Press-fit type stapleless stapler

A needleless, press-fit technology, applied in binding and other directions, can solve the problems of waste of resources, easy to rust, and the needle tip of the stapler is easy to scratch paper or users, etc., to achieve the effect of ensuring the quality of binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings so that those embodiments can be easily realized by those having ordinary skill in the art to which the present invention pertains. However, the present invention can also be realized in various forms, so the present invention is not limited to the embodiments described hereinafter. In addition, in order to describe the present invention more clearly, parts not connected with the present invention will be omitted from the drawings.

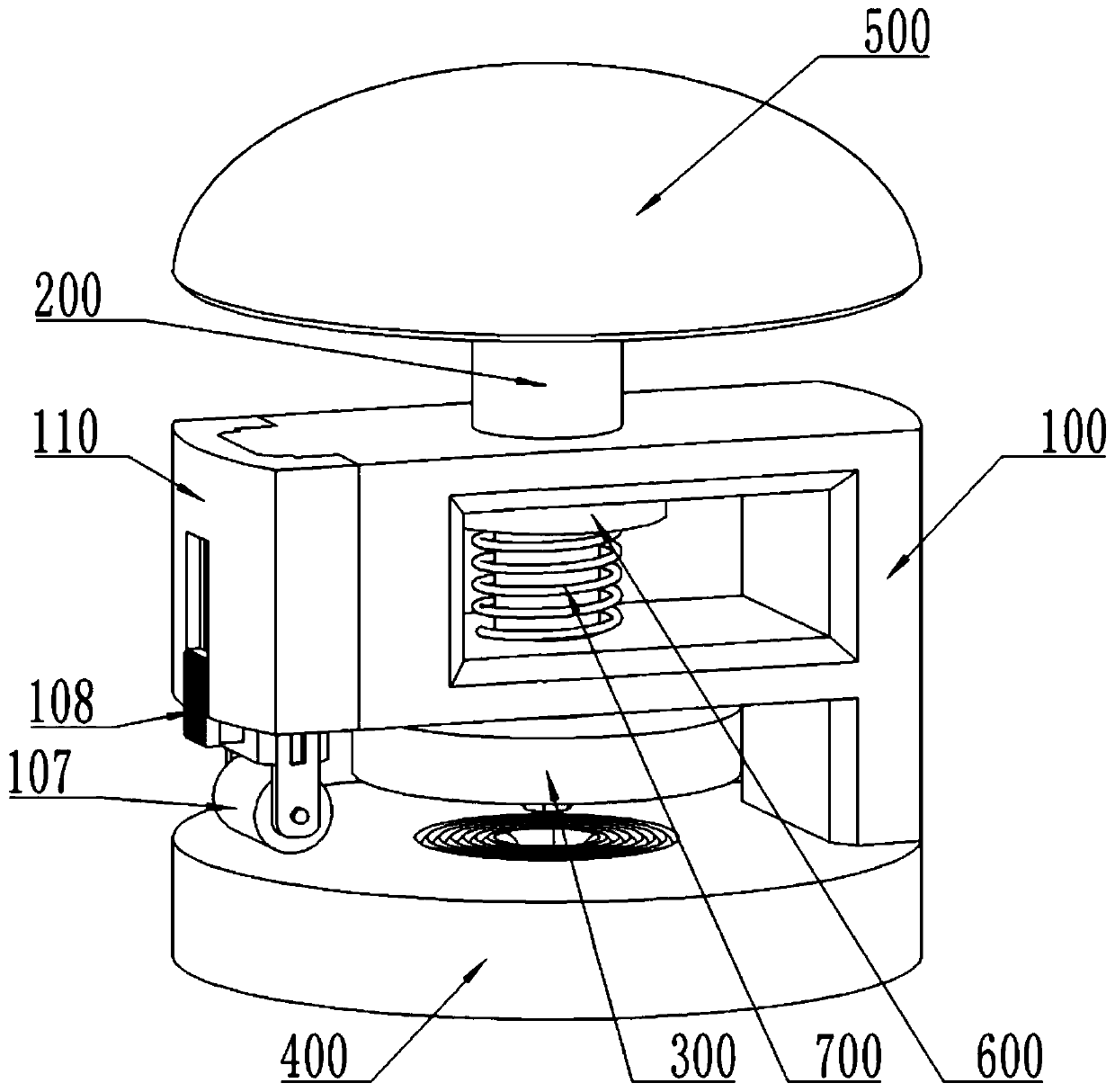

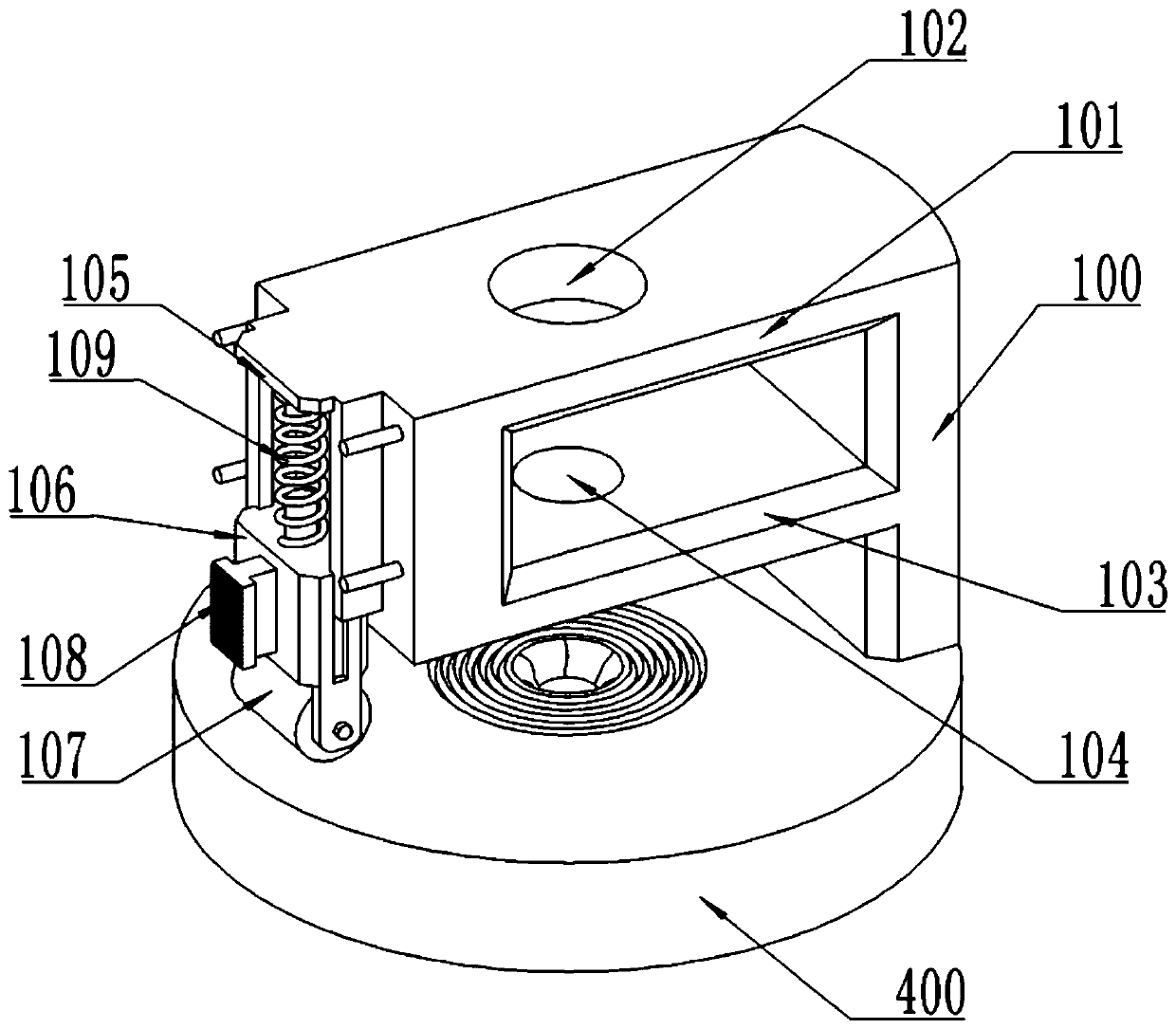

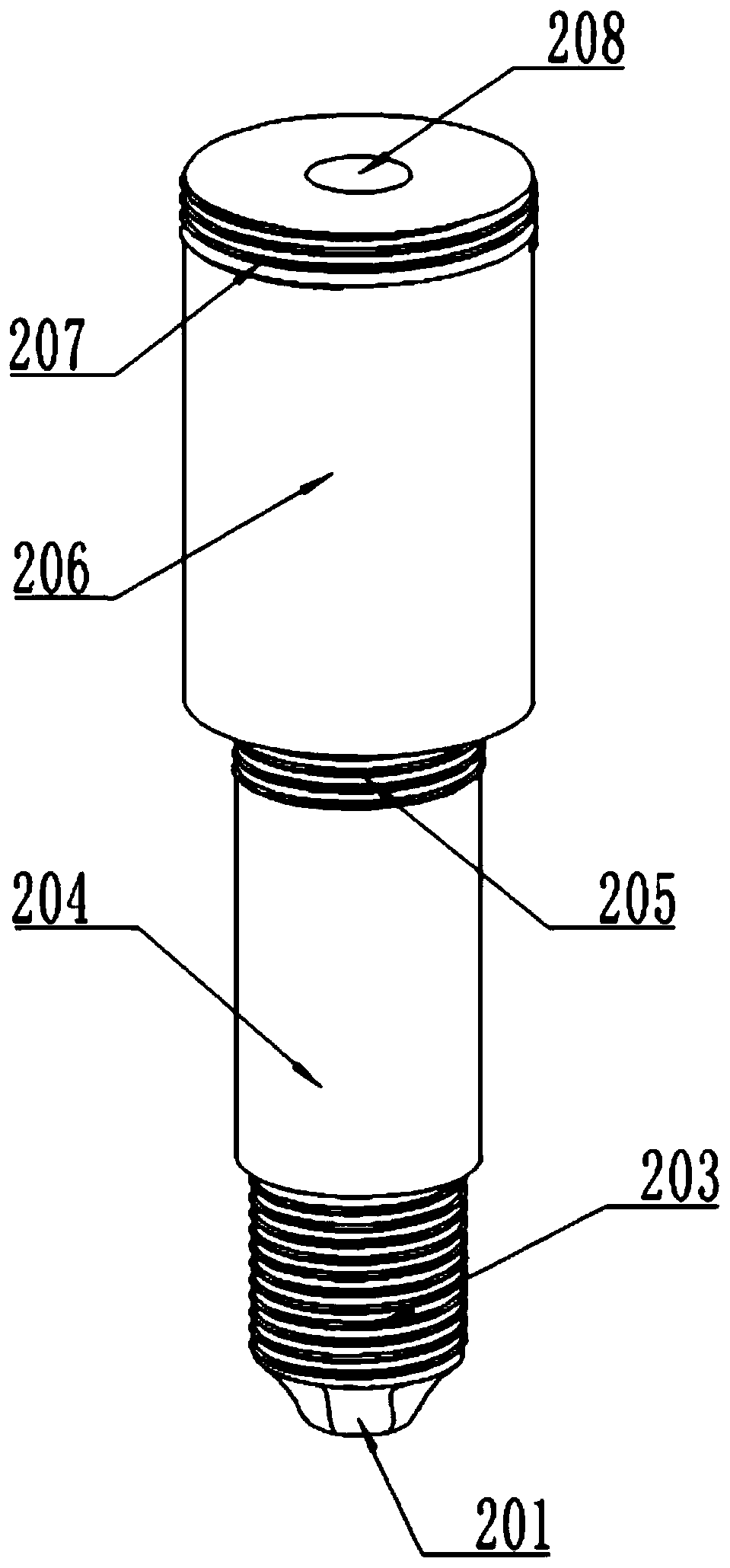

[0023] Such as Figure 1-Figure 7 As shown, a press-fit needleless stapler includes: a support frame 100, a hole head 200, a pressing block 300, a base 400, a pressing handle 500, a limit ring 600, and a spring 700;

[0024] Such as Figure 1-Figure 2 As shown, the cross-section of the support frame 100 is in the shape of 9, the upper beam 101 is provided with a through hole A102 penetrating the top and bottom of the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com