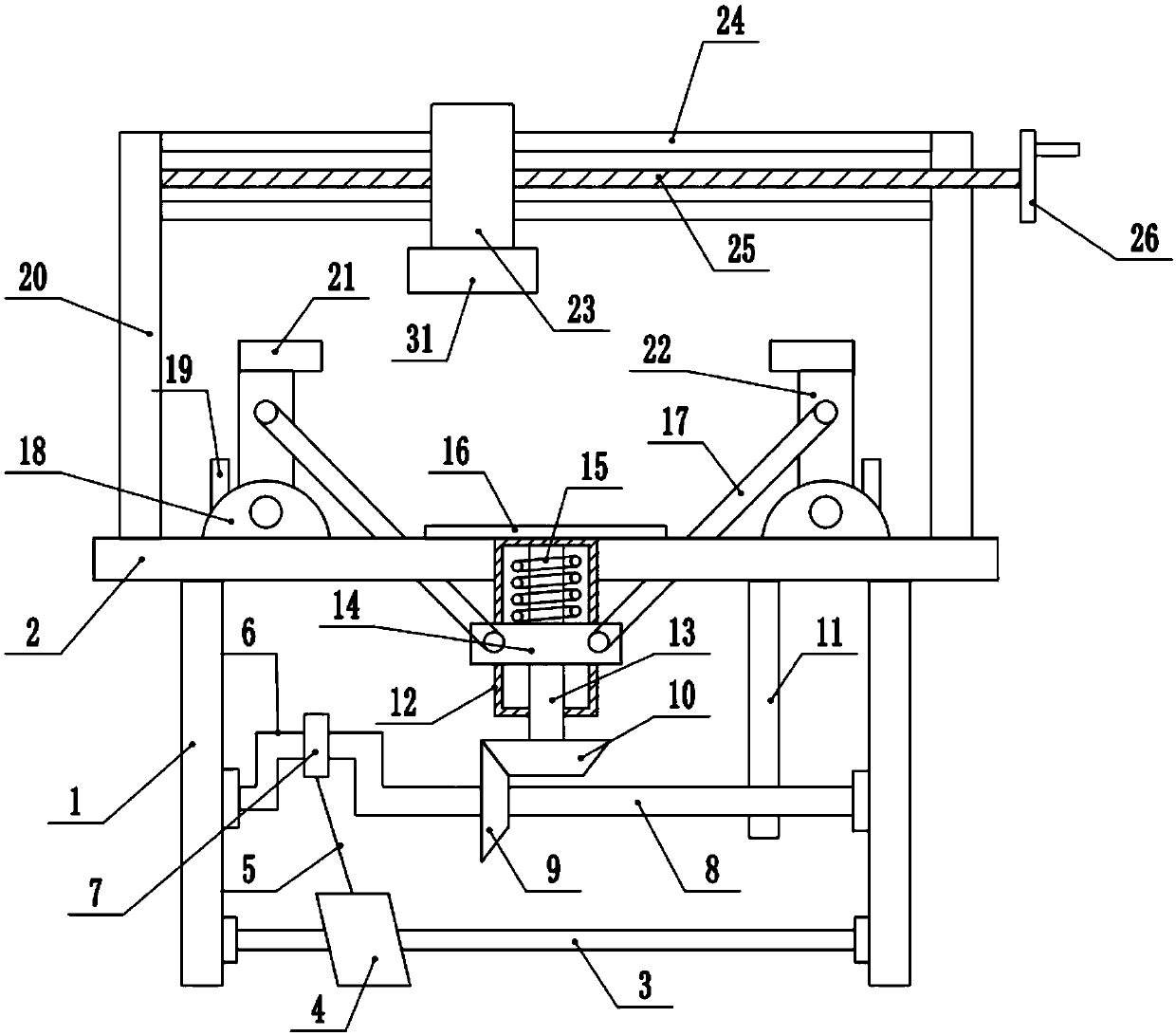

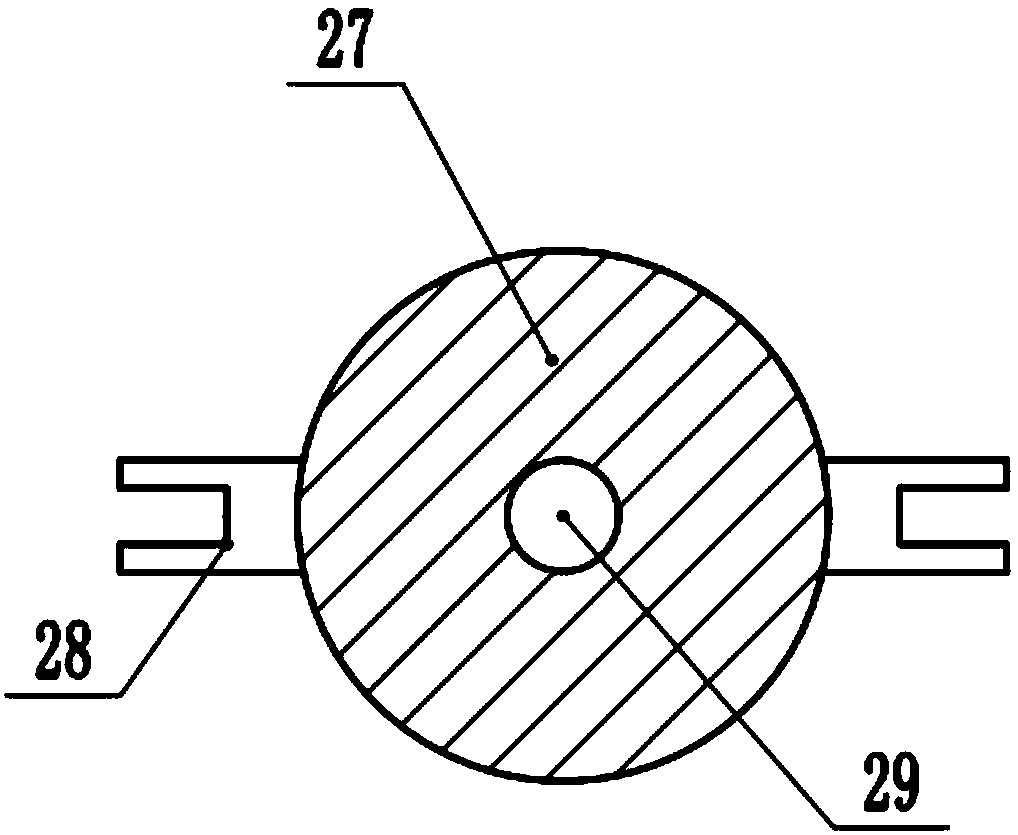

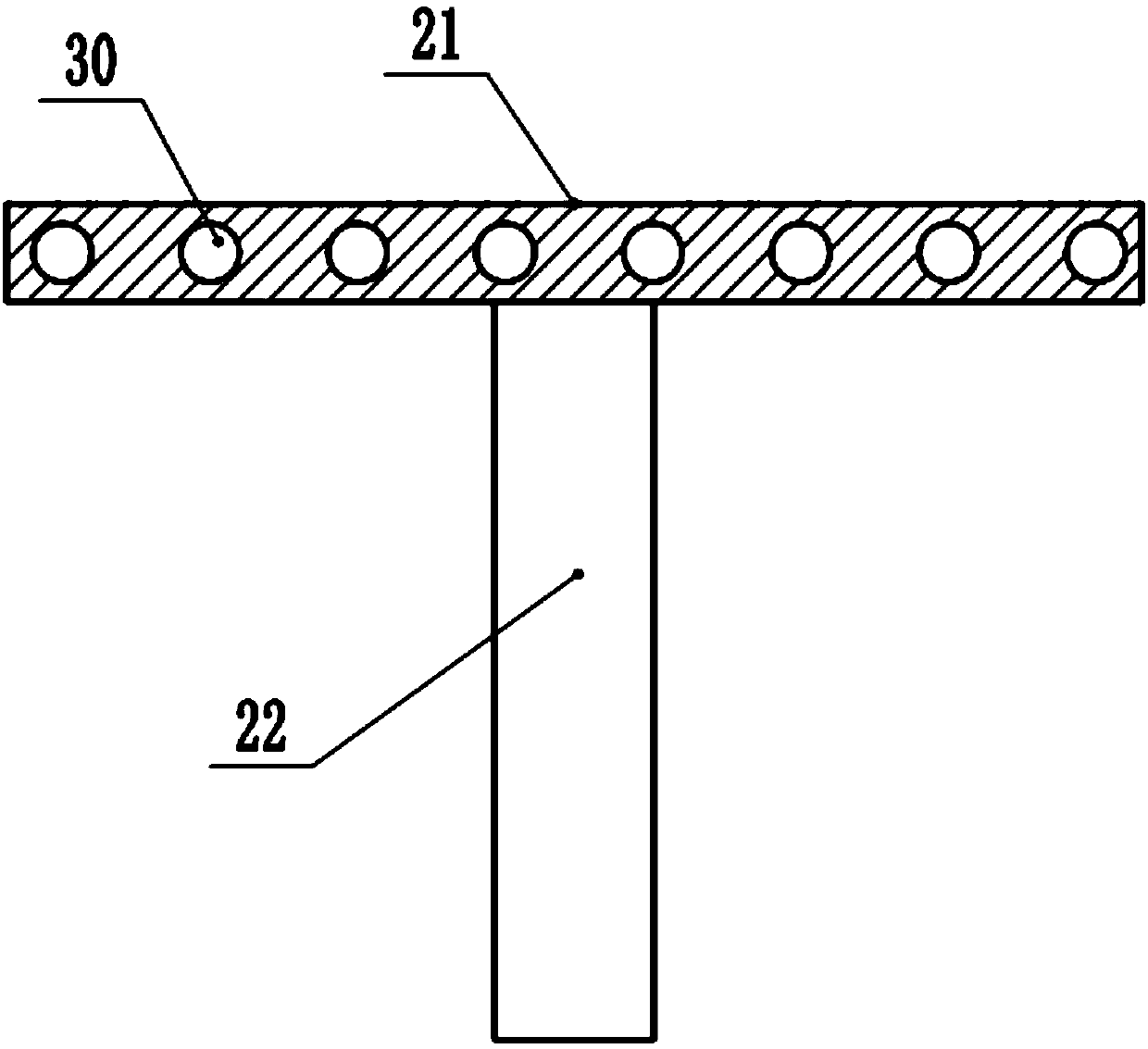

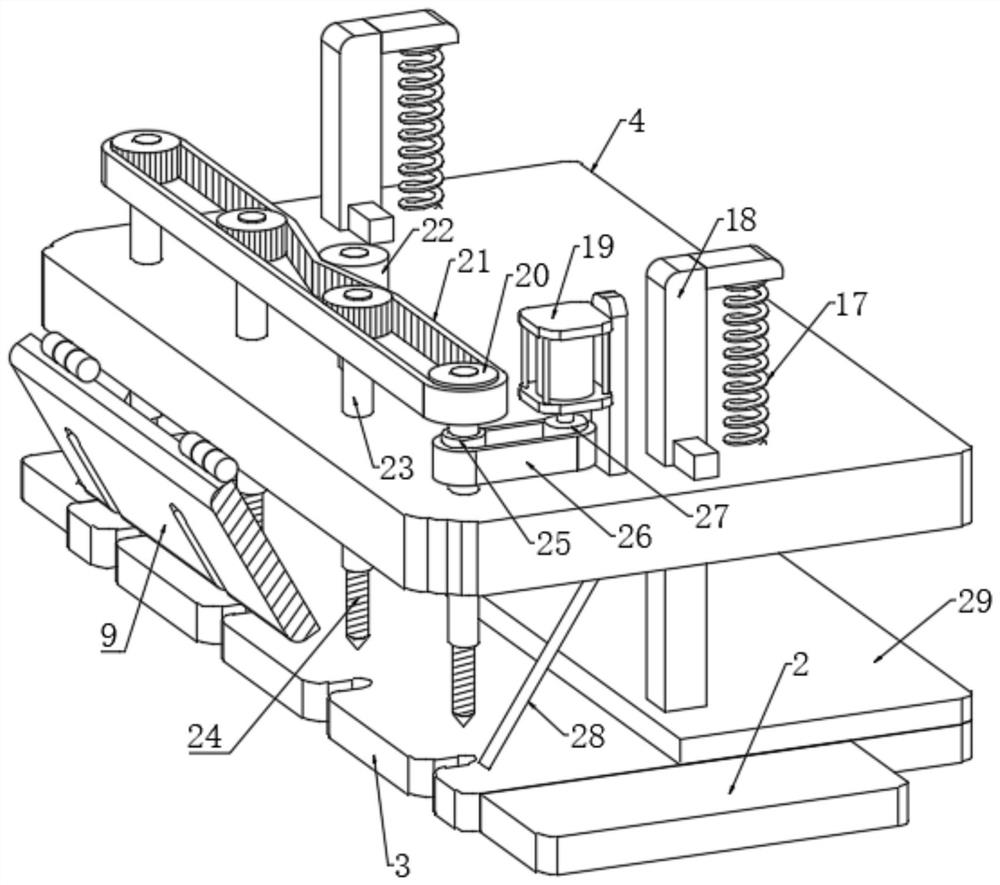

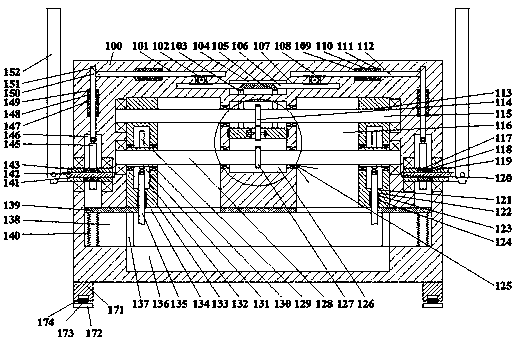

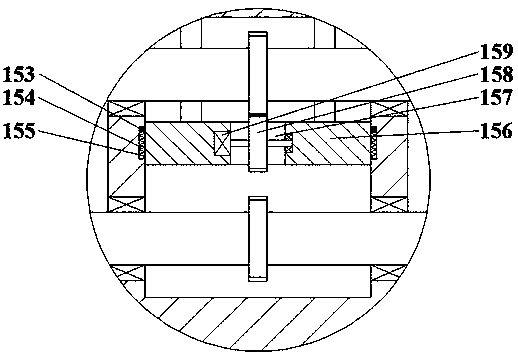

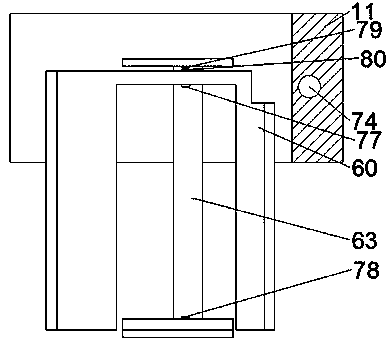

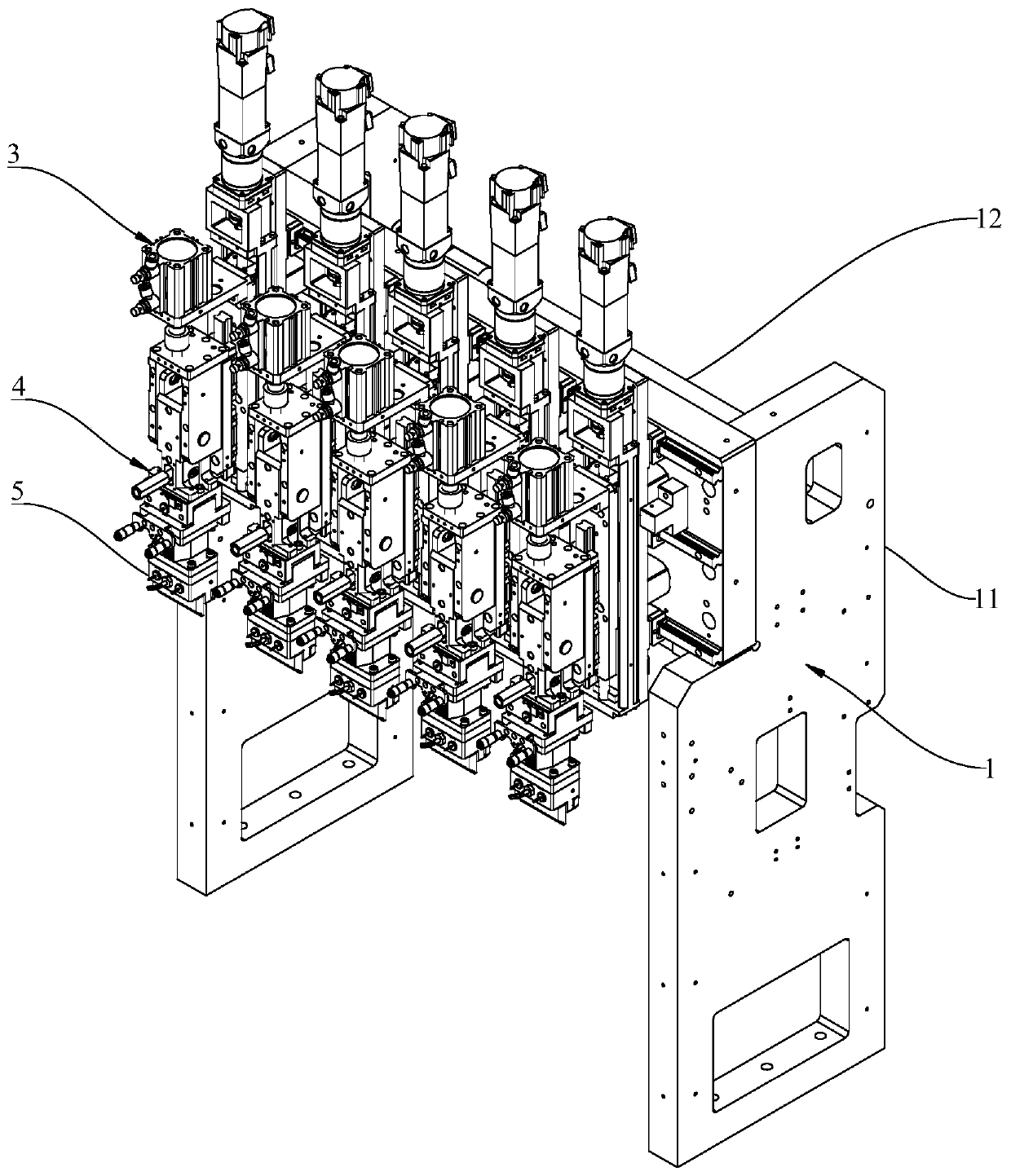

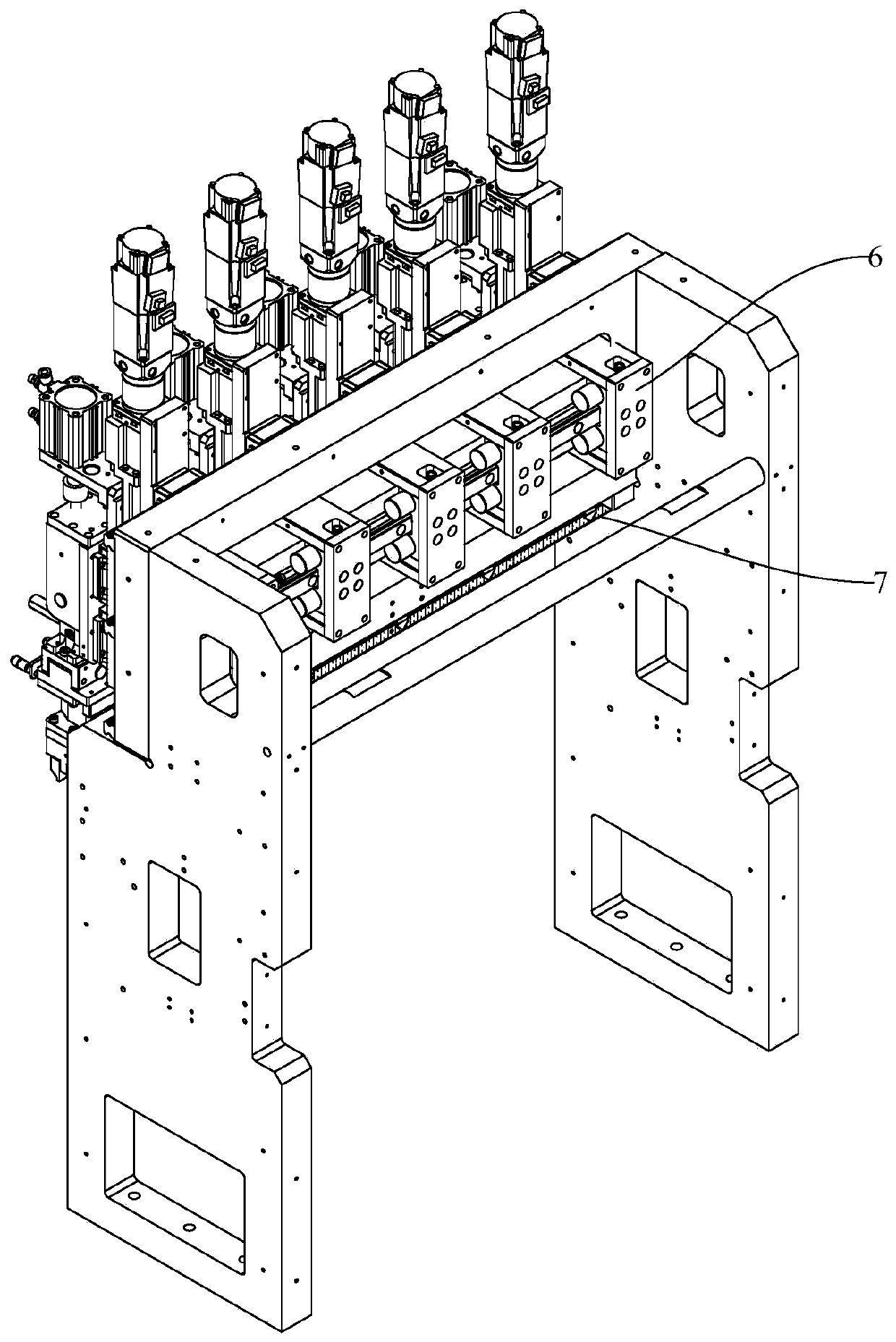

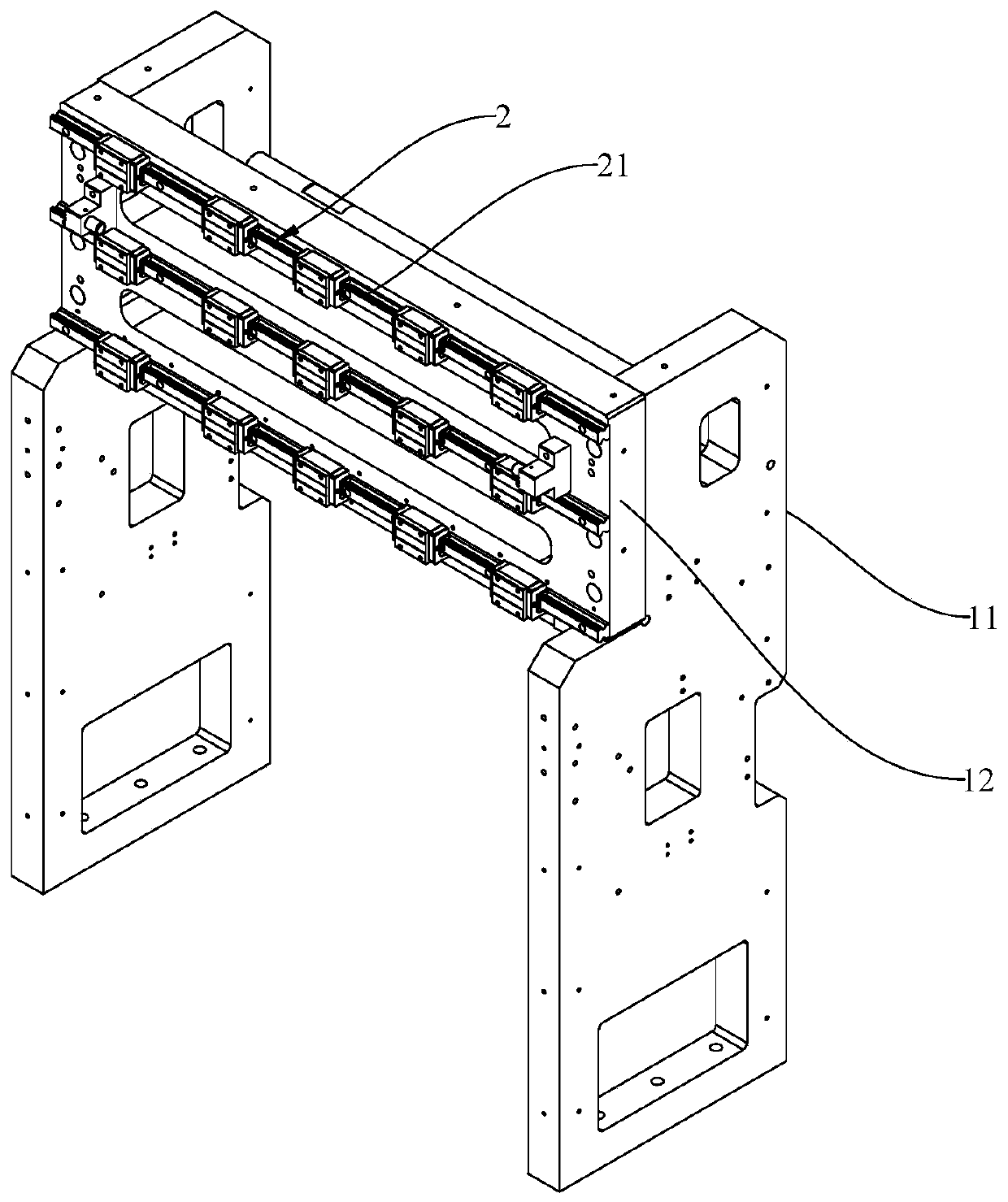

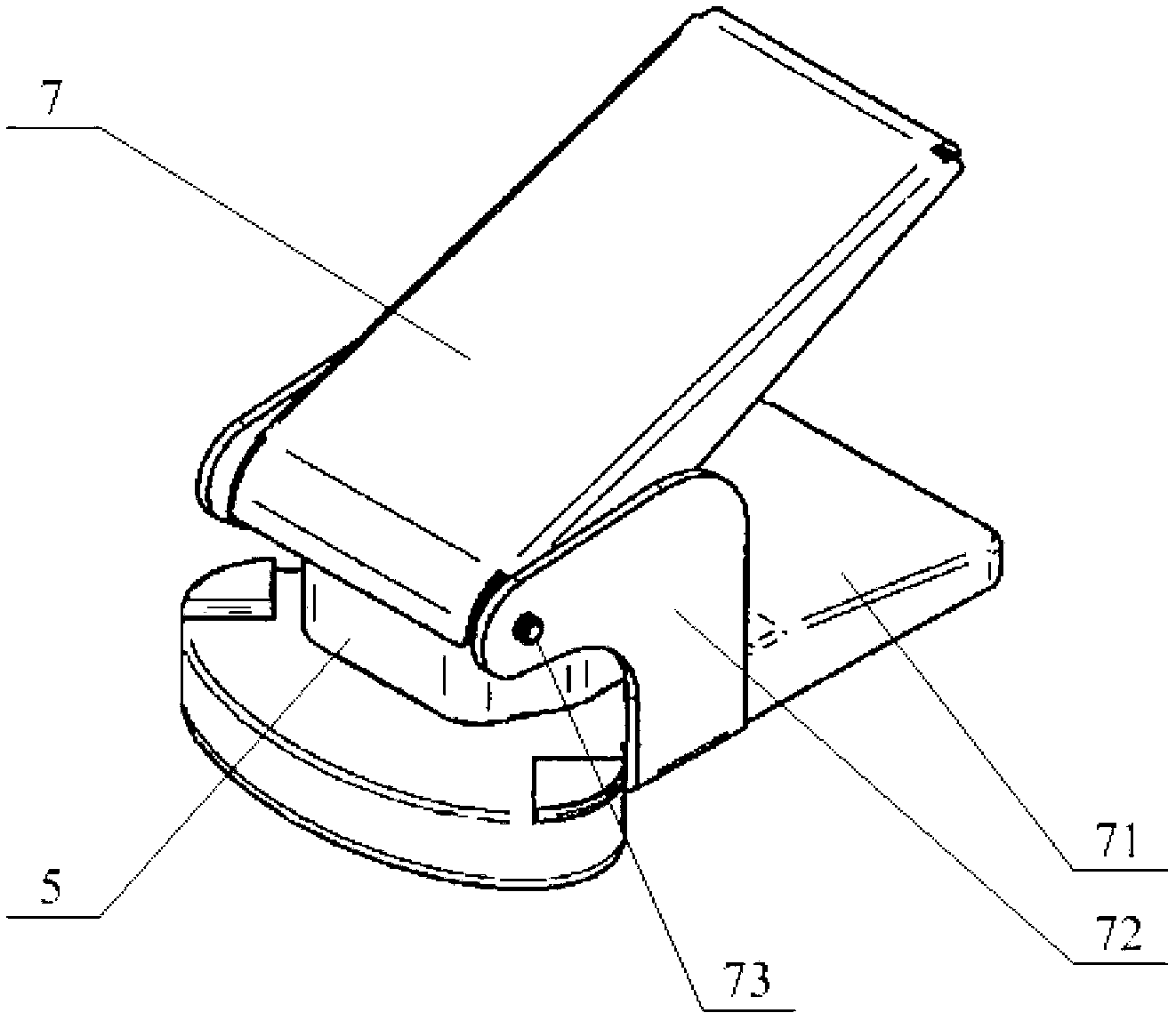

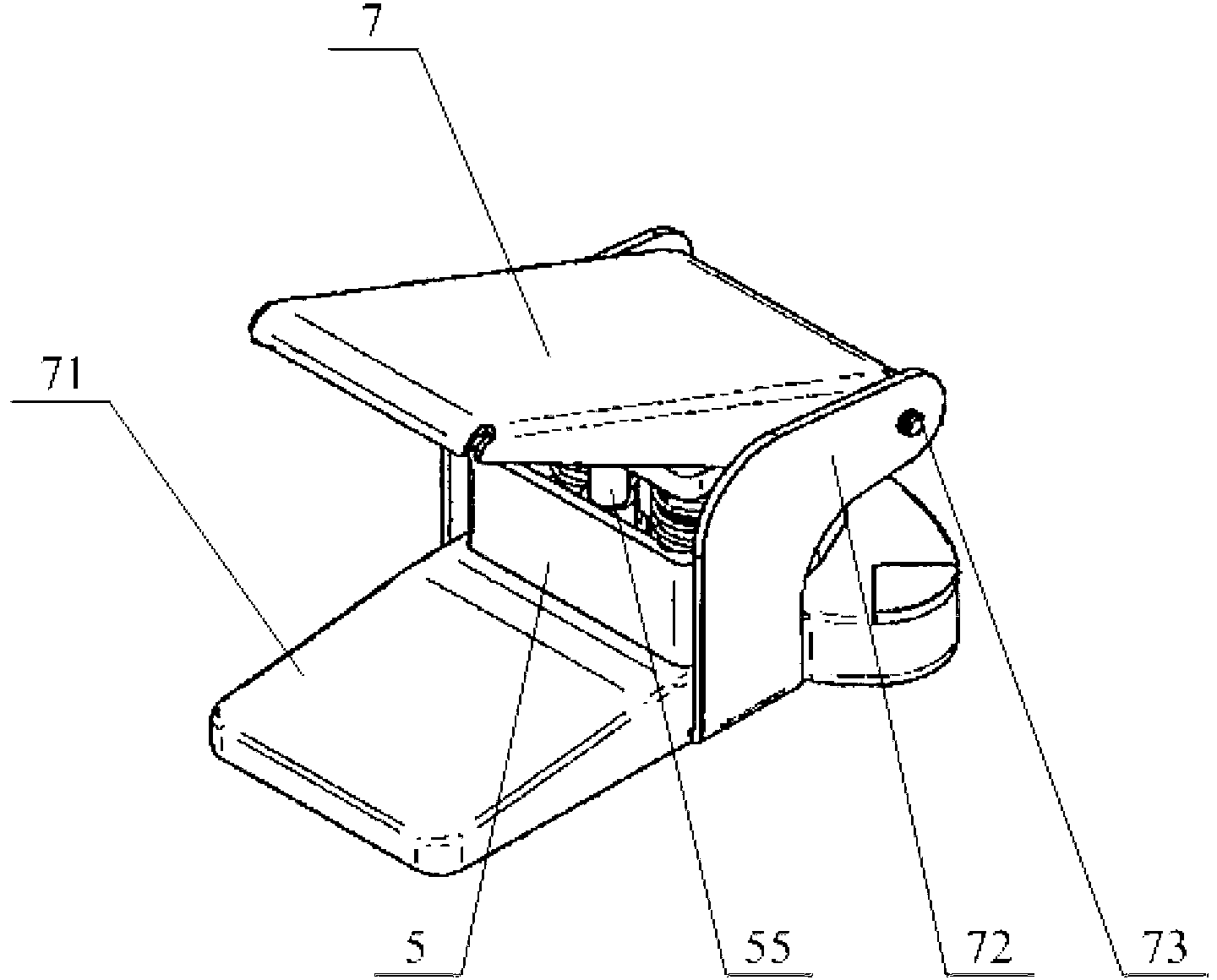

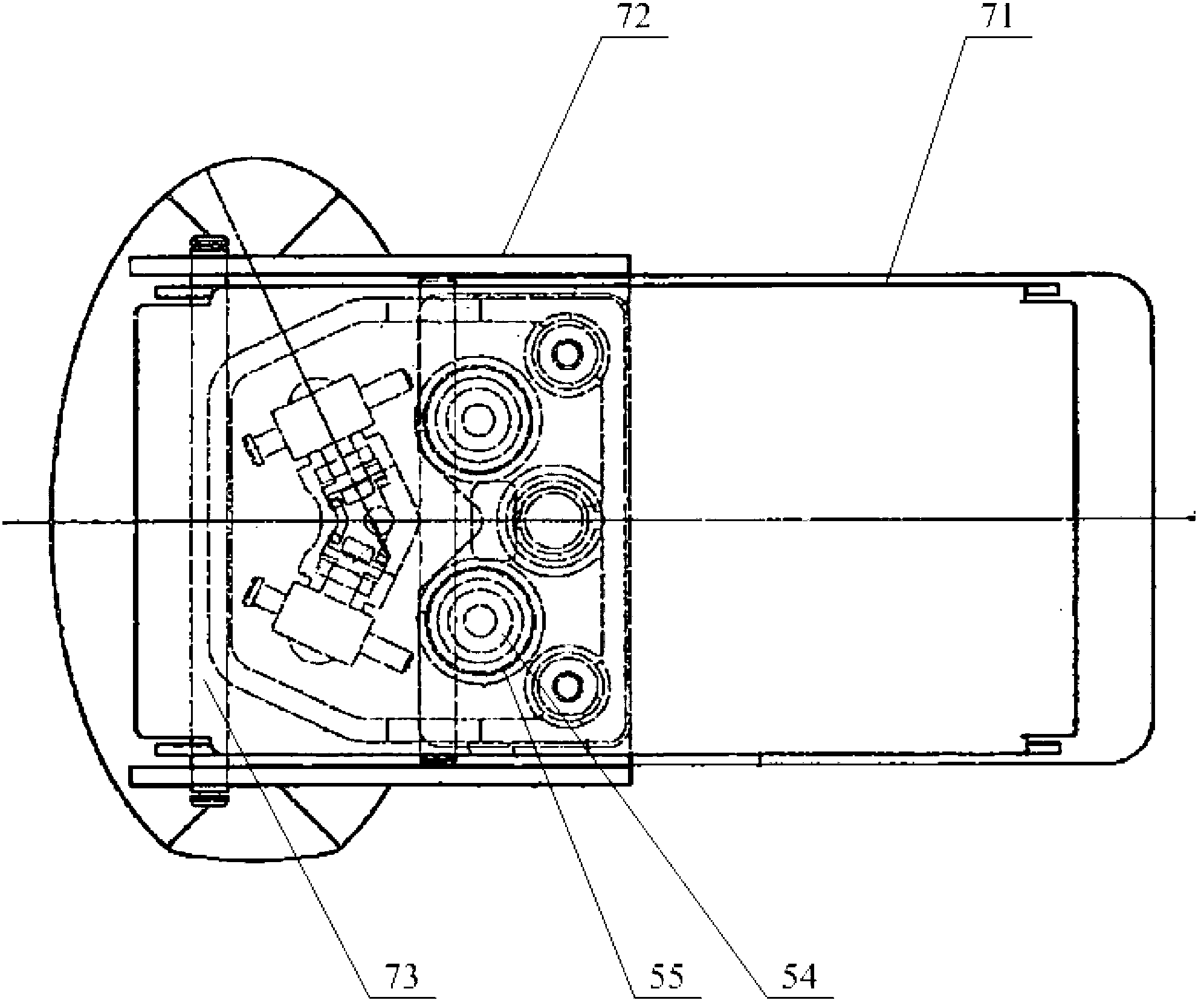

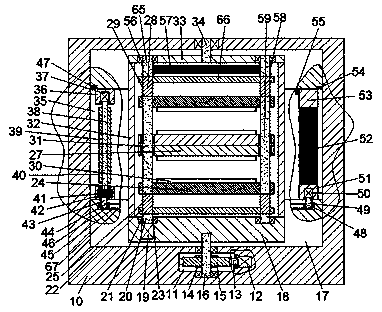

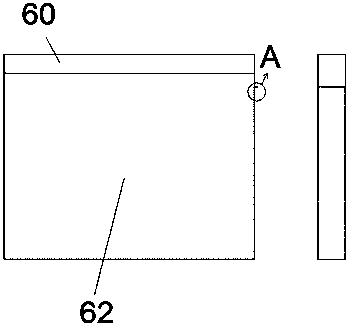

Multi-group hot pressing head device capable of being independently adjusted

ActiveCN110913607ARapid positioningImprove stabilityPrinted circuit assemblingStructural engineeringMechanical engineering

The invention discloses a multi-group hot pressing head device capable of being independently adjusted. The multi-group hot pressing head device comprises a frame, a guide rail installed on the frame,a plurality of lifting devices connected with the guide rail in a sliding mode, a plurality of horizontal adjusting mechanisms installed below the lifting devices and a plurality of hot pressing heads installed below the horizontal adjusting mechanisms. The hot-pressing heads are arranged at intervals in the length direction of the guide rail and can be adjusted in position, the horizontal adjusting mechanism can adjust the levelness of the hot-pressing heads, and the lifting device can drive the hot-pressing heads to ascend and descend. According to the invention, multiple groups of hot-pressing head units are adopted, the distance and the position of the hot-pressing head can be independently adjusted; the horizontal adjusting mechanism is adopted at the same time, so that the levelnessof the hot-pressing head is not easy to change, and the horizontal adjusting mechanism is simple in structure and is beneficial for an operator to adjust the levelness of the hot-pressing head more simply and quickly, thereby improving the binding stability and the binding quality.

Owner:东莞市集银智能装备有限公司

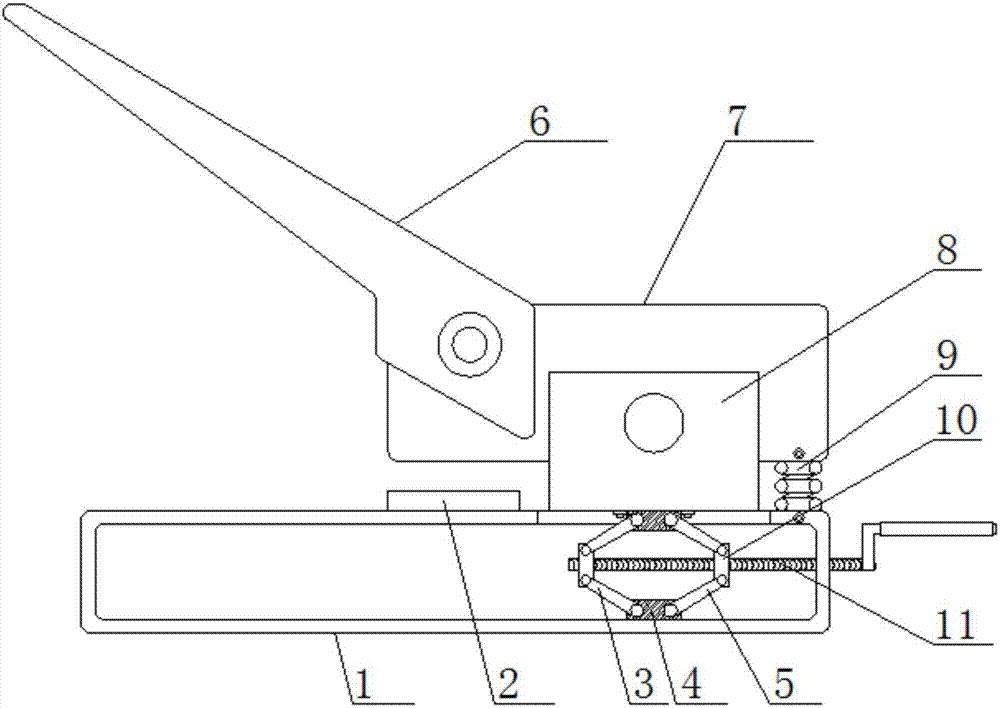

Nailless binding device

InactiveCN102935771APlay the role of positioningAvoid offsetSheet bindingEngineeringMechanical engineering

The invention provides a nailless binding device. The nailless binding device comprises a handle, a base platform and a binding machine, two sides along the longitudinal direction of the base platform are respectively provided with a supporting plate, the front end of the handle is arranged between the two supporting plates and hinged with the two supporting plate through a rotating shaft, a slicing device and a notch blade are arranged in the binding machine, and the bottom of the binding machine is fixedly connected with the base platform. A positioning device is arranged in the binding machine and comprises a guide block and a guide groove which are mutually matched, and the cross sections of the guide block and the guide groove are both trapezoid. The nailless binding device completes nailless binding through the handle, the base platform and the binding machine, the guide block and the guide groove which are arranged in the binding machine and both have trapezoid cross sections can perform the positioning function on the binding machine, relative sliding of the guide block and the guide groove is guaranteed, a matching gap between the guide block and the guide groove is simultaneously reduced as far as possible, the fact that sliding and displacement of the binding machine at the same time is avoided, accordingly accurate positioning of the binding machine is guaranteed, and binding accuracy and binding quality are improved.

Owner:徐静波

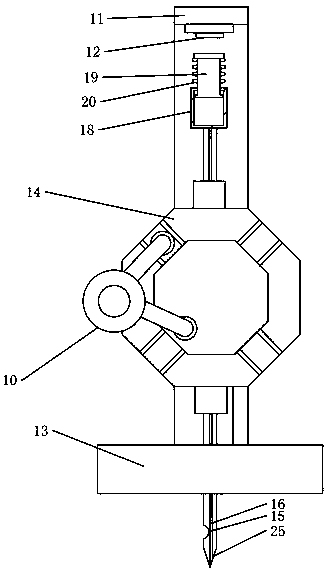

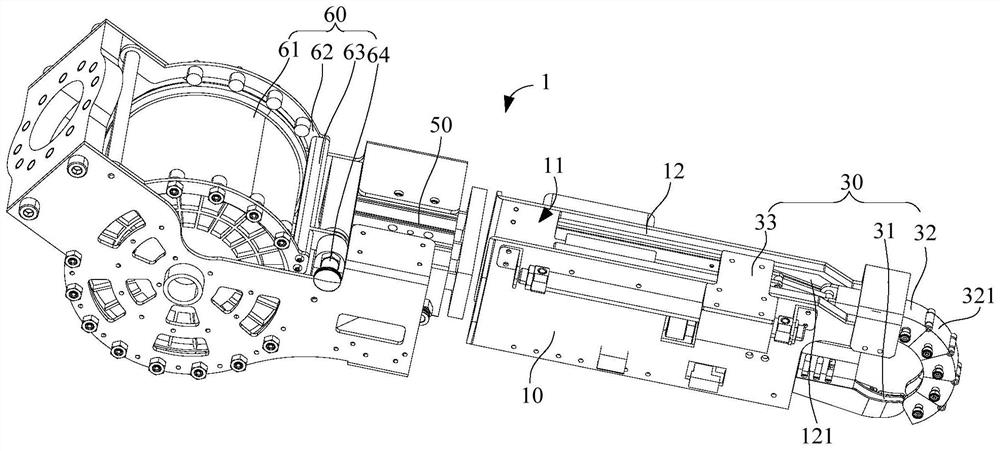

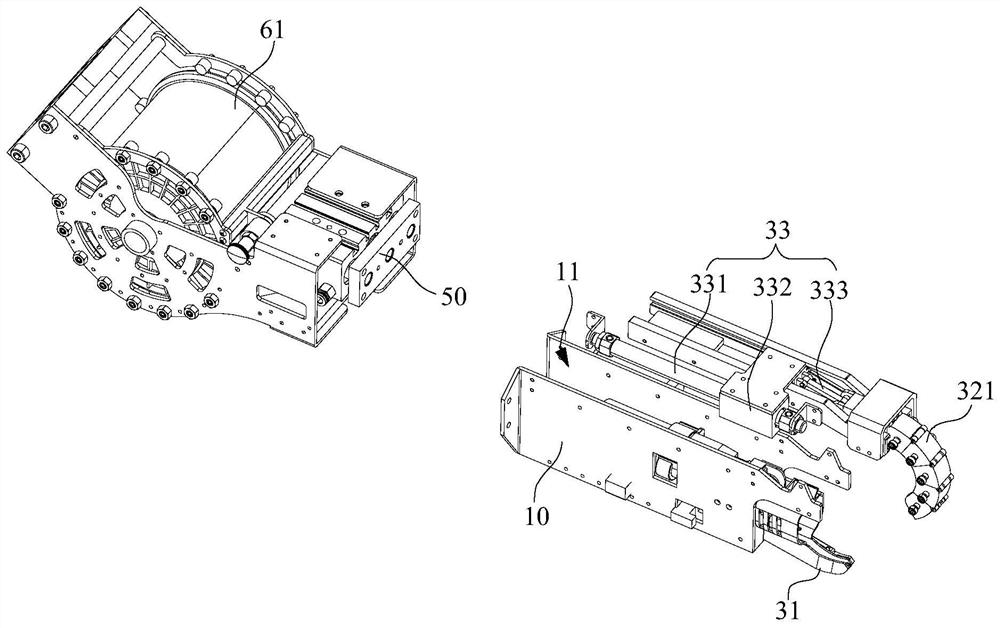

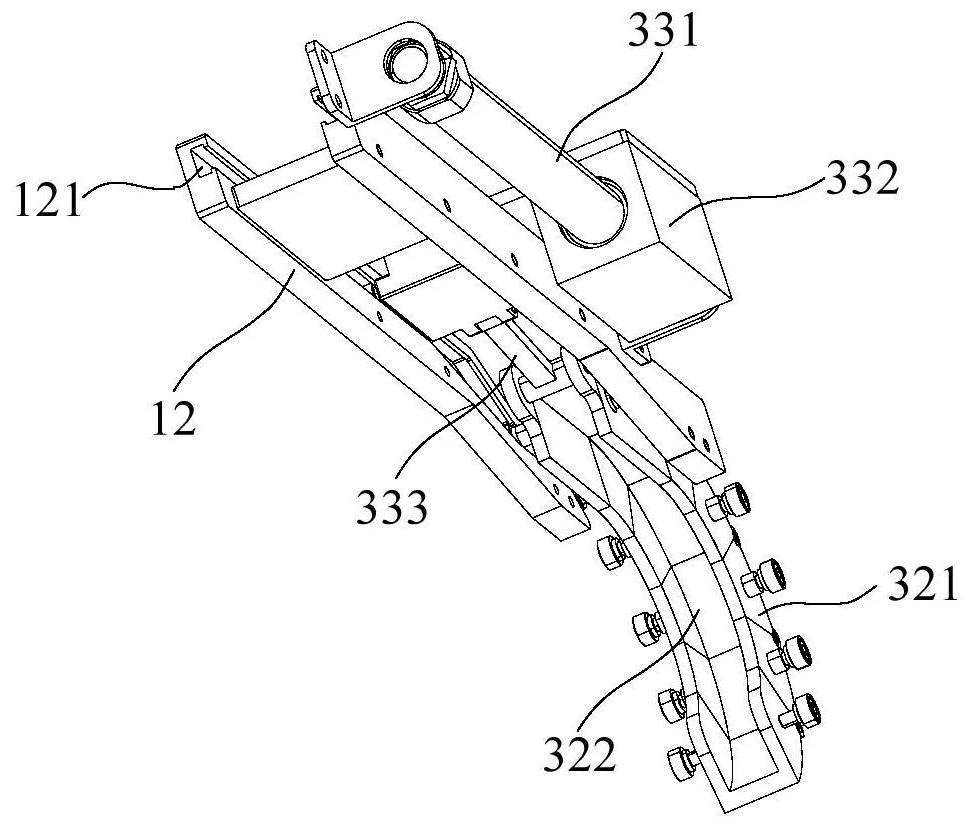

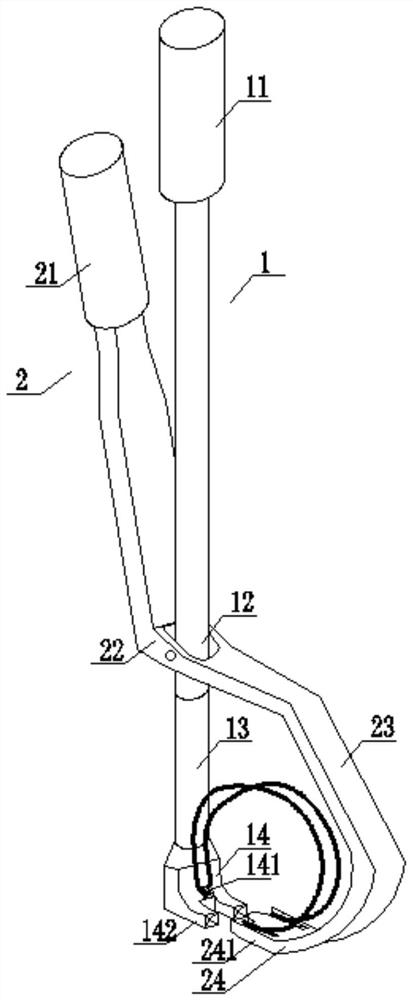

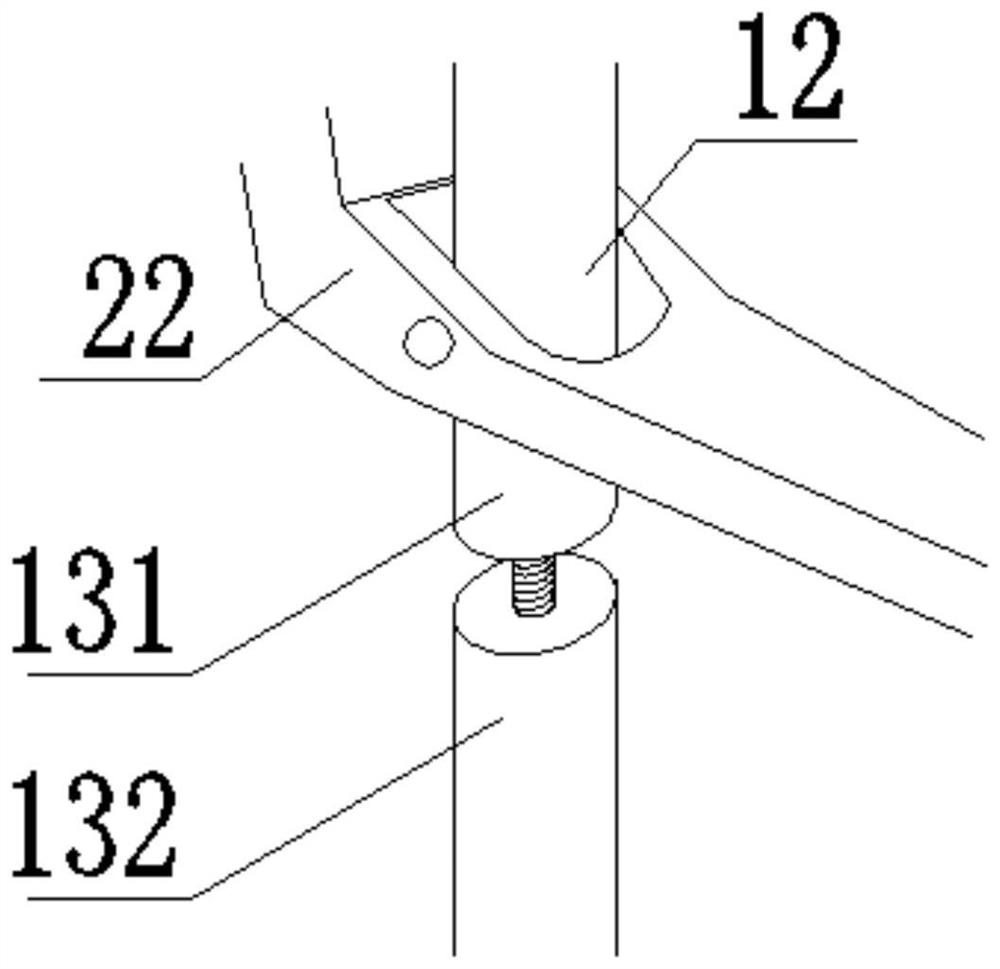

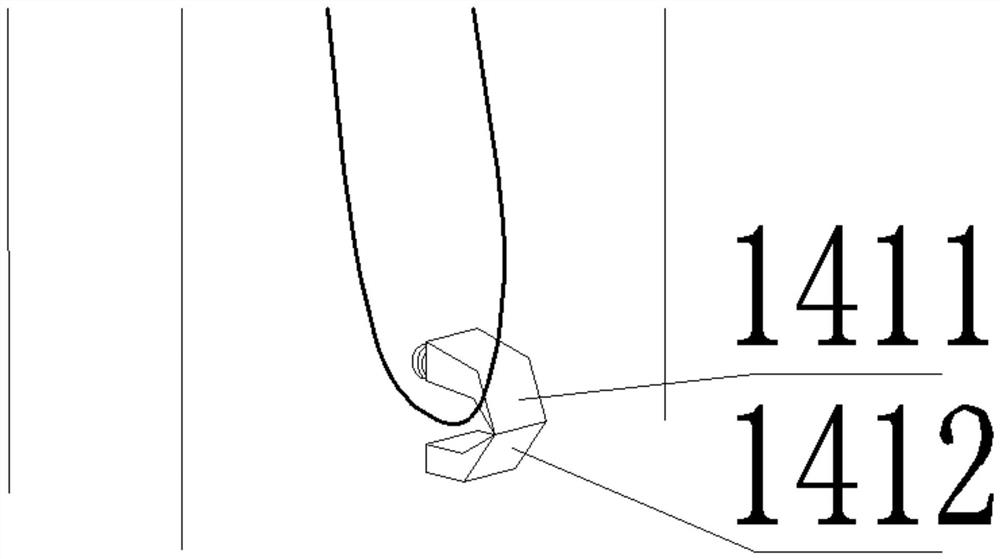

Binding device and automatic binding robot

PendingCN112343350AImprove the binding success rate and binding qualityIncrease success rateBuilding material handlingRebarMechanical engineering

The invention provides a binding device and an automatic binding robot. The binding device comprises an operation arm, a wire feeding mechanism, a wire bending mechanism and a screwing mechanism; thewire feeding mechanism is arranged on an operation arm and used for conveying binding wires to the wire bending mechanism; the wire bending mechanism is arranged at the front end of the operation armand comprises a guide jaw, a first guide part and a first drive assembly; the guide jaw is fixedly connected with the operation arm, the first guide part is movably connected with the operation arm, the first driving assembly is arranged on the operation arm, the first driving assembly is connected with the first guide part and used for driving the first guide part to surround a reinforcing steelbar intersection point so as to form a closed guide loop with the guide jaw, and the closed guide loop is used for guiding the binding wires, so that a binding ring is formed at the steel bar intersection point; the screwing mechanism is arranged on the operation arm and is adjacent to the wire bending mechanism; and the screwing mechanism is used for screwing the two ends of the binding ring so as to bind the steel bar intersection point.

Owner:CHINA CONSTR SCI & TECH CO LTD

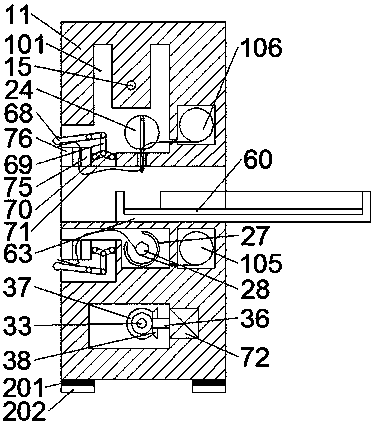

Binding machine and application method thereof

InactiveCN109177575ASimple structureEasy to operateBook making processesBookbinding adhesiveBody contactWorking temperature

The embodiment of the invention relates to a binding machine and an application method thereof. The binding machine comprises a device main body, a paper wrapping and clamping device fixedly arrangedin the device main body, a back milling device fixedly arranged in the device main body and a hot melting gluing device fixedly arranged in the device main body. Along with faster and faster development nowadays in China, many materials need to be bound in daily life or work. The materials are always stacked thickly. A common nail type binding machine cannot meet the demand of people. A hot melting gluing binding machine is designed to bind paper of different thicknesses simultaneously. In addition, as the working temperature of hot melting gluing is relatively high and commonly reaches about200 DEG C, the binding process is automated as a result of a simultaneously structural design of the device. Meanwhile, an operator can observe the binding process clearly while the body is not in contact with the machine inside, so that the safety performance of the device is improved greatly and it is really necessary to invent the binding machine.

Owner:王晓

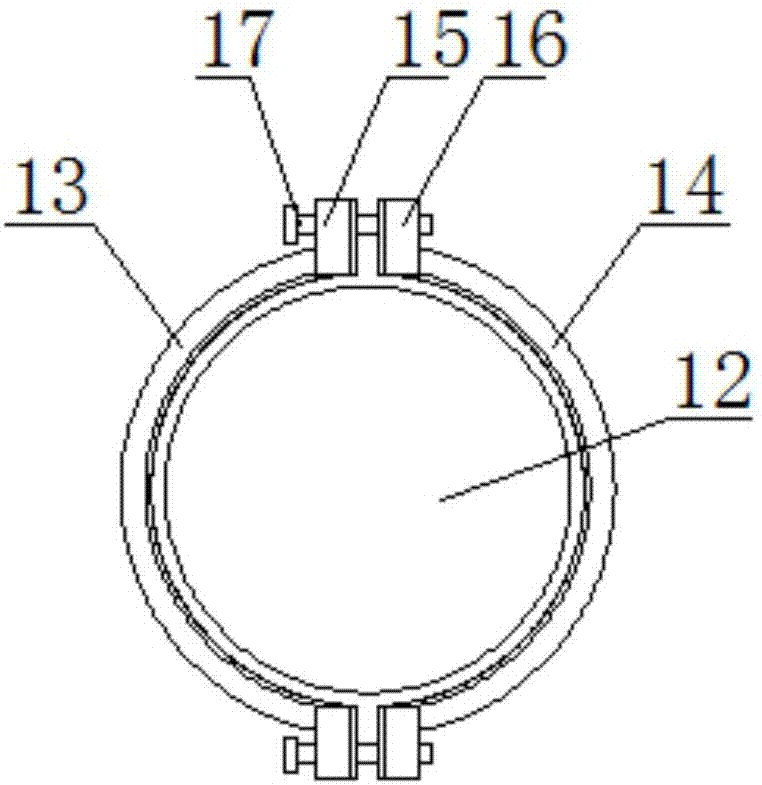

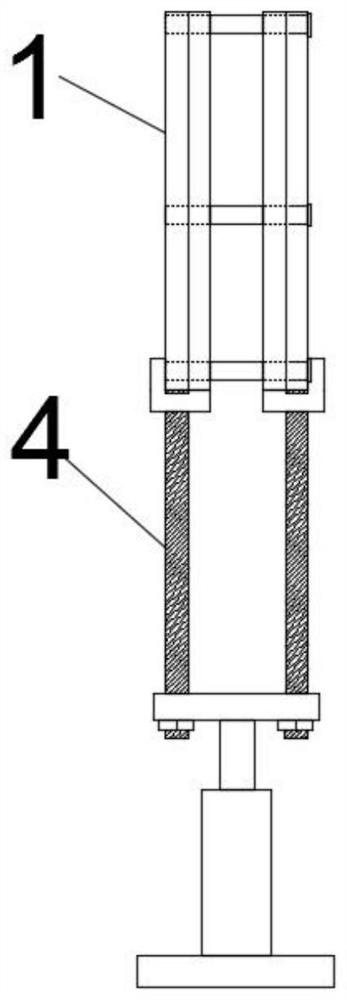

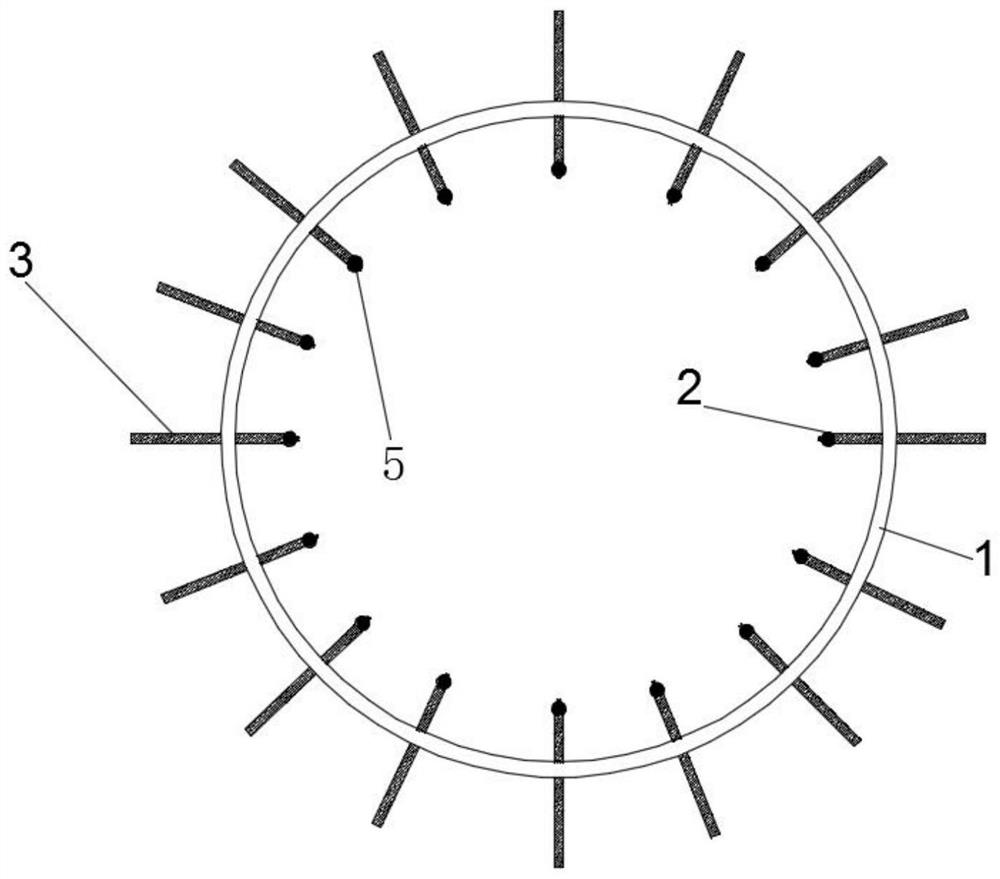

Building construction steel bar positioning device

ActiveCN113235823AImprove welding qualitySave spaceBuilding reinforcementsArchitectural engineeringRebar

The invention discloses a building construction steel bar positioning device. The building construction steel bar positioning device comprises a positioning disc, a plurality of steel bar positioning structures and a positioning frame; the positioning disc is installed on the positioning frame, and the steel bar positioning structures are movably arranged on the positioning disc; the positioning disc comprises two symmetrically arranged positioning rings and a plurality of connecting rods, the connecting rods are arranged between the two positioning rings, and a sliding groove is formed between the two connected positioning rings; each steel bar positioning structure comprises a positioning sleeve and a positioning rod; the lower end of the positioning sleeve is provided with a sleeving protrusion, the sleeving protrusion is connected with the corresponding positioning rod, and the other end of the positioning rod is movably arranged in the corresponding sliding groove; and the positioning frame comprises a bottom plate and a positioning mechanism, and the positioning mechanism is arranged on the bottom plate. According to the device, the positioning disc is arranged to be of a detachable structure and is assembled for use during use, space is saved, and transportation difficulty is lowered; the steel bar positioning structures can position and support main bars, the binding precision of a steel reinforcement cage is guaranteed, and the building construction steel bar positioning device has the advantages of being convenient to use, reasonable in structure and capable of greatly shortening the construction process and improving the construction quality.

Owner:SHANGHAI GREENLAND CONSTR GRP

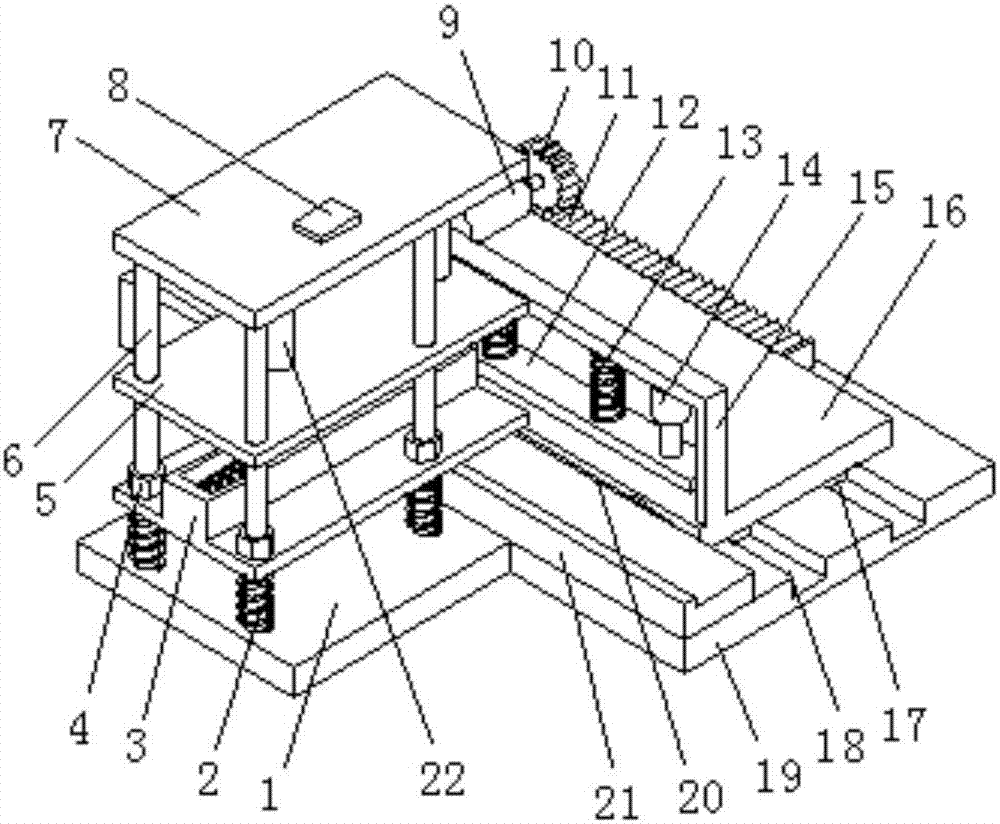

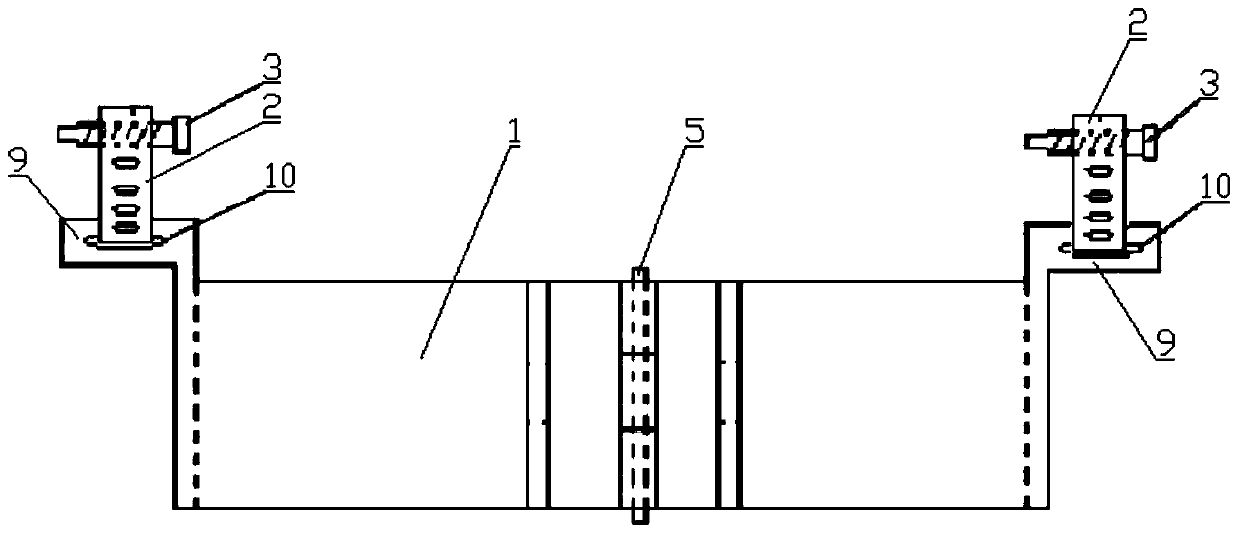

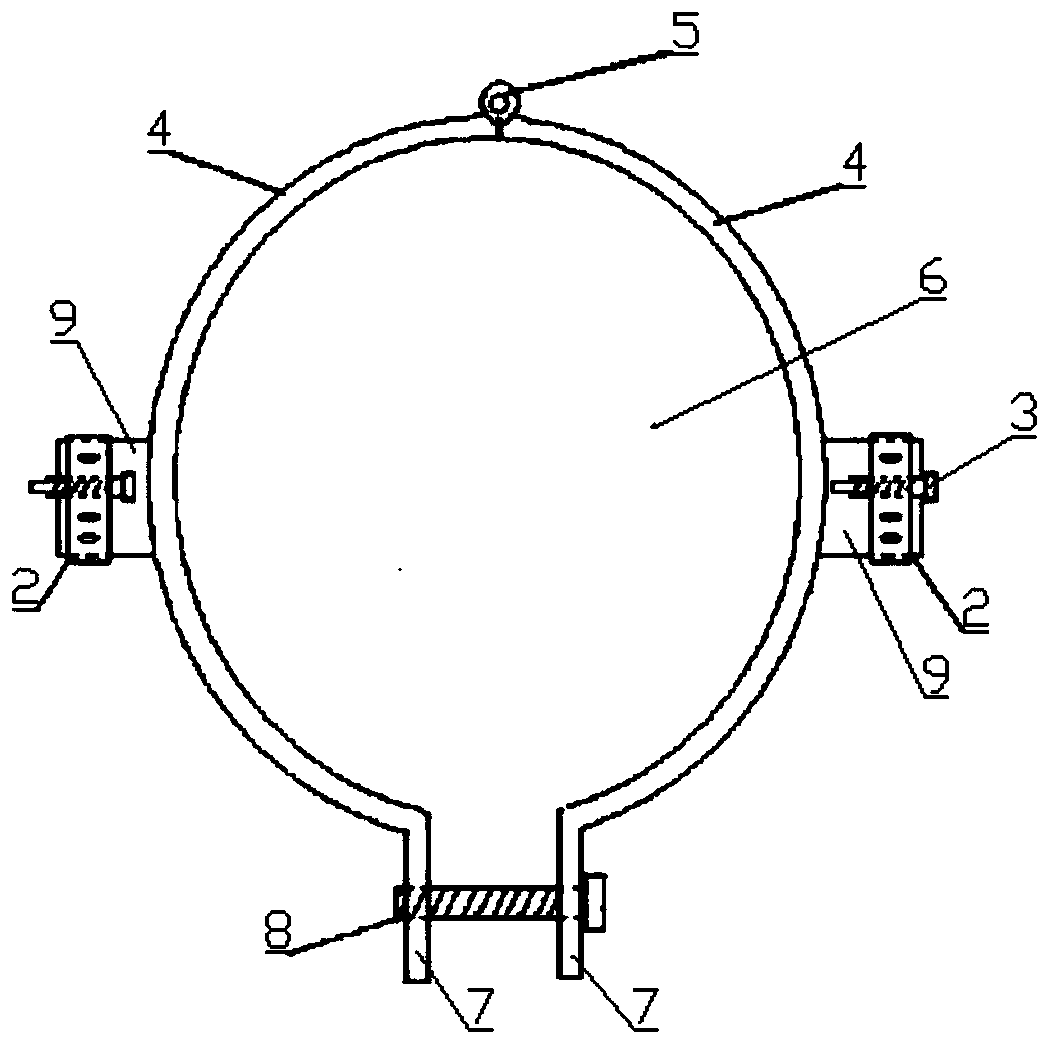

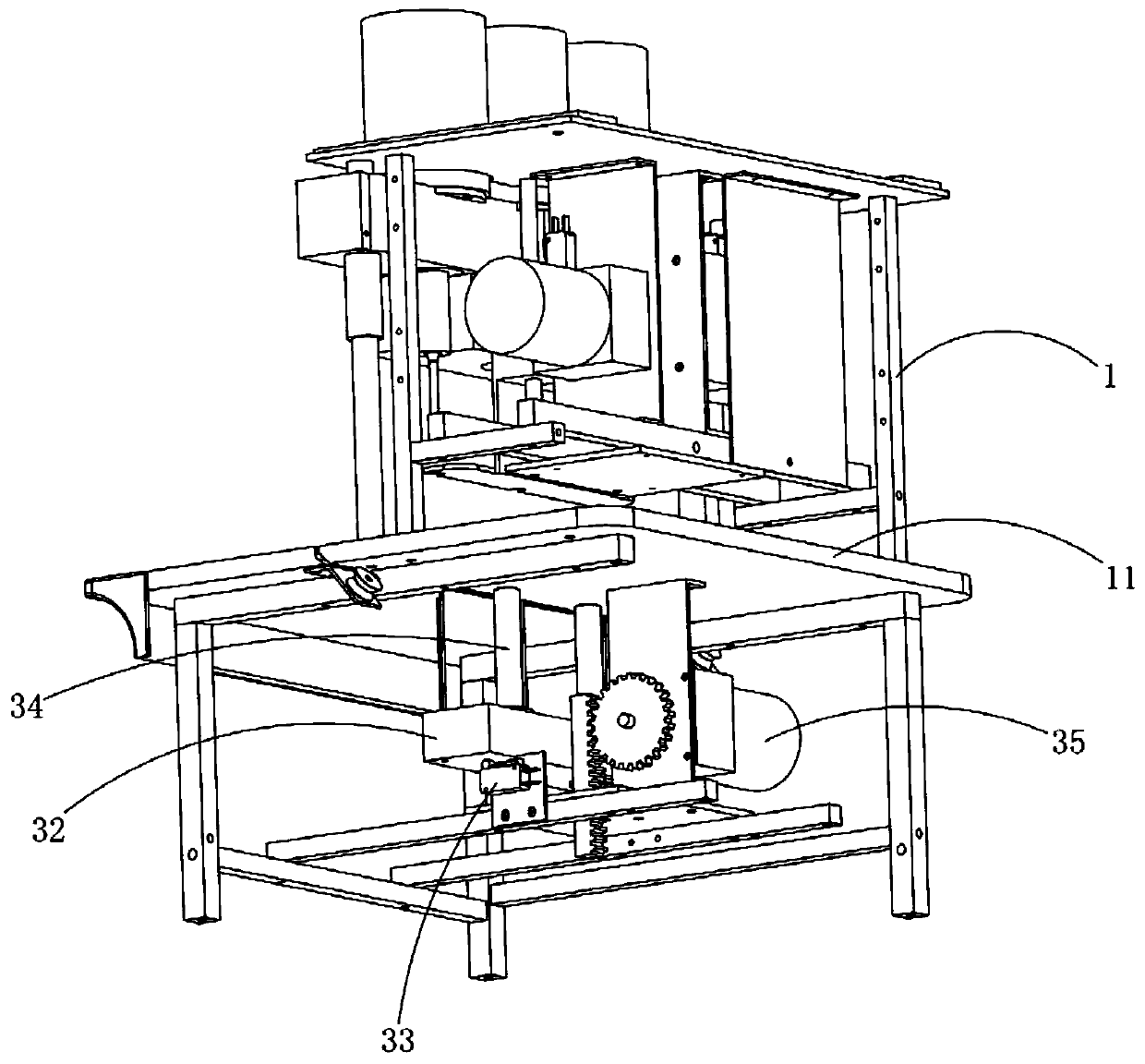

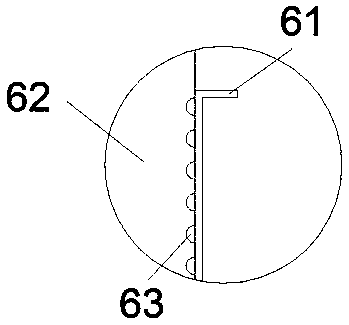

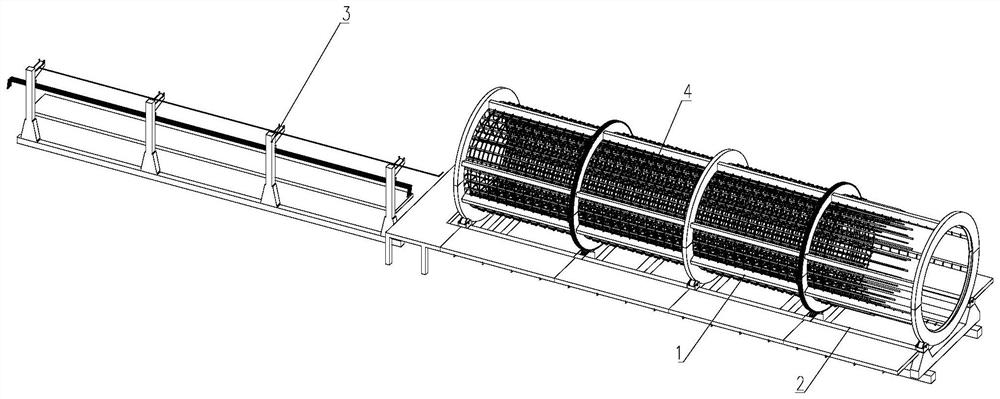

Rolling type cylindrical hollow pier reinforcement cage binding jig frame

PendingCN113732215ASimple structureEasy to manufactureWire networkBridge erection/assemblyGear wheelEngineering

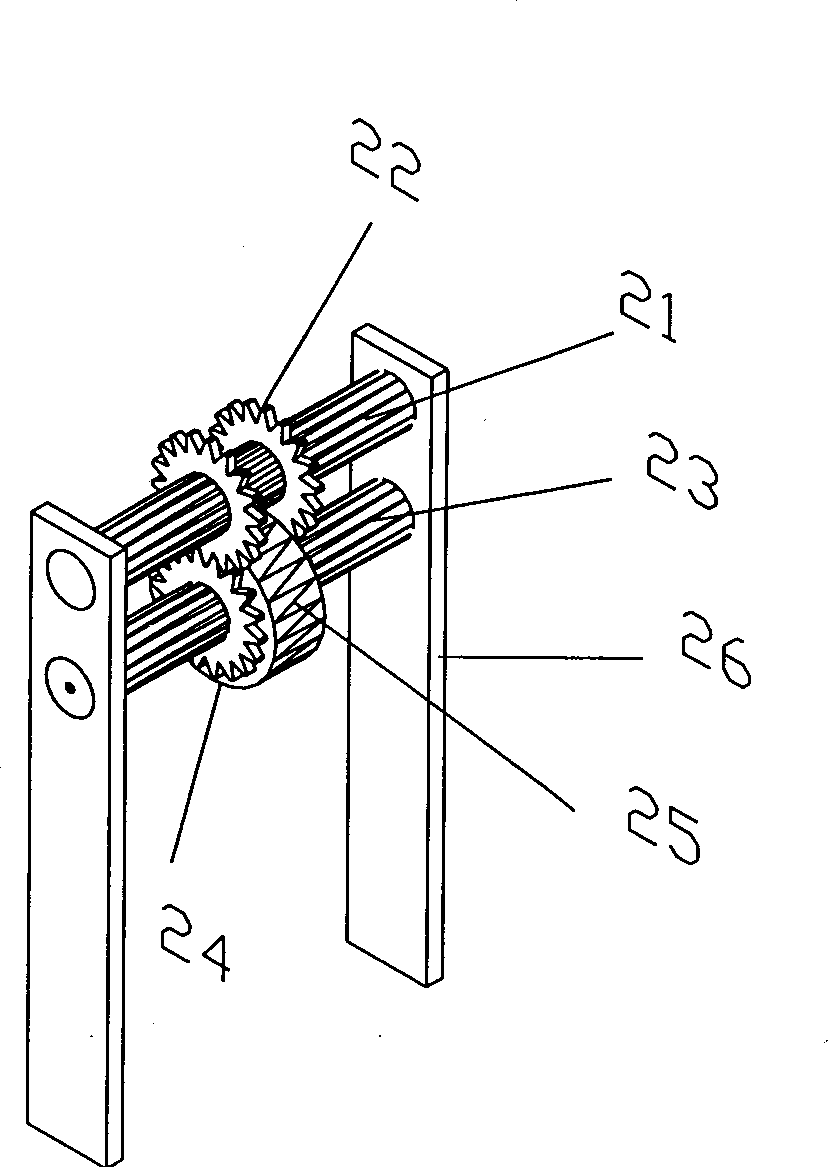

The invention discloses a rolling type cylindrical hollow pier reinforcement cage binding jig frame which comprises a reinforcement cage limiting frame, a base, a vertical rib auxiliary penetrating and conveying mechanism and an electric control system. The reinforcement cage limiting frame is formed by splicing two semicircular limiting frame bodies, each limiting frame body comprises a plurality of annular toothed rails and a plurality of limiting longitudinal beams which are arranged in the circumferential direction and used for connecting the annular toothed rails into a whole in series, and a plurality of limiting grooves are formed in the limiting longitudinal beams; and a plurality of driving gears which are controlled by the electric control system to rotate are rotationally assembled on the base, and the driving gears are in one-to-one correspondence with the annular toothed rails and are in meshing transmission with the corresponding annular toothed rails. In the reinforcement cage binding process, the reinforcement cage limiting frame and a reinforcement cage can be driven by the driving gears to rotate by an angle of a vertical rib and are locked, the vertical rib does not need to be conveyed by 360 degrees in the circumferential direction around the reinforcement cage, the forming quality of the reinforcement cage is effectively assisted and controlled, and meanwhile, the convenience and safety of binding operation of the reinforcement cage are improved.

Owner:湖南五新智能科技股份有限公司

Semi-automatic manufacturing method of cast-in-place pile reinforcement cage

InactiveCN112317660AImprove binding efficiencyImprove binding qualityWire networkBuilding reinforcementsElectric machinerySemi automatic

The invention discloses a semi-automatic manufacturing method of a cast-in-place pile reinforcement cage. The semi-automatic manufacturing method comprises the following steps that 1, reinforcement cage main reinforcement limiting clamps are installed on a hardened site; 2, the axes of machined reinforcement cage reinforcing rings are connected in series, the reinforcing rings connected in seriesare welded to a first reinforcing steel bar, the reinforcing rings are rolled to a second main reinforcing steel bar to be welded, and so on, welding is conducted, and binding of main reinforcing steel bars is completed; and 3, two rolling shafts with the interval of 30 cm are arranged at the last main reinforcing steel bar, one end of each rolling shaft is connected with a motor and rotates alongwith the motor, and one end of each stirrup penetrates through a movable sliding block to be welded to the reinforcement cage. Manufacturing is easy, operation is convenient, and the binding efficiency and quality of stirrups can be improved through the sliding blocks and the rolling shafts. The main reinforcing steel bars can be distributed on a bracket according to a fixed interval, the reinforcement cage reinforcing rings are placed on the first main reinforcing steel bar and the second main reinforcing steel bar, meanwhile, the longitudinal interval of the reinforcement cage reinforcing rings is adjusted according to design requirements, and welding is conducted.

Owner:中国建筑土木建设有限公司

Steel bar binding tool and method

ActiveCN113187246AEasy to operateWork requires little spaceBuilding material handlingEngineeringRebar

The invention discloses a steel bar binding tool and method, relates to the technical field of building construction, and can go deep into some narrow parts to preliminarily bind steel bars at the narrow parts. The tool comprises a main arm and an auxiliary arm which are hinged to each other, wherein the main arm is provided with a first frame body part and a first clamping end, the first frame body part comprises an upper frame body part and a lower frame body part which are in threaded connection, the first clamping end is provided with a pre-clamping part and a rear clamping part, the auxiliary arm is provided with a second frame body part and a second clamping end, and a front clamping part is arranged on the second clamping part. Through cooperation of the main arm and the auxiliary arm, surrounding and binding operation of steel bars can be completed without other tools, operation is easy and fast, the space needed by the operation is small, the tool can enter some complex positions for binding conveniently, and the binding quality of the steel bars at complex positions is improved.

Owner:四川国恒建筑设计有限公司

Automatic efficient binding machine for accounting finance

The invention discloses an automatic efficient binding machine for accounting finance in the technical field of accounting financial binding. A ruler is arranged on the front side of a limiting block,telescopic air cylinders are correspondingly arranged on the outer sides of two sets of stand columns, and a guide rod is arranged at the top of each telescopic air cylinder; inner cavities of the stand columns are provided with assembly barrel grooves, guide grooves are formed in the two sides of the left side wall and the right side wall of the assembling barrel grooves correspondingly, the guide rods penetrate through the assembly barrel grooves and then are connected with movable plates, and nail mounting grooves are formed in the tops of box bodies; plastic springs are arranged on the left side walls of the inner cavities of the box bodies, and the other ends of the plastic springs are connected with movable push plates; and the right sides of the movable push plates are provided with nail storage bins, and binding holes matched with binding plates are formed in the right sides of the nail storage bins. The automatic efficient binding machine for the accounting finance has the beneficial effects that the machine is reasonable in structural design, convenient to use and capable of realizing effective positioning and sorting of bills, so that unified binding is facilitated, themachine cannot be inclined in the using process, and the working efficiency is improved.

Owner:章静

Thin-wall hollow high pier reinforcing steel bar formwork support and construction method

InactiveCN108505442AImprove binding qualityGuaranteed Spacing RequirementsBridge structural detailsBridge erection/assemblyRebarHollow core

The invention provides a thin-wall hollow high pier reinforcing steel bar formwork support which comprises three square reinforcing steel bar plates arranged in parallel at certain intervals from highto low, uprights vertically connected with corresponding end points of the three reinforcing steel bar plates, reinforcing steel bar hoop frames horizontally tied to the uprights, and oblique reinforcing steel bars connecting the top ends of vertical reinforcing steel bars with the bottom ends of the adjacent vertical reinforcing steel bars, wherein reinforcing steel bar holes for the reinforcingsteel bars to pass through are vertically correspondingly formed in the three reinforcing steel bar plates. A provided construction method of the thin-wall hollow high pier reinforcing steel bar formwork support includes the steps that (1) the size is designed according to the size of a thin-wall hollow high pier; (2) the thin-wall hollow high pier reinforcing steel bar formwork support is manufactured; (3) the reinforcing steel bar formwork support is transported to the site; (4) the reinforcing steel bar formwork support is pre-buried in a bearing platform; (5) the bearing platform is poured; (6) a pier column formwork is installed; and (7) a pier column is poured. The thin-wall hollow high pier reinforcing steel bar formwork support has the beneficial effects of being simple in structure, low in manufacturing cost, capable of saving time and labor, high in production efficiency and capable of improving the tying quality of the reinforcing steel bar formwork support and guaranteeingthe construction quality.

Owner:CHINA SIXTH METALLURGICAL CONSTR

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com