Large-span factory building roof modular installation device and construction method

An installation device and modular technology, which is applied in the field of modular installation devices on the roof of large-span factory buildings, can solve the problems of high construction cost, slow construction speed, and danger of high-altitude operations, and achieve the goal of reducing construction cost, reducing consumption, and shortening the construction period. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

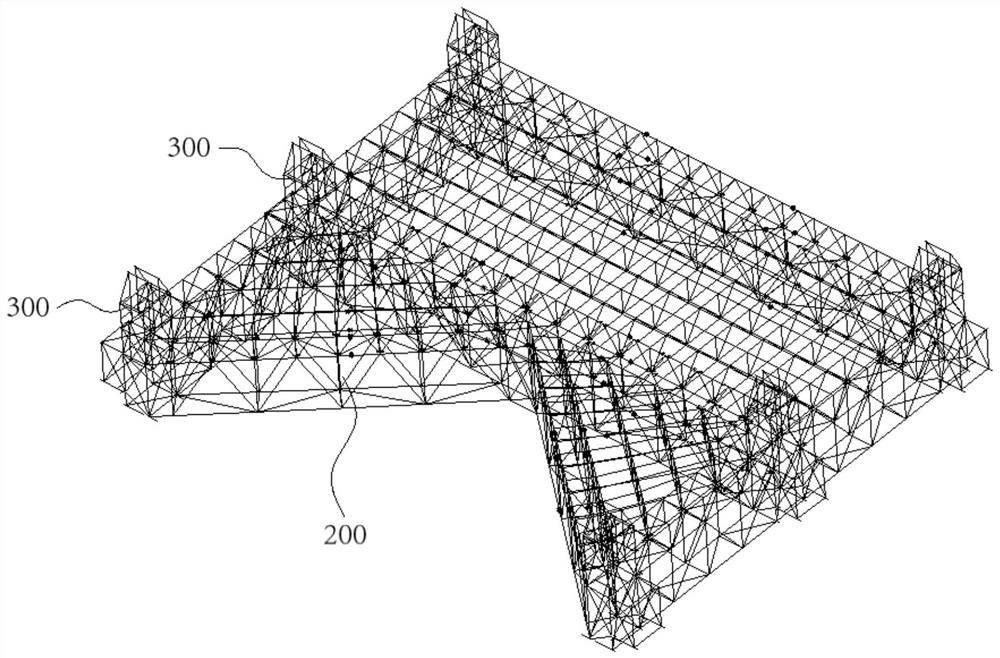

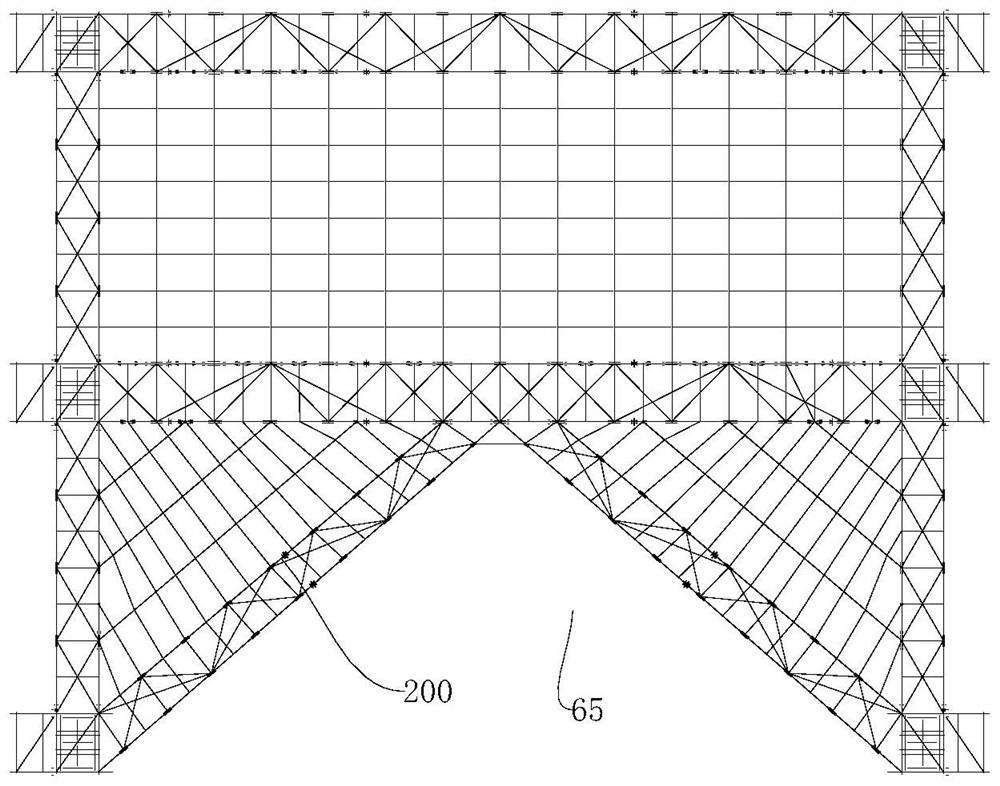

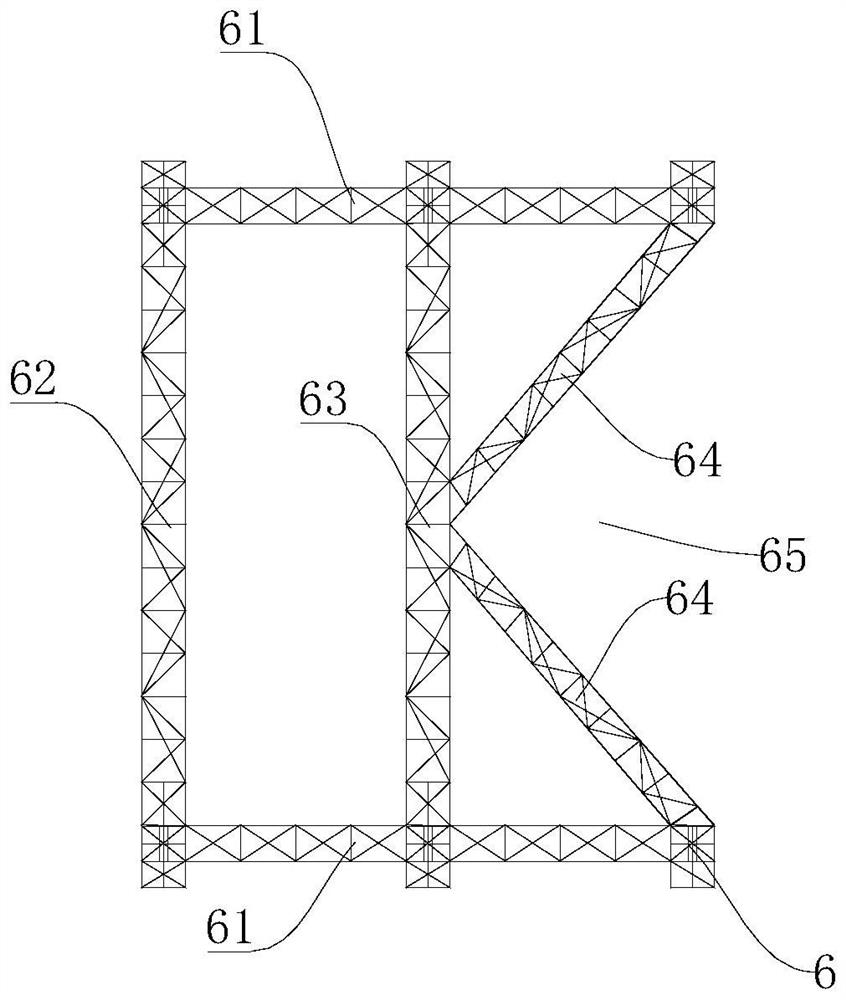

[0049] like figure 1 As shown, the present invention provides a large-span factory floor modular installation device, including a K-type tire frame 200, a roof truss limiting device 300 and a roof truss jacking device 400, wherein the K-type tire frame 200 is located in the upper part of the factory building and can be installed along the The length direction of the workshop reciprocates sliding; the K-type tire frame 200 is used to provide an operating platform for the assembly of the roof structure 21, and at the same time, it is used to carry the roof structure and slide it to the installation position in the horizontal direction. The roof truss limiting devices 300 are correspondingly arranged at the nodes of the K-type tire frames 200 to form a limit on the roof structure 21; the roof truss limiting device 300 is used to limit the roof structure to ensure that the Stability of roof structures during sliding. The roof truss jacking device 400 is arranged in the roof truss...

Embodiment 2

[0058] This embodiment provides a method for construction using the large-span factory floor modular installation device of Embodiment 1, including the following steps:

[0059] Step 1: Assemble the K-type tire frame 200, and lift the K-type tire frame 200 to the design elevation.

[0060] Specifically: assemble the K-type tire frame 200 in situ on the ground; use the standard section support frame 1 and the jacking assembly of the tire frame jacking device 700 to lift the K-type tire frame to the design track level; wherein, the temporary support adopts the prefabricated type Turn around the support frame, after the jacking device rises for one stroke, install a temporary support standard section until the tire frame is jacked up to the design track level, then install the sliding track and the driving end beam, and unload the K-type tire frame 200 to the sliding on track.

[0061] Step 2: Use a crane to hoist the roof components to the steel plate of the K-type tire frame f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com