Patents

Literature

41results about How to "Guarantee the quality of binding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

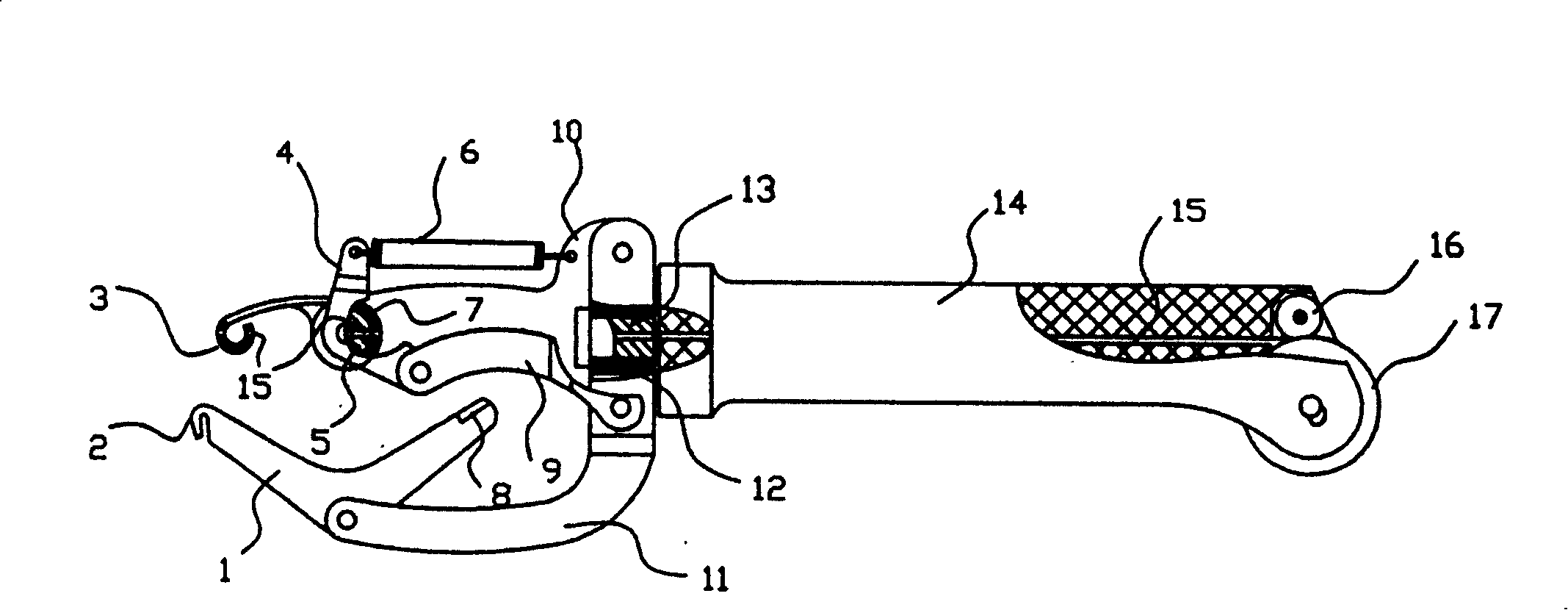

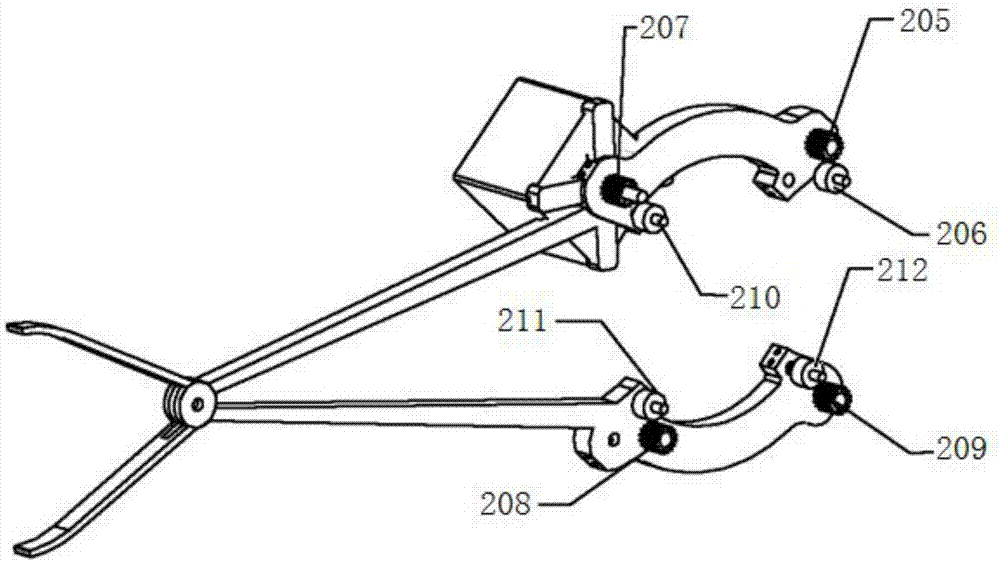

Reinforcing steel bar banding mechanical arm

InactiveCN101240660AGuarantee the quality of bindingIncrease productivityBuilding material handlingFixed frameWorking environment

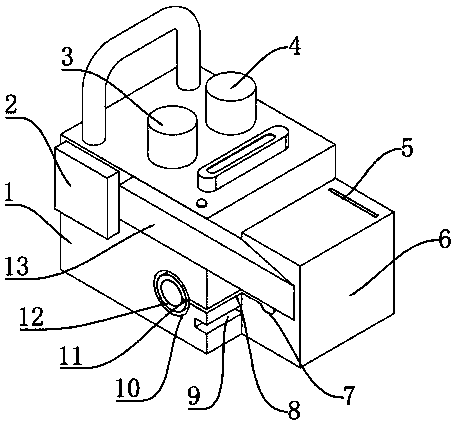

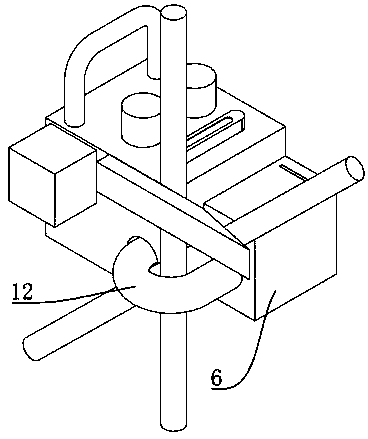

The present invention provides a technical scheme for tying the mechanical hand with the reinforcing steel bar, the scheme of the invention is characterized in that a handle with a thread-guiding hole is provided, two sides of the thread-guiding hole at one end of the handle are provided with a pressure roller and a wire moving wheel; at the other end of the handle a rotating shaft with a thread-guiding hole is fixed with the handle, the rotating shaft is sleeved with a axle base which can rotate around the rotating shaft, one side of the axle base is fixed with a connecting arm with a top hinged with a V-shaped abruption thread swing lever, the top of one arm at the outside of the abruption thread swing lever is arranged with a wire drawing hook, and the top of the other arm of the abruption thread swing levier is arranged with a wire abruption shifting block; the other side of the axle base is fixed with a fixing frame which is arranged with a wire disconnecting mechanism and a thread-knitting machine with a thread-guiding hole. The scheme can be operated with one hand and the tying quality can be guaranteed, the production efficiency can be increased more than four to seven times, the scheme can adapt any working environment and working surface and is used for replacing the mechanical hand which is manipulated by hand.

Owner:于双庆

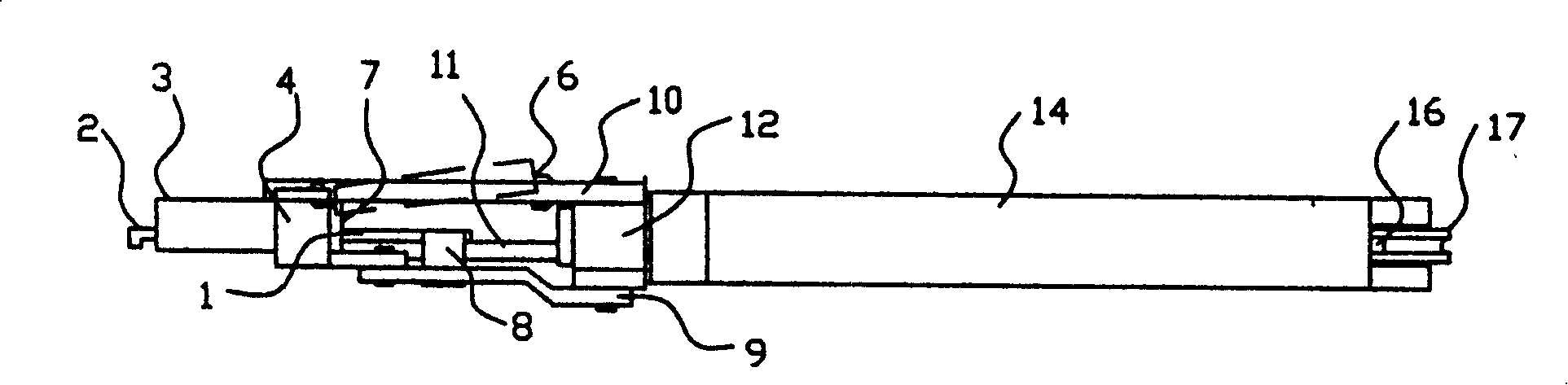

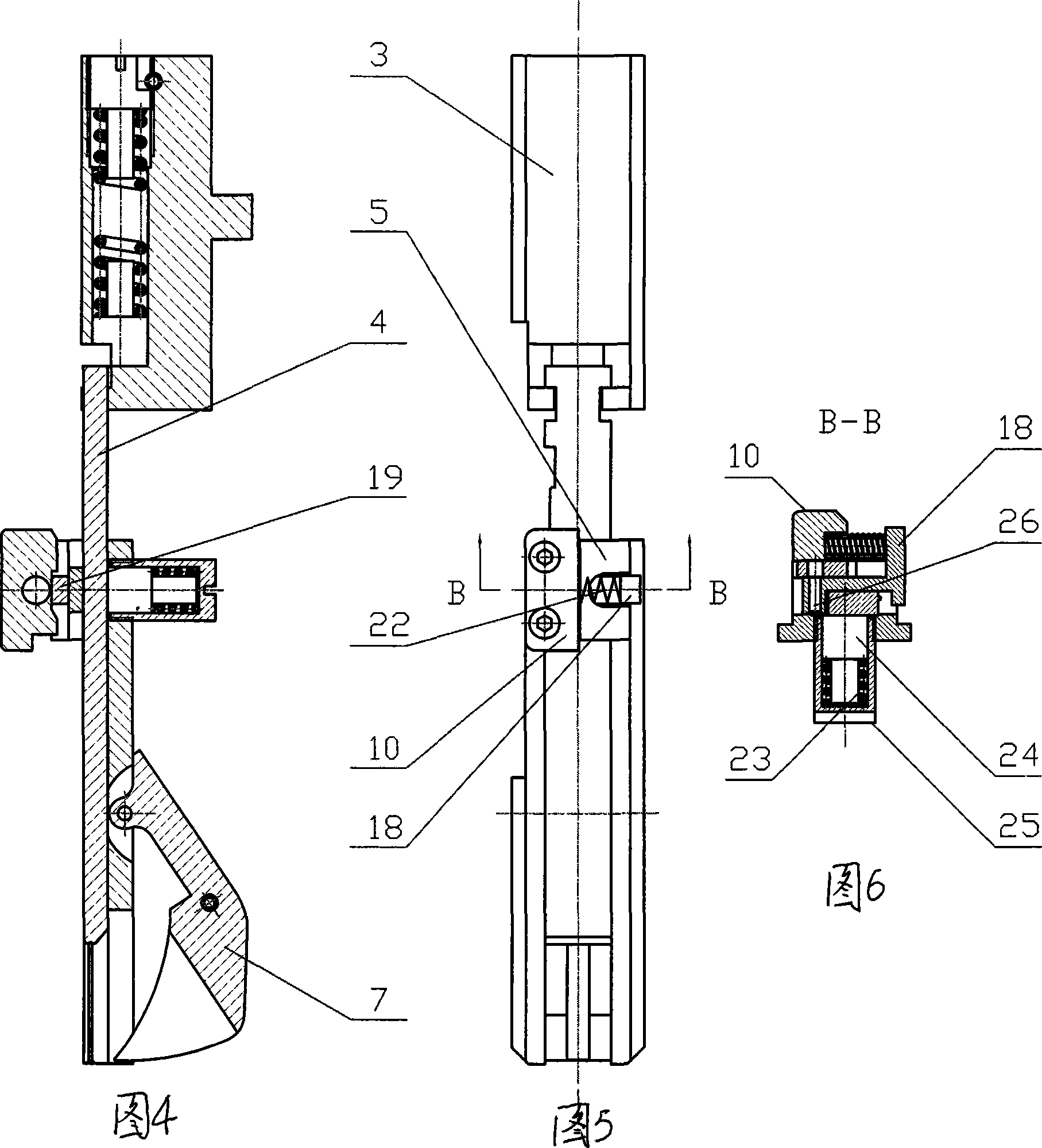

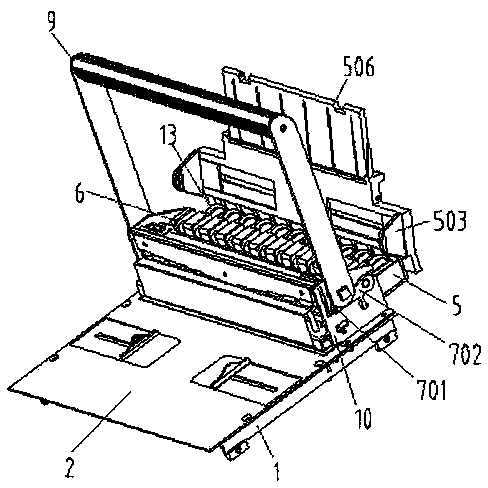

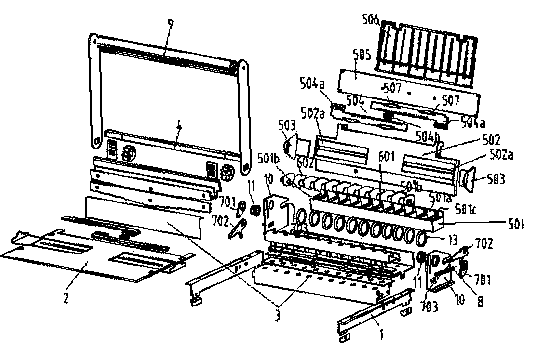

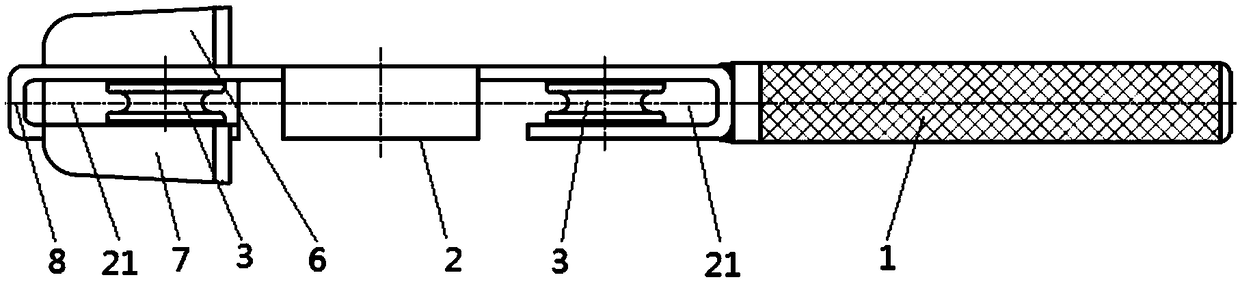

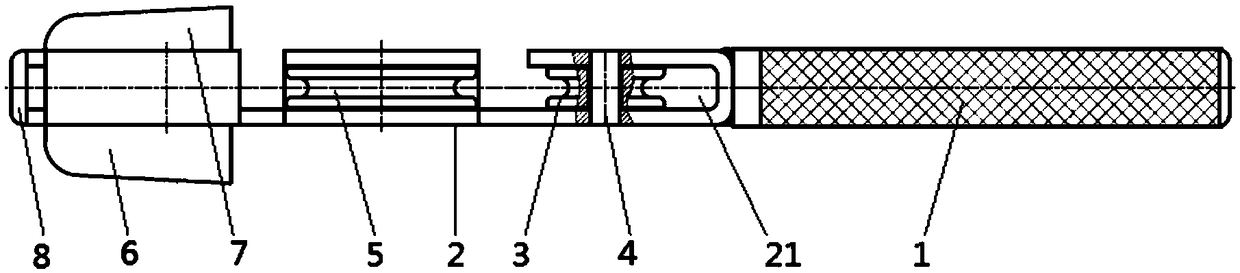

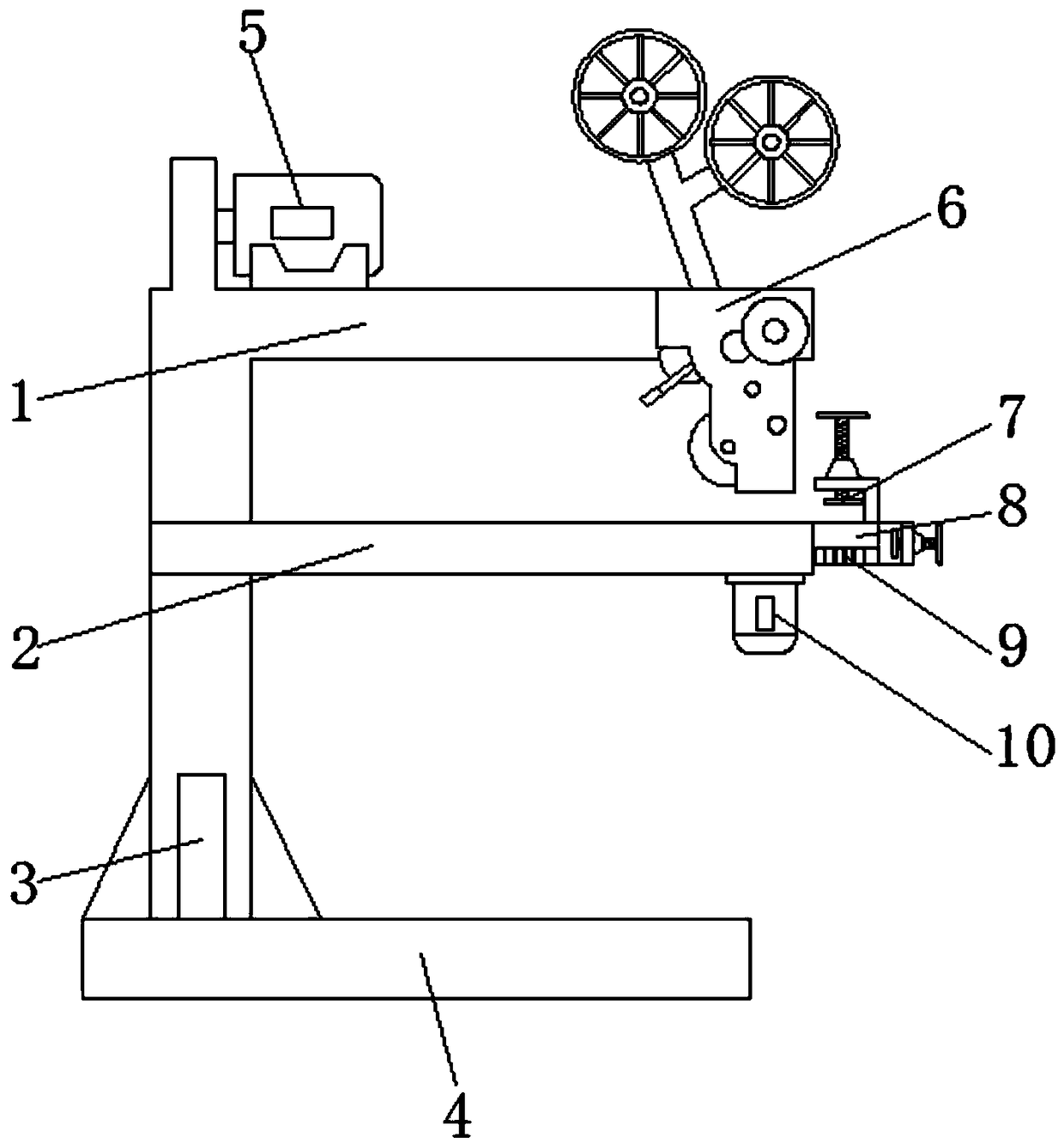

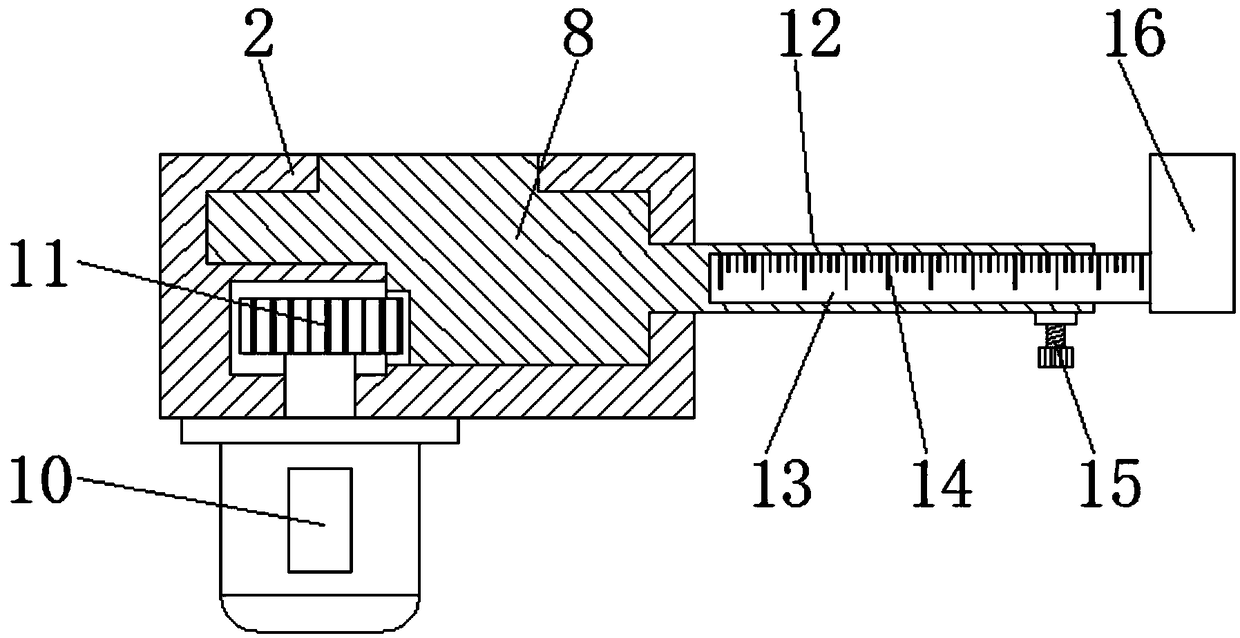

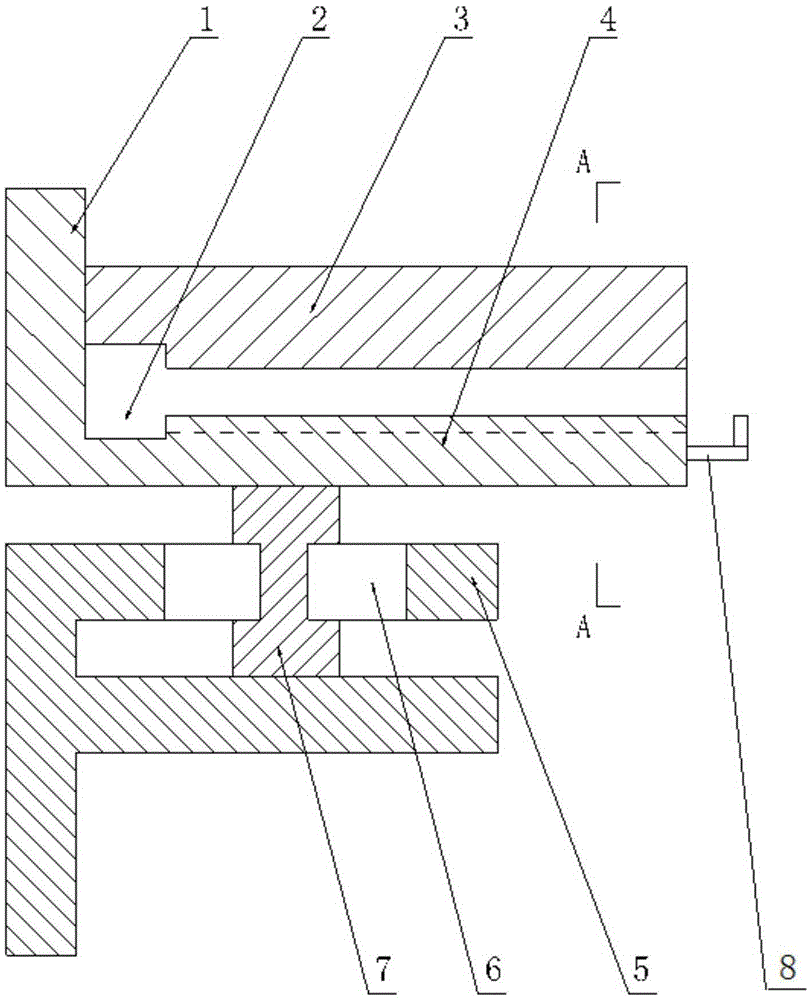

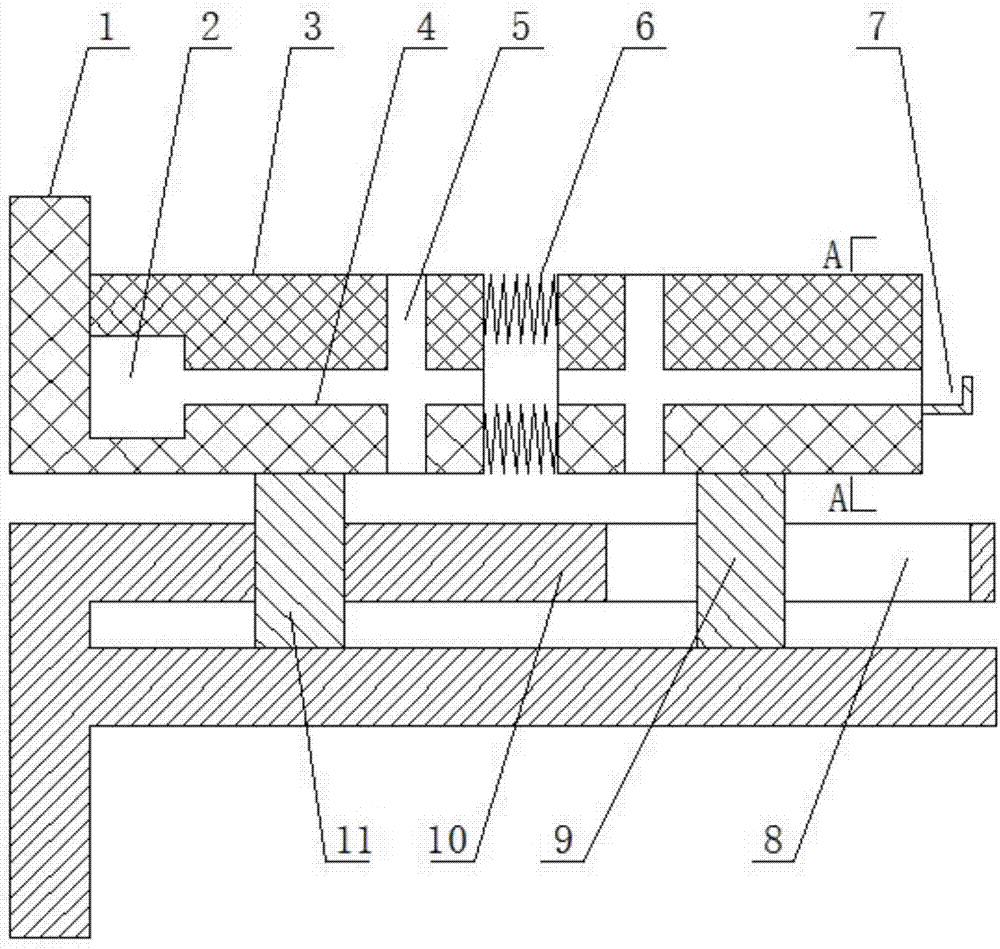

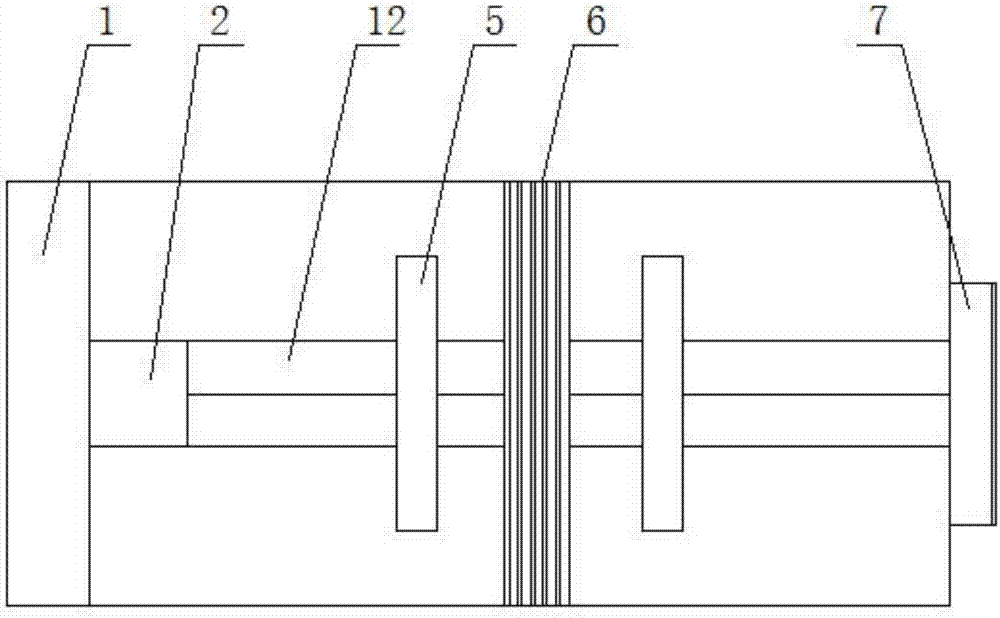

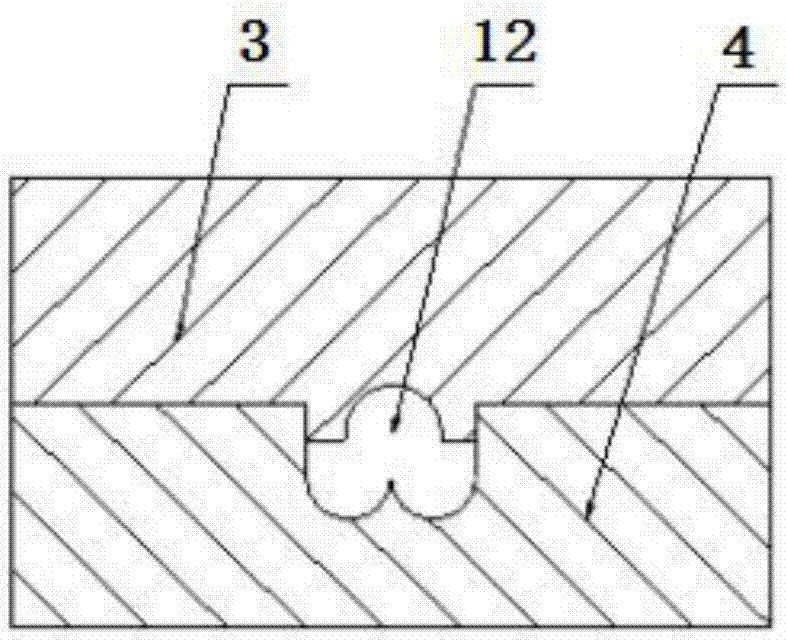

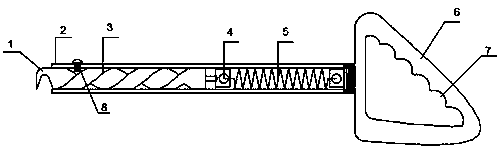

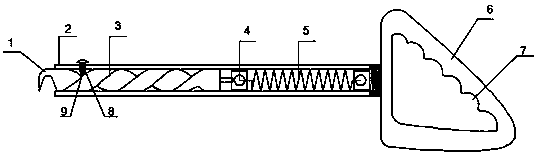

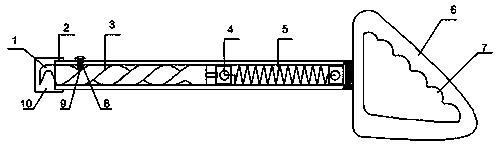

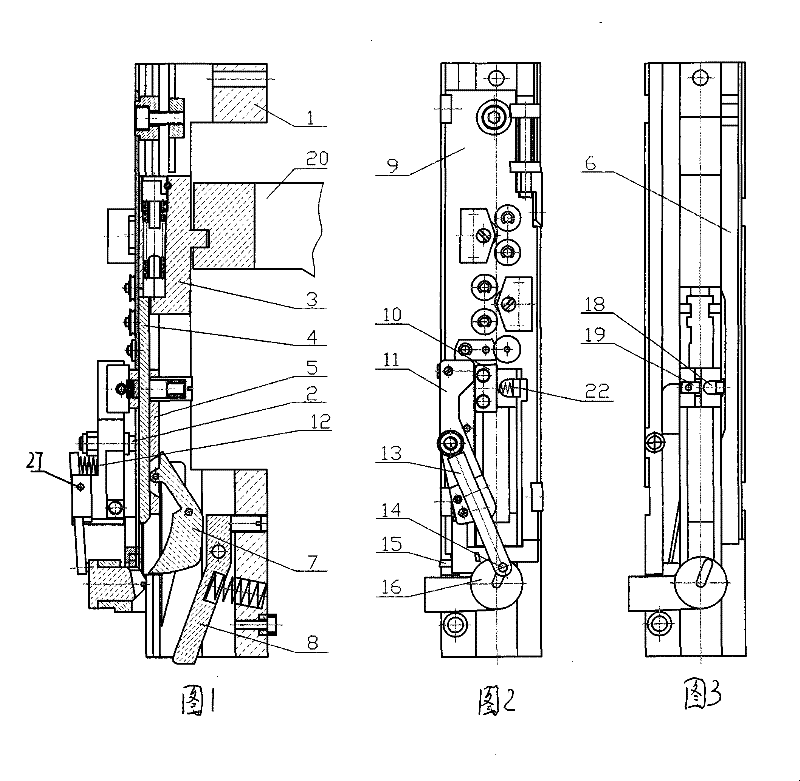

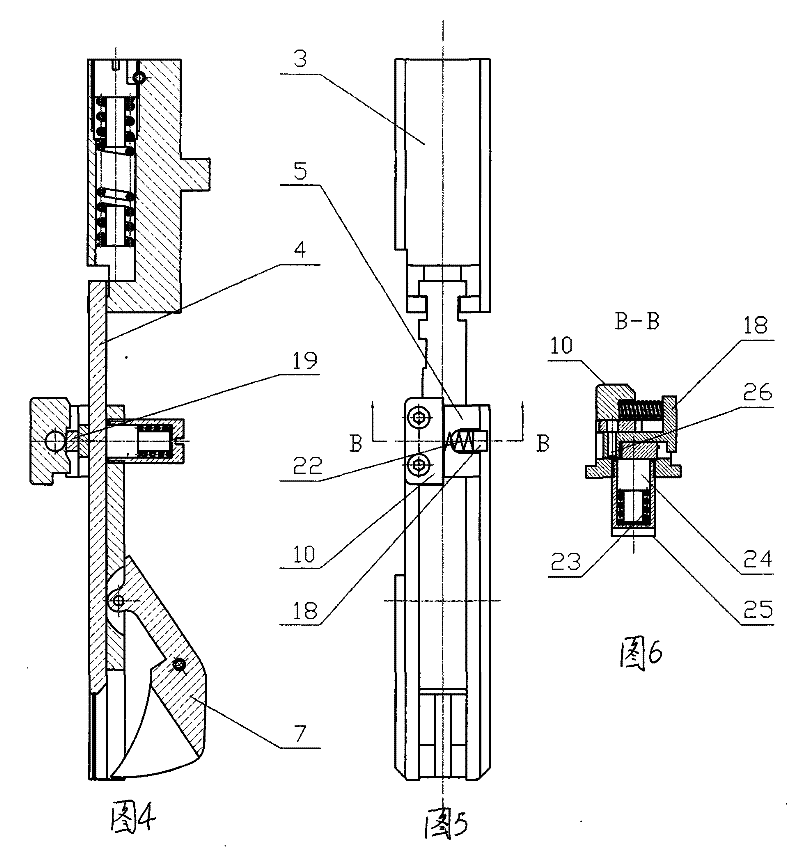

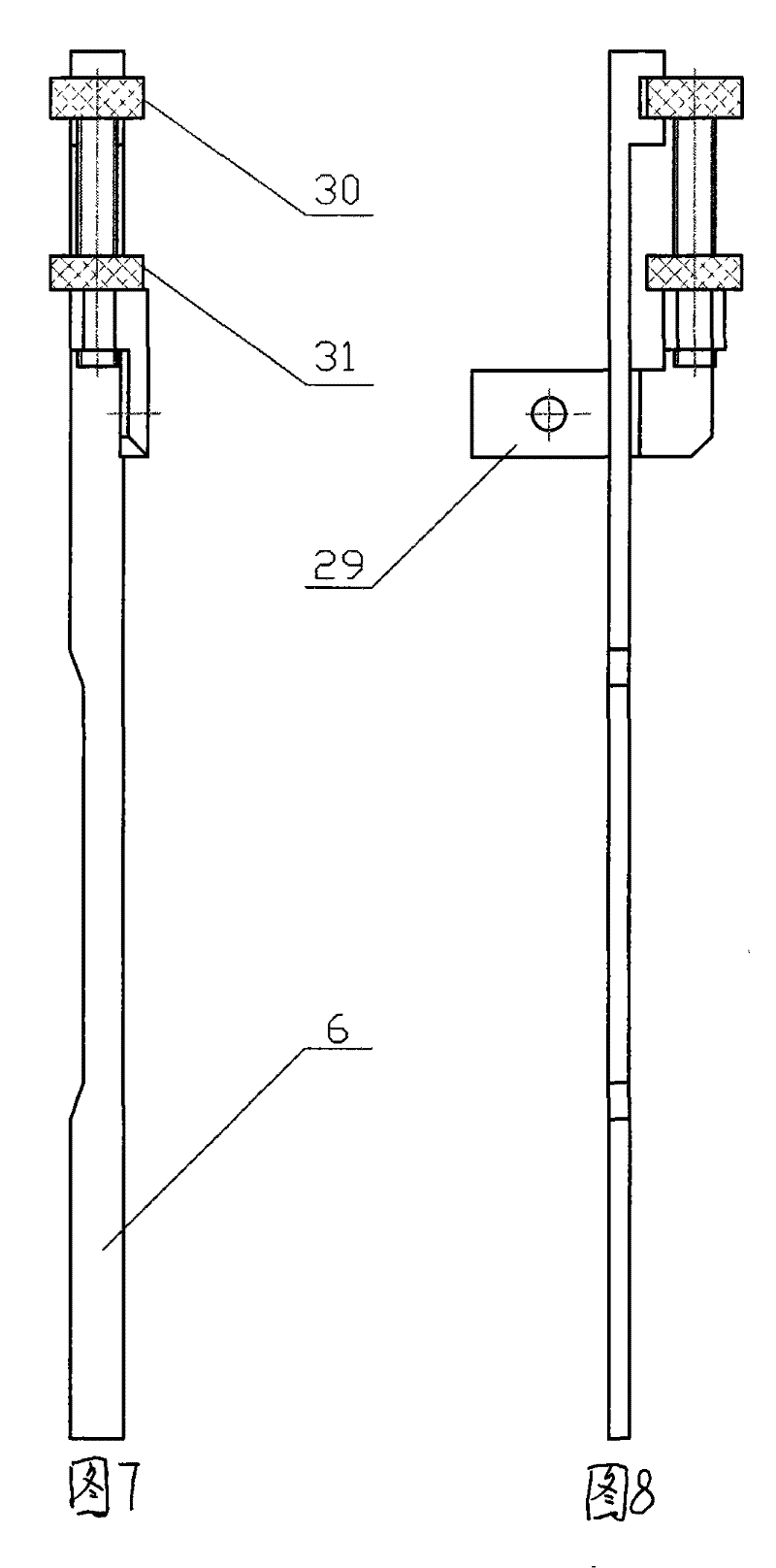

Improved book-binding machine handpiece

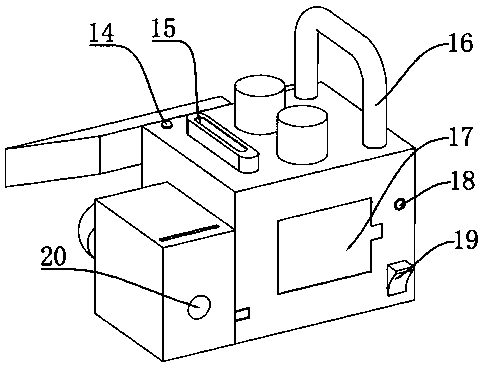

The invention discloses an improved machine head of a binding machine, which belongs to the technical field of binding machinery and equipment. The invention aims to provide the improved machine head of the binding machine having the advantages of high binding quality, high binding speed and wide range of binding thickness. The improved machine head has the technical key points that a swinging block component consisting of a swinging block, a pressure arm, a pressure spring, a column and a spigot shaft is arranged between the lower part of an outer shell (1) of the machine head and a molding column (16); the swinging block (11) in the swinging block component is fixed on the outer shell of the machine head by taking the spigot shaft (2) as a rotating pair and is also adjacent to the left side of a striking block (10) on a hook sliding plate (5); the upper part of the pressure arm (13) is arranged in a guide slot of the swinging block and is also connected with the guide slot by a cylindrical pin to form the rotating pair; and the column (14) on the tail end of the pressure arm is inserted into a radial slot on the outer end surface of a forming column, and the pressure spring (12) is arranged between the upper end of the pressure arm and the swinging block. The improved machine head has the advantages of ensuring binding quality, improving binding speed, and making the binding thickness reach the range between 0.2 and 15 mm.

Owner:淮南市耀华机械厂

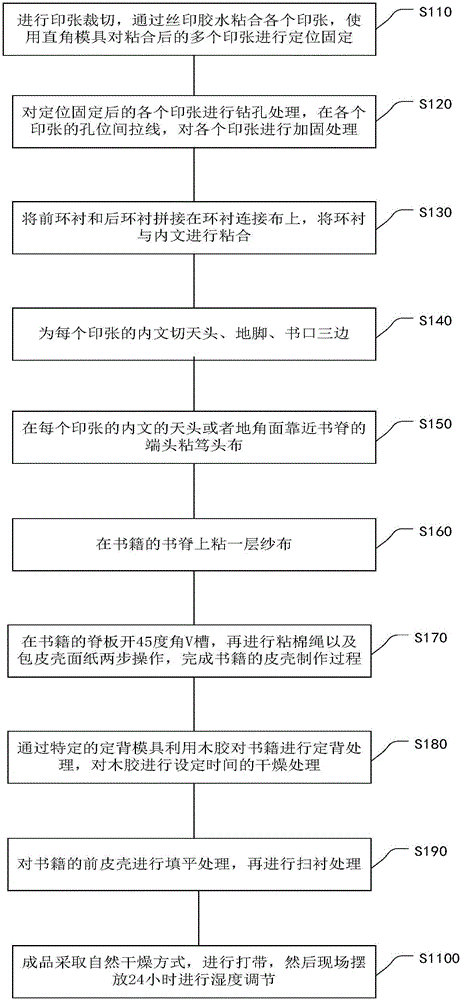

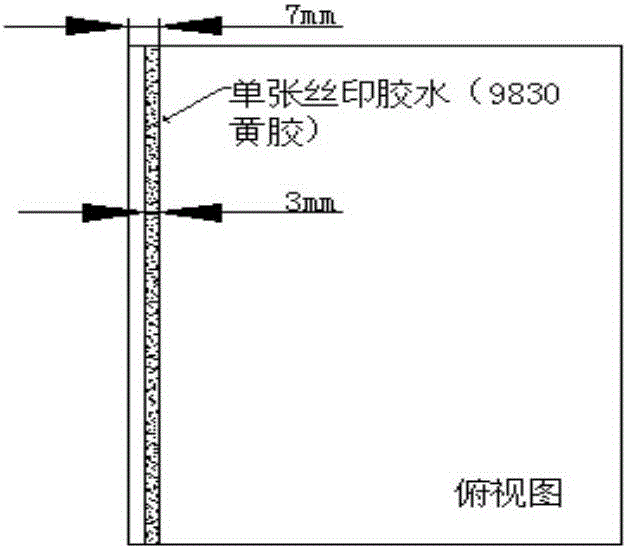

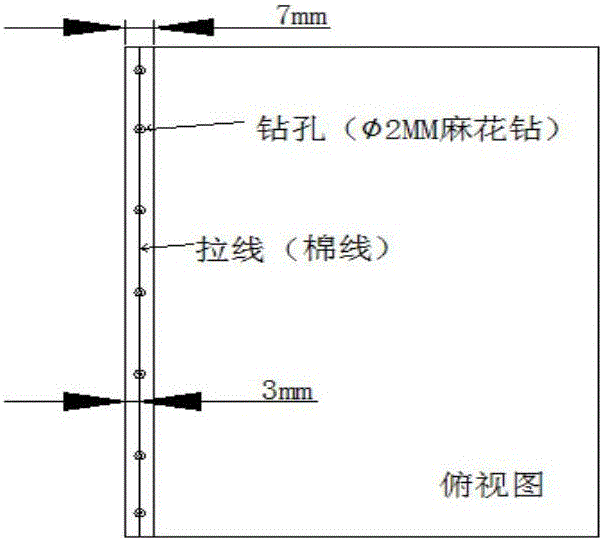

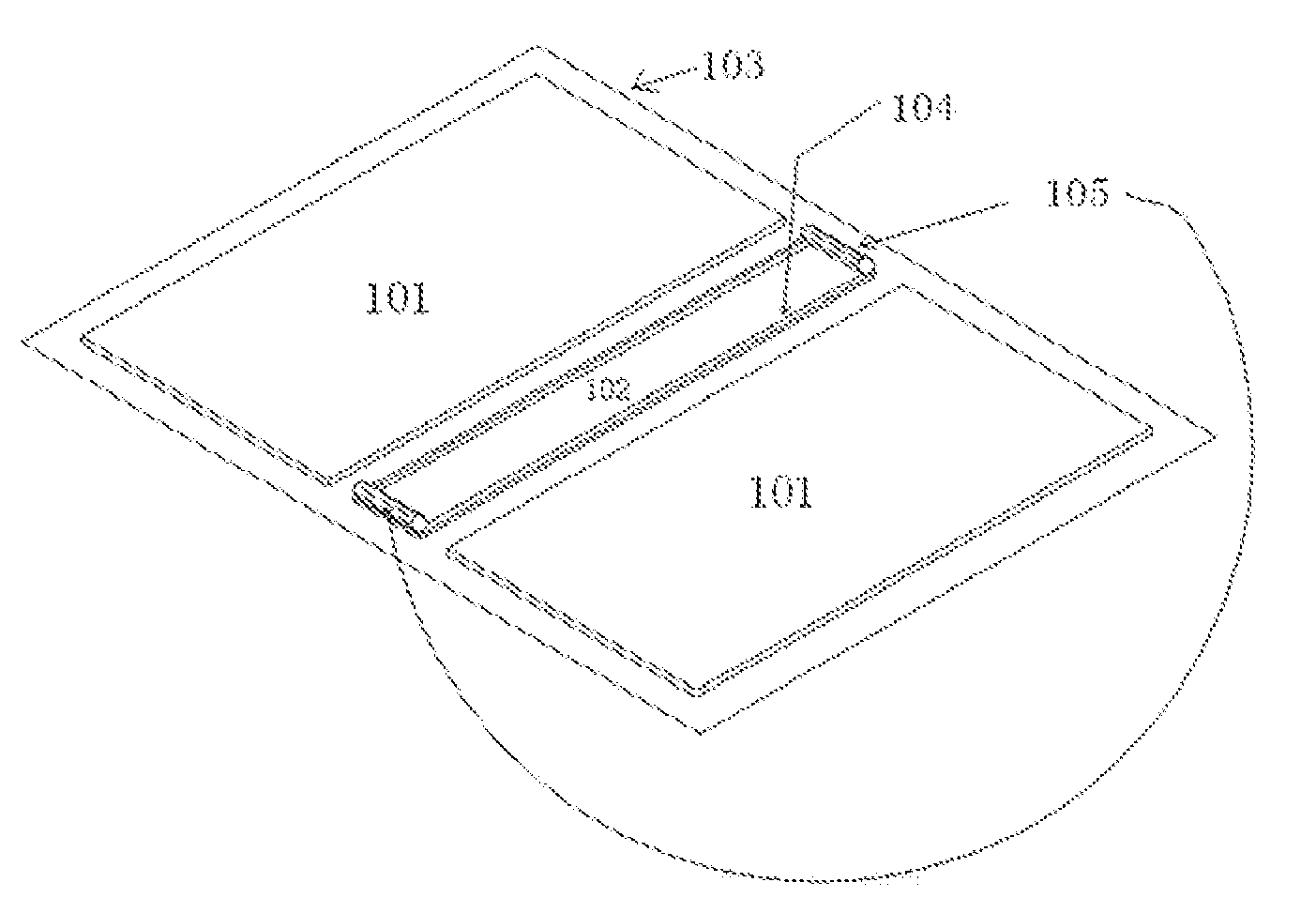

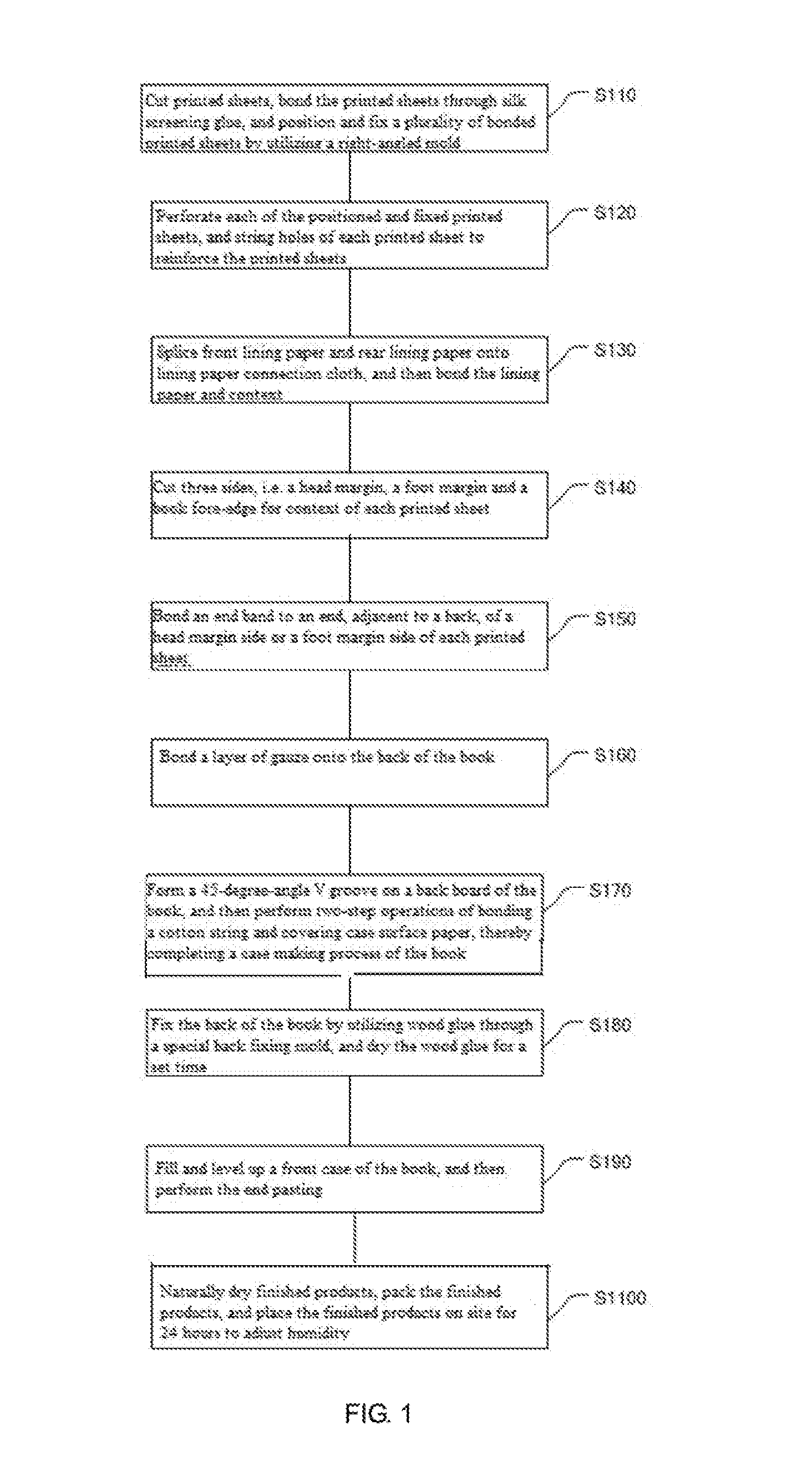

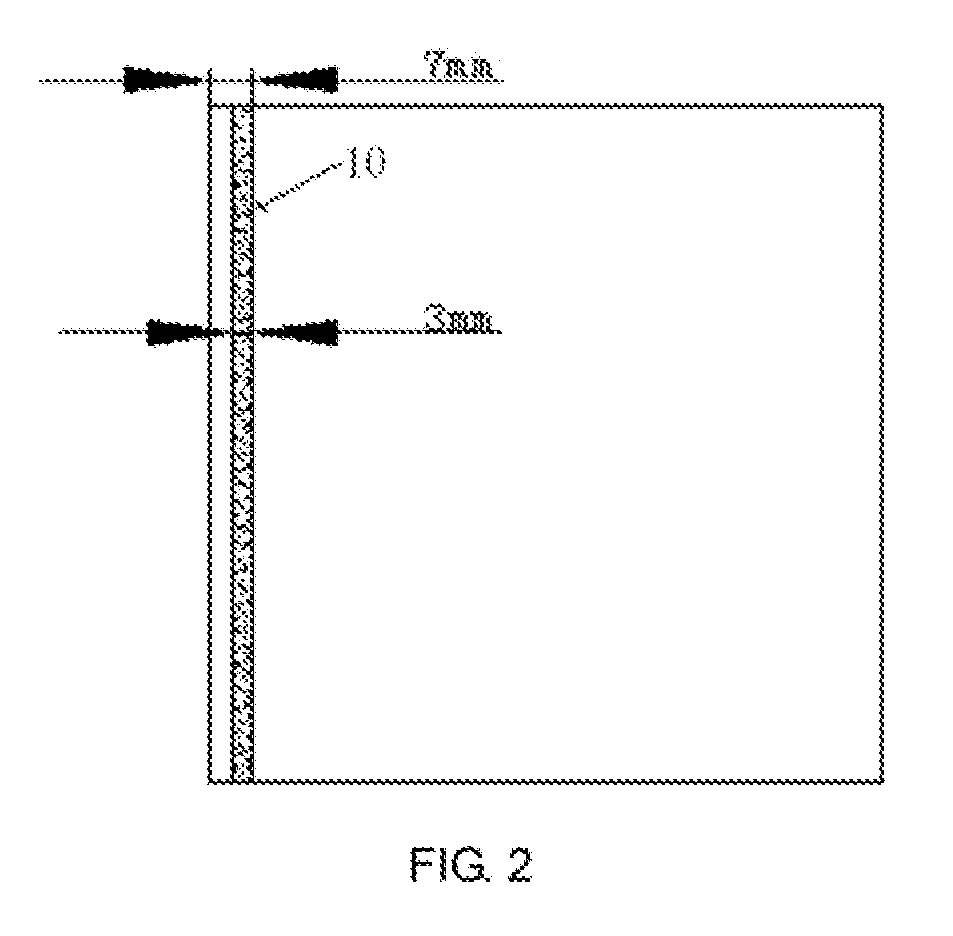

Large-size book production method

ActiveCN105128554ANot prone to misalignmentGuarantee the quality of bindingBook making processesSheet bindingEngineeringLarge size

The invention provides a large-size book production method. The method mainly comprises the following steps: papers of books are cut, glue is brushed at the edges of the papers, all the papers are bonded through the glue, and the multiple bonded papers are positioned and fixed by using a right-angled mold; and all the positioned and fixed papers are drilled, wires are pulled among holes of all the papers, and all the papers are reinforced. Front ring liners and back ring liners are spliced on ring liner connecting cloth; and then, the ring liners are bonded with contents. The right-angled mold is adopted to position, align and fix the multiple bonded papers, so that the papers are not easy to generate the dislocation, the book binding quality is guaranteed, the book beauty is increased, the book production time is shortened, and the book production efficiency is improved. The method can break through the limitation of 787*544 mm size of traditional books to realize the production of books with a larger size.

Owner:北京市文化科技融资租赁股份有限公司

Punching and binding integrative machine

The invention discloses a punching and binding integrative machine, which comprises a base, a punching table on the base, a punching device arranged on the base and a rotating shaft, and further comprises a placing device used for placing papers with binding holes, and binding rings matched with the binding holes, a pressing in device used for pressing the binding holes into the binding rings through exerting pressure on the papers, and a linkage device connected with the rotating shaft and used for converting the rotation of the rotating shaft into the movement that allows the pressing in device to press the binding holes into the binding ring so as to complete the paper binding, wherein the rotating shaft rotates around the base so as to finish the punching on the papers. The integrative machine is simple in structure, low in construction cost, and convenient to operate, is high in working efficiency and fast in speed as punching and binding are completed on one set of bookbinding machine, and realizes punching and binding at the same time. Moreover, the papers can be bound in batches, without messing the sequence.

Owner:ZHEJIANG ZHIYUAN OFFICE EQUIP MFG

Simple stretched iron wire binding device

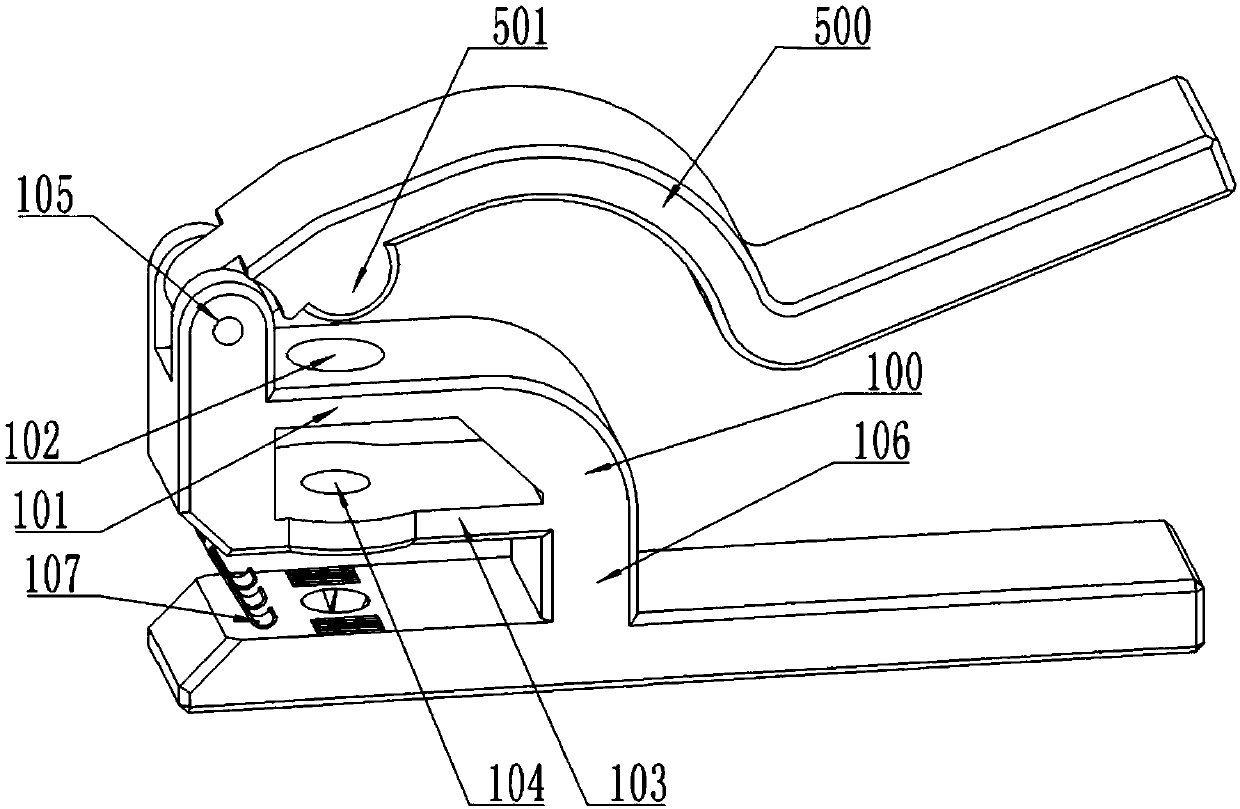

PendingCN109057505ABinding tightly and firmlyModerate binding forceRopes and cables for vehicles/pulleyTowersWire wheelEngineering

The invention discloses a simple stay wire and iron wire binding device. The device comprises a clamp body and a handle connected with the rear portion of the clamp body, three wire wheels are disposed on the clamp body at intervals, and the wire wheels can freely rotate on the clamp body; annular grooves used for limiting iron wires are formed in the wire wheels, and an L-shaped supporting plateused for supporting stay wires during binding is further arranged at the front part of the clamp body. According to the binding device, the problems that excessively large force is needed during binding and zinc-plated layers on the surfaces of the iron wires are easy to damage are solved, the iron wires can have proper binding force, and the surfaces are kept smooth and free of damage. The binding device make the iron wires tightly and firmly bound, the binding quality of the stay wires and the iron wires is guaranteed, and meanwhile, the zinc-plated layers on the surfaces of the iron wires are not damaged; abrasion of a steel wire clamp jaw is avoided, the service life of the steel wire clamp is prolonged, and the stay wire and iron wire binding efficiency can be improved.

Owner:眉山市三新供电服务有限公司

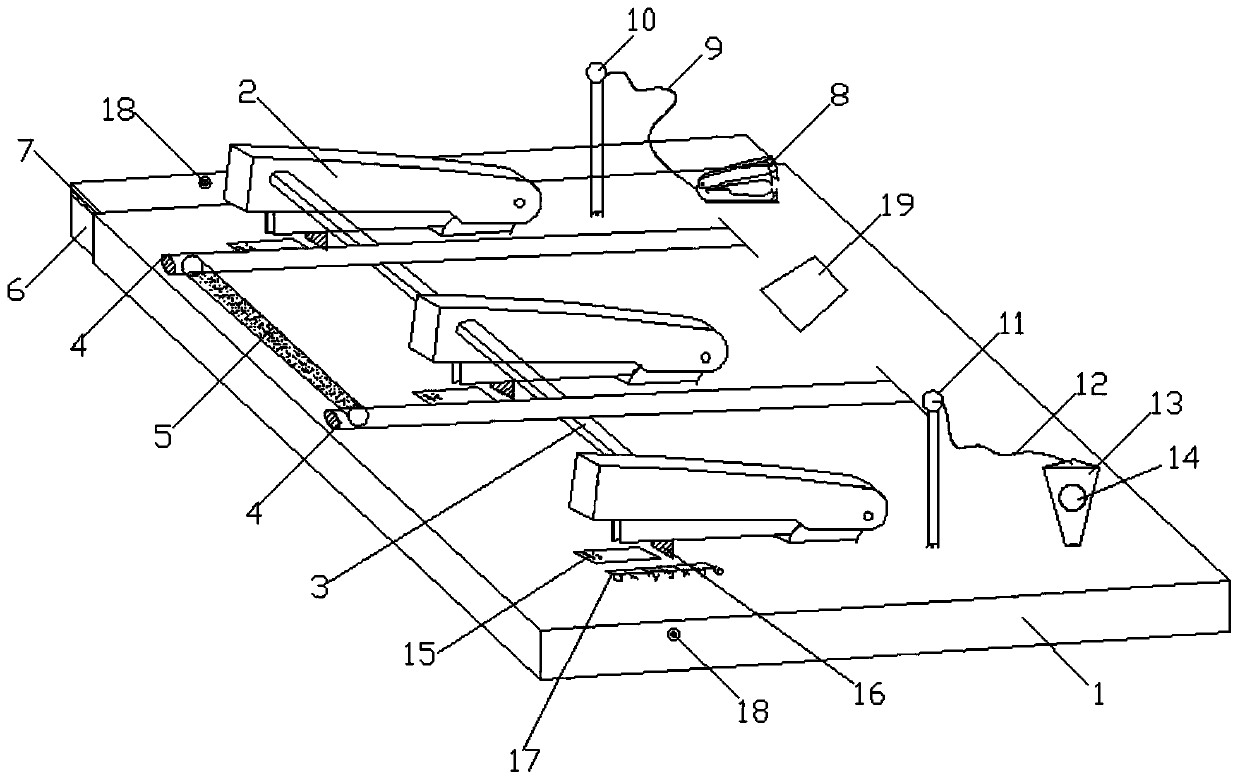

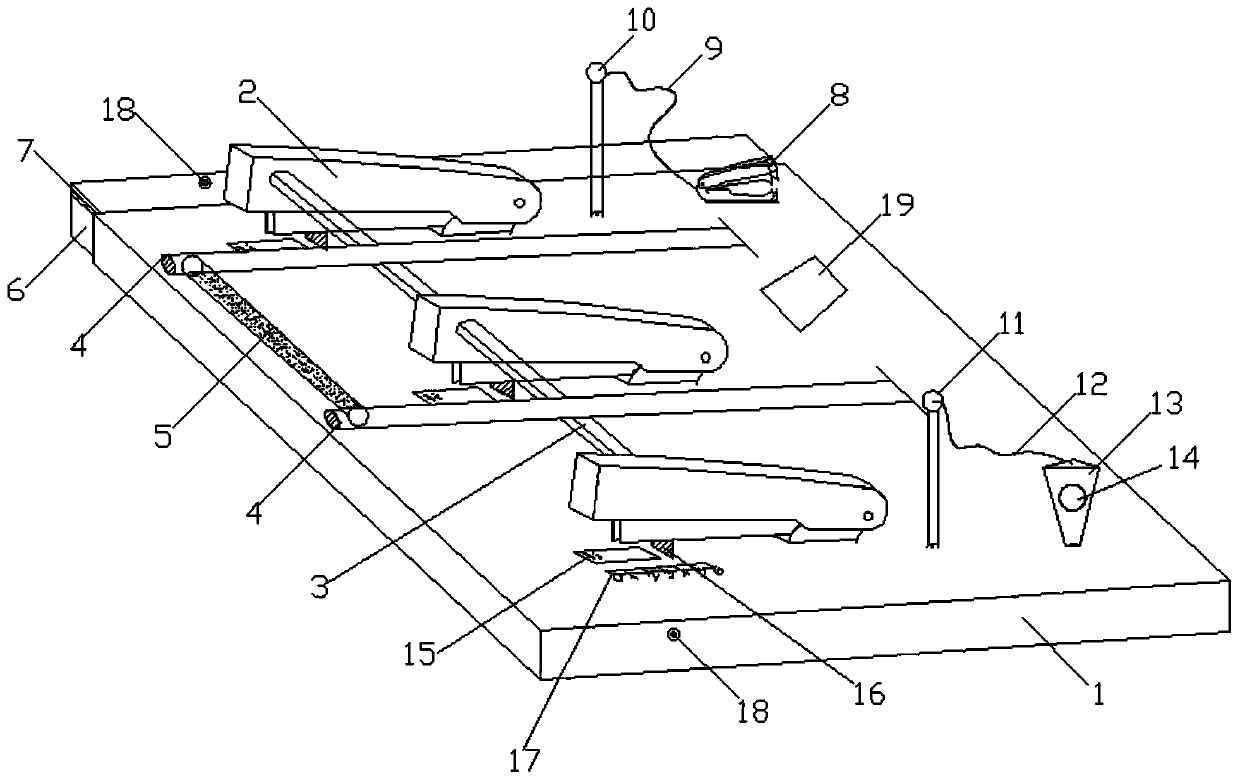

Novel stapler capable of simultaneously binding plurality of nails

PendingCN110026949AAvoid misalignmentFirmly nailedStapling toolsNailing toolsEngineeringBinding efficiency

The invention provides a novel stapler capable of simultaneously binding a plurality of nails. The novel stapler comprises a stapler base and a plurality of stapler main bodies arranged on the staplerbase, wherein the plurality of stapler main bodies are connected through a linkage connecting rod, and a pressing rod is further arranged between every two adjacent stapler main bodies; and one end of each pressing rod is hinged to the stapler base, the other end of each pressing rod extends towards the direction of the linkage connecting rod and is connected to the linkage connecting rod, and apressing rod handle is arranged among the other ends of the plurality of pressing rods. The novel stapler has the advantages that the structure is simple, the practicability is high, the plurality ofnails can be bound at the same time through the plurality of stapler main bodies, binding is convenient, the nails can be nailed into a straight line so that different nails are prevented from being staggered, the stress is ensured to be uniform through the pressing rods, then the to-be-bound paper can be nailed stably, and the binding efficiency is further improved; the neatness of the binding area is ensured through a nail storage box; and meanwhile, the raised nails can be flattened through a nail pressing device, the binding quality is ensured, and meanwhile, the user is prevented from being damaged by the raised nails.

Owner:WUYI UNIV

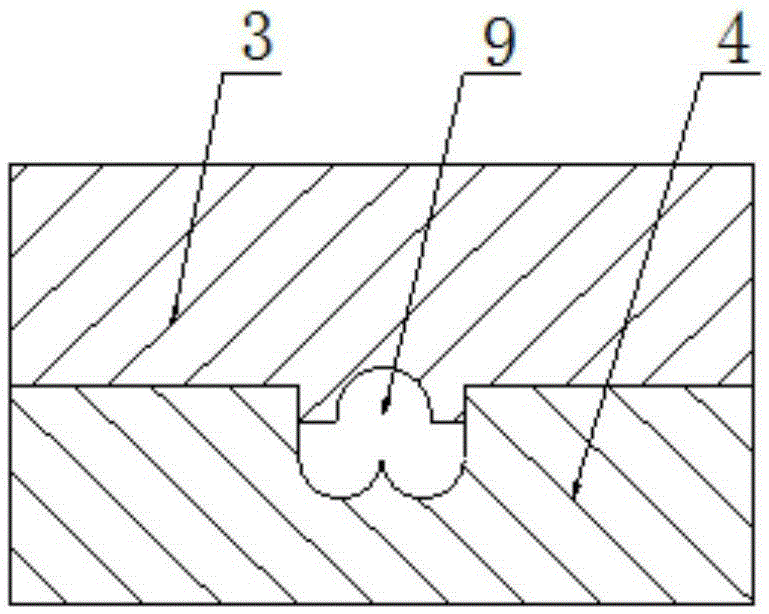

Press-fit type stapleless stapler

InactiveCN109693466AEnhanced binding effectGuarantee the quality of bindingSheet bindingFiberEngineering

The invention relates to the related technical field of office supplies, in particular to a press-fit type stapleless stapler. The press-fit type stapleless stapler comprises a supporting frame, a hole opening head, a pressing block, a base, a pressing handle, a limiting ring and a spring, wherein the section of the supporting frame is 9-shaped, a through hole A is formed in an upper cross beam ofthe supporting frame, a through hole B is formed in a lower cross beam of the supporting frame, an inverted-U-shaped slide way is arranged at the front end of the upper cross beam, a sliding block isarranged in the slide way, a rolling wheel is arranged below the sliding block, the hole opening head is located in the through hole A and the through hole B, the pressing block is a circular ring body, and is located below the lower cross beam, and the pressing handle is arranged above the hole opening head. The hole opening head and the pressing block which are provided by the press-fit type stapleless stapler cooperate with the base so that multi-dimensional fiber adhesion can be formed among paper, then a good binding effect can be achieved; and the supporting frame which is provided by the press-fit type stapleless stapler can make the hole opening head and the pressing block vertically move up and down, so that the binding quality is ensured.

Owner:安徽冠东电子科技有限公司

Needleless stapler

InactiveCN109664631AEnhanced binding effectGuarantee the quality of bindingSheet bindingFiberEngineering

The invention relates to the technical field of office supplies, in particular to a needleless stapler. The needleless stapler includes a support frame, opening heads, a pressing block, a base, a pressing handle, a limit ring and a spring. The support frame has a 9-shaped cross section; the upper beam of the support frame is provided with a through hole A; the lower beam of the support frame is provided with a through hole B; the opening heads are located in the through hole A and the through hole B; and the pressing block is located below the lower beam of the support frame. The opening headsand the pressing block fit with the base to form multi-dimensional fiber adhesion between paper sheets, so that a good binding effect is achieved; and the support frame can make the opening heads andthe pressing block vertically move up and down to ensure the binding quality.

Owner:安徽冠东电子科技有限公司

Financial voucher arranging and binding device

InactiveCN111497486ARealize automatic operationImprove work efficiencyMetal working apparatusSheet bindingEngineeringStructural engineering

The invention discloses a financial voucher arranging and binding device and relates to the technical field of finance equipment. The financial voucher arranging and binding device comprises a base and a cylinder fixedly installed on the base. The cylinder is internally and fixedly provided with a middle shaft. The outer side of the middle shaft and the inner side of the cylinder are provided witha sliding way A and a sliding way B respectively. The two ends of a drilling assembly and the two ends of a hot melting binding assembly are installed on the sliding way B and the sliding way B in asliding manner respectively. The middle shaft is provided with a drive piece for driving the hot melting binding assembly and the drilling assembly to rotate. The middle shaft is fixedly installed onthe cylinder through a supporting connection rod. The outer side of the supporting connection rod is rotationally sleeved with a sleeve. The two sides of the sleeve are fixedly provided with connection pieces. The end portions, far away from the sleeve, of the connection pieces on the two sides are internally provided with driving rods in an up-down sliding manner. The driving rods on the two sides are fixedly installed on the drilling assembly and the hot melting binding assembly. The sleeve is further provided with an interval drive mechanism. By means of the financial voucher arranging andbinding device, drilling and binding can be completed at a time, the working efficiency is improved, meanwhile automatic running is achieved, and the labor intensity is reduced.

Owner:SUIHUA UNIV

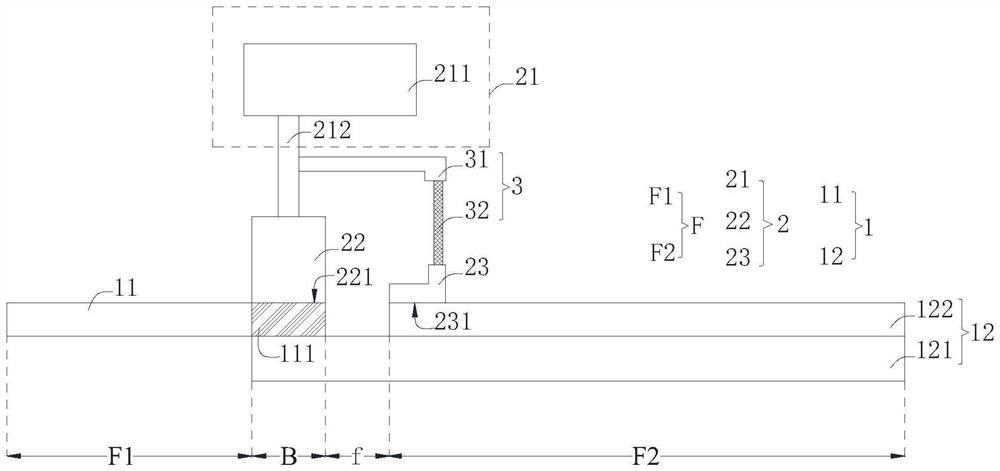

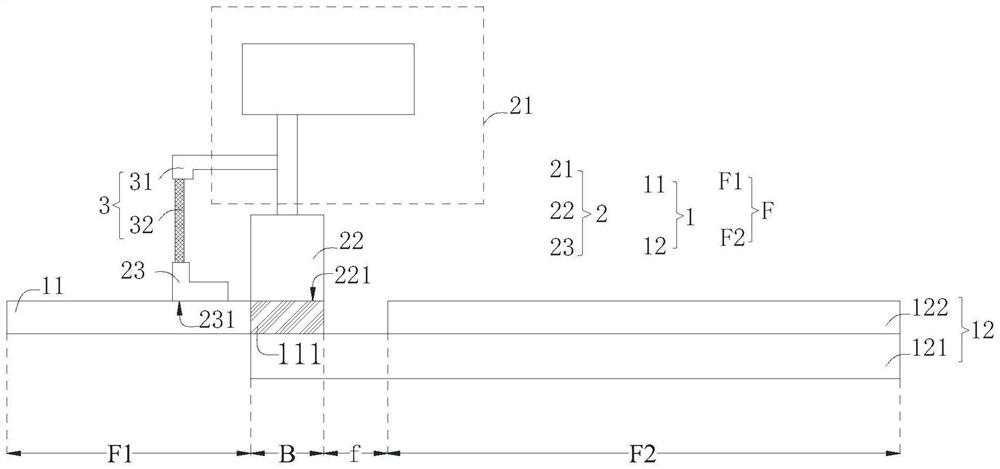

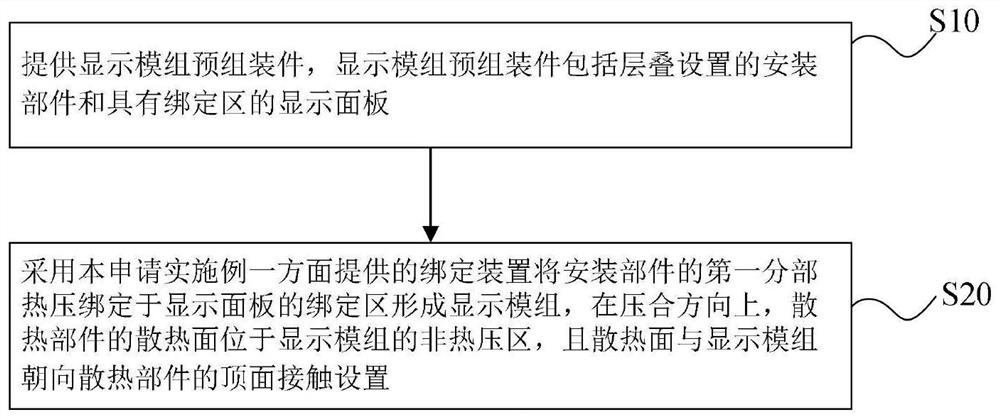

Binding device and binding method for binding display module

PendingCN114286620AAvoid thermal deteriorationGuarantee the quality of bindingElectrical componentsEngineeringMechanical engineering

The embodiment of the invention provides a binding device and a binding method for binding a display module, the display module comprises a mounting component and a display panel, the binding device is used for hot-pressing and binding a first branch of the mounting component to a binding area of the display panel, and the binding device comprises: a bearing component; the heating component is arranged on one side of the bearing component, the heating component is movably arranged in the pressing direction, and the heating component is provided with a heating surface used for heating the first subsection; the one or more heat dissipation parts and the heating part are arranged on the same side of the bearing part, and the heat dissipation part is provided with a heat dissipation face used for making contact with a non-hot-pressing area of the display module so that the heat dissipation part can absorb heat of the non-hot-pressing area of the display module through the heat dissipation face. According to the binding device, the heat dissipation component is arranged to absorb heat of the non-hot-pressing area of the display module, the quality of the display module formed after hot-pressing binding is improved, and the preparation yield of the display module is increased.

Owner:BAZHOU YUNGU ELECTRONICS TECH CO LTD

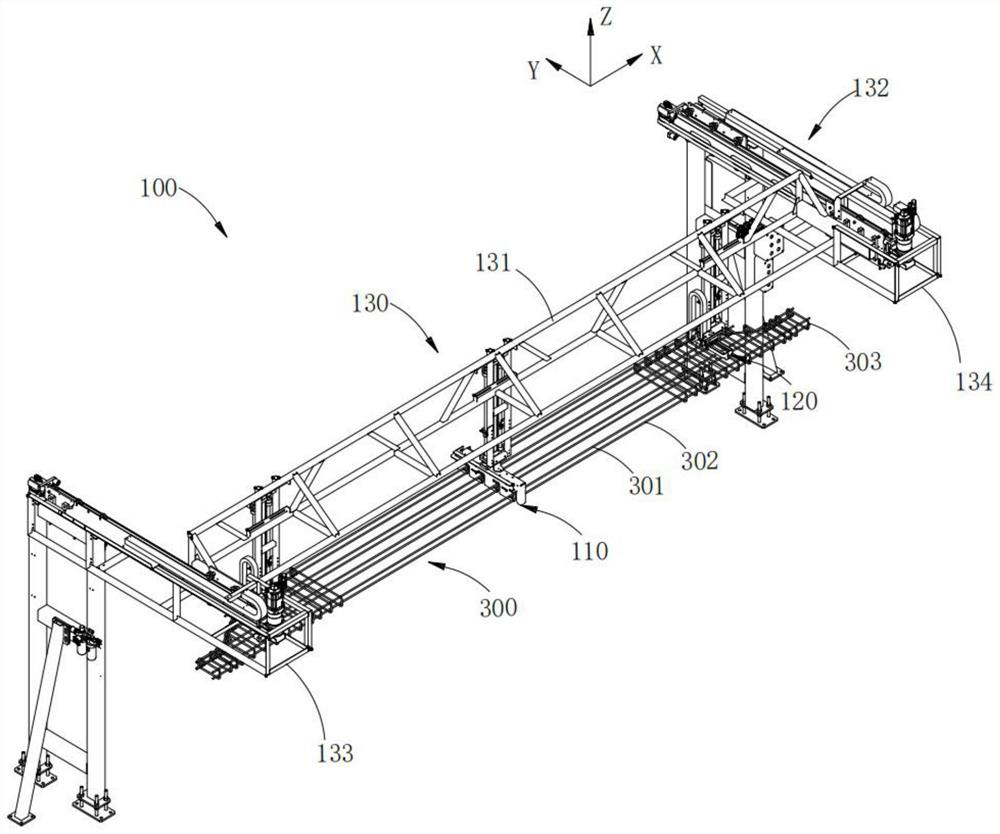

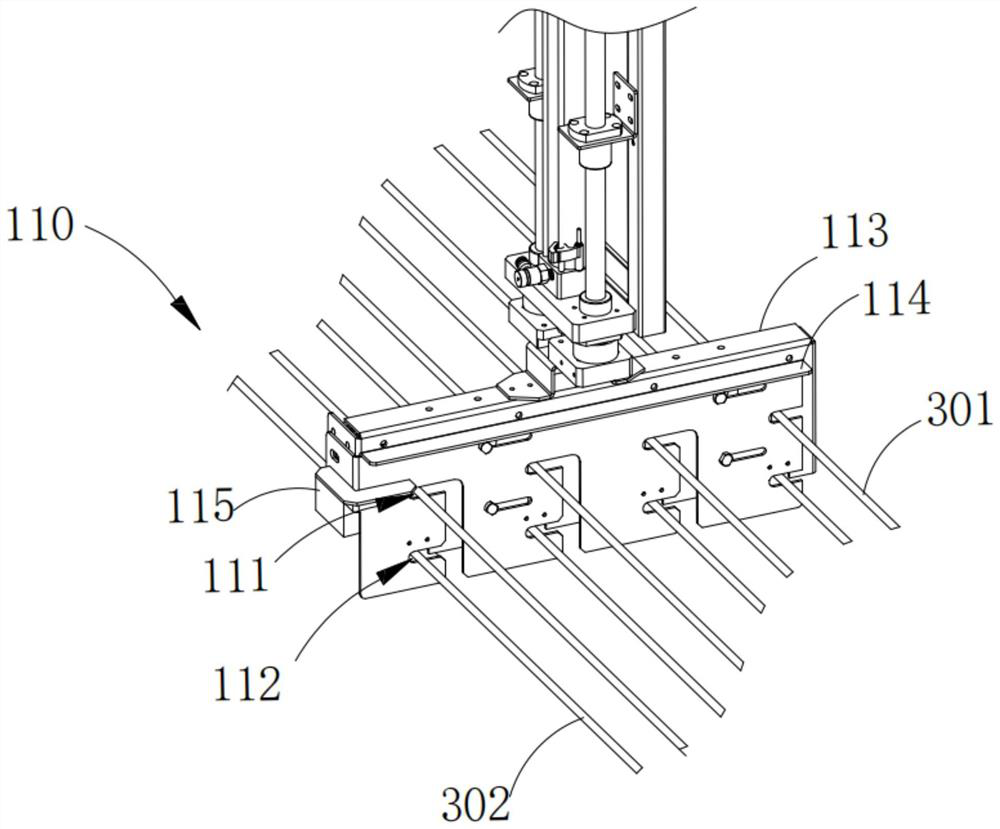

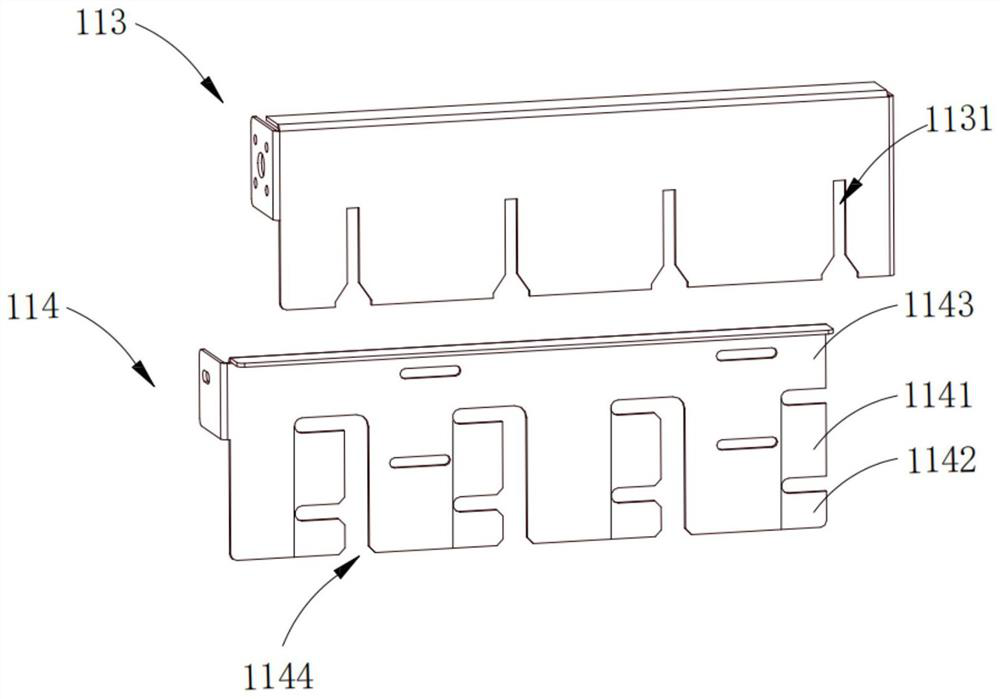

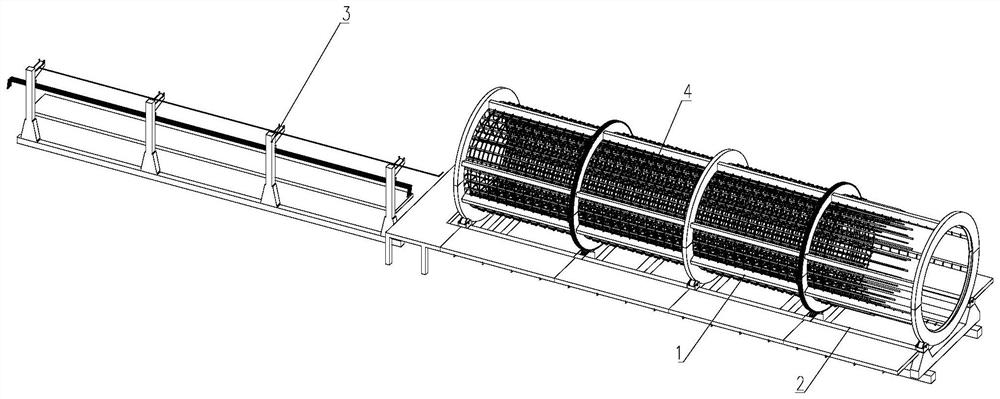

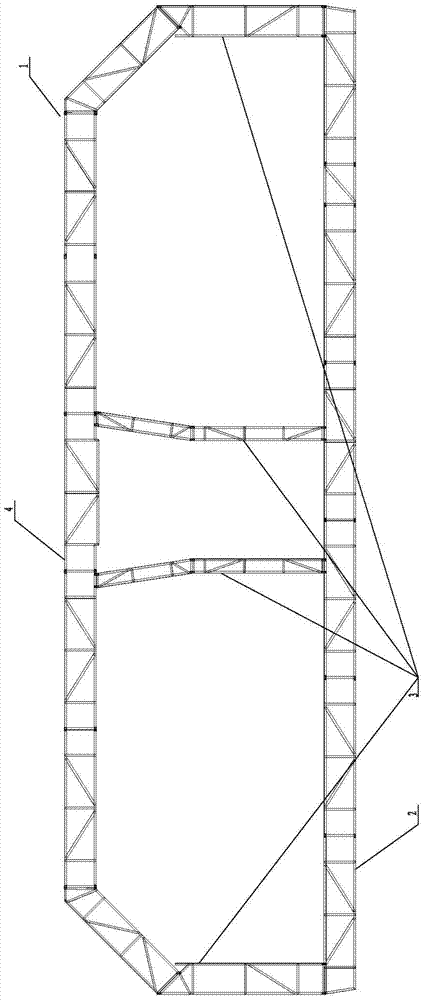

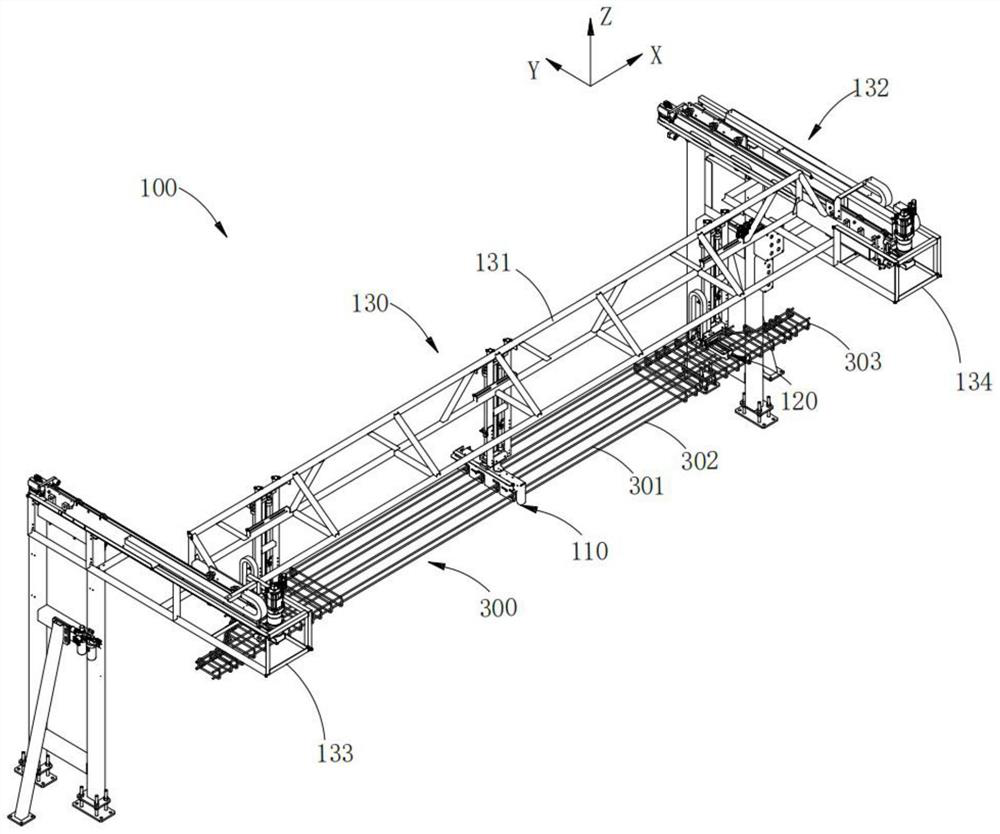

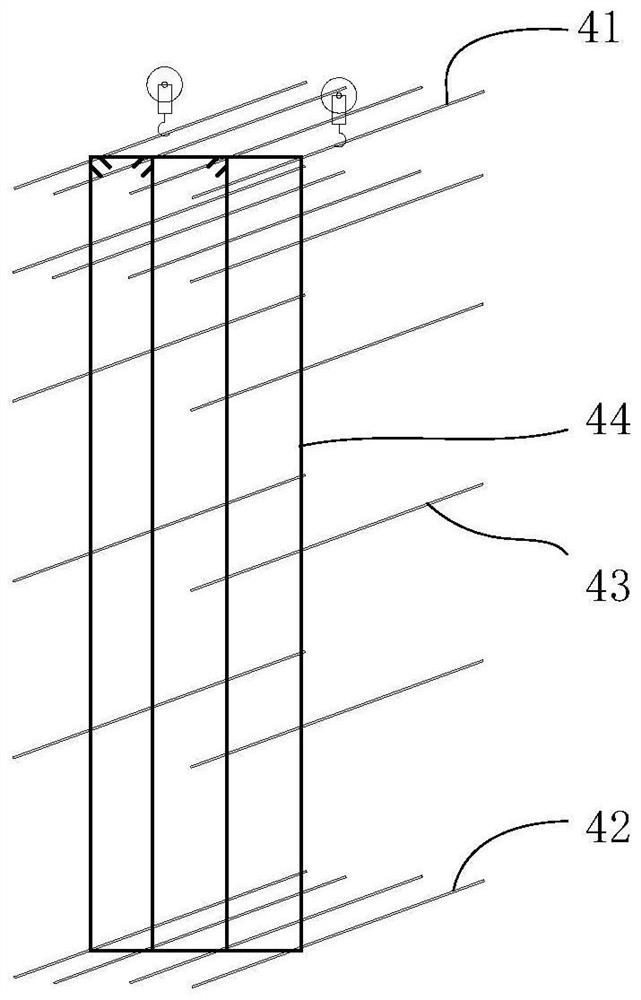

Reinforcement cage hoisting device and reinforcement cage carrying equipment

ActiveCN112374339AAvoid deformationImprove hoisting efficiencyBase supporting structuresBraking devices for hoisting equipmentsStructural engineeringControl theory

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

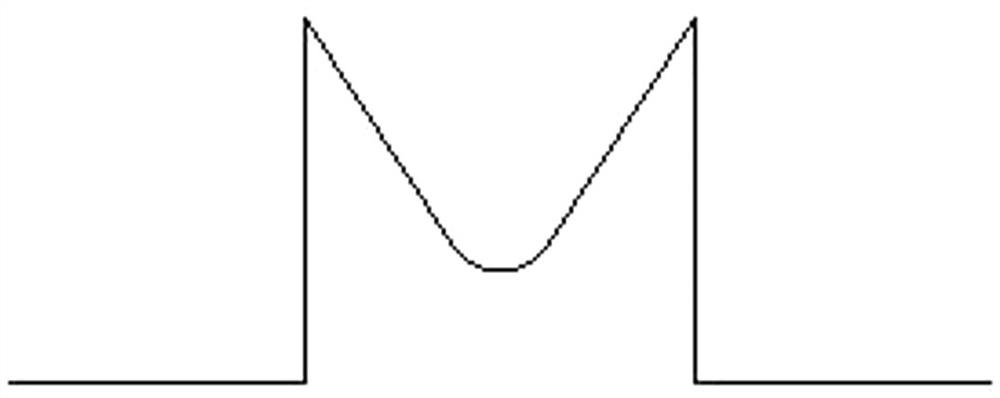

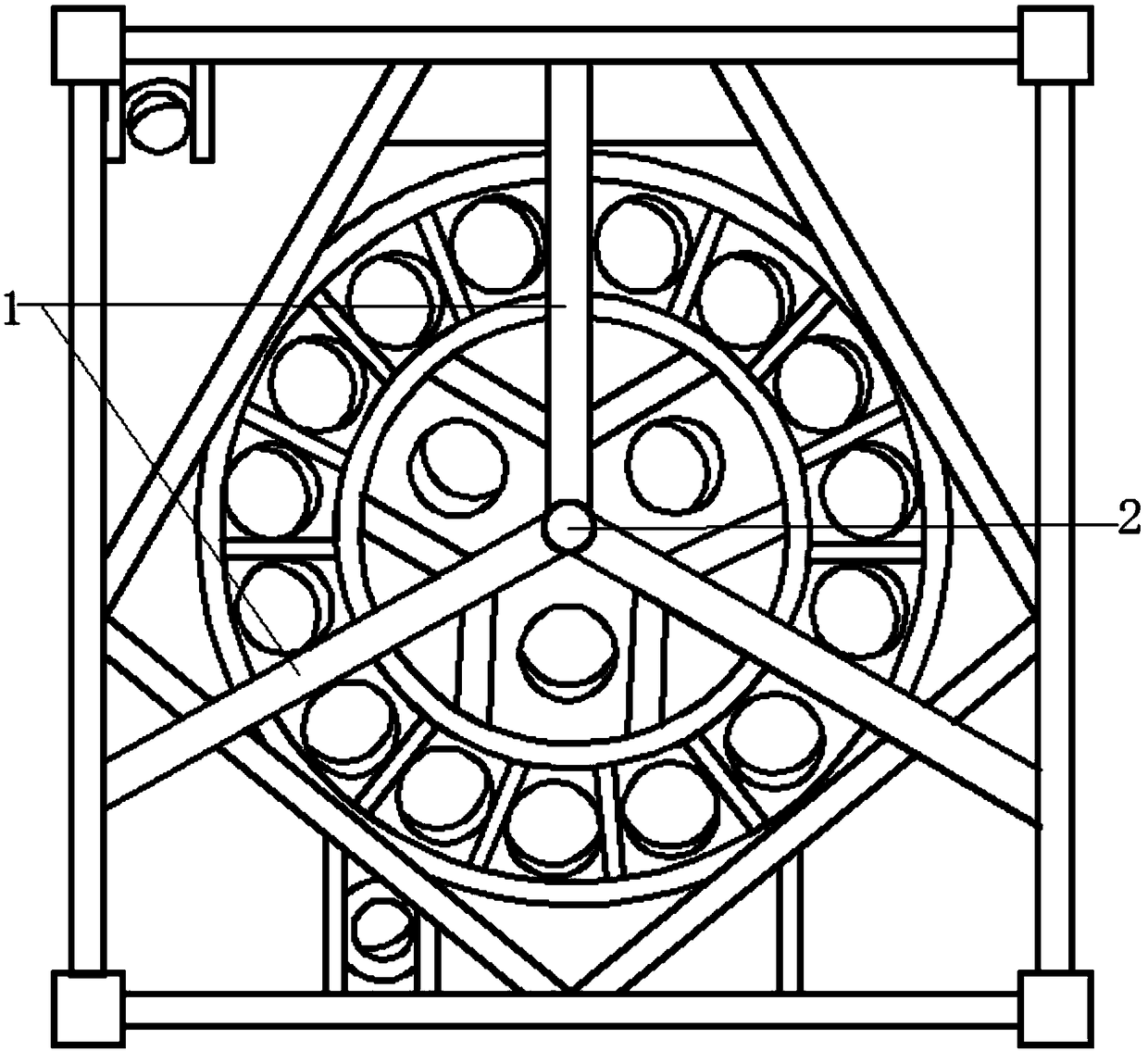

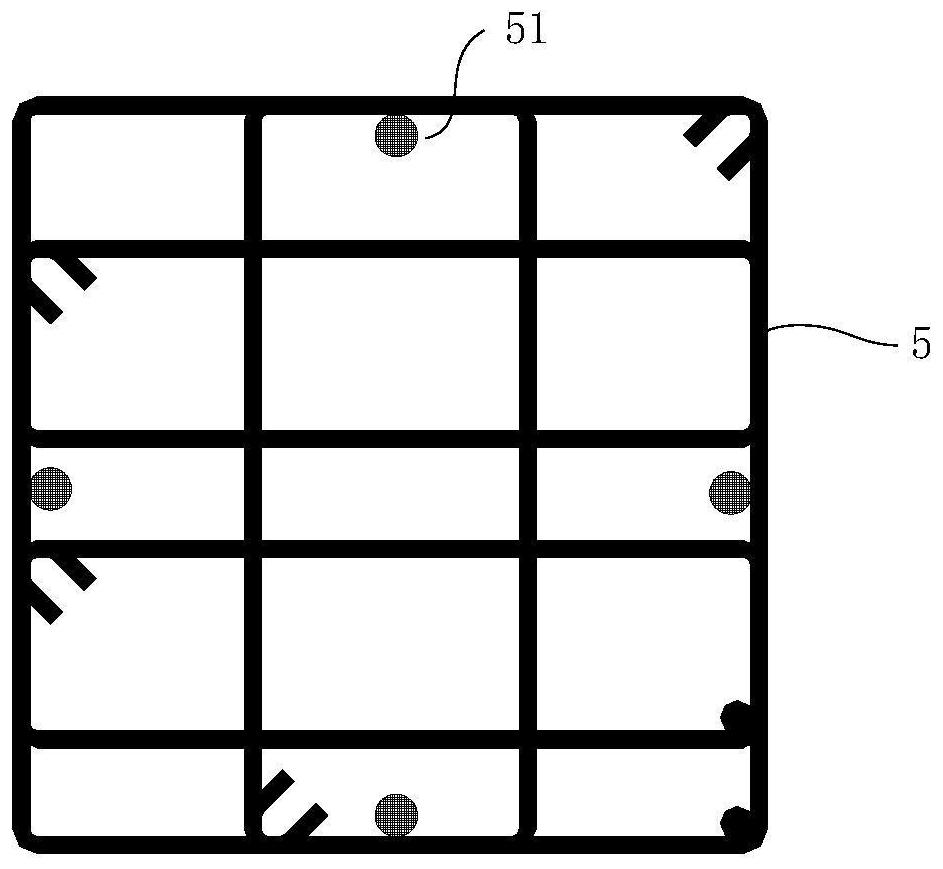

Rolling type cylindrical hollow pier reinforcement cage binding jig frame

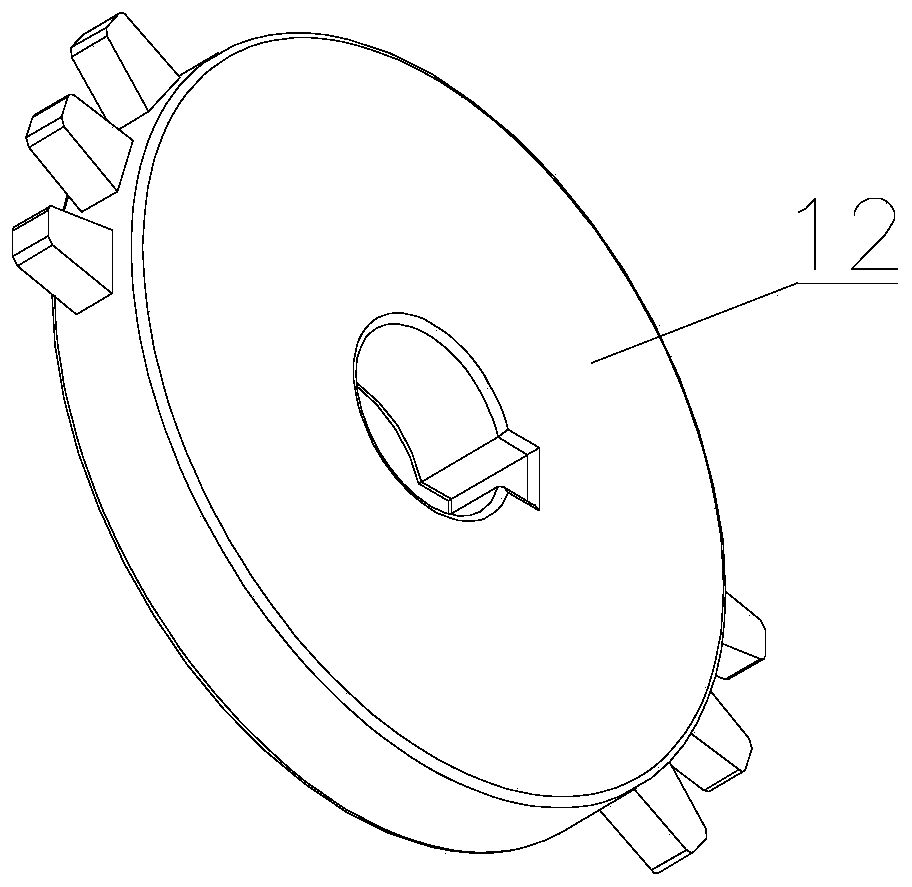

PendingCN113732215ASimple structureEasy to manufactureWire networkBridge erection/assemblyGear wheelEngineering

The invention discloses a rolling type cylindrical hollow pier reinforcement cage binding jig frame which comprises a reinforcement cage limiting frame, a base, a vertical rib auxiliary penetrating and conveying mechanism and an electric control system. The reinforcement cage limiting frame is formed by splicing two semicircular limiting frame bodies, each limiting frame body comprises a plurality of annular toothed rails and a plurality of limiting longitudinal beams which are arranged in the circumferential direction and used for connecting the annular toothed rails into a whole in series, and a plurality of limiting grooves are formed in the limiting longitudinal beams; and a plurality of driving gears which are controlled by the electric control system to rotate are rotationally assembled on the base, and the driving gears are in one-to-one correspondence with the annular toothed rails and are in meshing transmission with the corresponding annular toothed rails. In the reinforcement cage binding process, the reinforcement cage limiting frame and a reinforcement cage can be driven by the driving gears to rotate by an angle of a vertical rib and are locked, the vertical rib does not need to be conveyed by 360 degrees in the circumferential direction around the reinforcement cage, the forming quality of the reinforcement cage is effectively assisted and controlled, and meanwhile, the convenience and safety of binding operation of the reinforcement cage are improved.

Owner:湖南五新智能科技股份有限公司

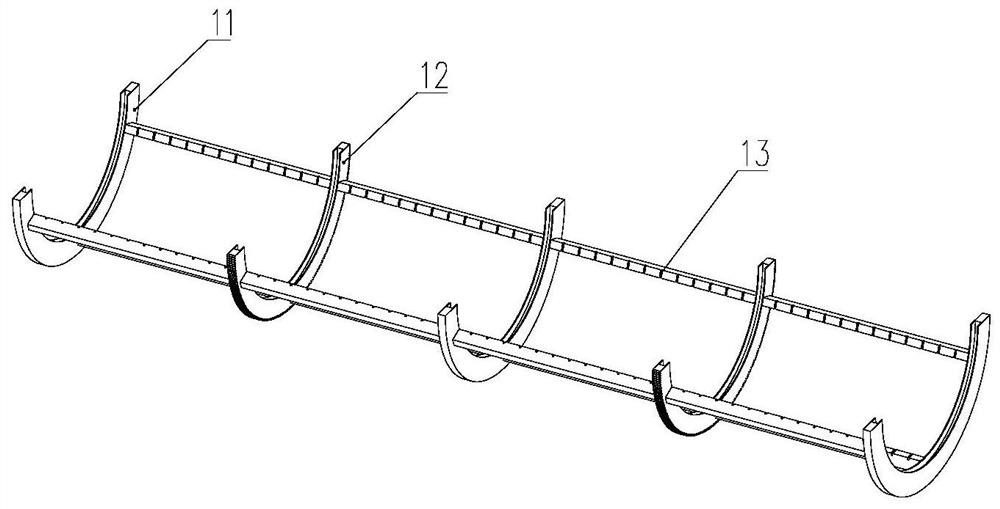

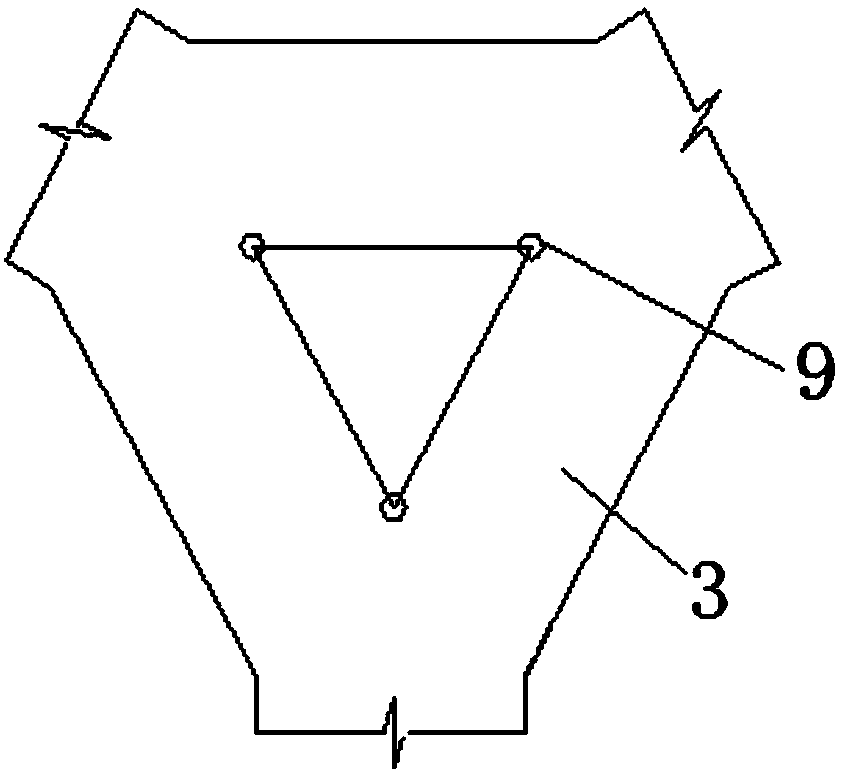

Semi-automatic manufacturing method of cast-in-place pile reinforcement cage

InactiveCN112317660AImprove binding efficiencyImprove binding qualityWire networkBuilding reinforcementsElectric machinerySemi automatic

The invention discloses a semi-automatic manufacturing method of a cast-in-place pile reinforcement cage. The semi-automatic manufacturing method comprises the following steps that 1, reinforcement cage main reinforcement limiting clamps are installed on a hardened site; 2, the axes of machined reinforcement cage reinforcing rings are connected in series, the reinforcing rings connected in seriesare welded to a first reinforcing steel bar, the reinforcing rings are rolled to a second main reinforcing steel bar to be welded, and so on, welding is conducted, and binding of main reinforcing steel bars is completed; and 3, two rolling shafts with the interval of 30 cm are arranged at the last main reinforcing steel bar, one end of each rolling shaft is connected with a motor and rotates alongwith the motor, and one end of each stirrup penetrates through a movable sliding block to be welded to the reinforcement cage. Manufacturing is easy, operation is convenient, and the binding efficiency and quality of stirrups can be improved through the sliding blocks and the rolling shafts. The main reinforcing steel bars can be distributed on a bracket according to a fixed interval, the reinforcement cage reinforcing rings are placed on the first main reinforcing steel bar and the second main reinforcing steel bar, meanwhile, the longitudinal interval of the reinforcement cage reinforcing rings is adjusted according to design requirements, and welding is conducted.

Owner:中国建筑土木建设有限公司

Box nailing machine avoiding binding deformation and for corrugated carton production

InactiveCN108859251AAvoid Scattered and Distorted ConditionsGuarantee the quality of bindingPaper-makingBox making operationsBinding stateCarton

The invention discloses a box nailing machine avoiding binding deformation and for corrugated carton production. The box nailing machine comprises a main supporting frame and a positioning bolt. An auxiliary supporting frame is fixed to the lower side of the main supporting frame, and a supporting base is connected to the lower end of the main supporting frame through a connecting supporting foot.A driving motor is mounted on the upper side of the main supporting frame, a nail head is connected to the front end of the driving motor, a first compression pad is arranged on the front side of thenail head, and a moving rod is connected to the lower end of the first compression pad. A rack is arranged on the lower side of the moving rod, a stepping motor is connected to the outer side of therack through a gear, a main supporting rod is fixed to the outer side of the moving rod, and an auxiliary supporting rod is arranged on the inner side of the main supporting rod. The box nailing machine avoiding the binding deformation and for the corrugated carton production is provided with a stabilizing rod, the stable binding state of corrugated paper can be further strengthened, the situationof scattering and deformation occur in the binding process of the corrugated paper is avoided, the working quality of the box nailing machine is improved, and the use value of the whole box nailing machine is improved.

Owner:赵云姿

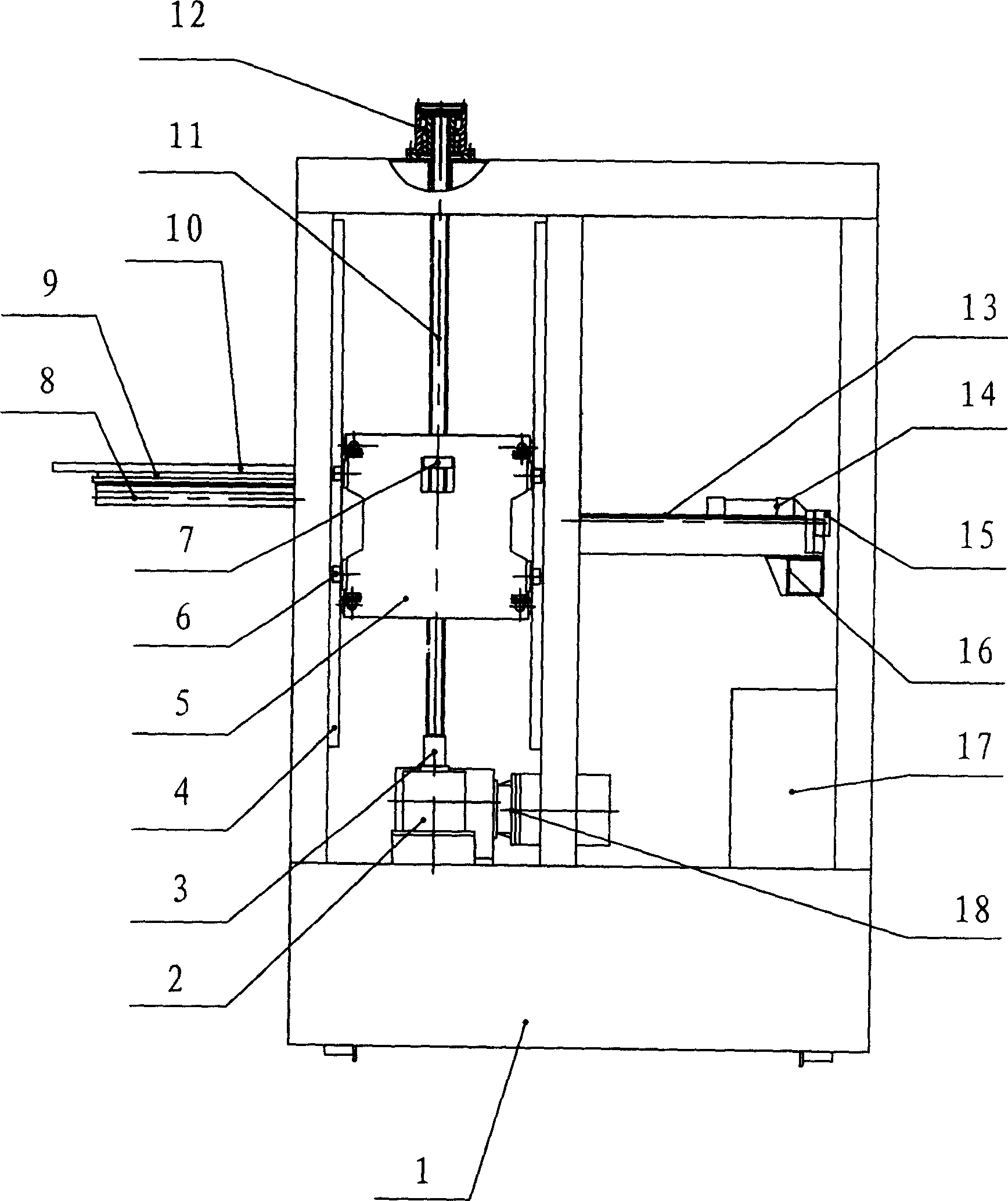

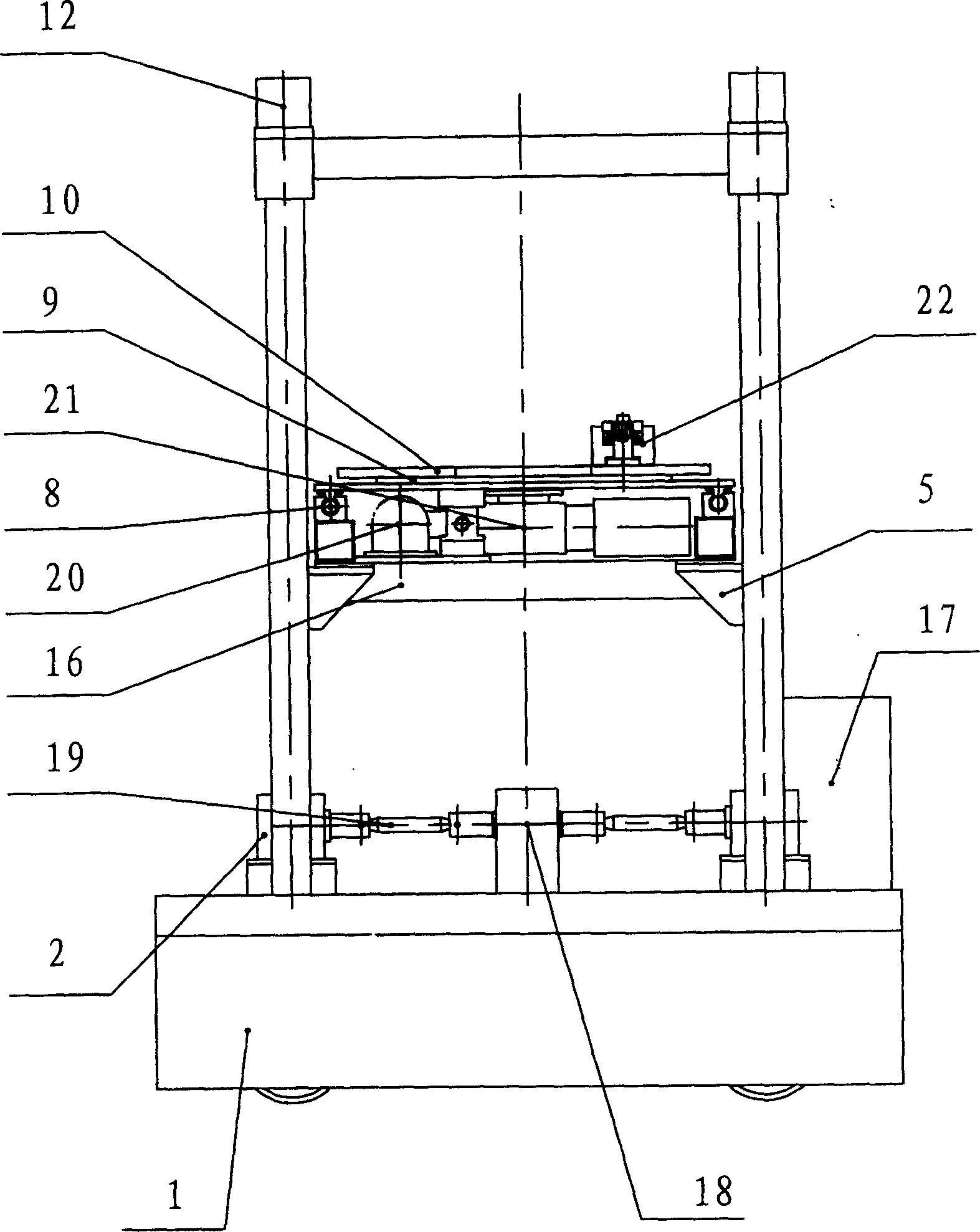

Transformer iron core adhesive band vertical bundling machine

InactiveCN1235244CContinuous windingWind evenlyInductances/transformers/magnets manufactureAdhesive beltTransformer

The machine includes frame, rising and falling transmission mechanism, winding gear and drive unit installed on the frame. Sliding supporter of the rising and falling transmission mechanism through nut on screw is installed between guide rails of frame, moving along rails to and fro. Bottom end of each screw is connected to output shaft of orthogonal reducer driven by drive unit. Movable bracket is connected between two sliding supporters. Tray of winding gear through nut on screw is installed on slide way of movable bracket. Driving gear on the tray through idle pulley drives winding gear. The invention possesses features of reasonable structure, small oscillation noise, and continuous stable seizing operation, even tight adhesive tape enwinding, labor saving and material saving.

Owner:陈星

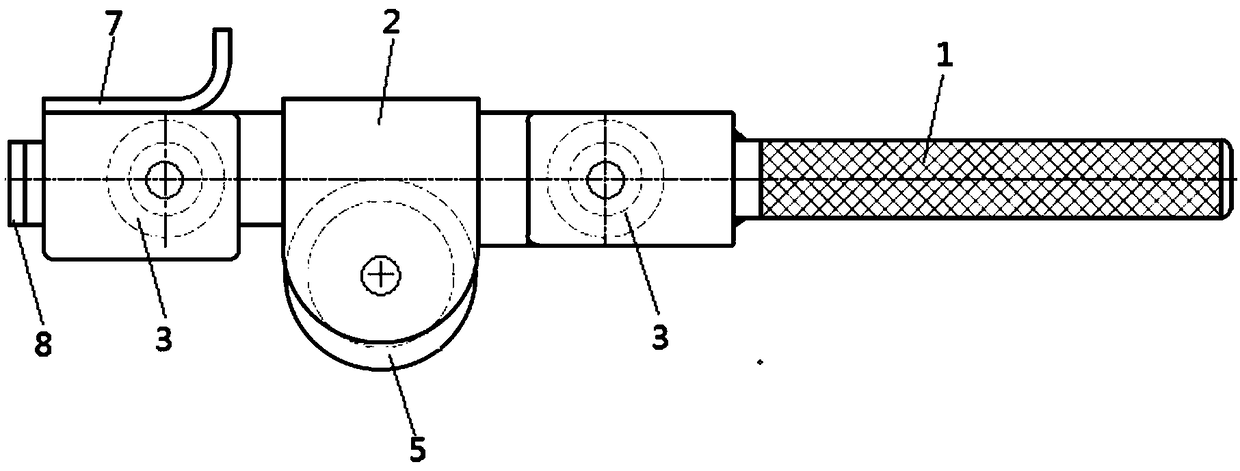

Mini connector assembly colligation tool

InactiveCN105356193AStable positioningGuarantee binding quality and efficiencyLine/current collector detailsEngineeringMechanical engineering

The invention relates to a mini connector assembly colligation tool, which is characterized in that the tool comprises a support, a slide block, a positioning plate, a positioning baffle plate, a positioning cover and a colligation rope rack; the support is F-shaped; a chute is installed in the horizontal part of the F-shaped support; the slide block is slidingly installed in the chute; the positioning plate is fixedly installed on the top of the slide block; the positioning baffle plate is installed at one end of the positioning plate and the colligation rope rack is installed on the other end of the positioning plate; and the positioning cover is put on the upper portion of the positioning plate. The invention provides the mini connector assembly colligation tool that has the advantages of scientific and reasonable design, good colligation effect, high efficiency, convenient operation and high innovation; manpower waste is reduced; and worker labor intensity is lowered.

Owner:TIANJIN HUAZHIYANG SPECIAL CABLE

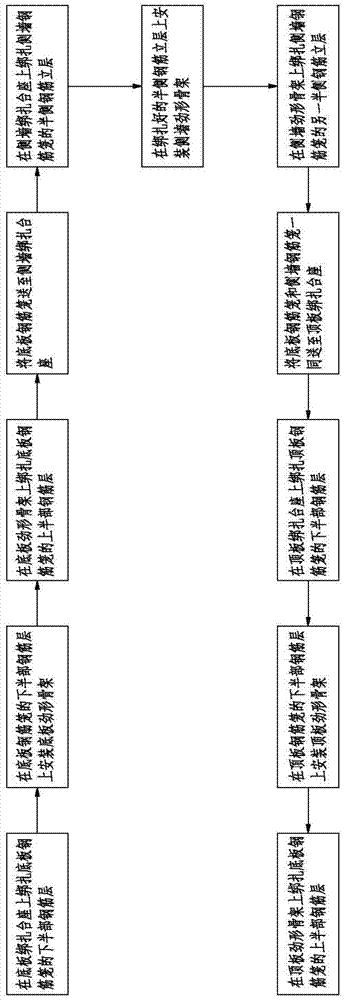

Large-volume anti-deformation steel reinforcement cage and binding method thereof

ActiveCN103758288AAvoid deformationSolve the problem of anti-deformationArtificial islandsShaping reinforcementsRebarMaterials science

The invention relates to a large-volume anti-deformation steel reinforcement cage and a binding method thereof. The binding method comprises the following steps: binding the lower half steel-bar layer of a base-plate steel reinforcement cage to a base-plate binding pedestal; installing a base-plate stiff skeleton on the lower half steel-bar layer of the base-plate steel reinforcement cage; binding the upper half steel-bar layer of the base-plate steel reinforcement cage to the base-plate stiff skeleton; sending the base-plate steel reinforcement cage to a side-wall binding pedestal; binding the half-side steel-bar vertical layer of a side-wall steel reinforcement cage to the side-wall binding pedestal; installing a side-wall stiff skeleton to the bound half-side steel-bar vertical layer; binding another half-side steel-bar vertical layer of the side-wall steel reinforcement cage to the side-wall stiff skeleton; sending the base-plate steel reinforcement cage and the side-wall steel reinforcement cage to a top-plate binding pedestal together; binding the lower half steel-bar layer of a top-plate steel reinforcement cage to the top-plate binding pedestal; installing a top-plate stiff skeleton on the lower half steel-bar layer of the top-plate steel reinforcement cage; and binding the upper half steel-bar layer of the base-plate steel reinforcement cage to the top-plate stiff skeleton, so as to form the top-plate steel reinforcement cage.

Owner:CCCC SECOND HARBOR ENG +3

Inflaming-retarding environmentally-friendly special-type motor wire group binding assist device

PendingCN107097989AChange lengthSmall range of motionBinding material applicationBundling machine detailsEngineeringUltimate tensile strength

The invention relates to an inflaming-retarding environmentally-friendly special-type motor wire group binding assist device. The device comprises a support, a fixing block, a sliding block, a positioning plate, a positioning baffle, a corrugated telescopic section and a positioning cover, the support is an F-shaped support, and the vertical end of the F-shaped support is fixed to a working table; the horizontal portion of the F-shaped support is sequentially provided with a fixing hole and a sliding groove from left to right, the fixing block is inserted into the fixing hole, and the sliding block is mounted in the sliding groove; the positioning plate is fixedly mounted at the tops of the fixing block and the sliding block, the positioning cover is arranged on the positioning plate in a buckling and pressing mode, and the position, corresponding to the positioning cover, of the positioning plate is provided with the corrugated telescopic section; and wire binding ports mutually communicating in the up-down direction are formed in the positions, at the two ends of the corrugated telescopic section, of the positioning plate and the positioning cover correspondingly, and the positioning baffle is arranged at the head end of the positioning plate. The inflaming-retarding environmentally-friendly special-type motor wire group binding assist device is scientific and reasonable in design and has the advantages of being good in binding effect, high in efficiency, convenient to operate, capable of reducing manpower waste and relieving the labor intensity of workers and the like.

Owner:TIANJIN HUAZHIYANG SPECIAL CABLE

Three-purlin beam center node steel bottom plate prefabricating method

InactiveCN108468344AGuarantee the quality of bindingEliminate deformation modulusFurnace componentsFoundation engineeringPurlinDeformation modulus

The invention discloses a three-purlin beam center node steel bottom plate prefabricating method. The method comprises the following steps that firstly, a non-spliced two layers of special-shaped steel plates are manufactured, then the steel plates and steel bars are welded in advance into a whole, and next a whole module which is relatively independent and is formed one time is formed through pouring. According to the three-purlin beam center node steel bottom plate prefabricating method, the whole can be hoisted to a design position during use, then the deformation modulus generated in the welding process of a steel template can be eliminated, the steel bar binding quality is also greatly guaranteed, the binding space and time are also saved, and the working efficiency is improved; and hole digging in the node steel plates and inter-plate concrete in-advance pouring construction method are adopted, so that the quality invisibility problems that air in the closed space cannot be discharged when concrete is poured, the concrete compactness is not easy to guarantee, and the saturation of the concrete cannot be measured are solved, the concrete distribution uniformity and the structure continuity are facilitated, and the construction quality of welding, binding and pouring is guaranteed to a great extent.

Owner:中十冶集团有限公司

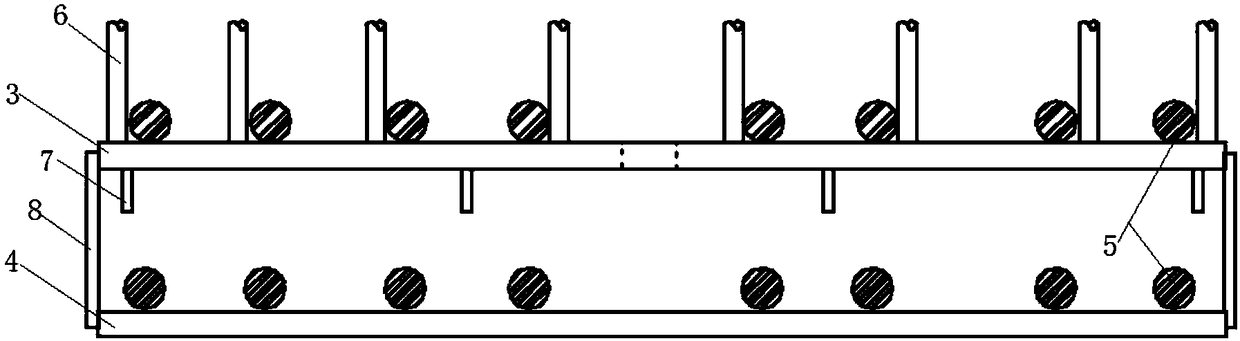

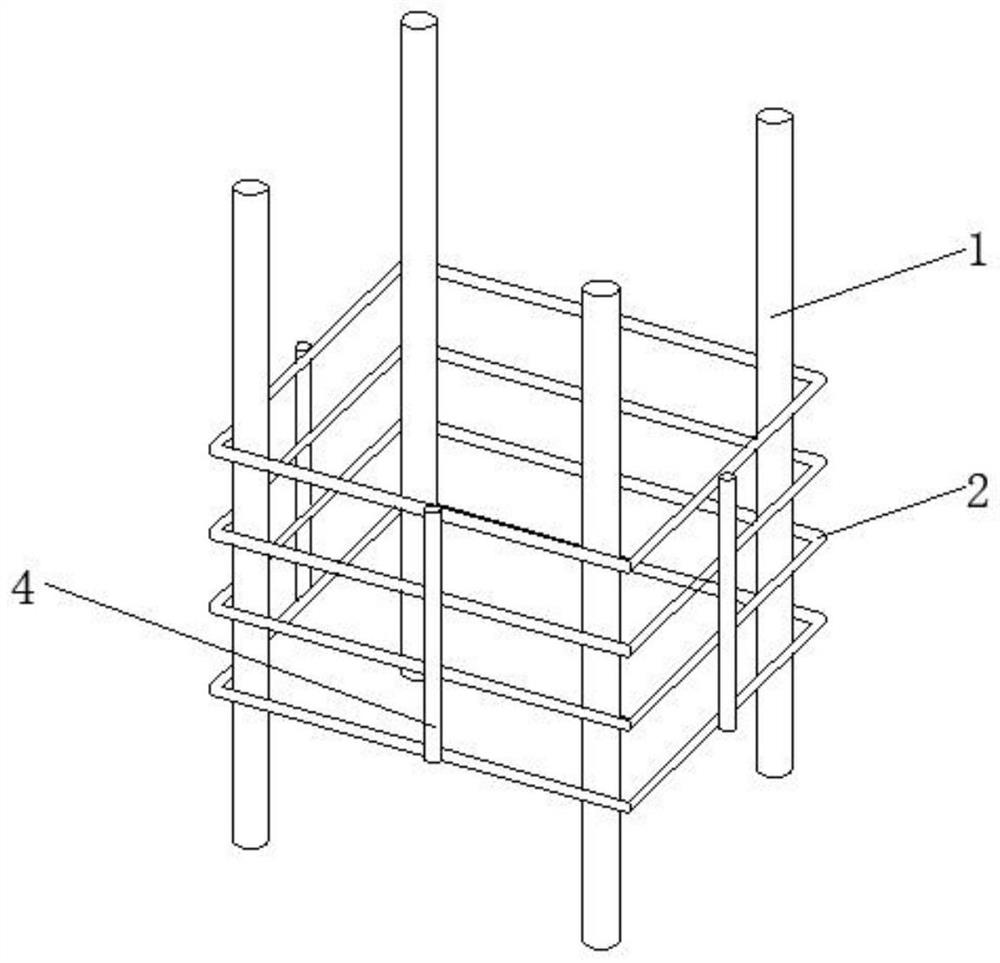

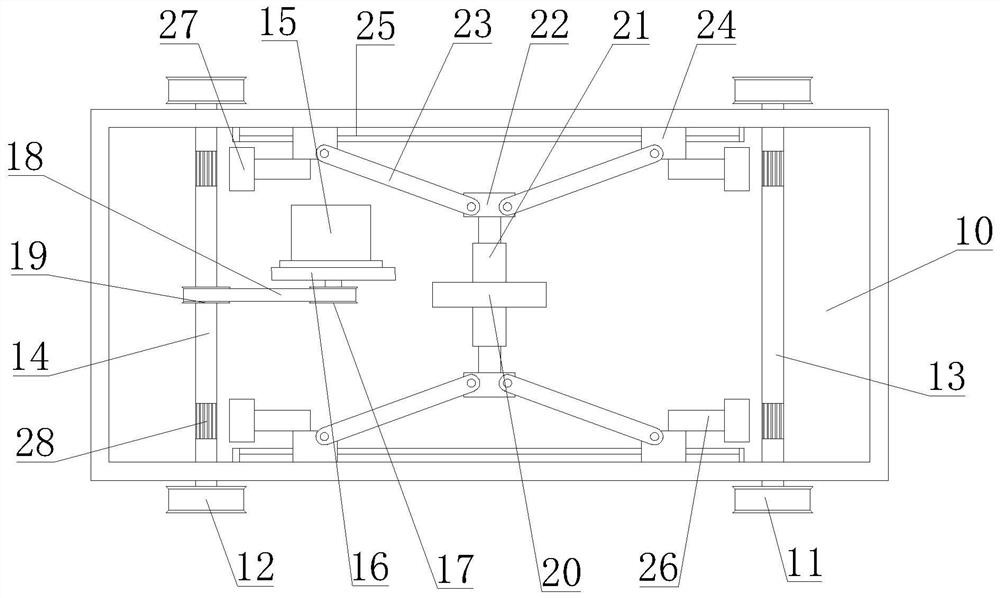

Rebar cage lifting device and reinforcement cage handling equipment

ActiveCN112374339BGood synergyGuarantee the quality of bindingBase supporting structuresBraking devices for hoisting equipmentsRebarMechanical engineering

The present application provides a hoisting device for a steel cage. The steel cage includes an upper surface and a lower surface. The hoisting device for the steel cage includes a first grabbing mechanism and a moving mechanism. The first grabbing mechanism is provided with a first grabbing mechanism for grabbing the upper surface. A grasping part and a second grasping part for grasping the lower mesh surface, the moving mechanism has at least two degrees of freedom of movement, and the first grasping mechanism is arranged on the moving mechanism. The steel cage lifting device provided by the present application can simultaneously fix the upper surface and the lower mesh surface of the steel cage by moving the first grasping mechanism, so as to ensure that the upper surface and the lower mesh surface can be grasped simultaneously during the lifting process. To avoid only hoisting the upper surface or lower mesh surface of the steel cage alone, which will cause one of them to be overstressed and deformed, and no manual hoisting is required during the entire hoisting operation, which improves the hoisting efficiency. In addition, a steel cage handling equipment is also provided.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

Method for making books

InactiveUS20170057271A1Efficient preparationReduce sizeBook making processesSheet bindingEngineeringMechanical engineering

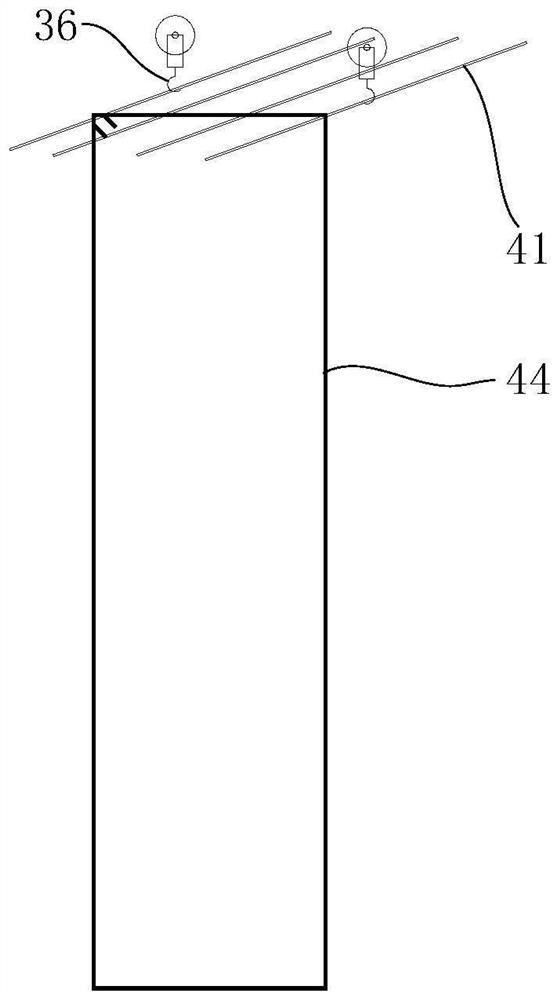

A method for making a book is provided in the embodiments of the present invention. The method mainly comprises: cutting printed sheets for a book, brushing glue onto edges of the printed sheets, bonding the printed sheets through the glue, and positioning and fixing a plurality of bonded printed sheets by utilizing a right-angled mold; perforating each, of the positioned and fixed printed sheets, and stringing holes of the printed sheets so as to reinforce the printed sheets; and splicing front endpaper and rear endpaper onto endpaper connection cloth, and then, bonding the endpaper and bookblocks. The embodiments of the present invention adopt a right-angled mold to position register and fix a plurality of bonded printed sheets, and pages are unlikely to dislocate, thereby guaranteeing the binding quality of the book, improving the attractiveness of the book, reducing a making time of the book, and improving the production efficiency of the book. The method of the present invention can break through a size limitation of a traditional book at 787*544 mm, thereby making a book of a greater size.

Owner:ARTRON ART GRP CO LTD +2

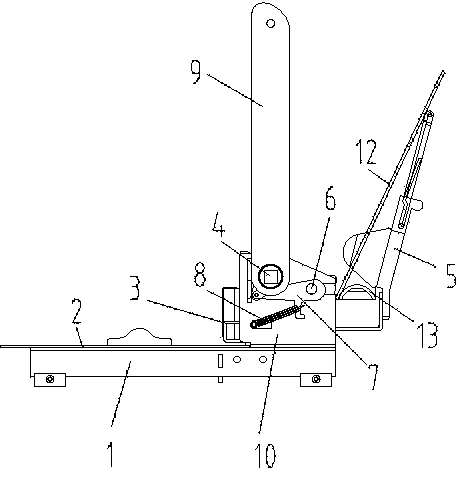

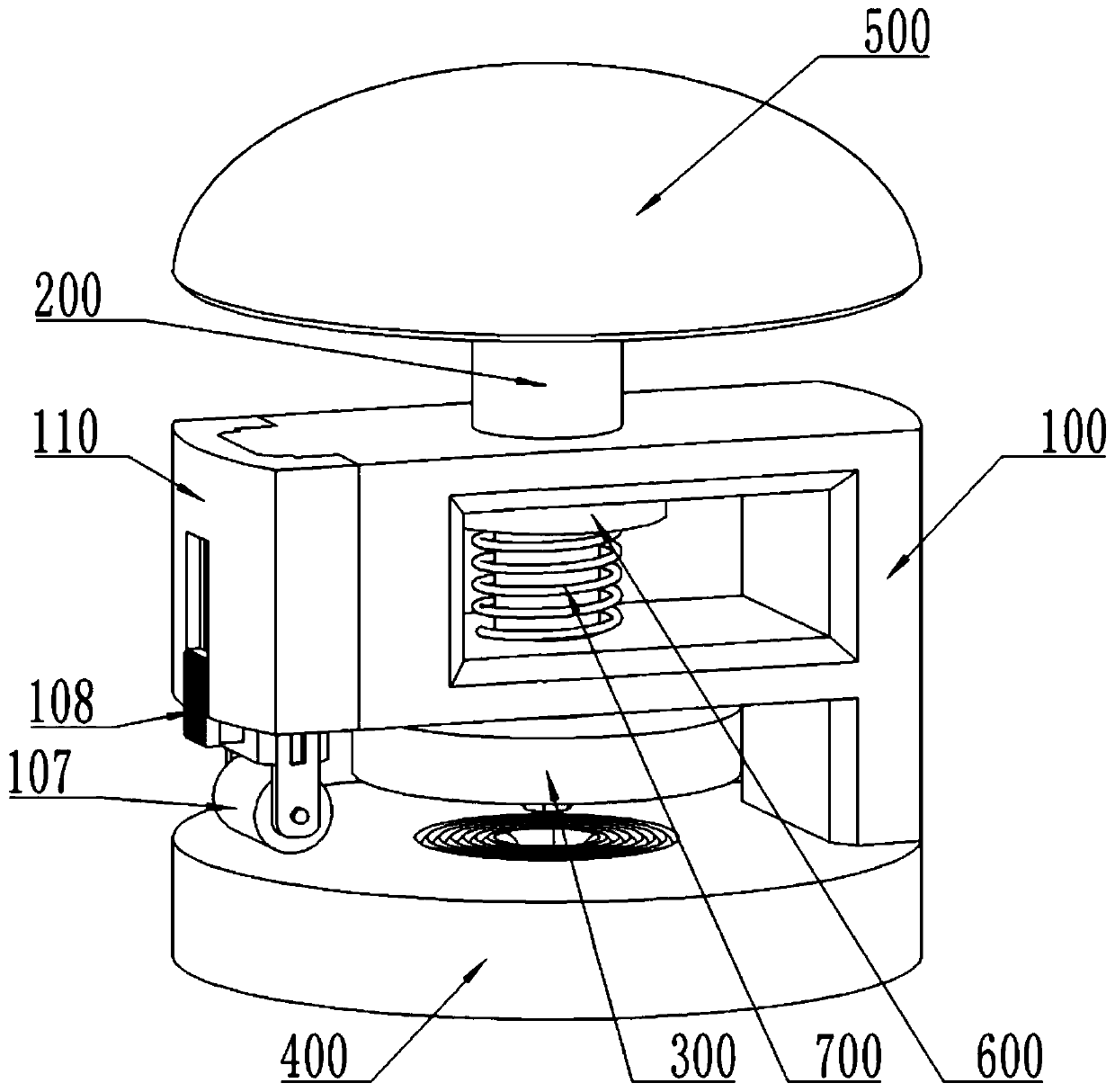

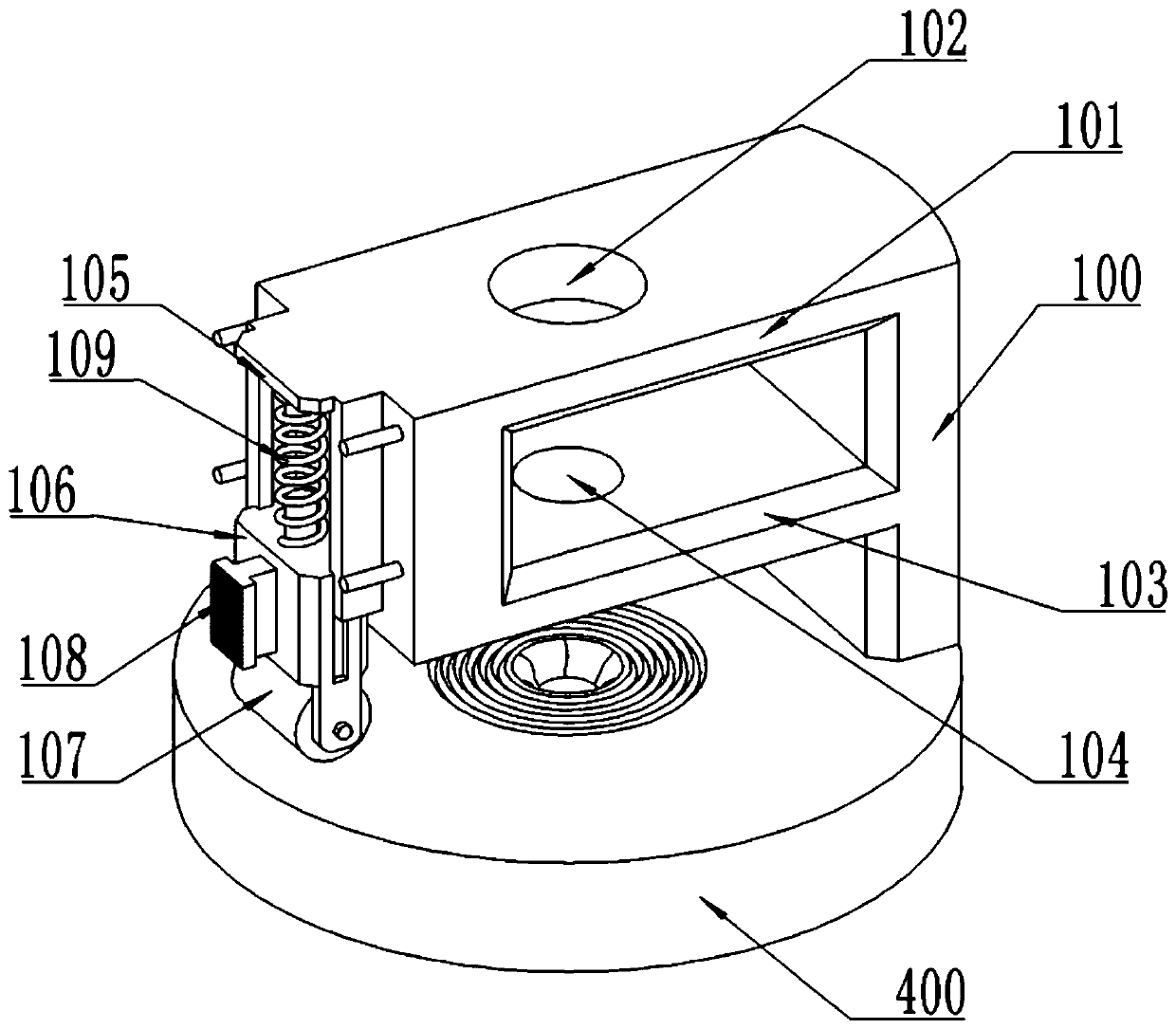

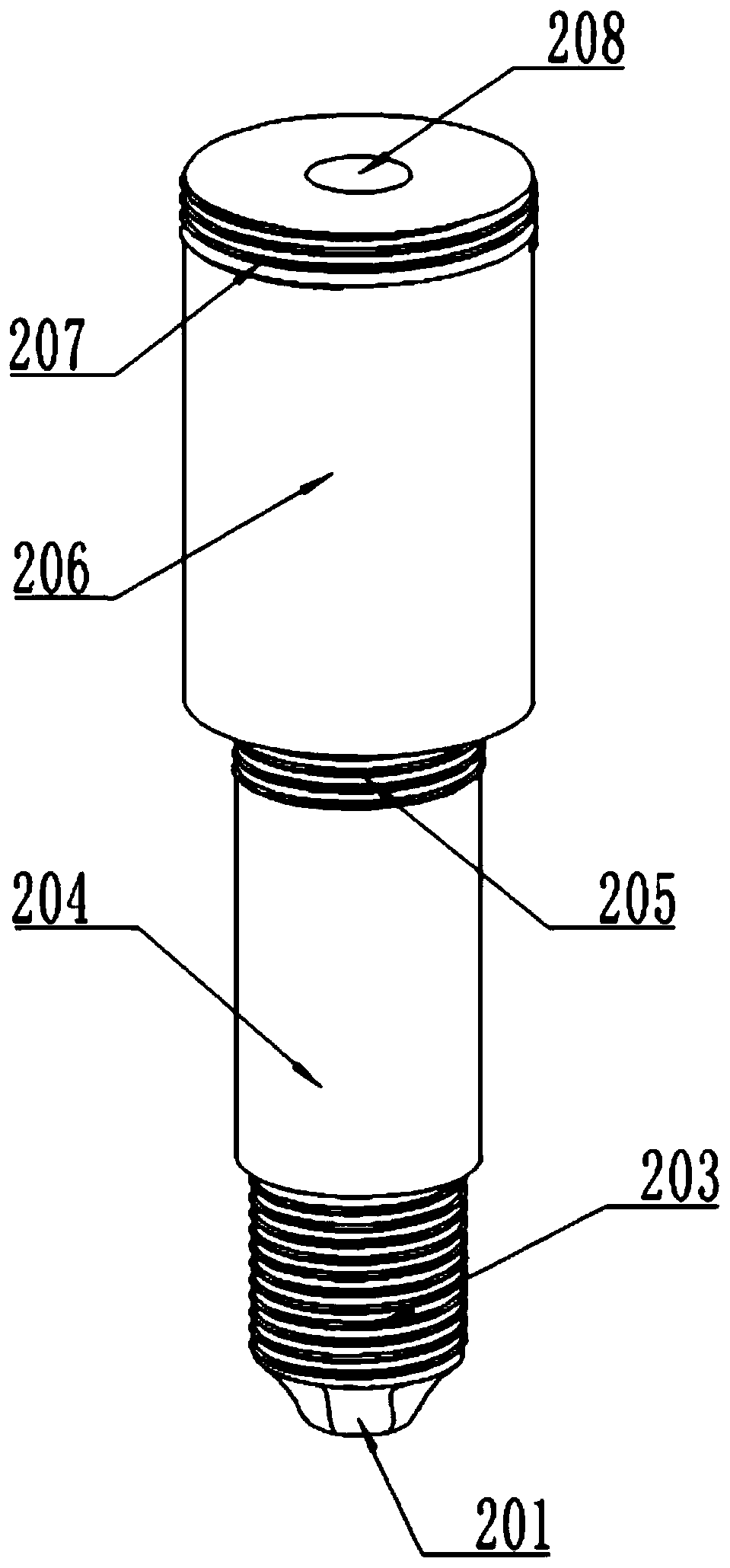

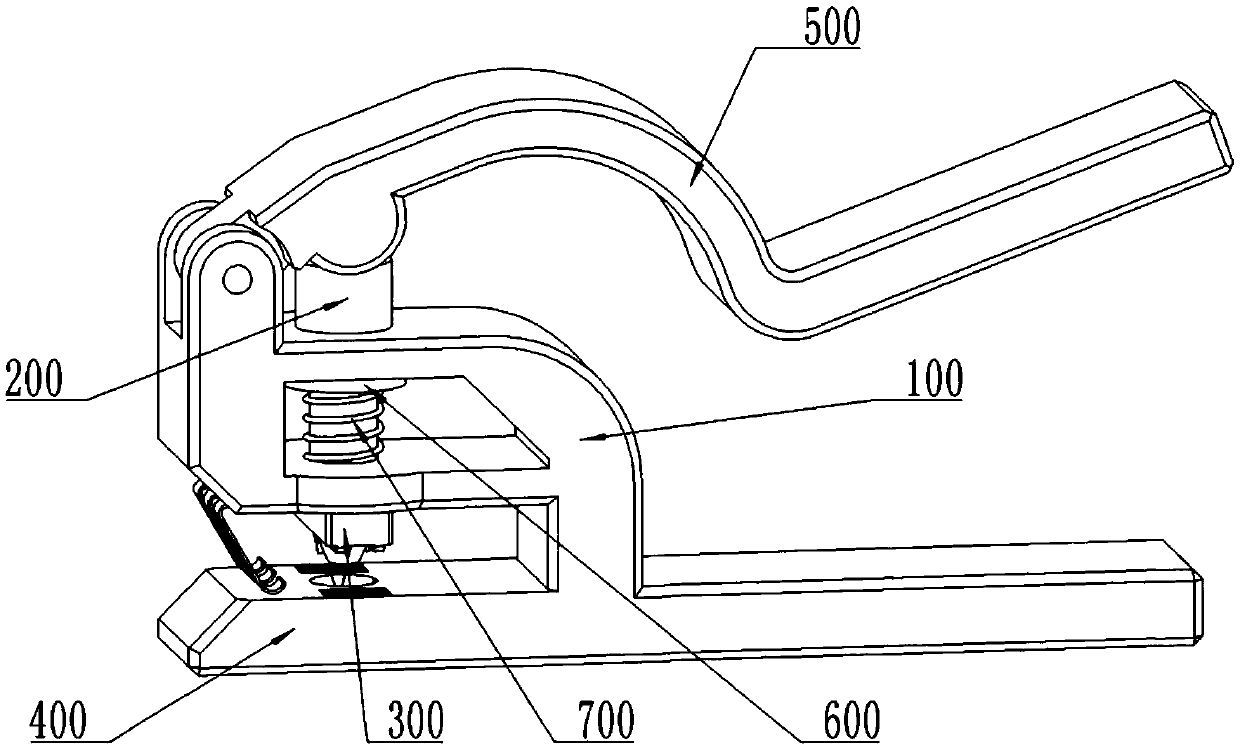

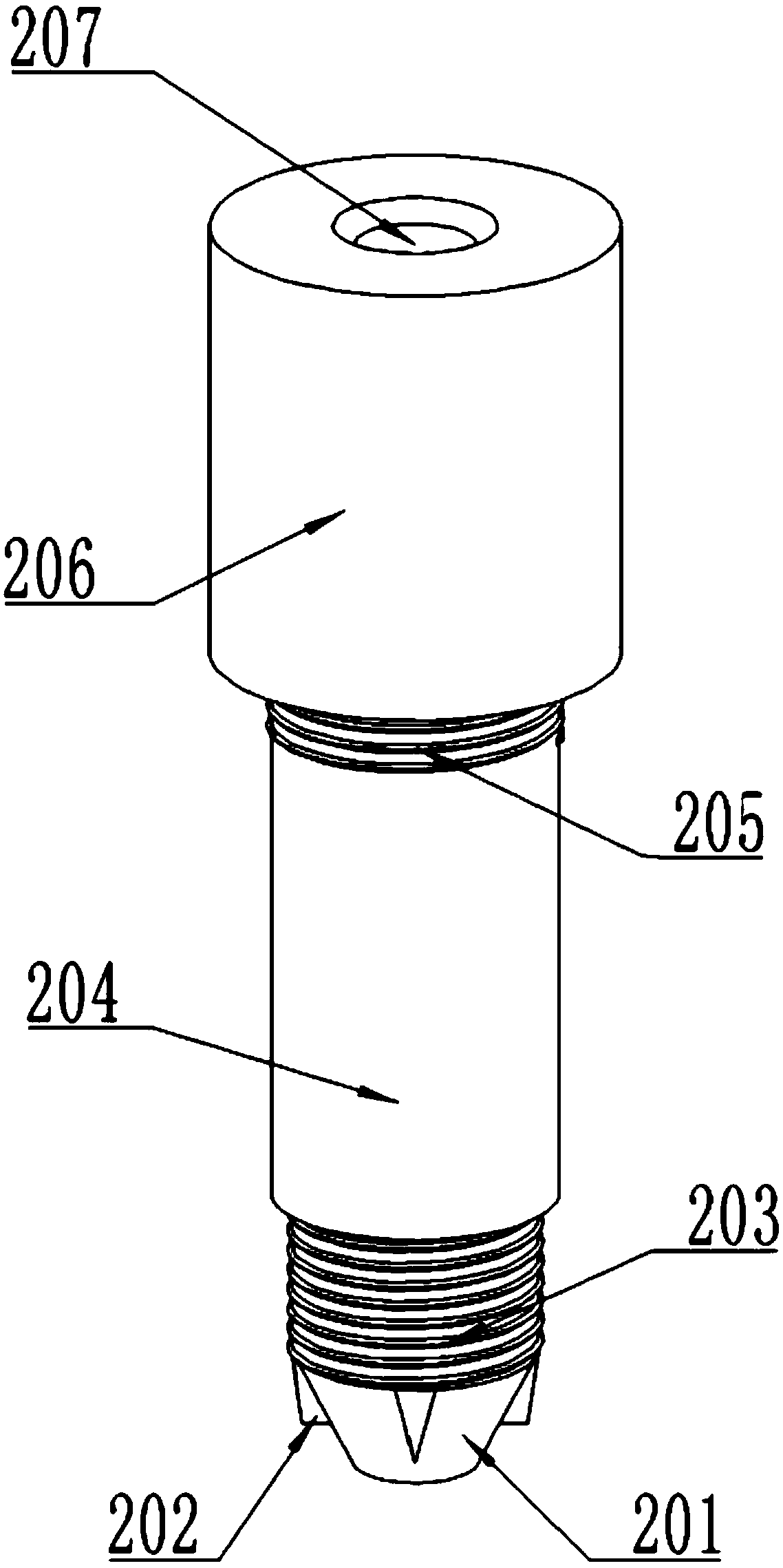

Hand-held spinning type steel bar binding device

PendingCN109138441ARealize binding and fixingEliminate the need for rotationBuilding material handlingHand heldArchitectural engineering

The invention discloses a hand-held spinning type steel bar binding device comprising a binding hook and a rod body. The rod body is provided with an outer rod having a cavity structure; an inner spiral rod is arranged in the cavity of the outer rod; one end of the inner spiral rod is fixedly connected with the binding hook and the other end of the inner spiral rod is hinged to one end of an extension spring by a rod end spring fixing piece; and the other end of the extension spring is fixed and connected with the outer rod. A guiding hole is formed in the side wall of the outer rod; a guidingbolt is fixed in the guiding hole; and the bottom of the guiding bolt is inserted and sleeved in an inner spiral groove. The inner spiral rod rotates under limiting by the guiding bolt; and thus thebinding hook is driven by the rotation of the inner spiral rod to rotate by using the axis of the inner spiral rod as the center. The hand-held spinning type steel bar binding device has advantages oflabor saving, simple operation, and high portability; automatic rotating binding is realized; the manual rotation operation step is saved; the steel bar binding efficiency is improved under the circumstance of intensive binding buckles; the steel bar binding quality is ensured on the premise that the construction period is accelerated; and a phenomenon that the wrist and arm ache because of long-time handle rotation in the prior art is avoided.

Owner:唐山曹妃甸二十二冶工程技术有限公司

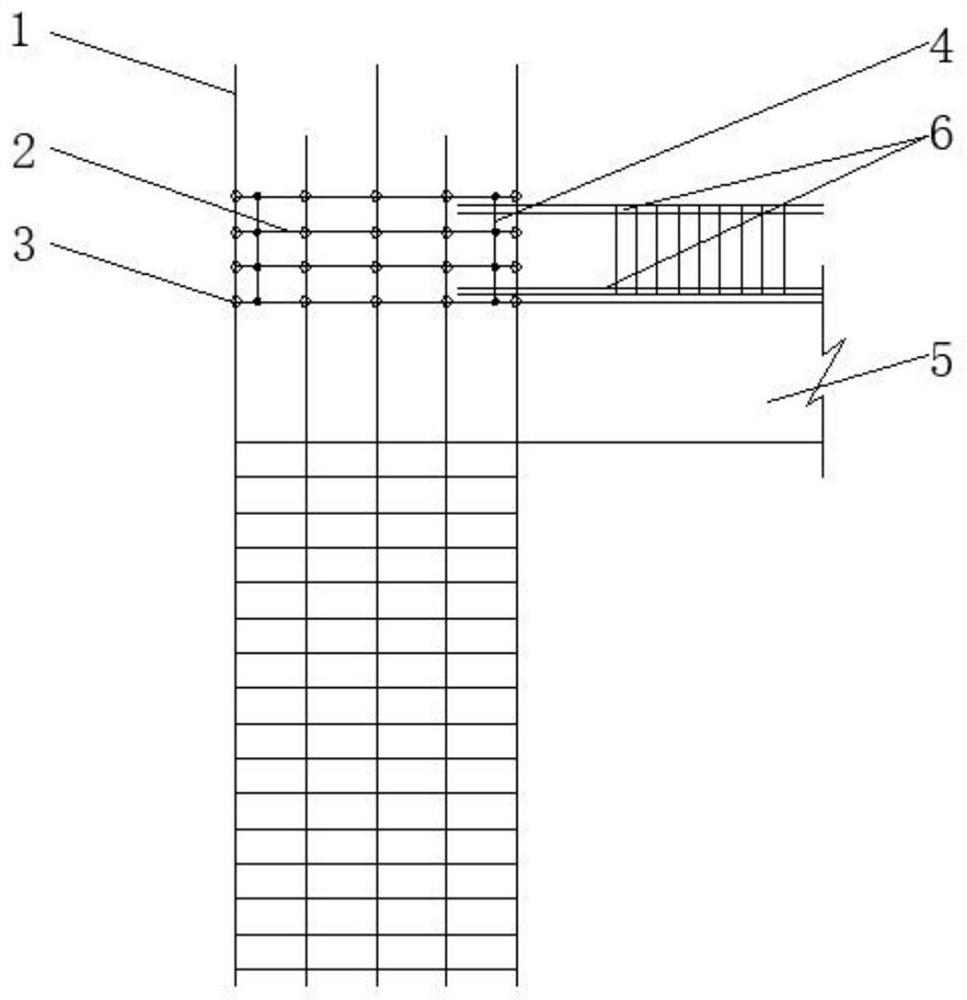

A device for binding steel bars at beam-column joints

InactiveCN105804408BGuarantee the quality of bindingEasy to operateBuilding material handlingEngineeringRebar

The invention discloses a device for beam column joint steel bar binding. The device comprises a fixing base, an ejector block and a binding base. A carrying handle is installed on the top of the fixing base. An ejector block button is installed on one side of the carrying handle. A binding button is installed on one side of the ejector block button. A level gauge is arranged on one side of the binding button. An indicator lamp is arranged on one side of the level gauge. The ejector block is installed on the front face of the fixing base. An ejector rod is installed on one side of the ejector block. A guiding hole is formed in the lower face of the ejector rod. A guiding tube is installed inside the guiding hole. An elastic groove is formed in the upper face of the guiding tube. A shrinking groove is formed in one side of the guiding hole. A sliding groove is formed in the lower face of the shrinking groove. A binding base is installed on the sliding groove. The device has the advantages that it is ensured that the binding quality of beam column stirrup and beam column joint beam bottom bar inside a beam column core area is ensured, no bridge side plate needs to be reserved by woodworking, operation is easy, carrying is convenient, the binding process can be efficiently and rapidly completed, and meanwhile the device can be used as the level gauge.

Owner:SHENZHEN SHENGANG CONSTR GRP

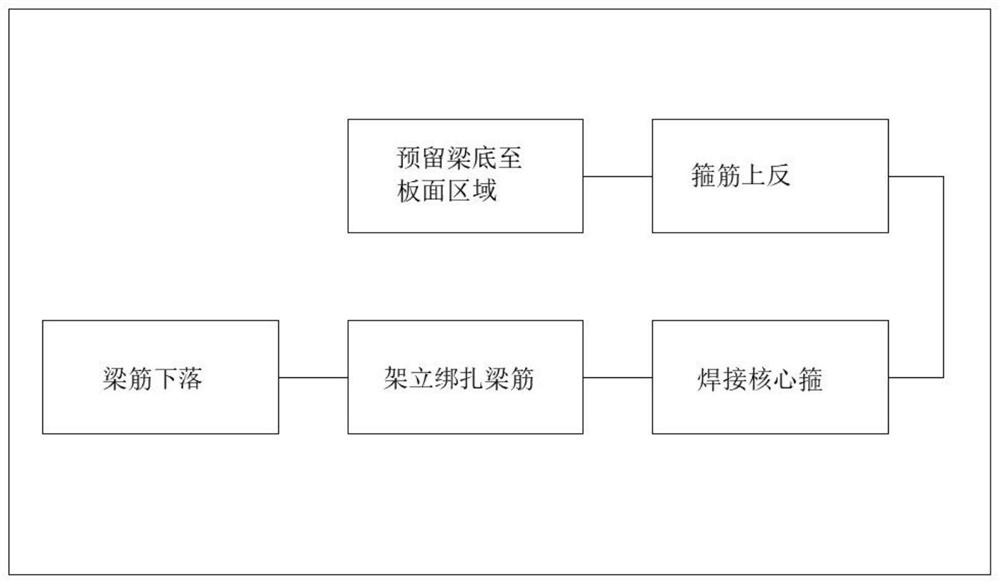

Beam steel bar binding and mounting method

PendingCN114482560AEasy to implementThe method is scientific and reasonableBuilding material handlingHydro energy generationRebarManufacturing engineering

The invention discloses a beam steel bar binding and mounting method which is simple and convenient to manufacture, assemble and implement, scientific and reasonable, capable of avoiding potential quality hazards and mounting hazards caused by a traditional beam steel bar binding and mounting method, capable of being popularized and applied to binding and mounting of beam steel bars on a large scale, good in use prospect and high in practicability. And the safety of the support frame body, the binding quality of beam bottom bars and the mounting quality of stirrups in a core area can be effectively ensured. The problem that an existing beam binding installation construction method has large safety and quality hidden dangers is solved.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

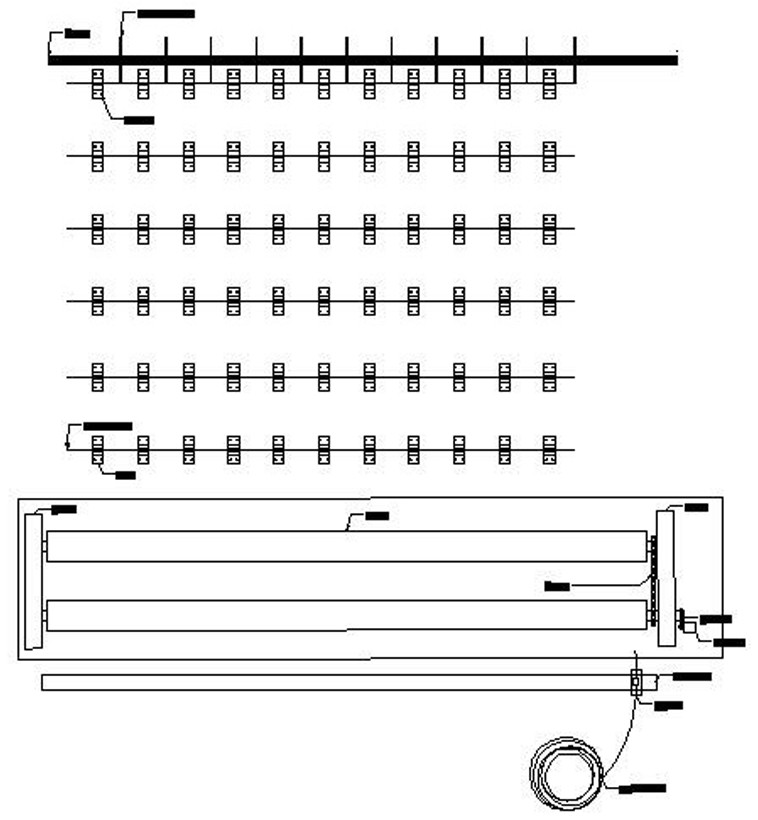

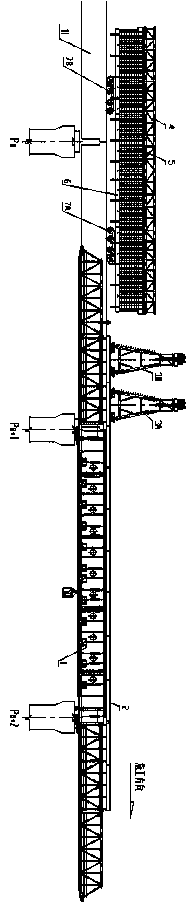

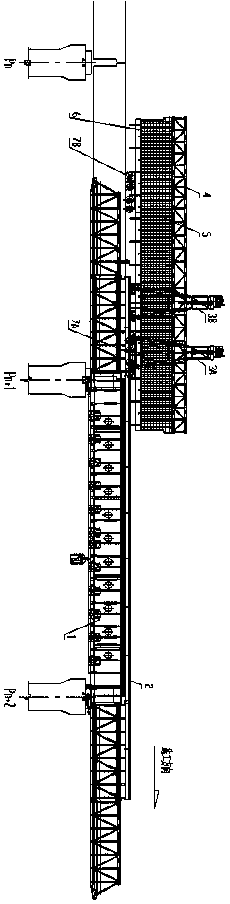

A kind of in-situ cast-in-place construction method for bridges

ActiveCN107905110BImprove the efficiency of beam makingLow costBridge erection/assemblyBridge materialsEngineeringRebar

The invention relates to a bridge in-situ cast-in-situ construction method. The bridge in-situ cast-in-situ construction method is implemented based on a bottom bearing type movable mold frame, and the work procedure of steel bar binding and the work procedures of bridge pouring, curing and tensioning are implemented simultaneously. According to the bridge in-situ cast-in-situ construction method,in cast-in-situ construction of the movable formwork, the modes that reinforcement cage binding and inner mold splicing are conducted on the bridge face, and a reinforcement cage is dragged and hoisted to the position above a mold bed to fall for mounting are adopted, sequential construction in an original construction method is changed into parallel construction, the beam manufacturing work efficiency of the movable mold frame can be effectively improved, and the bridge in-situ cast-in-situ construction period is greatly shortened; and the whole reinforcement cage is prefabricated in a semi-industrialization mode, the binding quality and efficiency are effectively ensured, and bridge in-situ cast-in-situ construction can be well matched.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

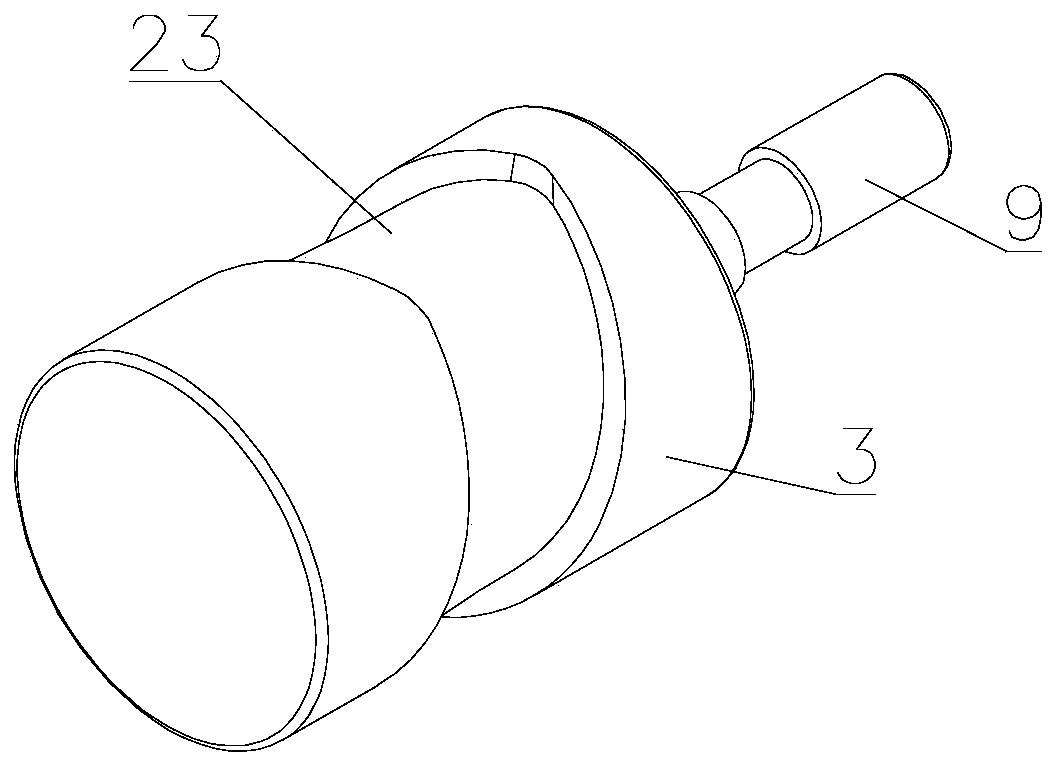

Improved book-binding machine handpiece

InactiveCN101462430BReduce in quantityGuarantee the quality of bindingSheet bindingMachineMechanical equipment

The invention discloses an improved machine head of a binding machine, which belongs to the technical field of binding machinery and equipment. The invention aims to provide the improved machine head of the binding machine having the advantages of high binding quality, high binding speed and wide range of binding thickness. The improved machine head has the technical key points that a swinging block component consisting of a swinging block, a pressure arm, a pressure spring, a column and a spigot shaft is arranged between the lower part of an outer shell (1) of the machine head and a molding column (16); the swinging block (11) in the swinging block component is fixed on the outer shell of the machine head by taking the spigot shaft (2) as a rotating pair and is also adjacent to the left side of a striking block (10) on a hook sliding plate (5); the upper part of the pressure arm (13) is arranged in a guide slot of the swinging block and is also connected with the guide slot by a cylindrical pin to form the rotating pair; and the column (14) on the tail end of the pressure arm is inserted into a radial slot on the outer end surface of a forming column, and the pressure spring (12)is arranged between the upper end of the pressure arm and the swinging block. The improved machine head has the advantages of ensuring binding quality, improving binding speed, and making the bindingthickness reach the range between 0.2 and 15 mm.

Owner:淮南市耀华机械厂

Installation and construction method for reinforcing steel bars in core area of beam-column joint

PendingCN114411954ASolve the problem of binding difficultiesGuarantee the quality of bindingBuilding reinforcementsArchitectural engineeringRebar

The invention discloses a beam column joint core area reinforcing steel bar installation construction method which comprises the following steps that stirrups in the range from the bottom of a beam column to a plate face are reserved and not installed, and the stirrups which should be originally installed in a beam column core area are reversely arranged above the plate face and fixed to column main reinforcements; arranging an electric welder to weld four sides of each upturned stirrup by using a steel bar head with the same beam height; after beam steel bars are bound, the uppermost set of stirrups fixed to column main bars are unfastened, meanwhile, the erected beam steel bar support is loosened, the whole beam steel bars fall to a beam bottom column, a core hoop is also installed in place, and the stirrup binding quality in a beam column core area is guaranteed; the beam bottom bar binding quality at the beam column joint is ensured; and the working efficiency is improved, the working efficiency of woodworking is improved, and good technical support is provided for promoting the engineering construction progress.

Owner:JIANGSU HUAJIAN CONSTR

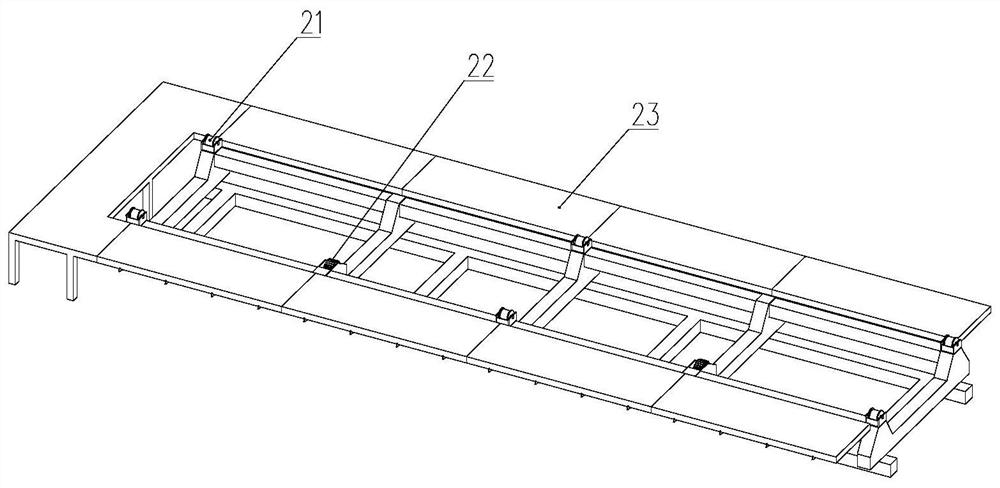

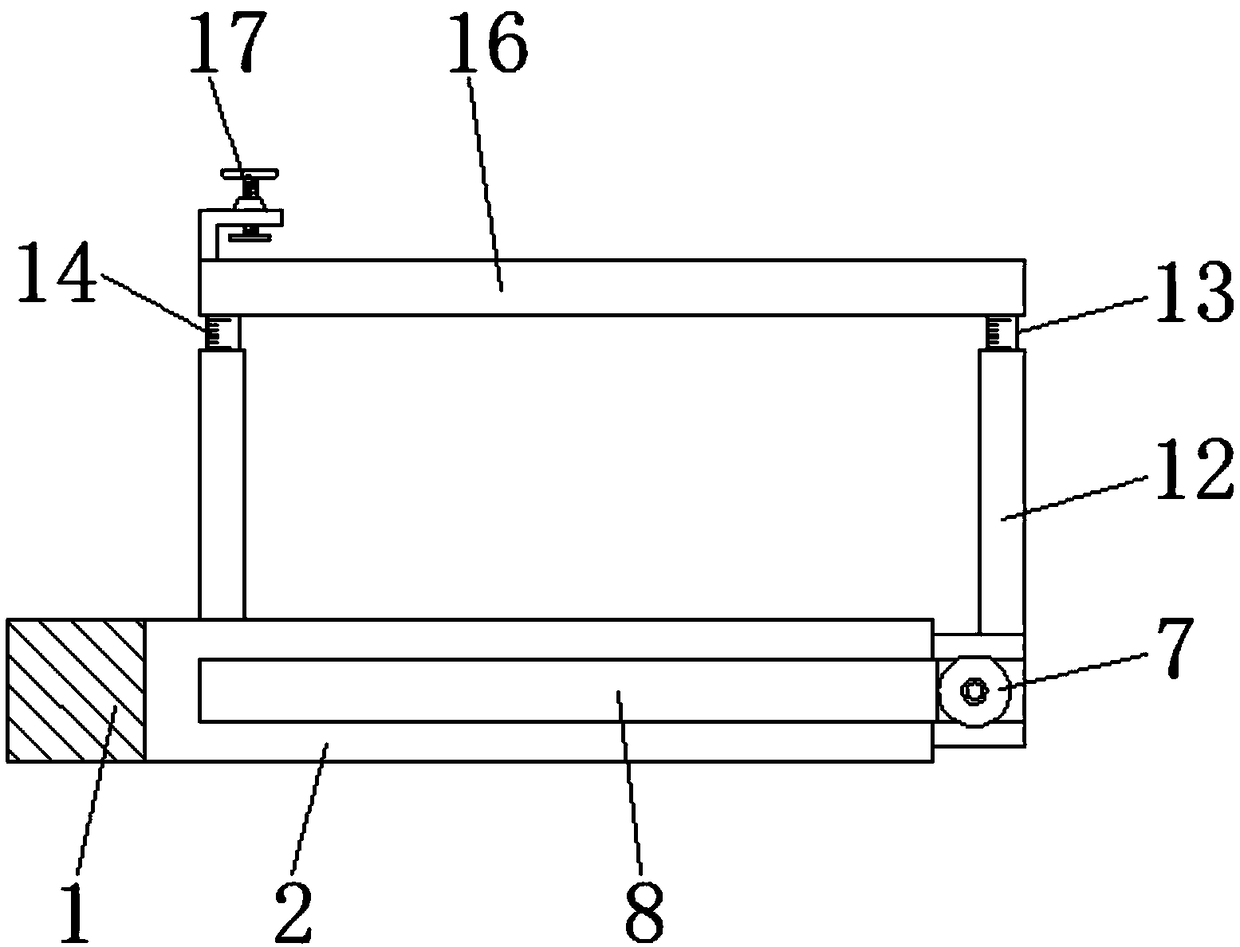

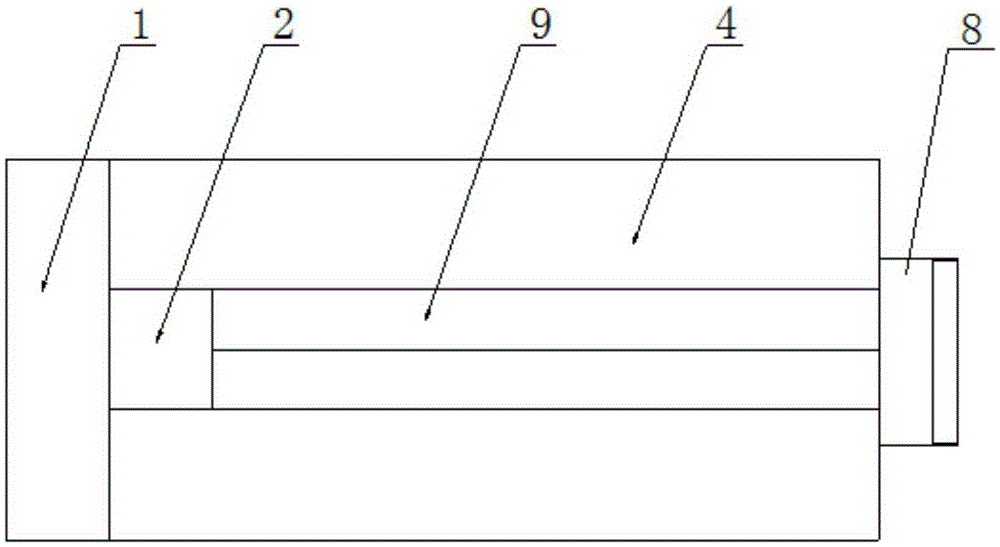

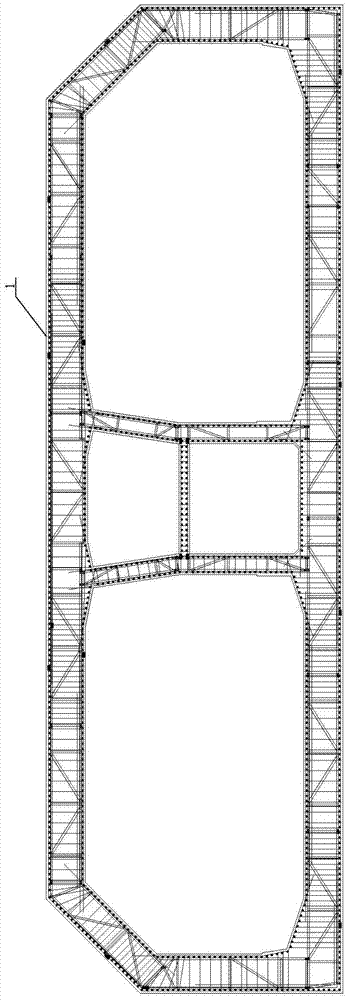

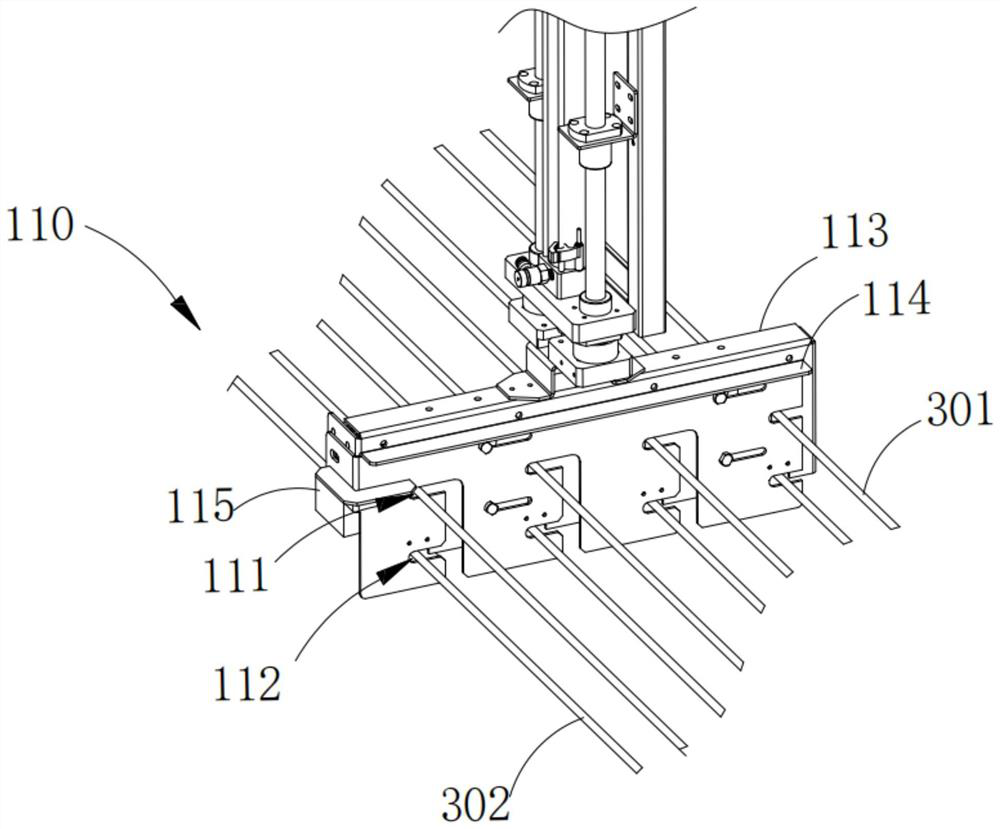

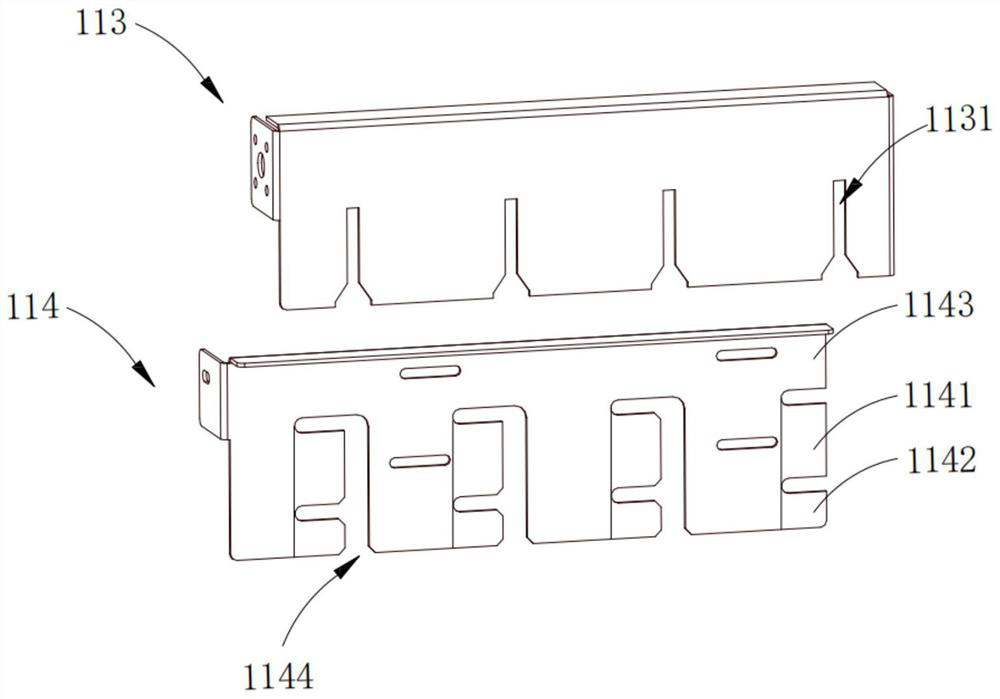

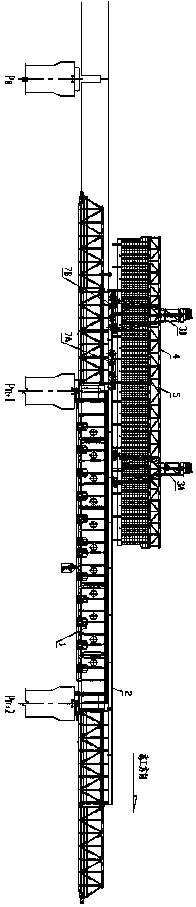

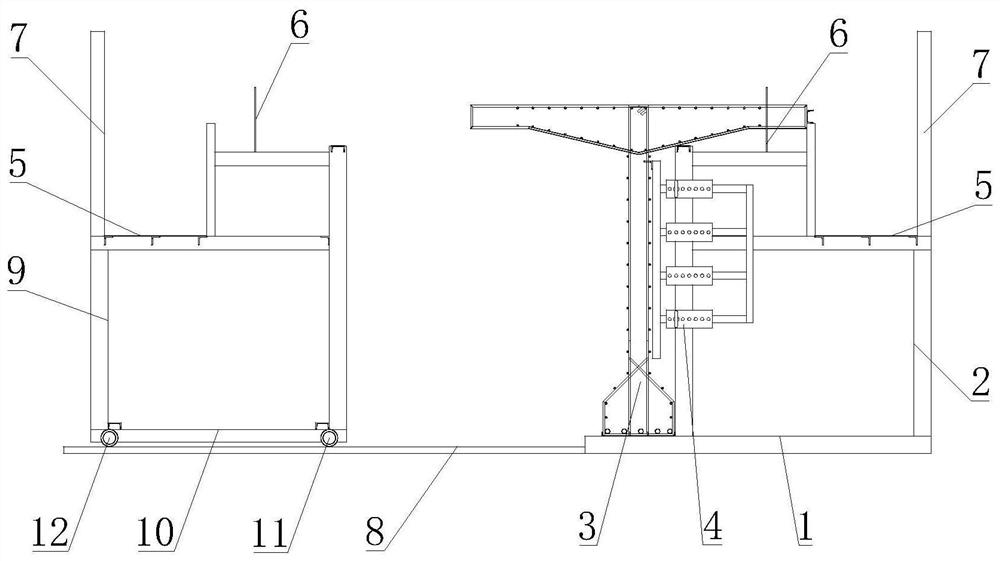

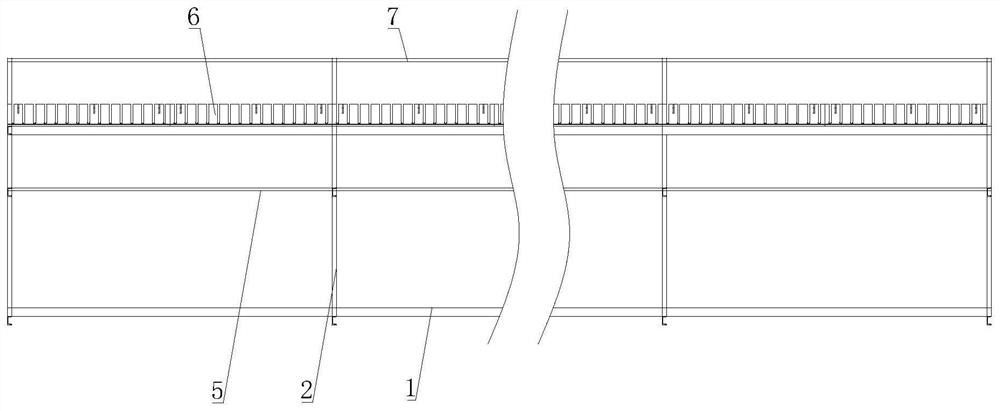

A prefabricated t-beam steel bar binding tire

The invention discloses a prefabricated T-beam steel bar binding tire, which comprises a fixed frame base and a guide rail, the fixed frame base and the guide rail are arranged side by side on the ground, a fixed side frame is fixedly installed on the fixed frame base, and a fixed side frame is slidably arranged on the guide rail. The movable frame base, the upper end of the movable frame base is fixed with a movable side frame, the upper end of the fixed frame base is provided with a positioning slot for placing the prefabricated T beam, and the fixed side frame and the movable side frame are provided with a working platform and a comb. A guardrail is provided on the side edge of the working platform away from the comb plate, and a horizontal positioning mechanism is fixedly installed on the side of the fixed side frame close to the prefabricated T-beam, and the horizontal positioning mechanism is used to support the prefabricated T-beam Position limit, the invention realizes the integral binding and forming of the prefabricated T-beam web and roof, while ensuring the quality of steel bar binding, the steel bar operation is concentrated on the tire frame to complete, without taking up the template work time, and improving the overall processing efficiency.

Owner:GUANGDONG PROVINCIAL CHANGDA HIGHWAY ENG

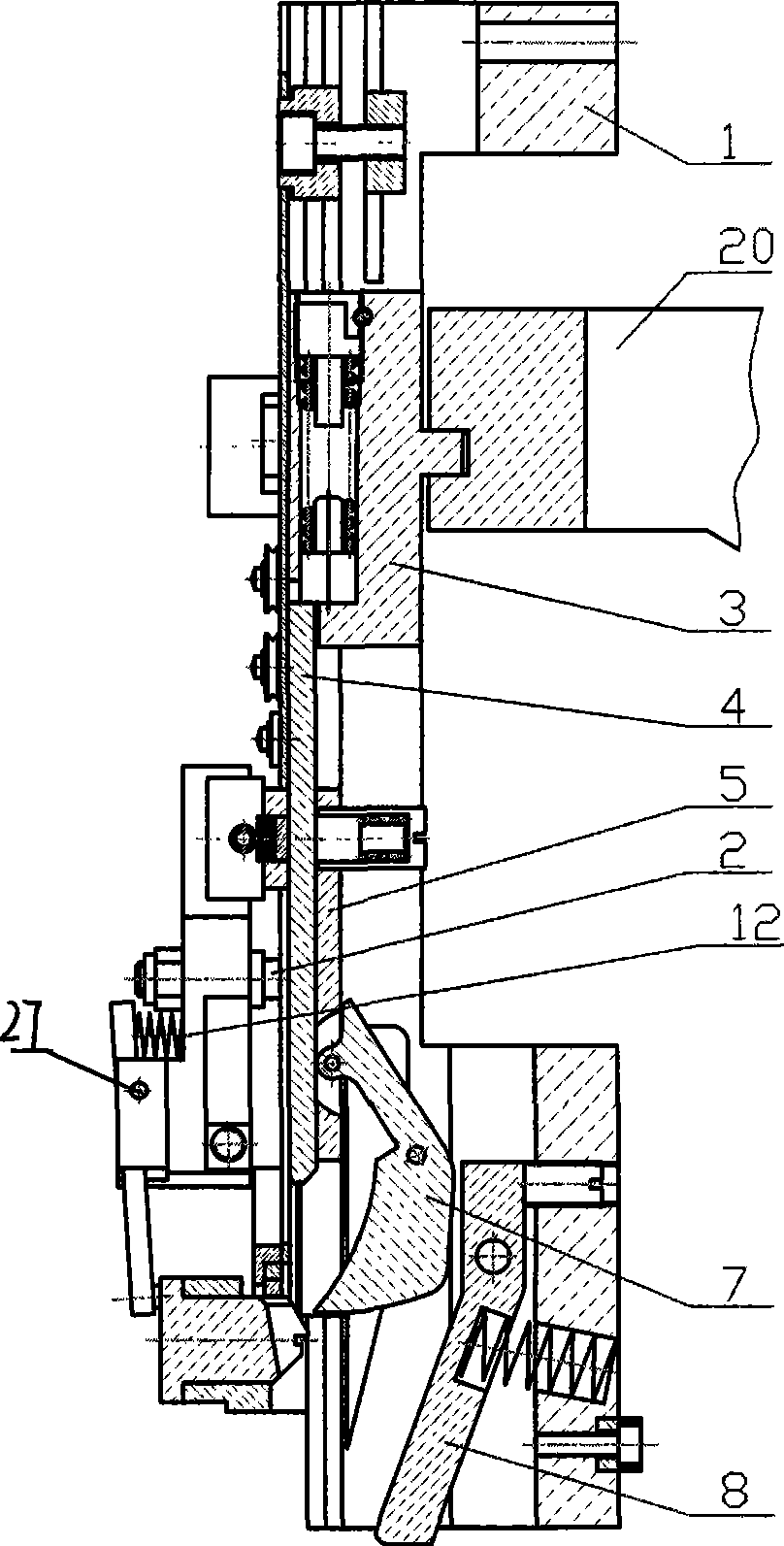

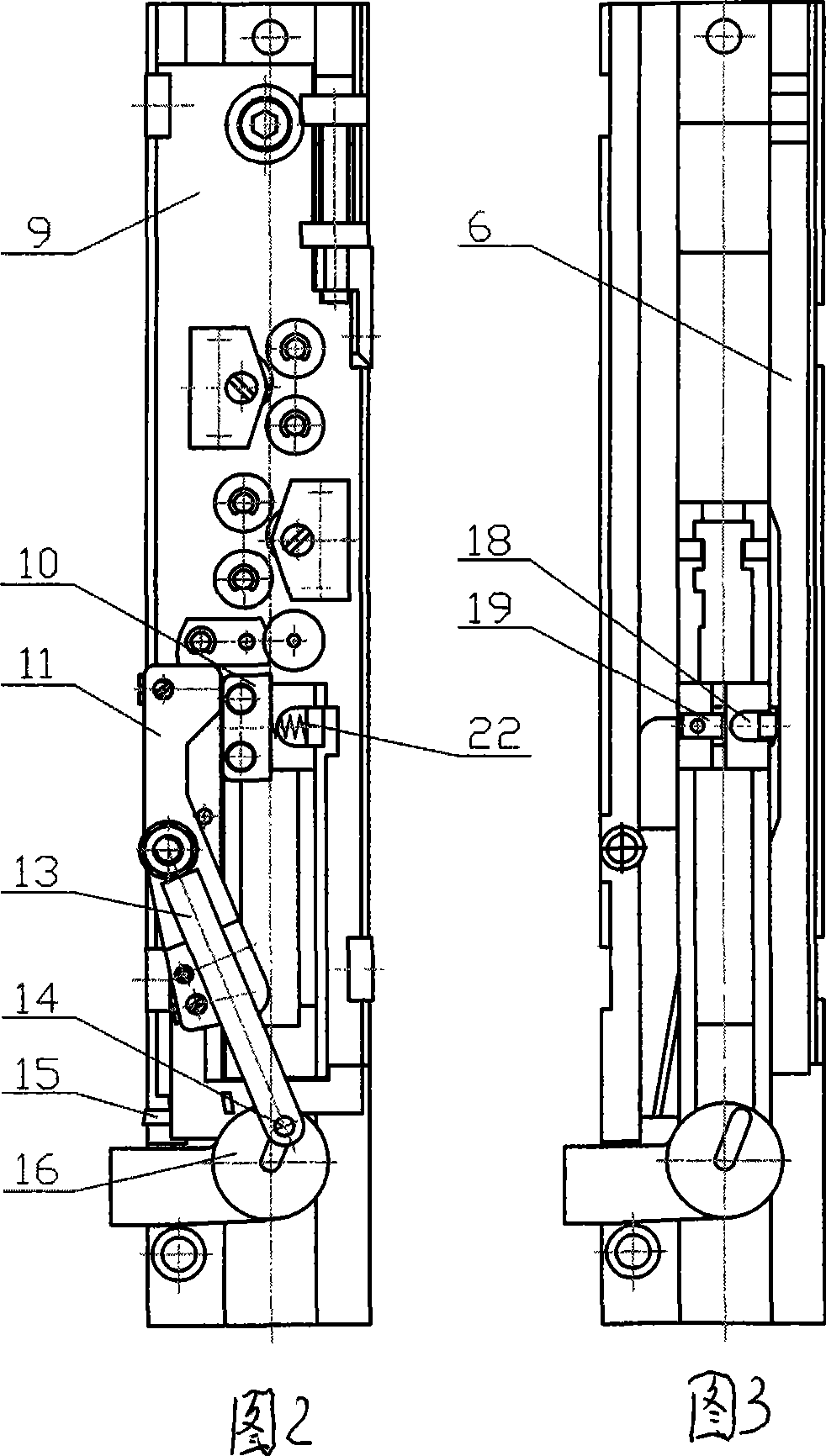

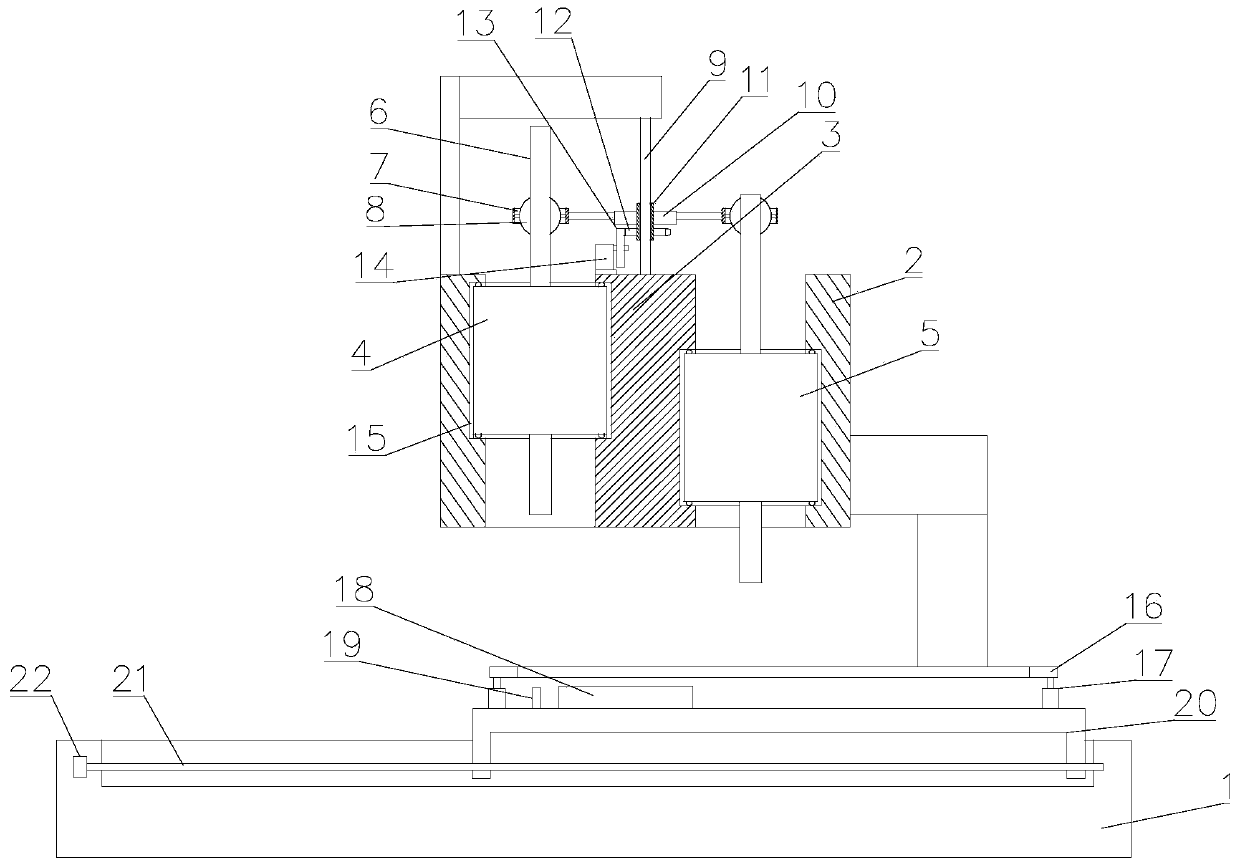

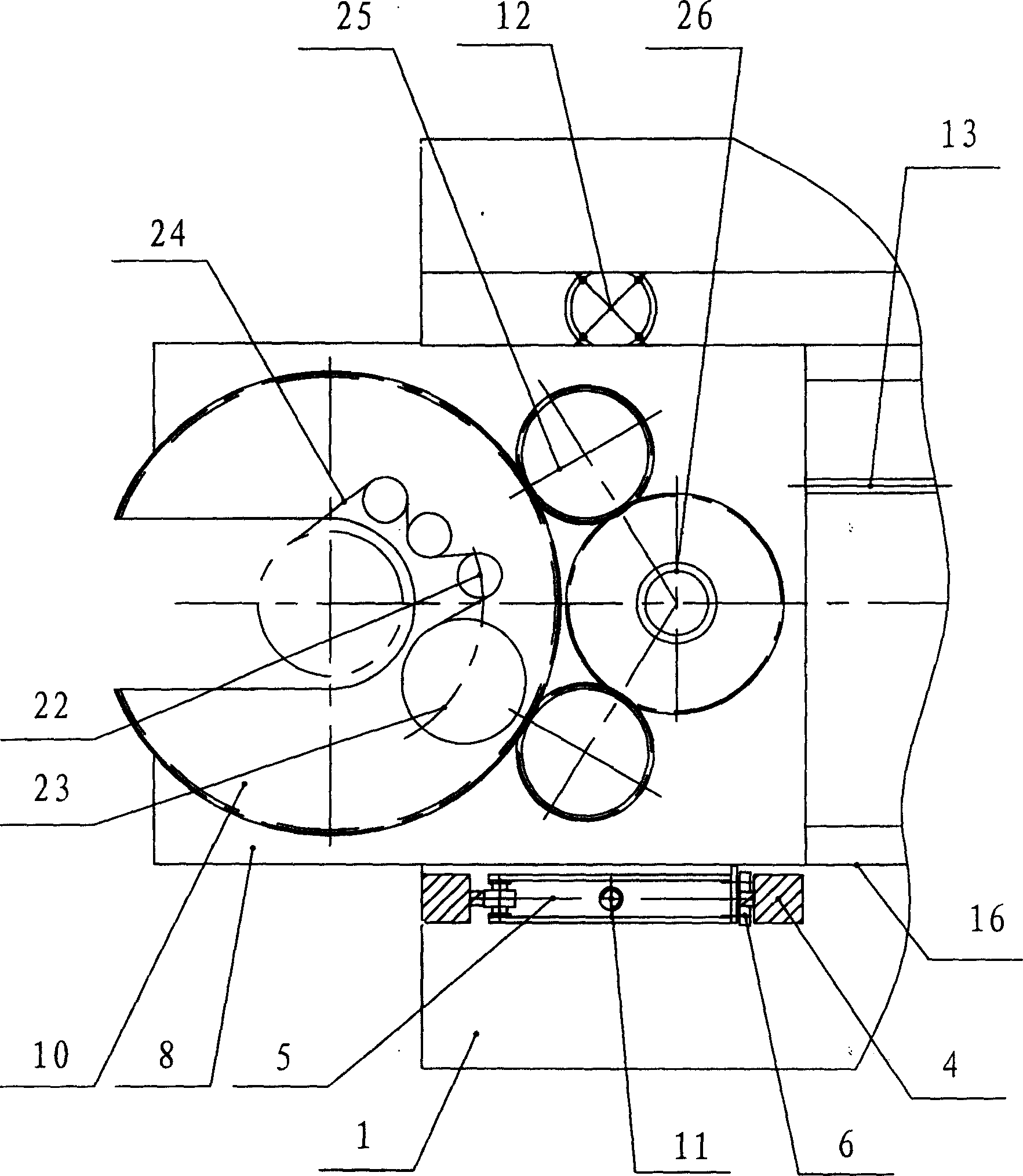

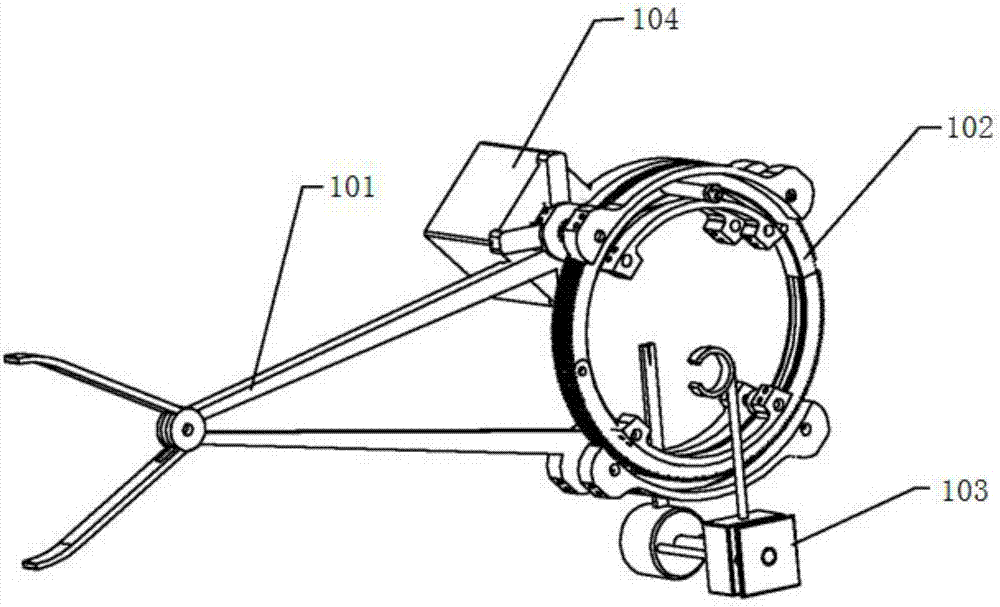

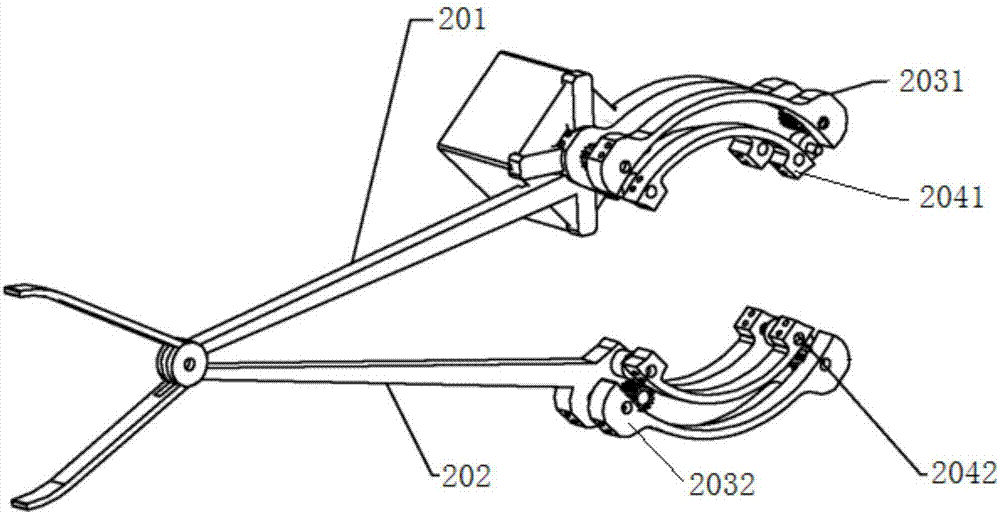

A semi-automatic strapping device

ActiveCN106531358BImprove efficiencyGuarantee the quality of bindingManufacturing wire harnessesGear wheelSemi automatic

The invention disclose semi-automatic bundling equipment for solving the problems of low efficiency, high labor intensity, and uneven bundling quality caused by manual cable bundling in an airplane main engine plant. The semi-automatic bundling equipment comprises a pair of gear opening-closing pliers, an openable gear, a linear motor and a servo motor, wherein the gear opening-closing pliers comprise an upper opening plier and a lower opening plier which are connected by pins; the upper opening plier is provided with a driving gear and a driven gear while the lower opening plier is provided with two driven gears; the servo motor is fixed on the upper opening plier and connected with the driving gear; the openable gear comprises an upper opening gear and a lower opening gear, one ends of which are hinged; the upper opening gear and the lower opening gear are mounted on the upper opening plier and the lower opening plier of the gear opening-closing pliers through tightening plates respectively, and meshed with the gears on the opening pliers; sliding ways are formed in the upper opening gear and the lower opening gear; the sliding ways are glidingly matched with pulleys on the upper opening plier and the lower opening plier respectively; the upper opening gear is also provided with a damping adjustment wheel; and the linear motor comprises a winding ring and a bayonet.

Owner:CHANGCHUN UNIV OF SCI & TECH +1

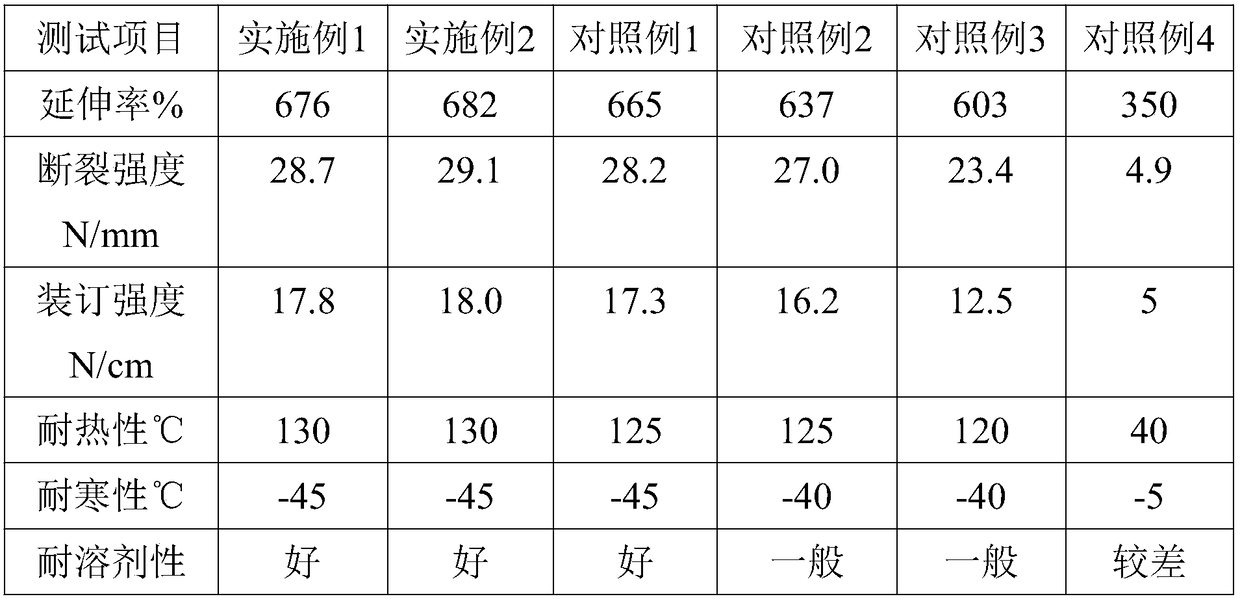

A kind of modified rosin hot-melt adhesive for bookbinding and preparation method thereof

ActiveCN107118739BGuarantee the quality of bindingInhibit sheddingNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolyethylene oxidePolymer science

The invention discloses a modified rosin hot melt glue for book binding and a preparation method thereof and relates to the technical field of hot melt glue. The modified rosin hot melt glue is prepared from the following raw materials in parts by weight: 15-25 parts of hydrogenated rosin, 10-15 parts of poloxamer 188, 3-5 parts of ultrafine magnesium oxide, 3-5 parts of polyglutamic acid / methoxypolyethylene glycols, 1-3 parts of microcrystalline cellulose, 0.5-1 part of cationic polyacrylamide, 0.5-1 part of polyethylene oxide, 0.1-0.5 part of hydrogenated castor oil and 0.05-0.1 part of ferrocene. The hot melt glue prepared according to the invention has excellent adhesiveness, high adhesive strength, excellent solvent resistance, excellent high / low temperature resistance and difficulty in breaking after solidification, so that the binding quality of the book is guaranteed, the book can be prevented from cracking and paper-falling in the transportation and use processes and the modified rosin hot melt glue is suitable for the binding of thicker books.

Owner:新丰县高德科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com