A method for binding steel bars of coupling beams between prefabricated laminated slabs

A technology of steel bar binding and laminated panels, which is applied in the processing of building materials, construction, building construction, etc., can solve troublesome problems and achieve the effect of solving the difficulty of binding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention is described below in conjunction with accompanying drawing:

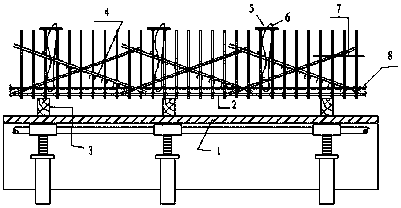

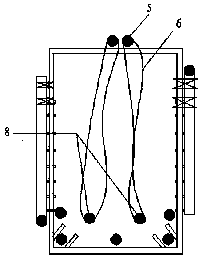

[0015] Such as figure 1 as shown, figure 1 It includes temporary binding operation platform 1, beam bottom reinforcement 2, frame 3, temporary fixing tool reinforcement 4, upper portable short reinforcement 5, binding wire 6, stirrup reinforcement 7, and beam upper longitudinal reinforcement 8. Beam bottom bars 2 and stirrups 7 are fastened, and squares 3 are 50*100 with a spacing of 800.

[0016] The construction process of the method for binding steel bars between the prefabricated laminated slabs of the present invention is specifically:

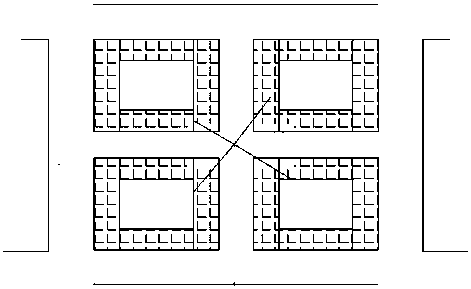

[0017] Firstly, a temporary binding operation platform 1 is set up on the side of the laminated slab across the beam, such as figure 2 shown.

[0018] Then on the horizontal formwork of the beam slab, the reinforcement beam binding frame body is supported on site.

[0019] Then bind the beam bottom reinforcement 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com