Box girder casting method and forming die frame for box girder steel reinforcement framework

A steel skeleton and box girder technology, which is applied in the field of shaped formwork, can solve the problems of difficult construction work, the quality of steel bar binding cannot be guaranteed, and the utilization rate of box girder prefabricated pedestals is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

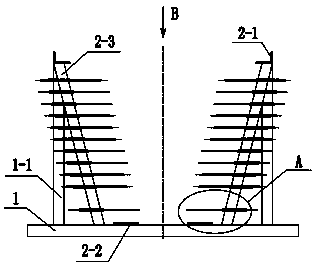

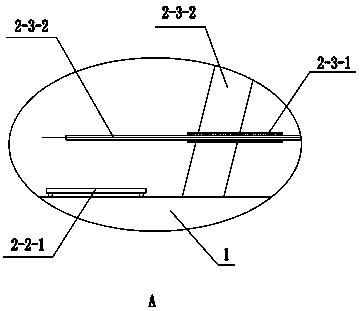

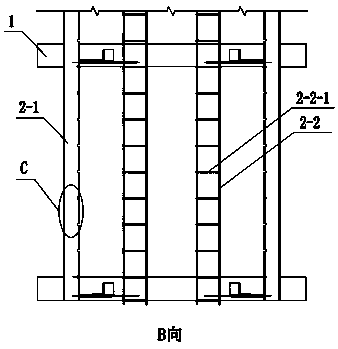

[0019] As shown in the accompanying drawings, the specific embodiment used to achieve the first purpose of the present invention: a method for pouring box girders, including: construction preparation, trimming and installation of prefabricated pedestals and side membranes of box girders, installation of steel skeletons, hoisting of inner membranes, Install roof reinforcement cage and pour concrete. Construction preparations include: deployment of construction personnel, preparation of construction materials and construction sites, installation and commissioning of machinery required for construction, etc.; trimming and installation of prefabricated pedestals and side membranes of box girders to ensure successful pouring of box girders and smooth demoulding; The skeleton is the pouring shape of the box girder, and the quality of the steel skeleton directly affects the stress of the box girder; the inner membrane further limits the pouring area; the steel cage on the top plate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com