Steel bar binding tool and method

A technology for binding steel bars and tools, which is applied in the processing of building materials, construction, building structure, etc., and can solve the problems of expensive, difficult binding of steel bars, and heavy weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

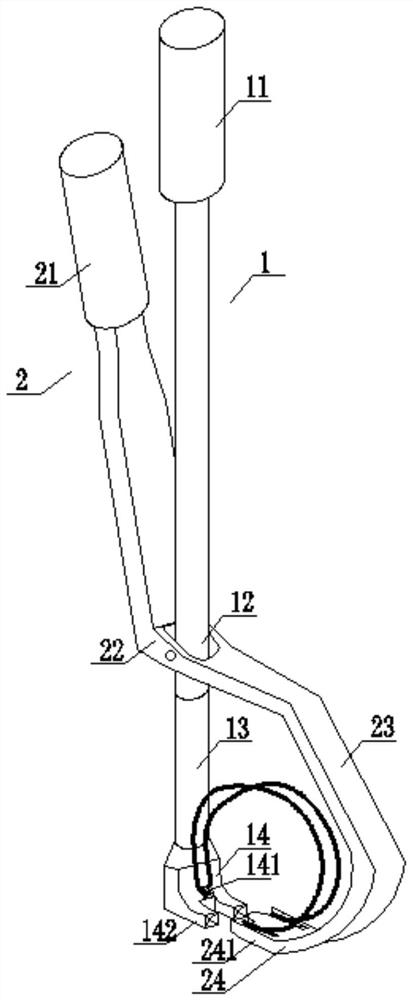

[0048] Such as figure 1 As shown, a steel bar binding tool, comprising:

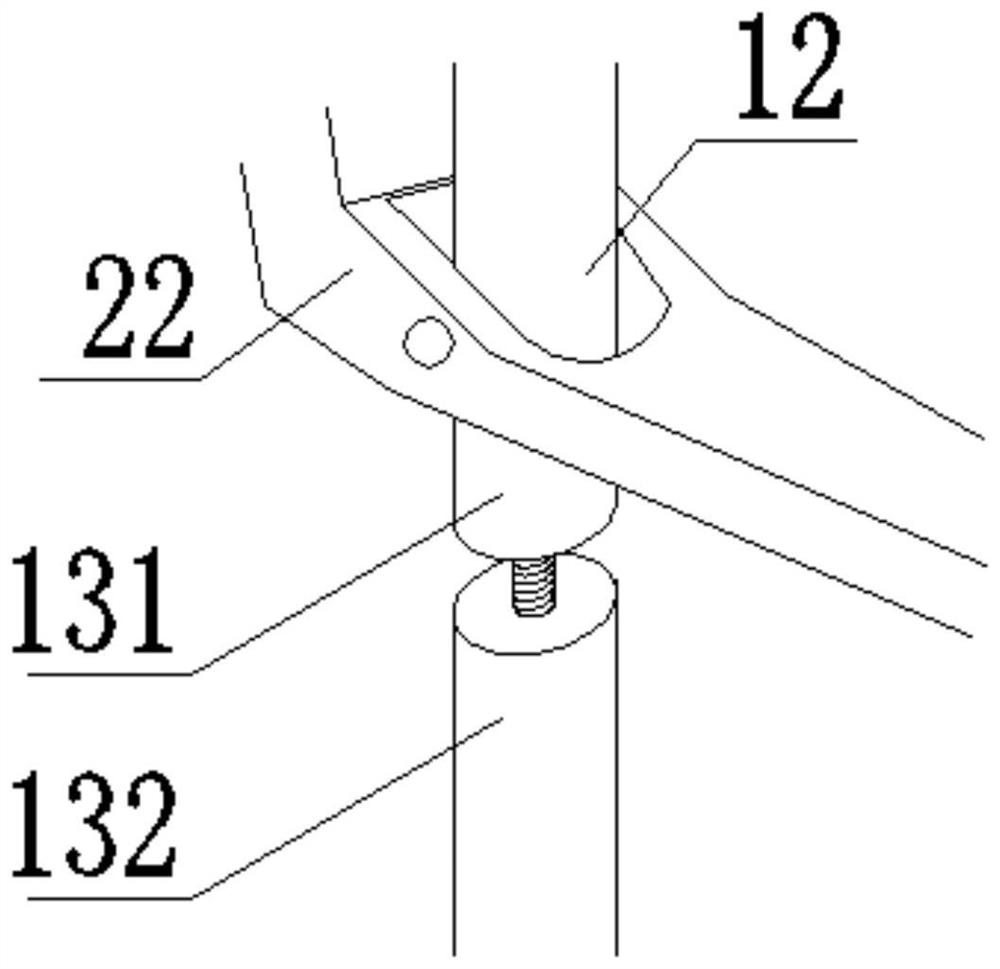

[0049] The main arm 1, the main arm 1 includes a first gripping end 11, a first hinge portion 12, a first frame portion 13 and a first clamping end 14 connected in sequence;

[0050] Among them, such as figure 2 As shown, the first frame part 13 includes an upper frame part 131 close to the first hinge part 12 and a lower frame part 132 close to the first clamping end 14, the upper frame part 131 One end close to the lower frame part 132 is provided with a threaded hole, and one end of the lower frame part 132 close to the upper frame part 131 is provided with a threaded rod adapted to the threaded hole. The rod is connected to the threaded hole, and the lower frame part 132 rotates around the axis of the threaded rod as the upper frame part 131 moves away;

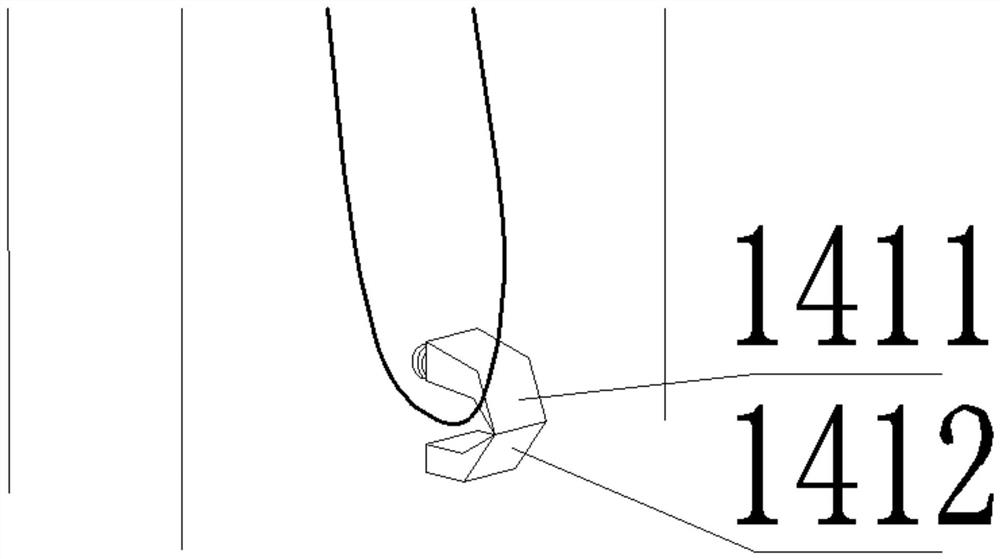

[0051] A pre-clamping part 141, the pre-clamping part 141 is arranged on the first clamping end 14, and is used to clamp one end of the binding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com