Concave-convex type wedge joint for underground continuous wall

A technology of underground diaphragm wall and wedge joint, which is applied in the field of construction, can solve the problems of large impermeability and shear resistance, and achieve the effects of improving shear resistance, convenient operation and easy quality assurance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

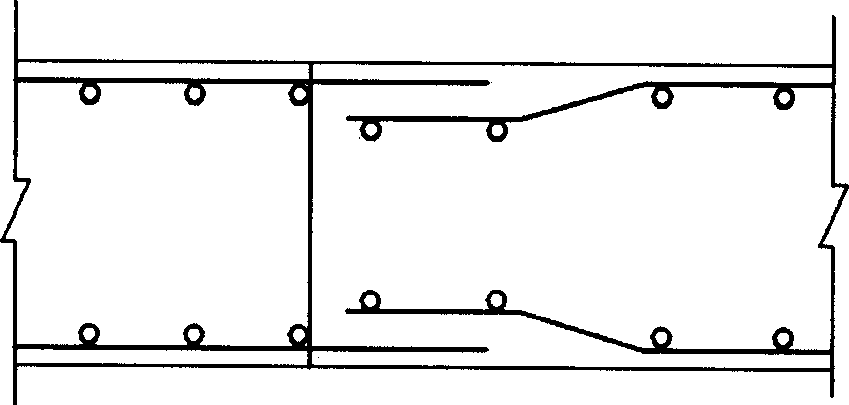

[0012] Below in conjunction with accompanying drawing and embodiment and applied construction method, the present invention will be further described.

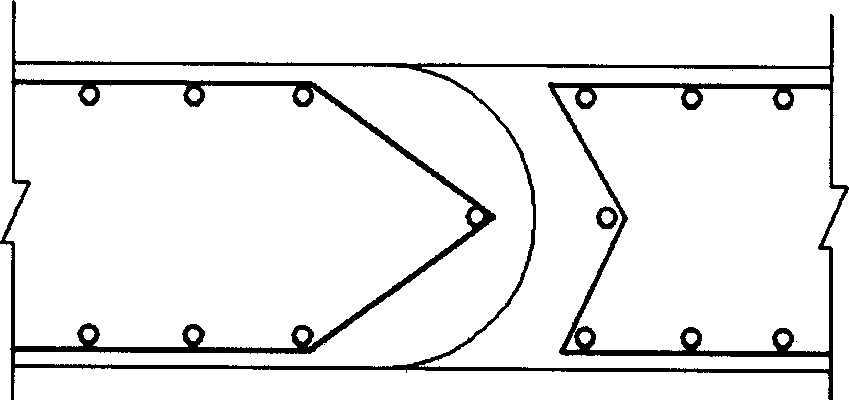

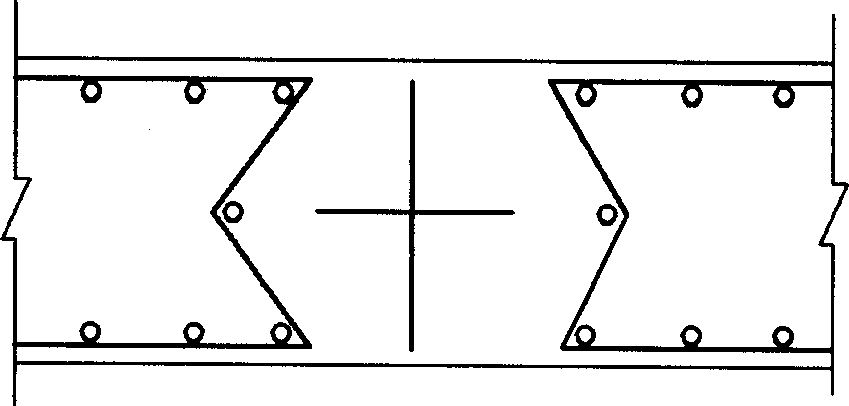

[0013] like Figure 4 As shown, a concave-convex wedge-shaped joint of an underground diaphragm wall is respectively located at the ends of two continuous underground joints. It is characterized in that one joint is concave and the other is convex, and a pair of concave-convex Wedge joints fit together.

[0014] The concave joint has a large opening, the bottom is small, and the depth is equal to the thickness of the convex joint; the convex joint has a small head and a large bottom, and the thickness is equal to the depth of the concave joint.

[0015] A construction method using a concave-convex wedge joint of an underground diaphragm wall, the construction steps of which are as follows:

[0016] (1) Grooving and reserved joint position;

[0017] (2) Clear base to control the thickness of the silt to be less than 10cm and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com