A kind of modified rosin hot-melt adhesive for bookbinding and preparation method thereof

A technology for modifying rosin and hot-melt adhesive, applied in the directions of rosin adhesive, non-polymer adhesive additive, adhesive additive, etc., can solve the problem of increasing the amount of hot-melt adhesive, affecting the aesthetics of binding, and limited adhesive strength and other problems, to achieve the effect of ensuring the quality of binding, good high and low temperature resistance, and good fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] (1) Mix 15g of hydrogenated rosin and 10g of poloxamer 188, raise the temperature to 135-140°C and grind for 3 hours, then add 2g of microcrystalline cellulose and 0.05g of ferrocene, and continue grinding at 135-140°C for 1 hour. The resulting mixture was frozen at -15°C for 5 hours, and was pulverized into powder to obtain modified hydrogenated rosin;

[0018] (2) Add 0.5g polyoxyethylene and 0.1g hydrogenated castor oil to 3g superfine magnesium oxide, after fully mixing, microwave treatment at microwave frequency 2450MHz, output power 700W for 5min, after standing for 30min, microwave treatment for 5min again, and Cool down at a cooling rate of 5°C / min to 0-5°C and heat-preserve and grind for 15 minutes to obtain modified magnesium oxide;

[0019] (3) Add modified magnesia to 3g of polyglutamic acid / polyethylene glycol monomethyl ether, mix well and transfer to 115-120°C for 10 minutes, then add modified hydrogenated rosin while hot and 1g of cationic polyacrylamid...

Embodiment 2

[0022] (1) Mix 25g of hydrogenated rosin and 15g of poloxamer 188, heat up to 135-140°C and grind for 5 hours, then add 3g of microcrystalline cellulose and 0.05g of ferrocene, and continue grinding at 135-140°C for 2 hours. The resulting mixture was frozen at -15°C for 8 hours, and was pulverized into powder to obtain modified hydrogenated rosin;

[0023] (2) Add 0.5g polyoxyethylene and 0.1g hydrogenated castor oil to 5g superfine magnesium oxide, after fully mixing, microwave treatment at microwave frequency 2450MHz, output power 700W for 5min, after standing for 30min, microwave treatment for 5min again, and Cool down at a cooling rate of 5°C / min to 0-5°C and keep grinding for 30 minutes to obtain modified magnesium oxide;

[0024] (3) Add modified magnesia to 5g of polyglutamic acid / polyethylene glycol monomethyl ether, mix well and transfer to 115-120°C for 15 minutes, then add modified hydrogenated rosin while hot and 0.5g of cationic polyacrylamide, ground to make it ...

Embodiment 3

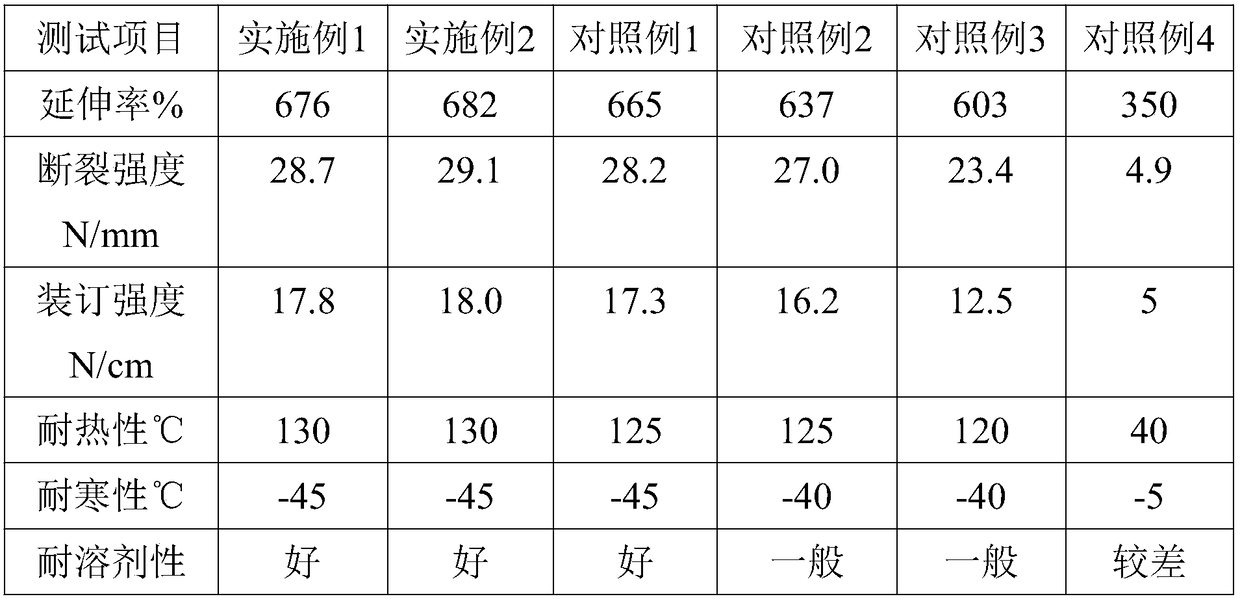

[0040] Performance tests were carried out on the hot melt adhesives made in Example 1, Example 2, Comparative Example 1, Comparative Example 2, and Comparative Example 3, and ordinary EVA hot melt adhesive was used as Comparative Example 4. The results are shown in Table 1.

[0041] Table 1 The performance of the hot melt adhesive produced by the embodiment of the present invention

[0042]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com