Turnover early-dismantling constructional column feeding port and construction method thereof

A construction method and technology for constructing columns, which can be applied to building structures, columns, piers, etc., can solve the problems of affecting the apparent quality of concrete, manual chiseling of concrete, and labor-intensive problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The technical solutions of the present invention are described in detail below through the examples, and the following examples are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, but cannot be construed as limitations to the technical solutions of the present invention.

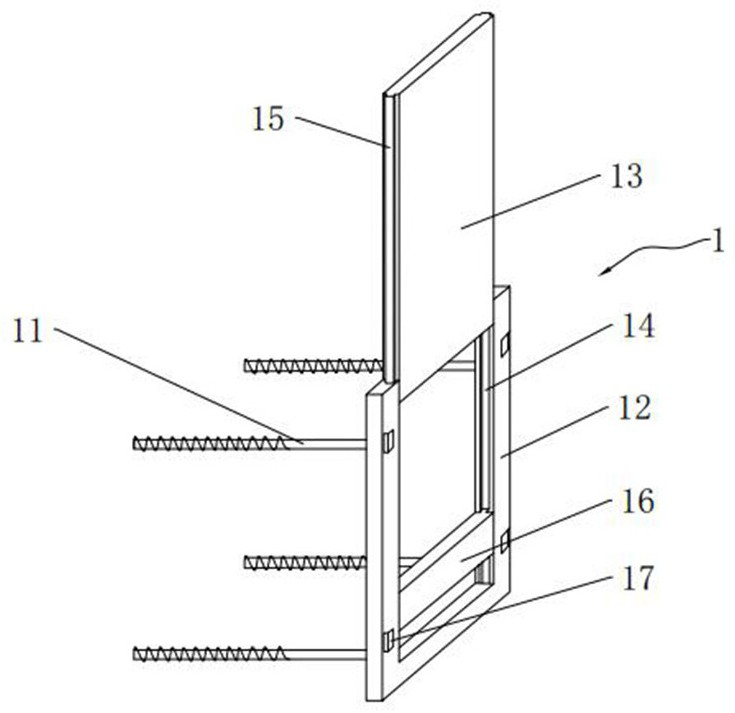

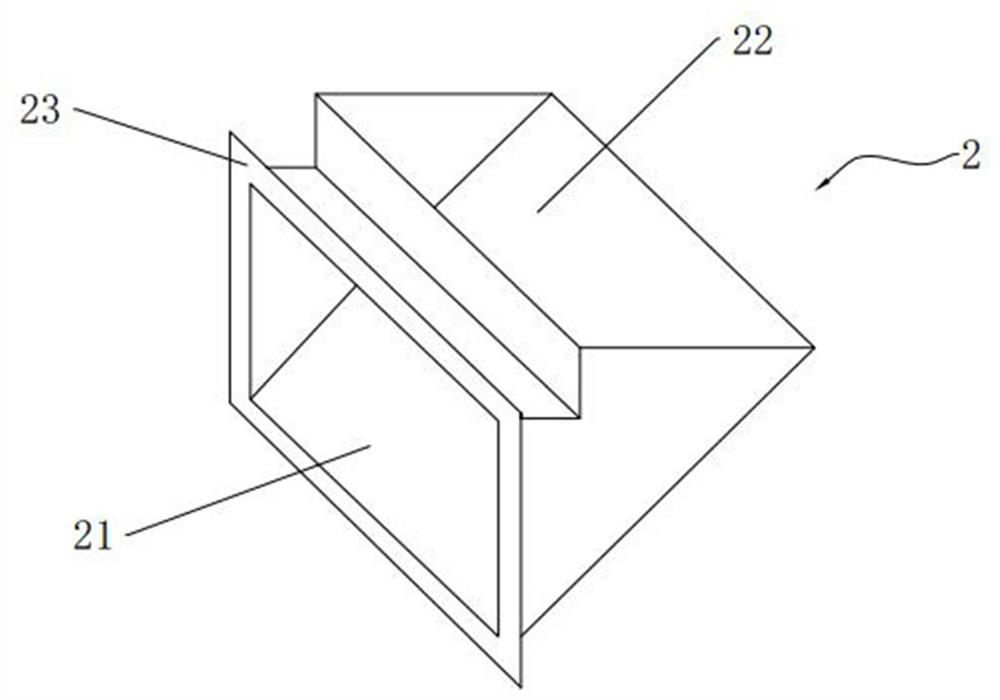

[0036] combine figure 1 and figure 2 , a turnaround and early dismantling construction column material inlet, including a sealing plate structure 1 fixedly installed on the top of the construction column formwork and a material feeding structure 2 fixed on the sealing plate structure 1, the sealing plate structure 1 includes a screw rod 11, a U-shaped The frame 12 and the main sealing plate 13, the screw rod 11 is vertically fixed on the U-shaped frame 12, one side of the U-shaped frame 12 is flush with the construction column template, and the other side is fixedly installed with the feeding structure 2, and the inner surface of the U-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com