Thin-wall hollow high pier reinforcing steel bar formwork support and construction method

A technology for supporting formwork and steel bars, which is applied in the direction of erecting/assembling bridges, bridge parts, bridges, etc., which can solve the problems of difficult control of the steel bar protection layer, difficult control of the steel bar cover layer, and potential safety hazards, etc., to improve the binding quality and structure Simple, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

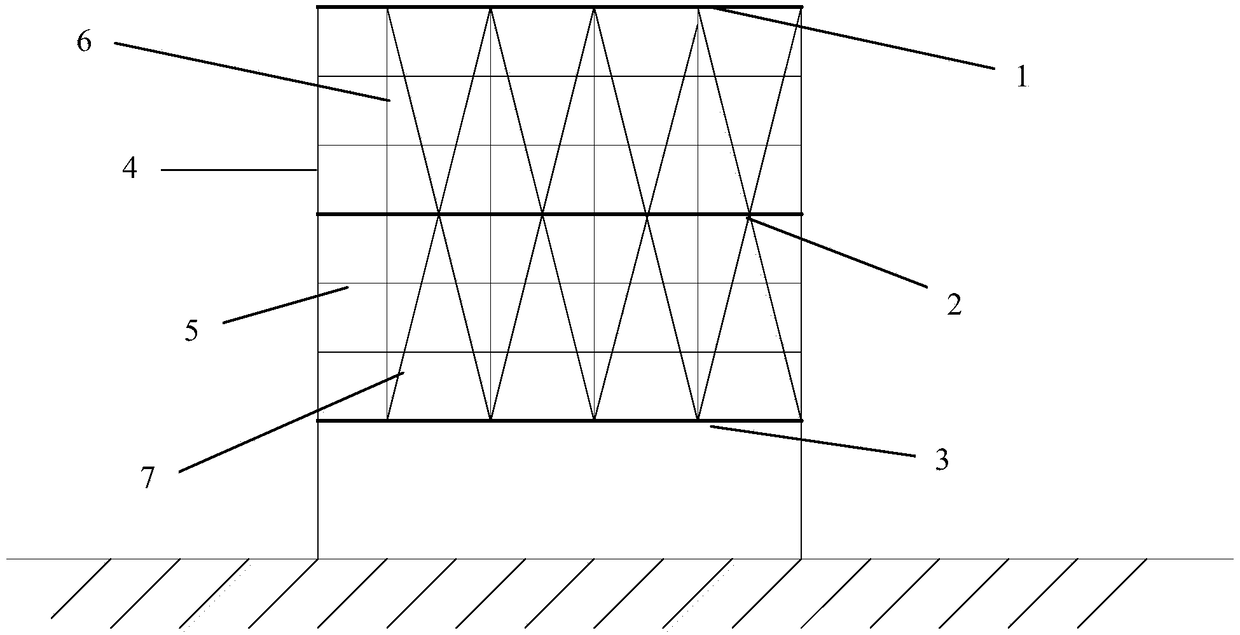

[0027] This embodiment provides a thin-walled hollow high-pier reinforced formwork support, comprising: three reinforced plates, which are square, arranged in parallel at a certain distance from high to low, and are respectively the upper reinforced plate 1, the middle reinforced plate 2 and The lower reinforced plate 3, the central connection line of the three reinforced plates is perpendicular to the ground; the column 4 is vertically welded and connected with the corresponding end points of the three reinforced plates respectively, and the vertical column constitutes a pier column steel bar binding vertical column , the bottom of the column 4 is fixedly connected with the shaped steel formwork by bolts, and the column 4 is a square steel; the reinforcement hoop 5 is bound horizontally on the column 4 at an interval of 10 cm; the upper reinforcement plate 1 1. The upper and lower reinforcement plates 2 of the middle layer and the lower reinforcement plate 3 are correspondingl...

Embodiment 2

[0029] This embodiment provides a thin-walled hollow high-pier reinforced formwork support, comprising: three reinforced plates, which are square, arranged in parallel at a certain distance from high to low, and are respectively the upper reinforced plate 1, the middle reinforced plate 2 and The lower reinforcement plate 3, the central connection line of the three reinforcement plates is perpendicular to the ground; the column 4 is vertically welded and connected with the corresponding end points of the three reinforcement plates respectively, and the column 4 constitutes a pier column steel bar binding vertical Pillar, the bottom of the column 4 is fixedly connected with the shaped steel formwork by bolts, and the column 4 is a square steel; the steel hoop frame 5 is bound horizontally on the column 4 at an interval of 20 cm; the upper reinforcement plate 1, the upper and lower reinforcement plates 2 of the middle layer and the reinforcement plates 3 of the lower layer are cor...

Embodiment 3

[0031] This embodiment provides a method for constructing a thin-walled hollow high pier steel bar formwork frame, the steps include: 1) designing the size of three reinforcement plates and columns according to the size of the thin-walled hollow high pier; 2) accurately cutting the material according to the design drawings, 3) Transport the steel formwork to the site; 4) Embed and install the steel formwork on the cap; 5) Pouring the cap; 6) Install the pier formwork; 7 ) to pour piers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com