Hand-held spinning type steel bar binding device

A steel bar binding and spin-type technology, which is applied in construction, building structure, and construction material processing, can solve the problems of workers' physical discomfort, etc., and achieve the effect of labor-saving installation, eliminating the need for rotating operation steps, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below in conjunction with embodiment, further illustrate the present invention.

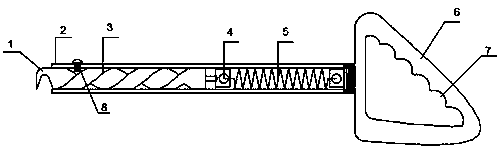

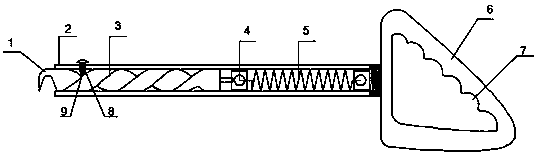

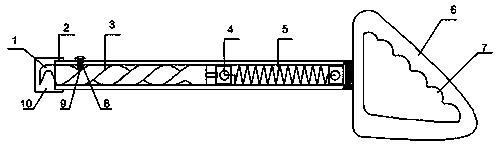

[0027] see figure 1 , a hand-held spin-type steel bar binding device is composed of a binding hook 1, an outer rod 2, an inner screw rod 3, a rod end spring fixing piece 4, a tension spring 5 and a guide bolt 8; the rod body is provided with an outer rod 2, an inner The screw rod 3, the outer rod 2 is a cavity structure, the cavity of the outer rod 2 is provided with an inner screw rod 3, a tension spring 5, one end of the inner screw rod 3 is connected and fixed with the binding hook 1; the other end of the inner screw rod 3 Through the rod end spring fixed piece 4 and one end of the tension spring 5 hinged, the other end of the tension spring 5 is connected and fixed with the outer rod 2; the side wall of the outer rod 2 is provided with a guide hole, and the guide bolt 8 is fixed in the guide hole, The bottom end of the guide bolt 8 is inserted into the groove of the inner screw, and w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com