A safe and rapid construction method for high pier in turning mode

A construction method and technology of high piers, applied in bridge materials, buildings, bridge construction, etc., can solve problems such as long construction period of high piers, inadequate safety protection measures, unsafe working platforms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

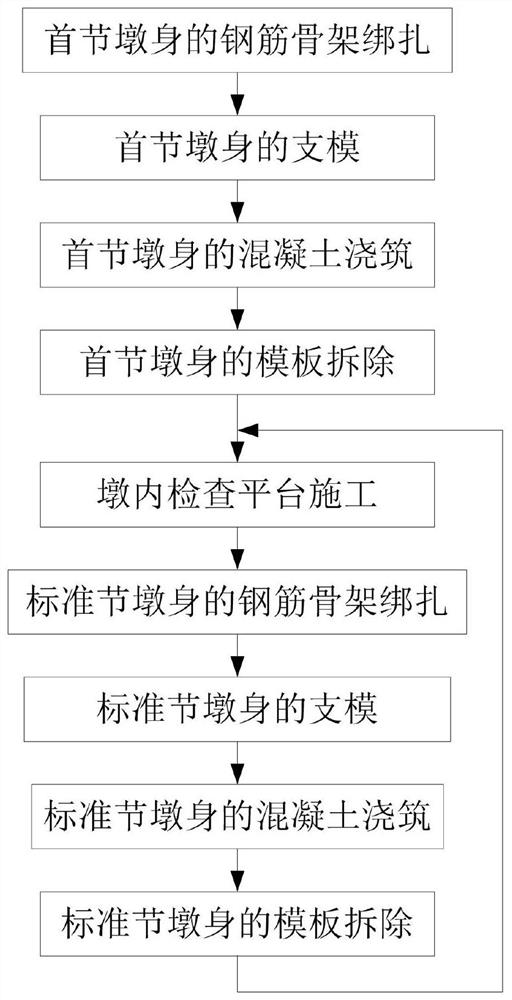

[0083] Such as Figure 1 to Figure 13 As shown, a method for safe and rapid construction of high pier in turning mode according to the present invention, the high pier is a hollow high pier with a round end and single-sided slope closure, and the method includes the following steps:

[0084] Step 1. Binding of the steel skeleton of the first pier body:

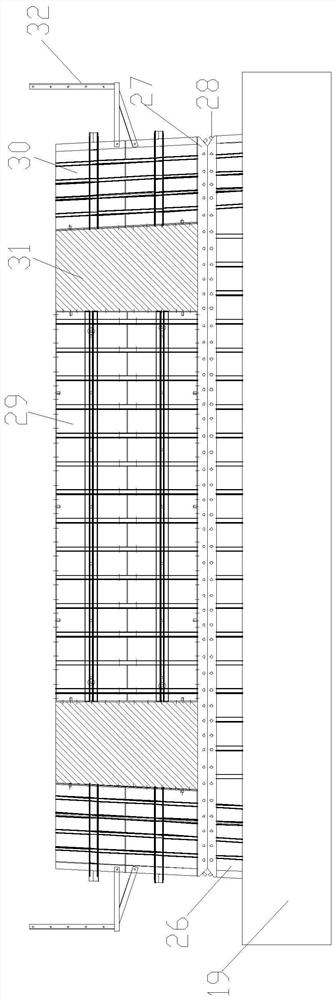

[0085] Step 101, such as figure 2 As shown, the pre-embedded steel bar 20 of the cap is pre-embedded on the cap 19, and the inner operation frame for connecting the main reinforcement of the steel bar is placed in the pre-embedded steel bar 20 of the cap;

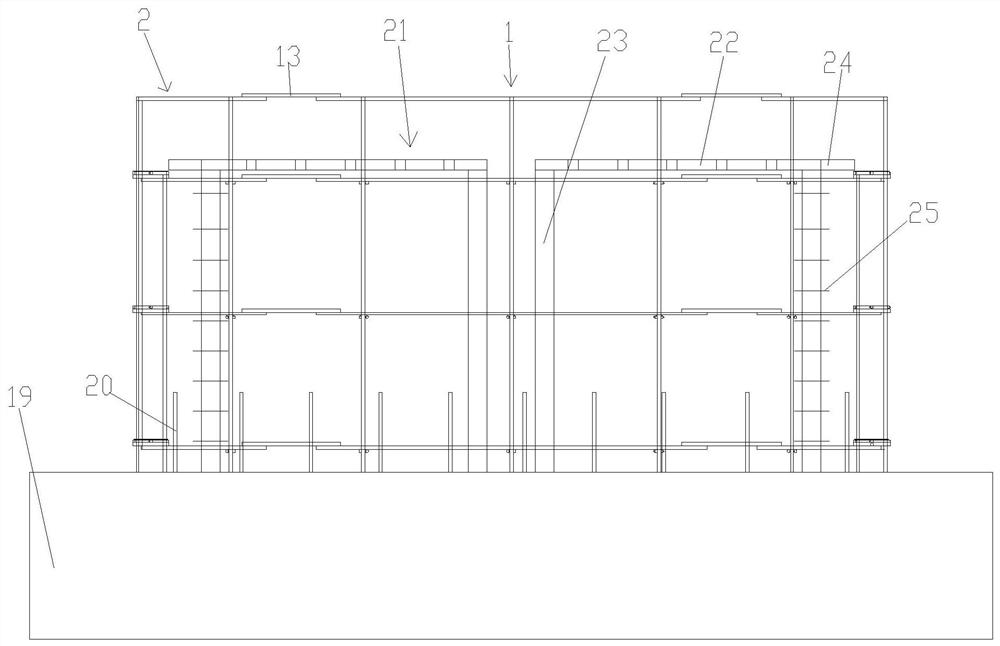

[0086] The operating frame in the pier includes two symmetrically arranged semi-pier operating frames 21, the distance between the two semi-pier operating frames 21 is adjusted according to the actual structural size of the pier body, and the semi-pier operating frame 21 includes a half pier The inner operating platform 22, a plurality of first pillars 23 for supporting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com