Semi-automatic manufacturing method of cast-in-place pile reinforcement cage

A kind of cage semi-automatic, manufacturing method technology, applied in sheet pile walls, structural elements, building components and other directions, can solve the problems of uncontrollable construction progress, slow steel bar binding, many hidden dangers after construction, etc., to achieve good promotion and application value, reduce Investment in equipment costs and the effect of improving binding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

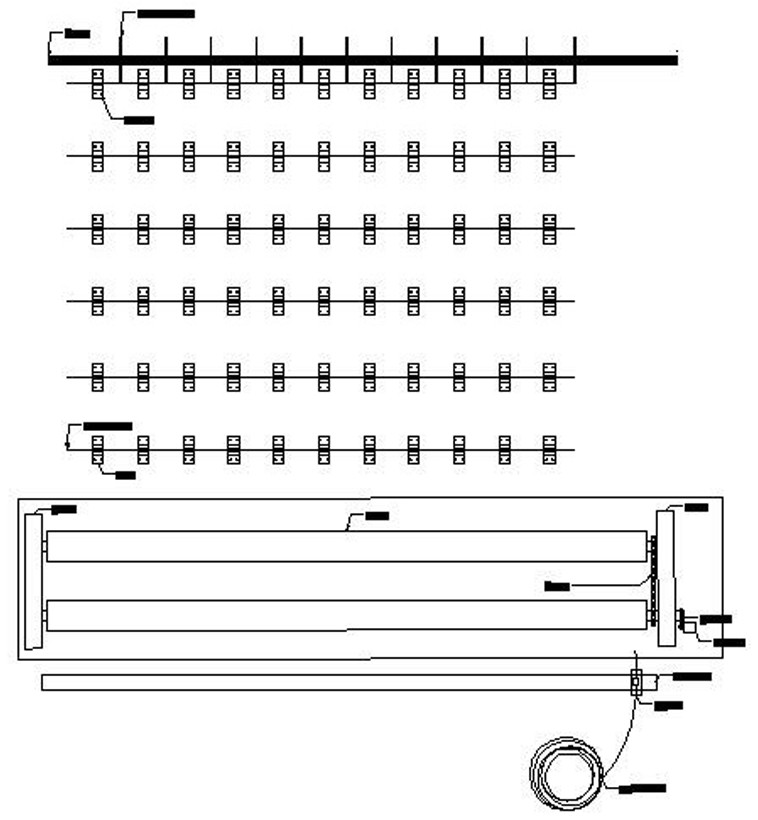

[0038] Such as Figure 1-7 As shown, the invention provides a semi-automatic manufacturing method for cast-in-place pile reinforcement cage, comprising the steps of:

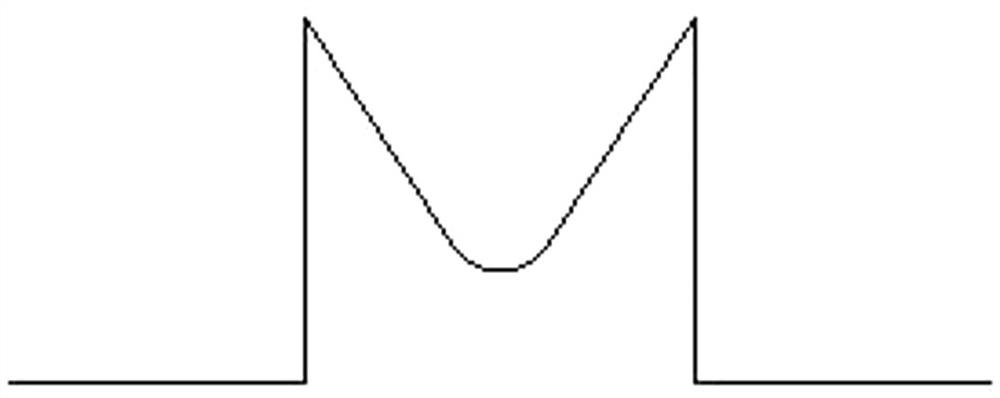

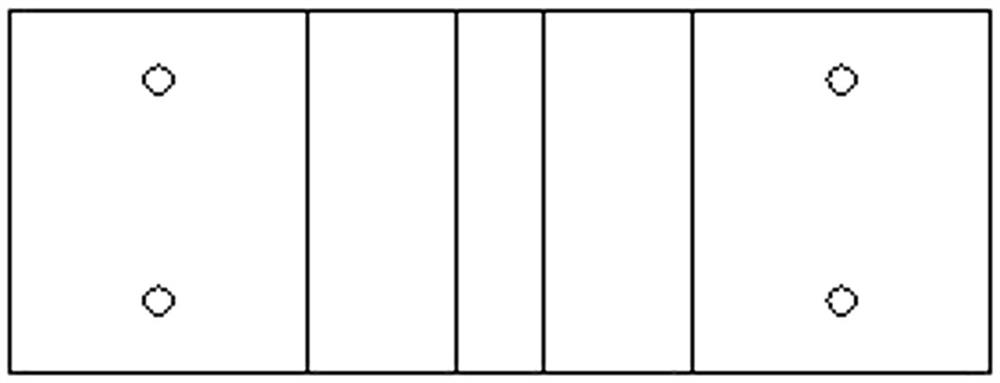

[0039] Step 1, install the limit card 1 of the main reinforcement of the reinforcement cage on the hardened site; the longitudinal spacing is 2m, and the horizontal spacing is set according to the spacing of the main reinforcement of the reinforcement cage d=2πr / n-1; r is the radius of the reinforcement cage, and n is the number of the main reinforcement of the reinforcement cage . The limit card 1 includes two L-shaped connecting parts with opposite openings and a V-shaped main rib receiving groove arranged between the L-shaped connecting parts; the L-shaped connecting part includes a vertical plate and a horizontal plate arranged on the ground, and the horizontal plate There are round holes for passing bolts on the top, and the two top ends of the V-shaped main reinforcement receiving groove are respectively ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com