Serial-connection circulating pressure grouting device and pressure grouting method

A series type, grouting pipe technology, which is applied in the direction of earthwork drilling, bolt installation, mining equipment, etc., can solve the problems of grouting pipe blockage, prestressed pipe grouting is not dense, etc., to improve strength, prevent cracks, The effect of ensuring effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

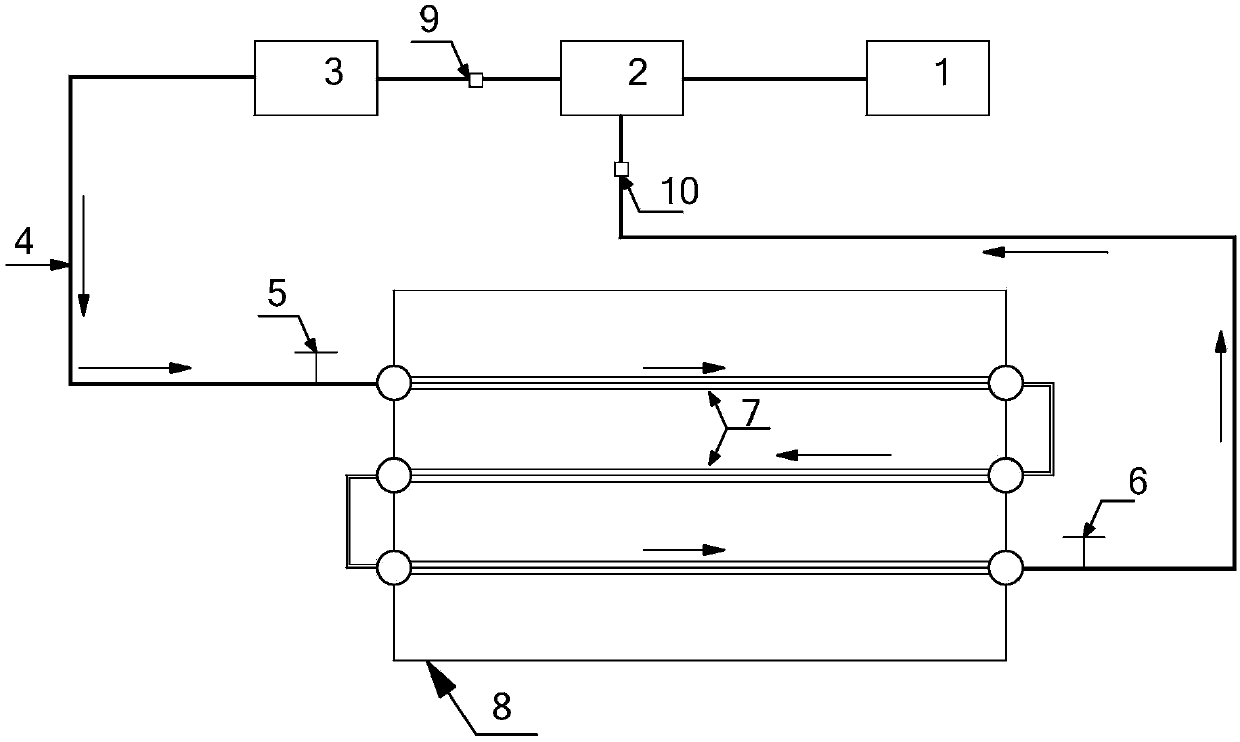

[0018] The central idea of the present invention is to adopt the design idea of prestressed pipe series connection and circulating grouting to ensure the continuous circulation of the grout in the prestressed corrugated pipe, so that the air in the prestressed corrugated pipe can be completely discharged to ensure that the prestressed corrugated pipe is filled There is no air chamber or air chamber in the grout, so that the grout in the prestressed corrugated pipe is fully compacted, which can make the concrete grout better fill the entire prestressed corrugated pipe, and then make the prestressed tendons in the prestressed corrugated pipe and the concrete bond firmly. Integrated to ensure the effectiveness of prestressing, improve the strength, stiffness and bending resistance of concrete components, and prevent premature cracks in concrete components.

[0019] The serial circulating grouting device proposed by the present invention will be further described in detail belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com