Installation and construction method for reinforcing steel bars in core area of beam-column joint

A construction method and technology of beam-column joints, which are used in construction, building reinforcements, building components, etc., can solve the problems of unguaranteed steel binding quality, long installation schedule, time-consuming and labor-intensive, etc., and achieve good technical support and good binding. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

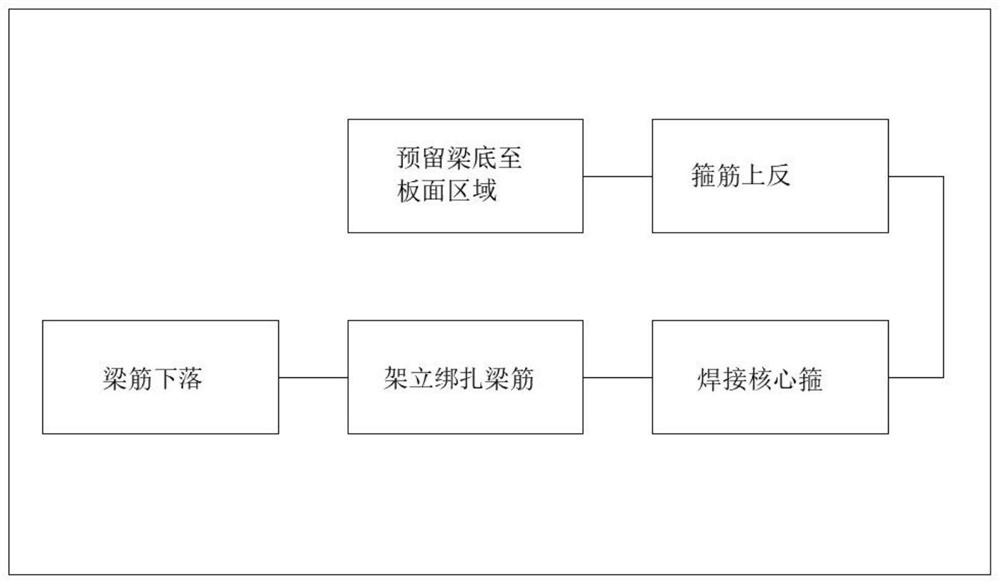

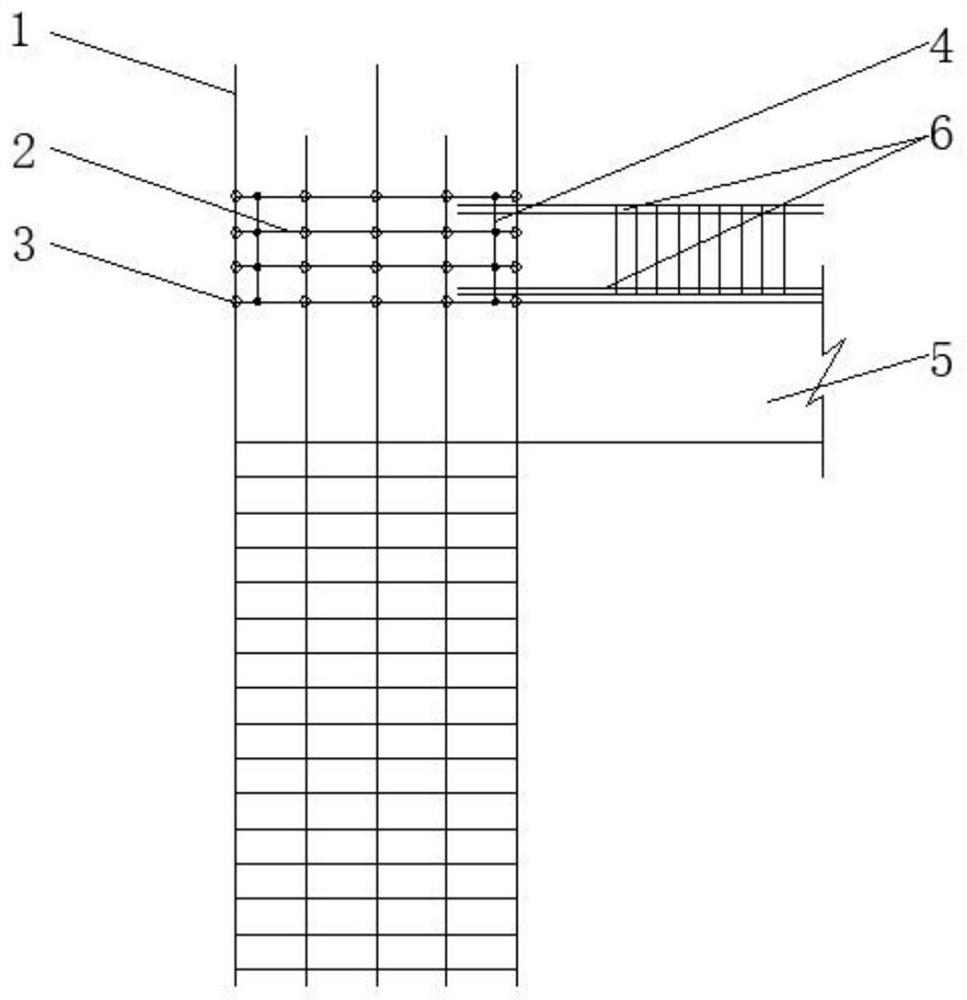

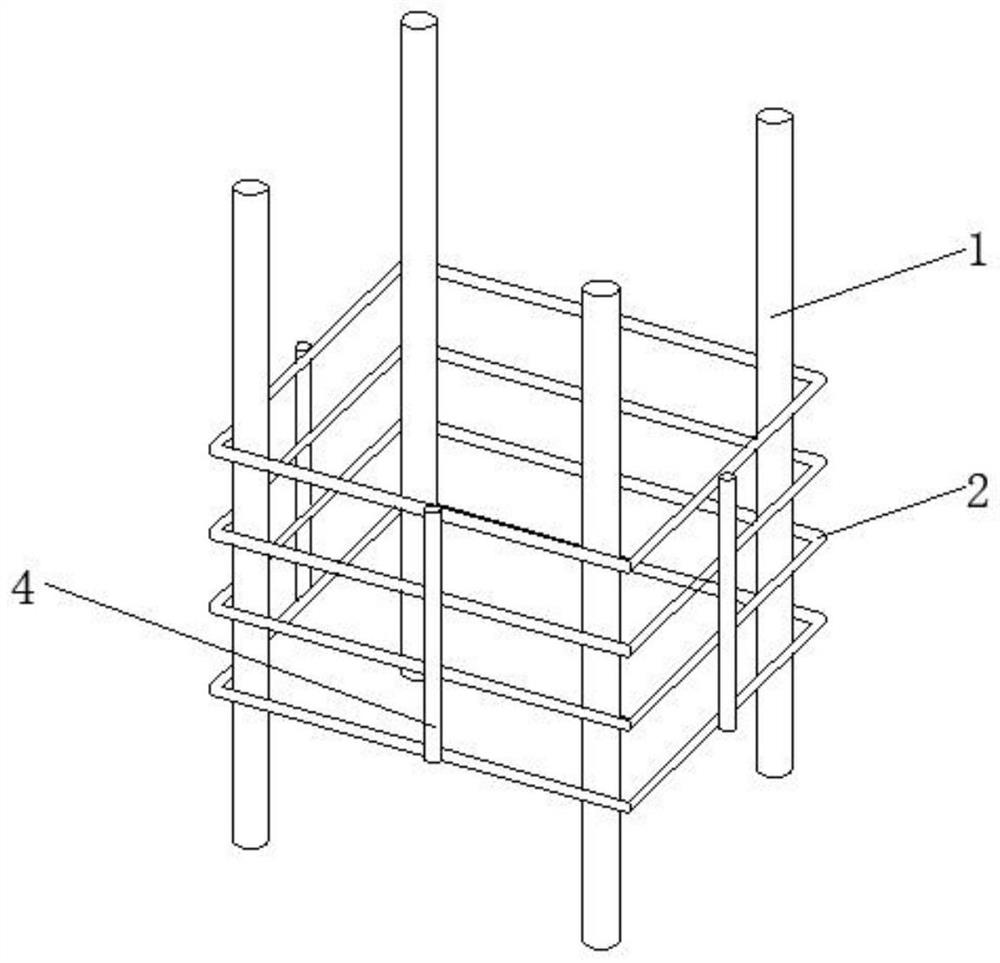

[0024] Example: refer to Figure 1-4 , the present invention provides a technical solution, a method for installing steel bars in the core area of beam-column joints. The installation method includes the following steps:

[0025] S1. During the binding construction of wall and column reinforcement, the stirrup 2 reserved from the bottom of the beam column to the slab surface is not installed, and the stirrup 2 that should have been installed in the core area of the beam column is reversed to above the slab surface and placed Fixed with column main reinforcement 1;

[0026] S2. During the construction of the structural slab formwork, arrange a welder to weld the four sides of each stirrup 2 on the upper reverse with a steel bar head 4 equal to the height of the beam, and at the same time tie and connect each set of stirrups 2 on the upper reverse Ok, tie the topmost set of stirrups 2 to the column main reinforcement 1;

[0027] S3. During the binding process of the beam r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com