Patents

Literature

162results about "Final package aspects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Smokeless tobacco products and processes

InactiveUS20110303511A1Improve barrier propertiesObstruct passageTobacco treatmentFinal package aspectsEngineeringSmokeless tobacco

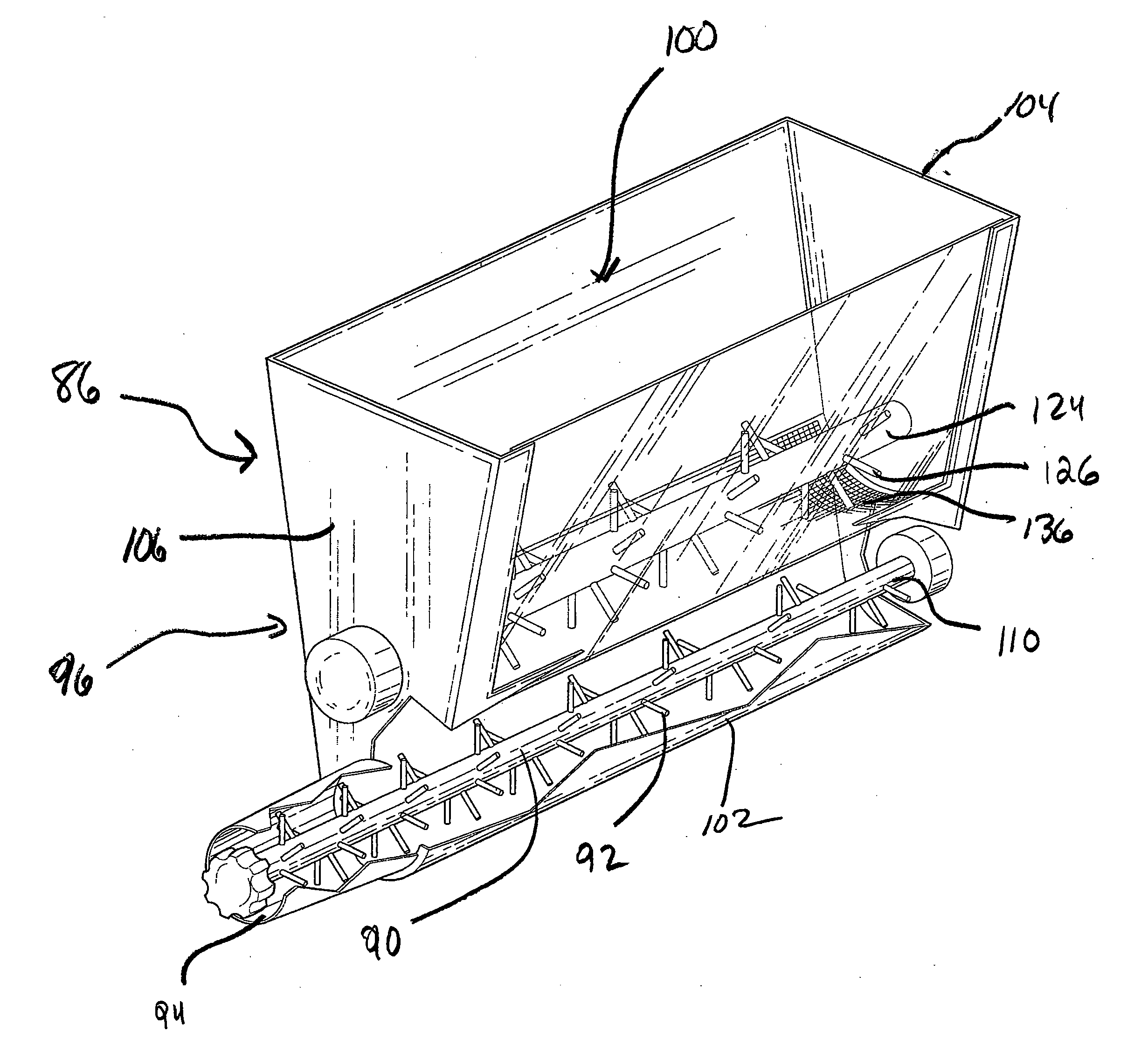

A method for preventing packing of tobacco in a tobacco hopper is provided. The method comprises the steps of providing a feed screw with a plurality of pins extending from an outer diameter of the feed screw and providing an agitator with a plurality of pins extending from an outer diameter of said outer diameter. The feed screw and said agitator screws are rotated in opposite directions to move tobacco through the hopper.

Owner:R J REYNOLDS TOBACCO COMPANY

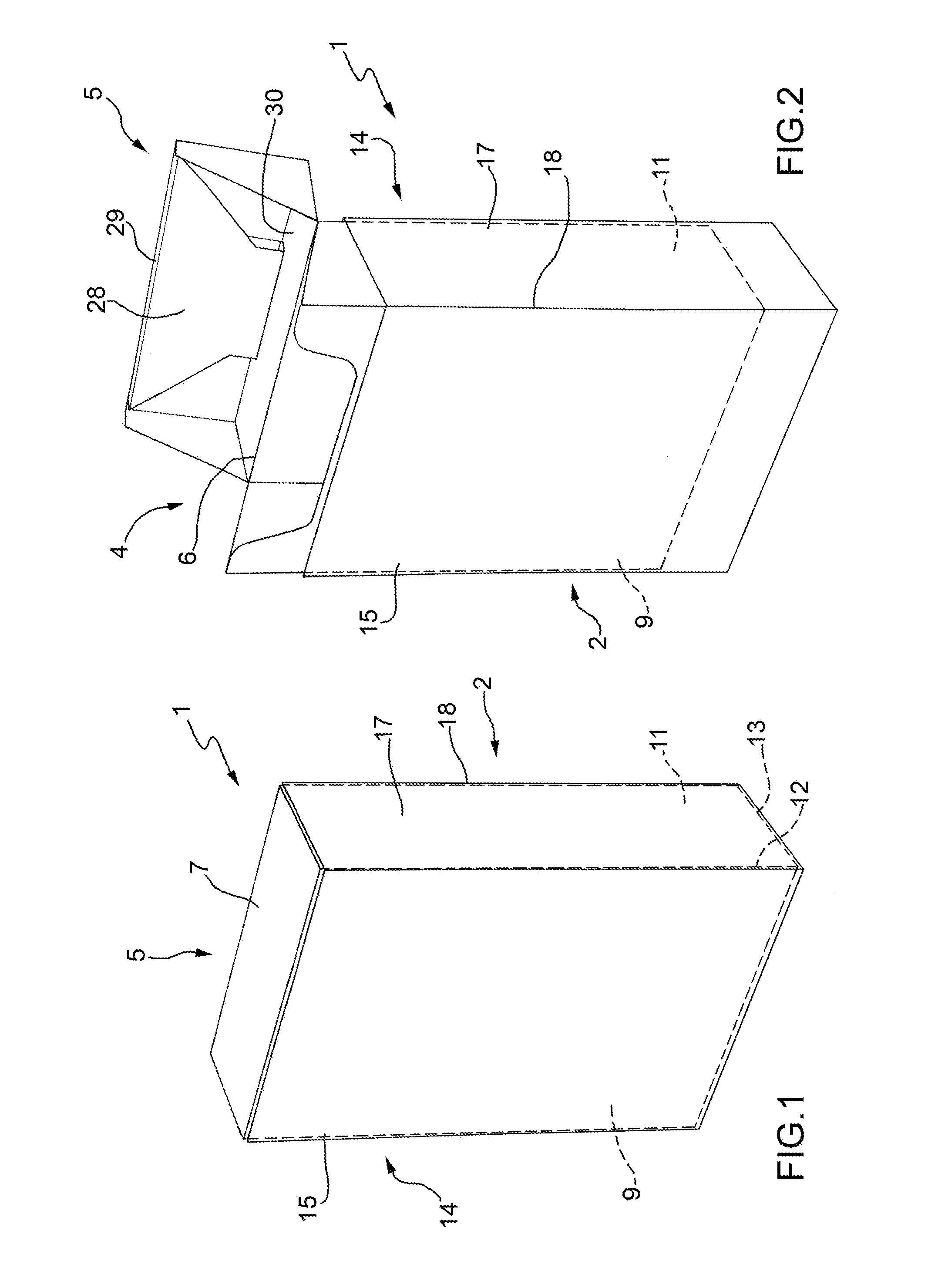

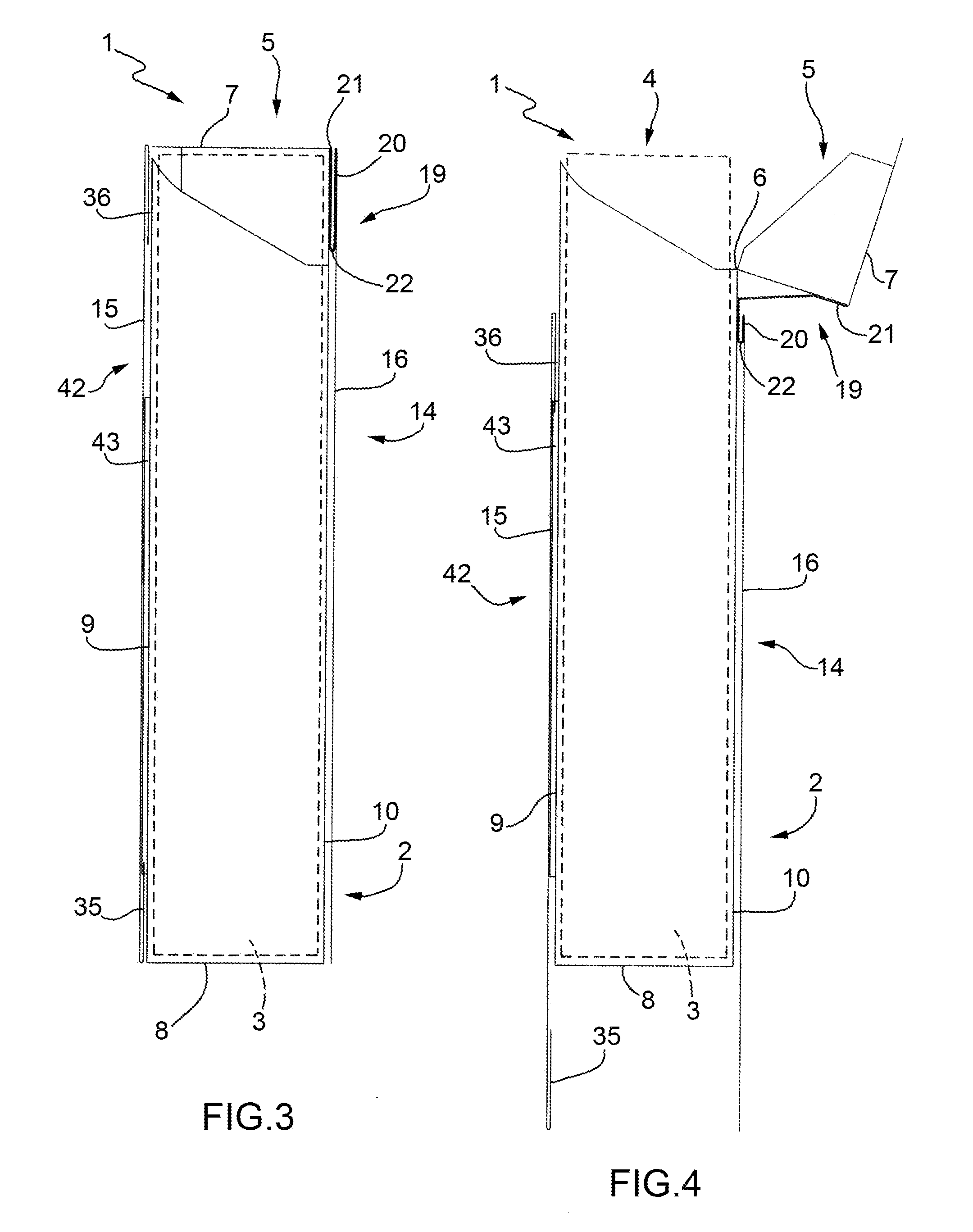

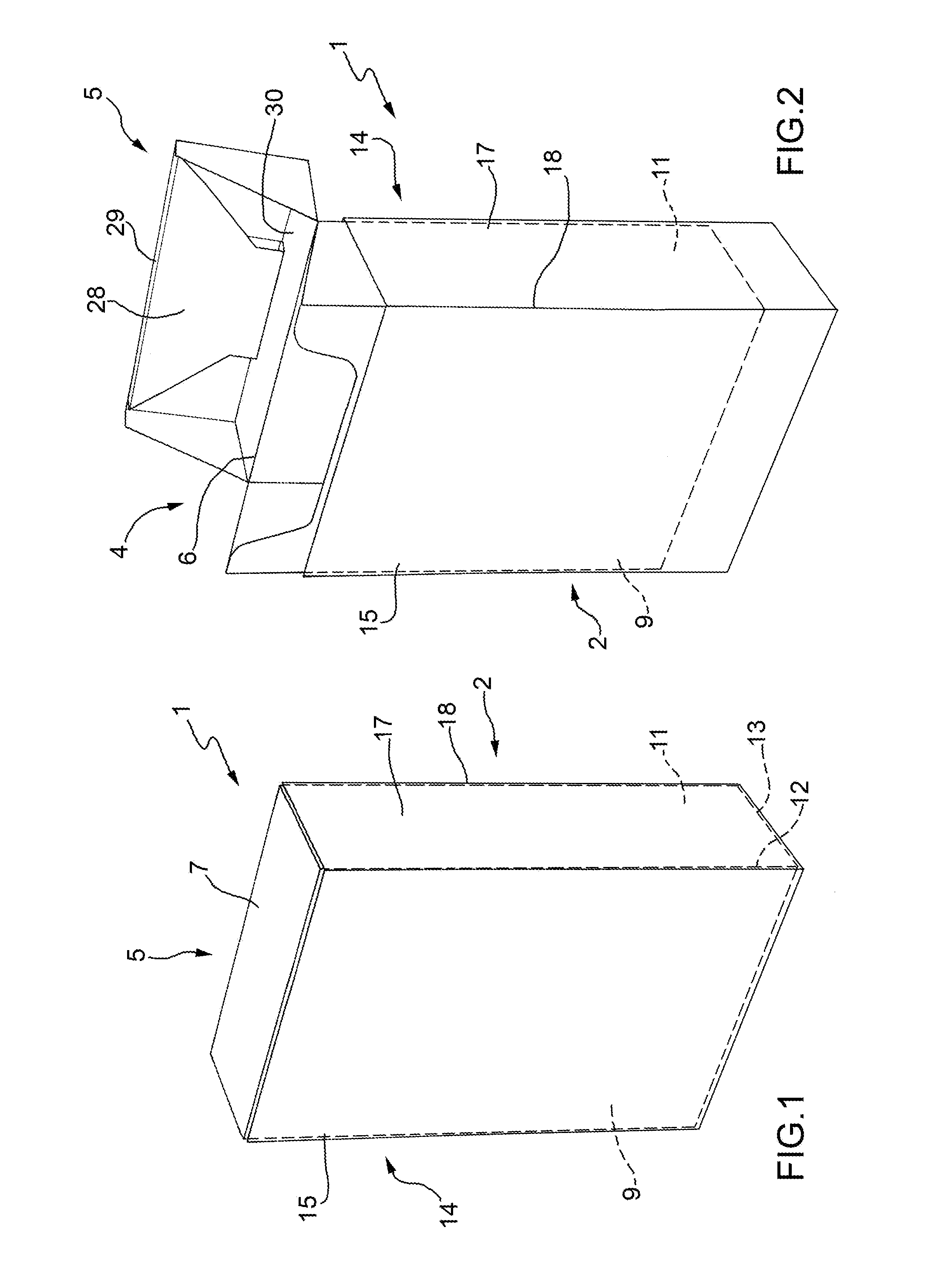

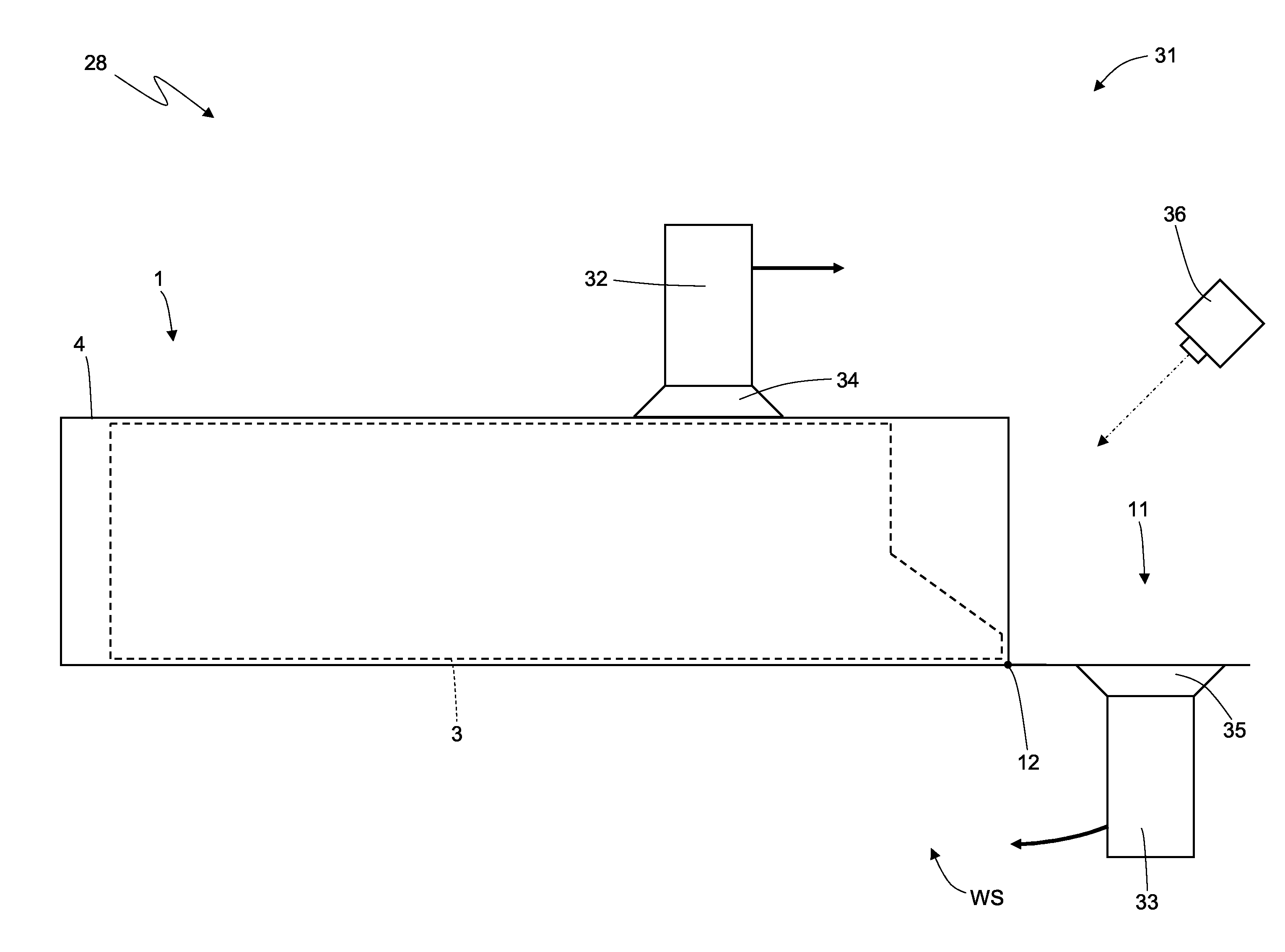

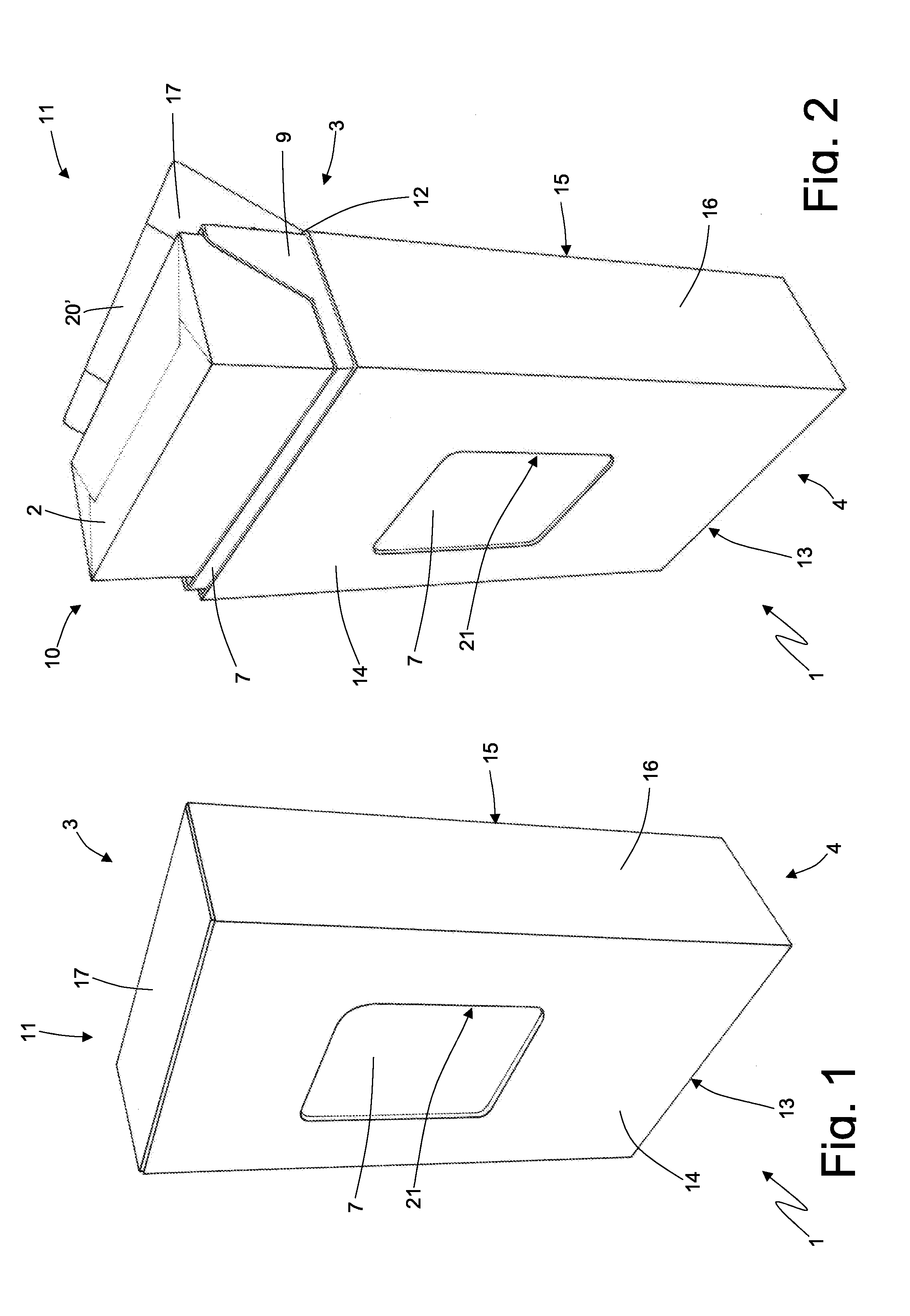

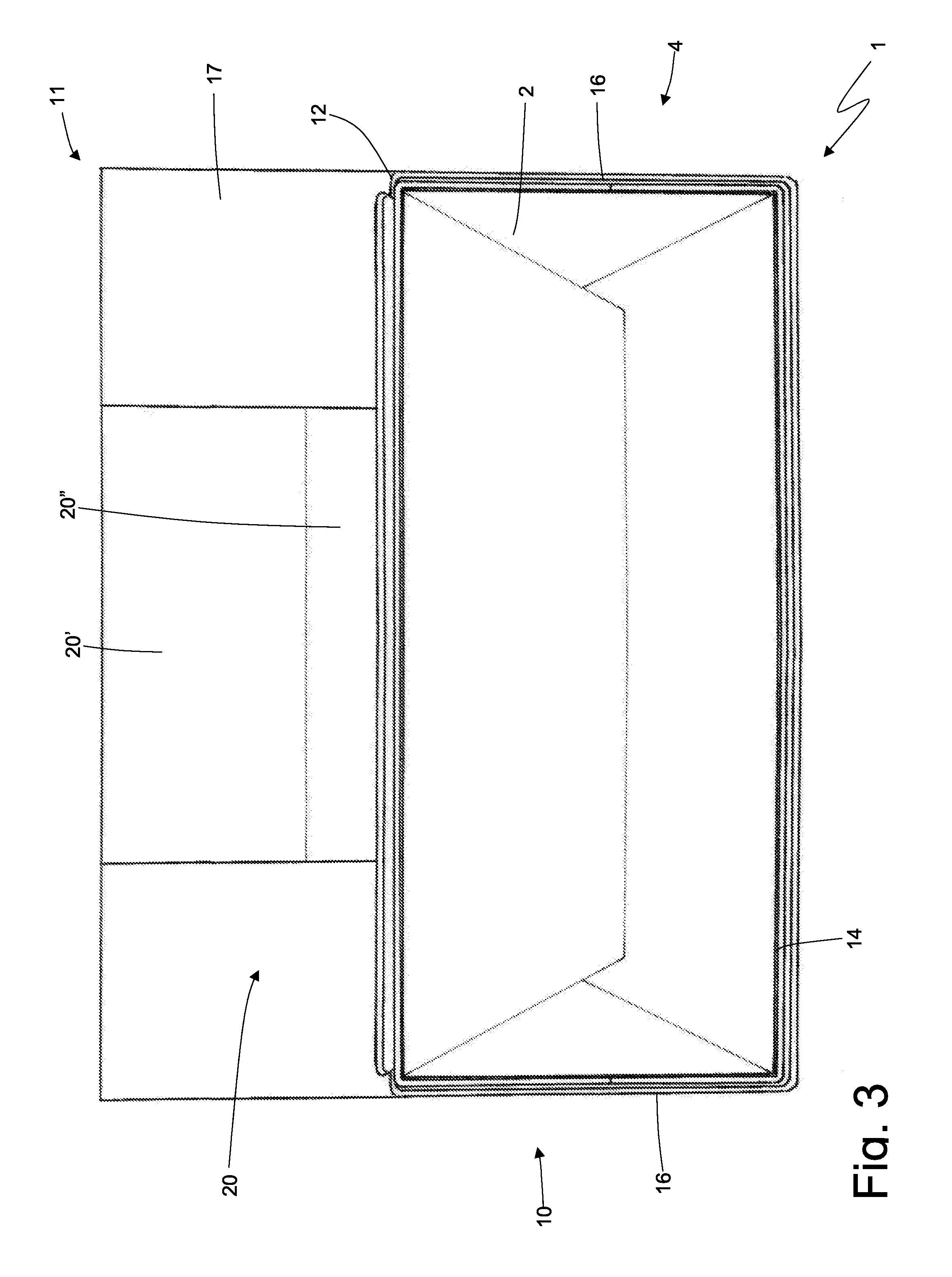

Cigarette Packing Machine for Producing a Rigid, Hinged-Lid Packet

InactiveUS20110041463A1Easy and relatively cheap to implementPackaging cigaretteWrapper folding/bending apparatusEngineeringCigarette pack

A cigarette packing machine for producing a rigid packet with a hinged lid has a first packing unit which folds a first blank about a group of cigarettes to form an outer container with a hinged lid; and a second packing unit which folds a second blank about the outer container to form a tubular slide surrounding the outer container to slide axially with respect to the outer container; the tubular slide has a transmission member, in turn having a first end integral with the lid, a second end opposite the first end and integral with the slide, and a deformable intermediate portion having a U-shaped fold between the outer container and the slide.

Owner:GD SPA

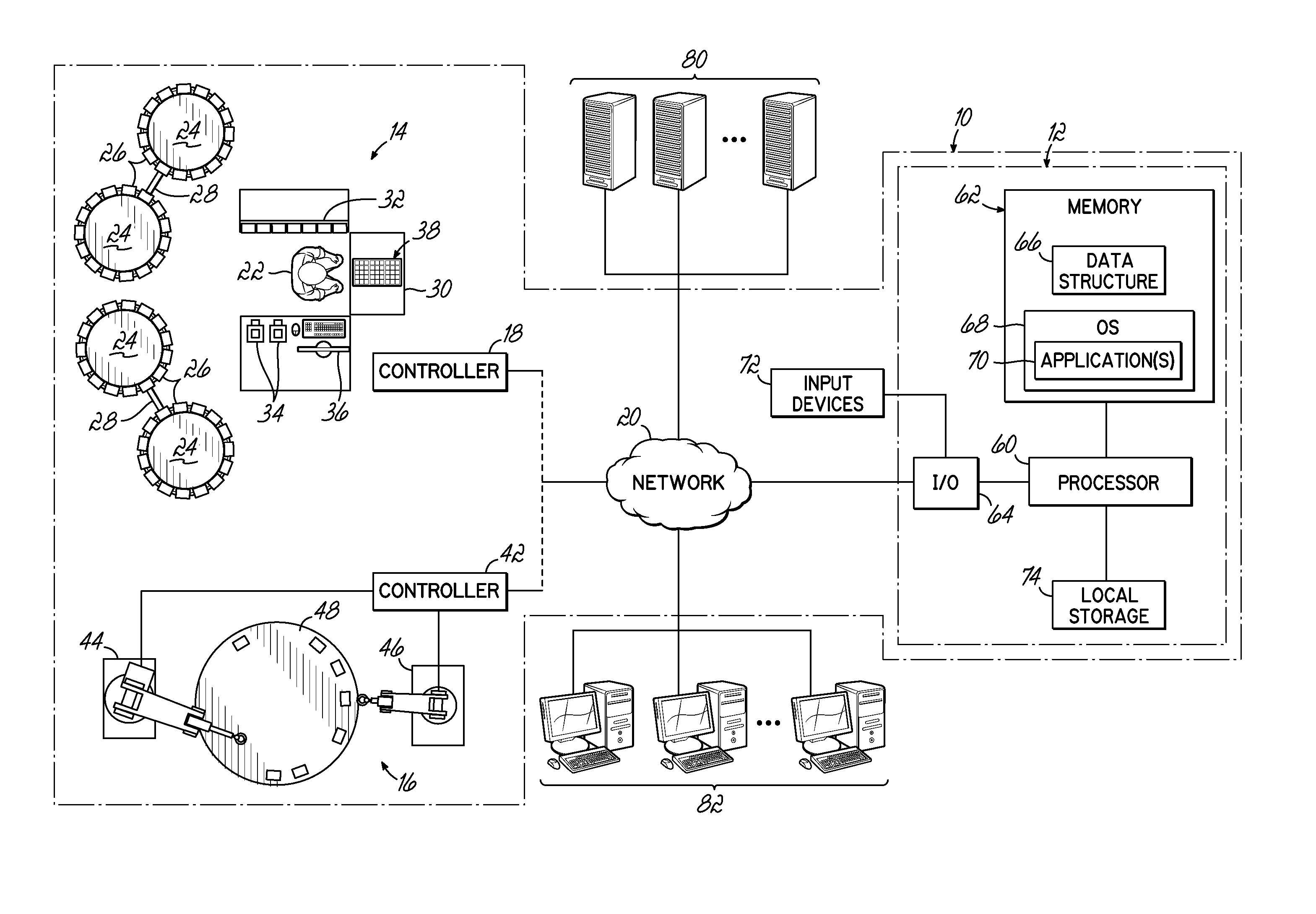

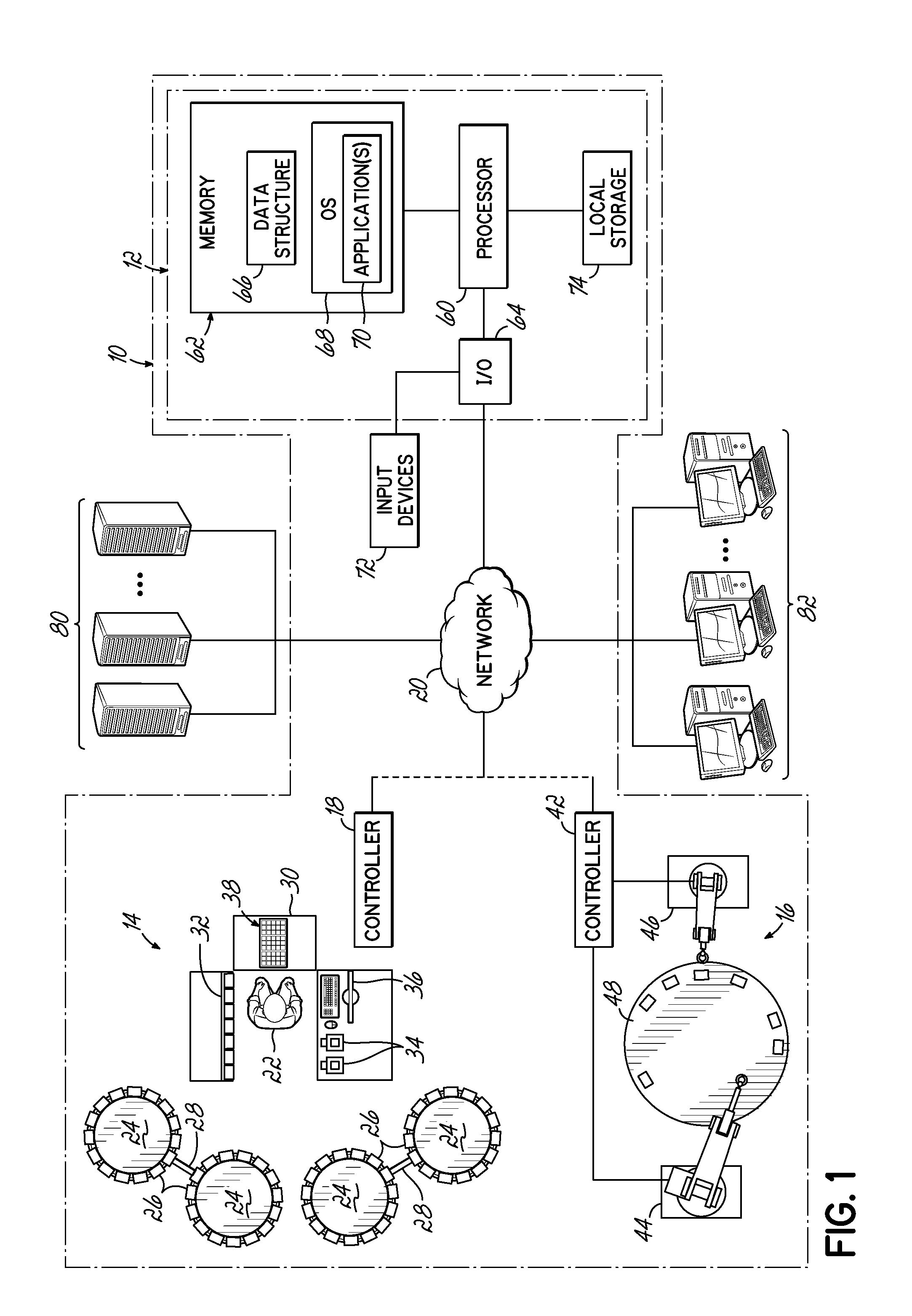

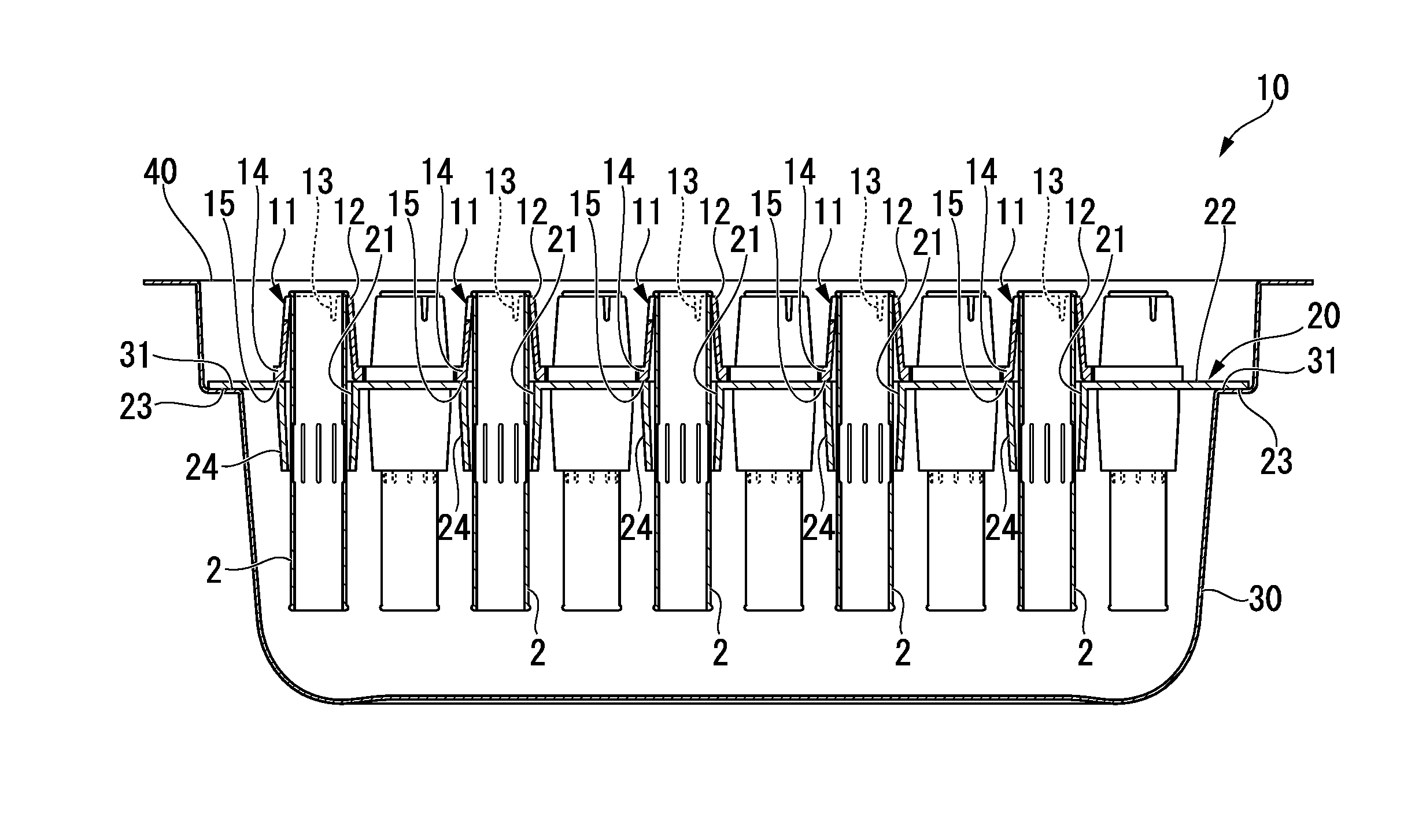

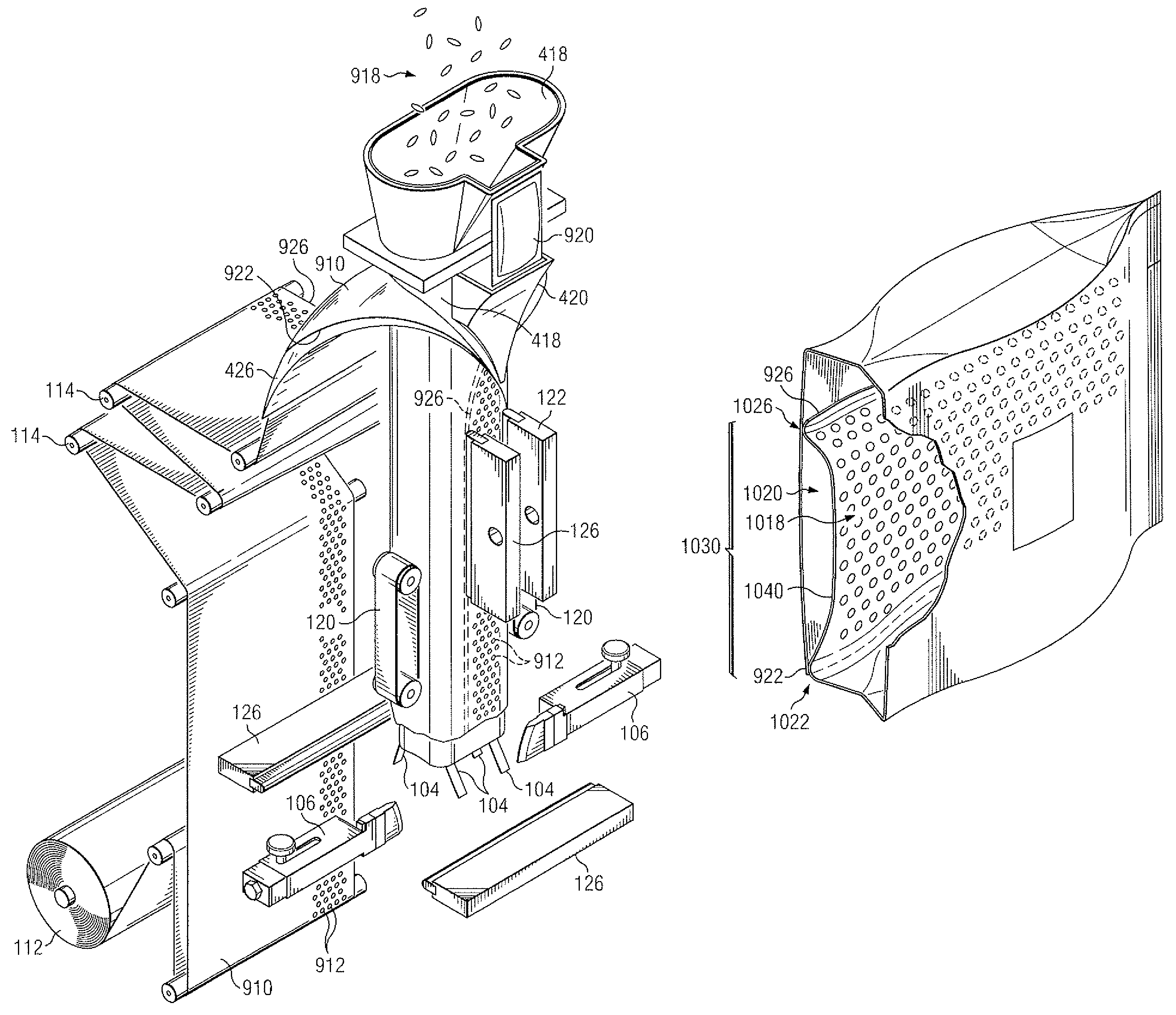

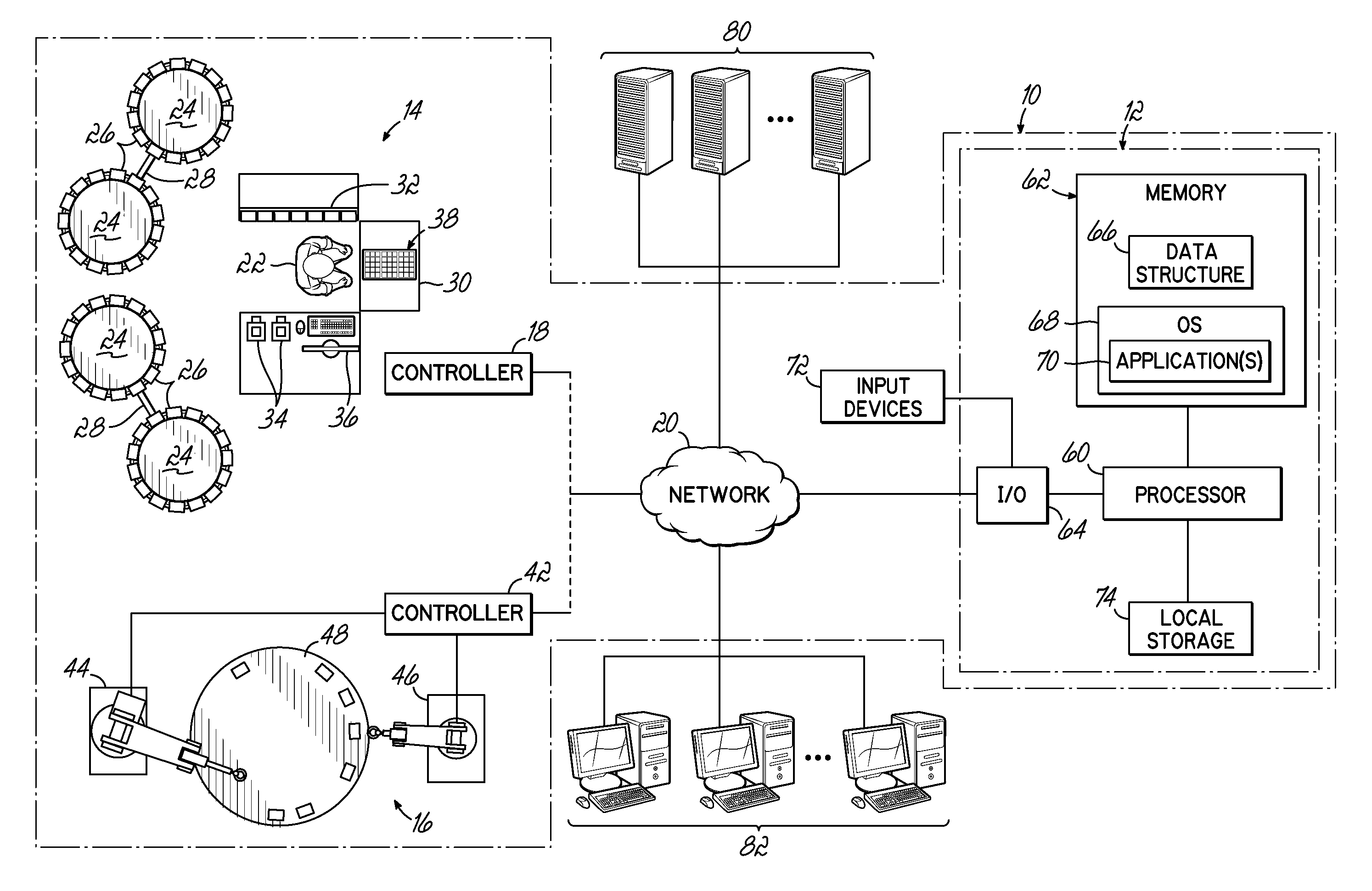

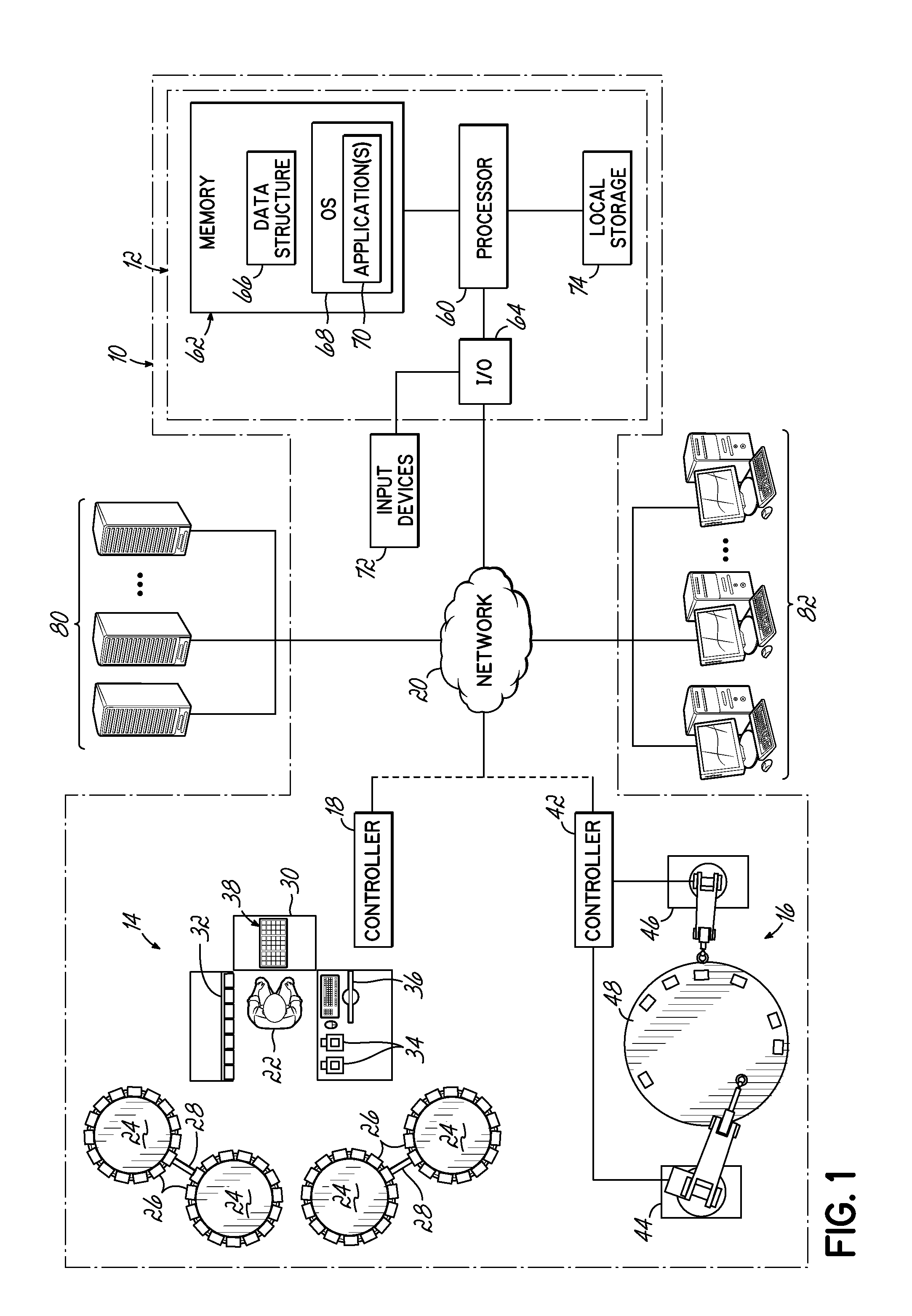

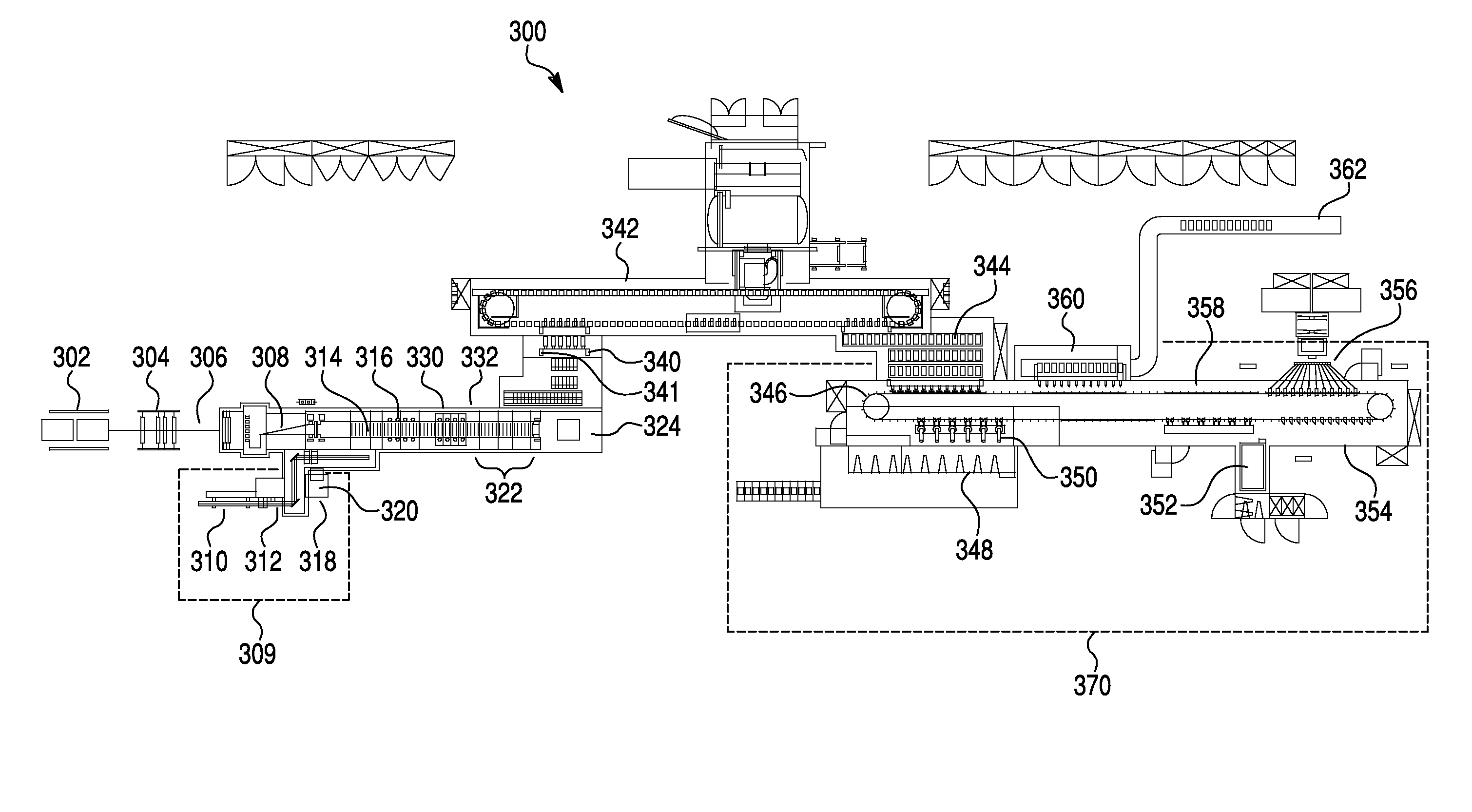

Methods and apparatus for automated filling of packagings with medications

ActiveUS20130340390A1Improving drug administration complianceImproving prescription filling processProgramme-controlled manipulatorDrug and medicationsBiomedical engineering

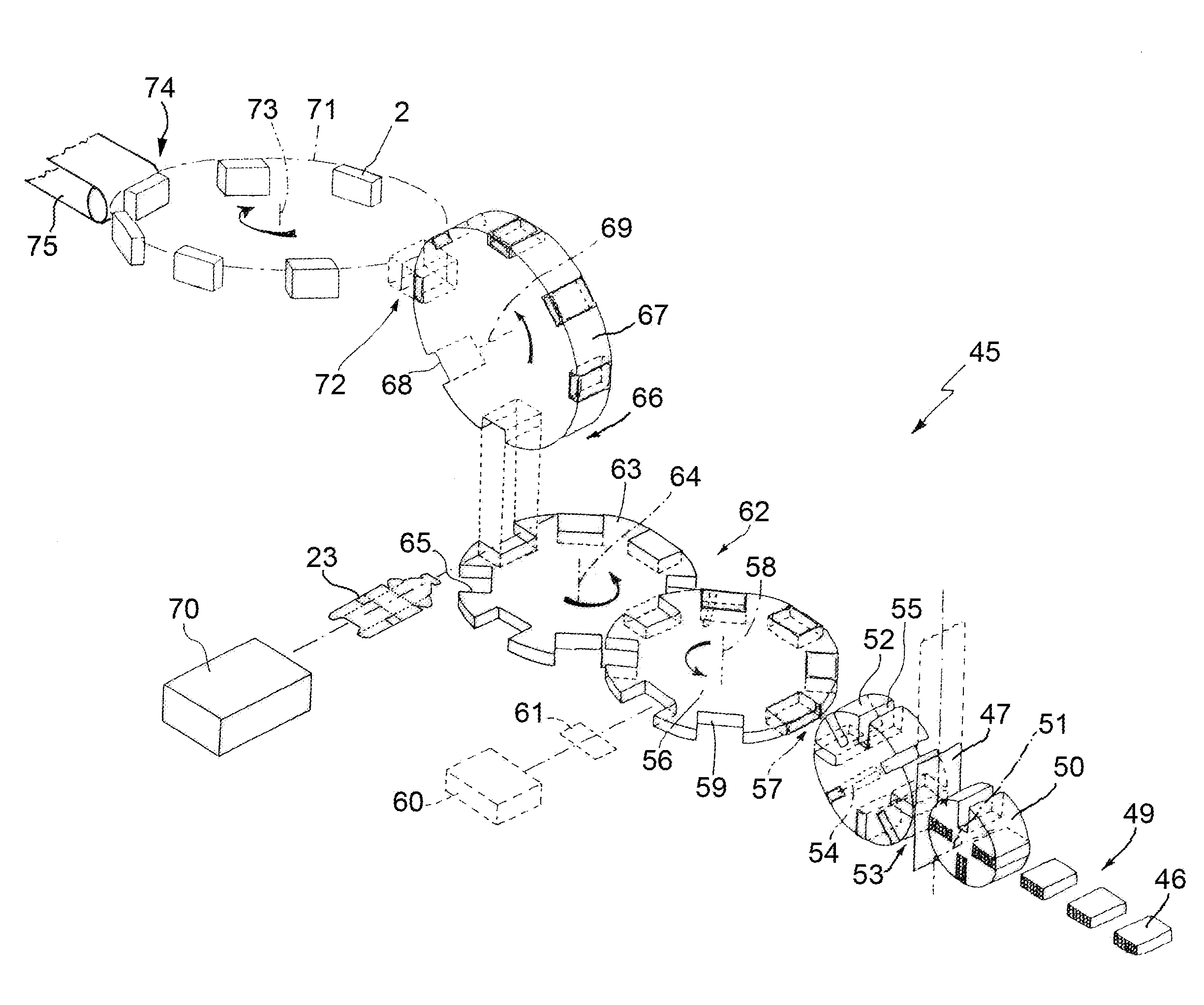

Methods for filling packagings with at least one medication includes receiving filling instructions for an order and operating an automated packaging station to fill a plurality of packagings making up an order. Operating the automated packaging station includes positioning a plurality of cassettes containing the medications needed for the order onto a feeder base at a single filling location, and moving each of the plurality of packagings to the filling location. The operation also includes actuating at least one of the cassettes at the feeder base simultaneously and according to the filling instructions when each packaging is located at the filling location. Automated packaging stations operable to perform the above filling instructions are also provided.

Owner:OMNICARE LLC

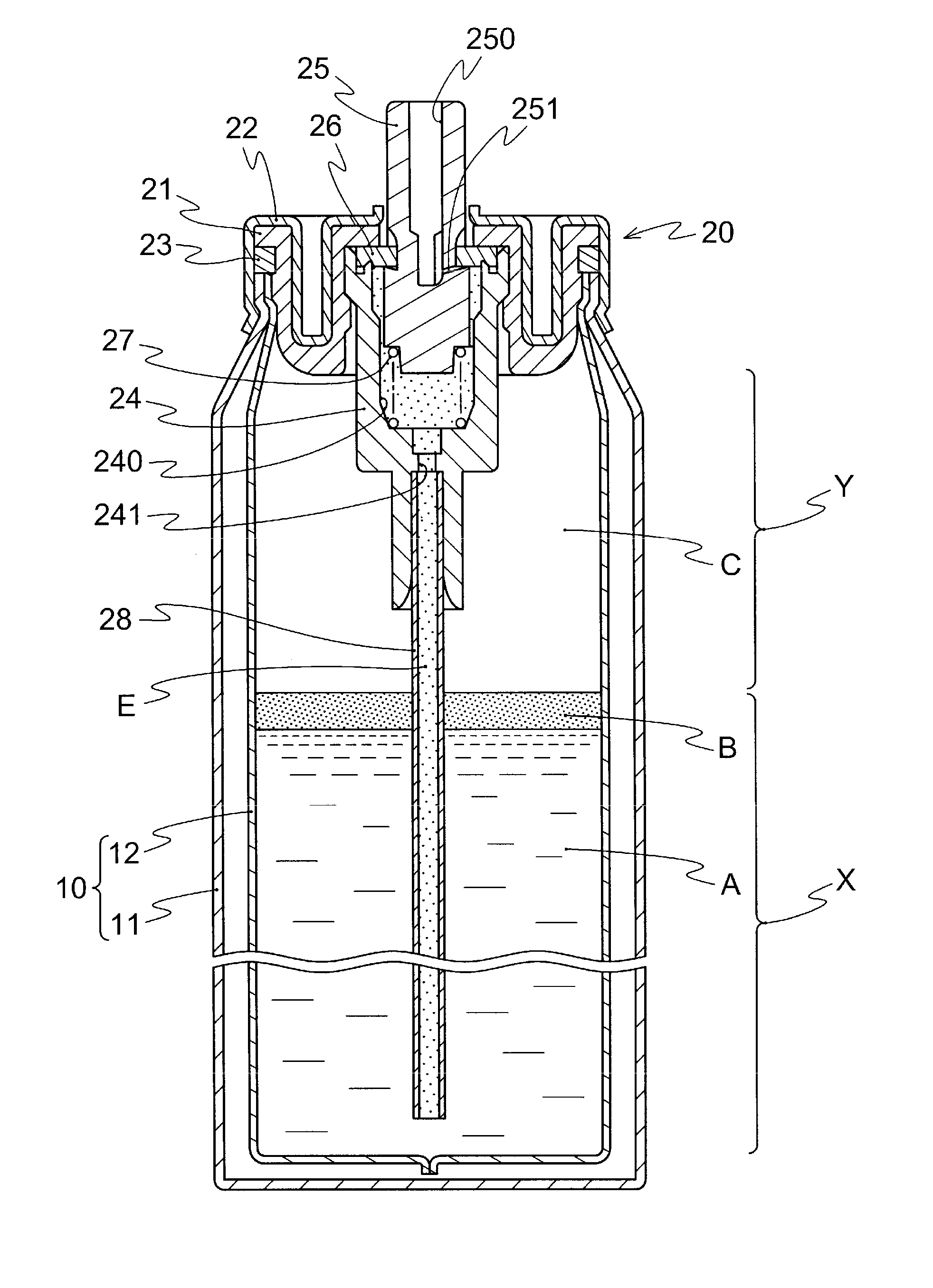

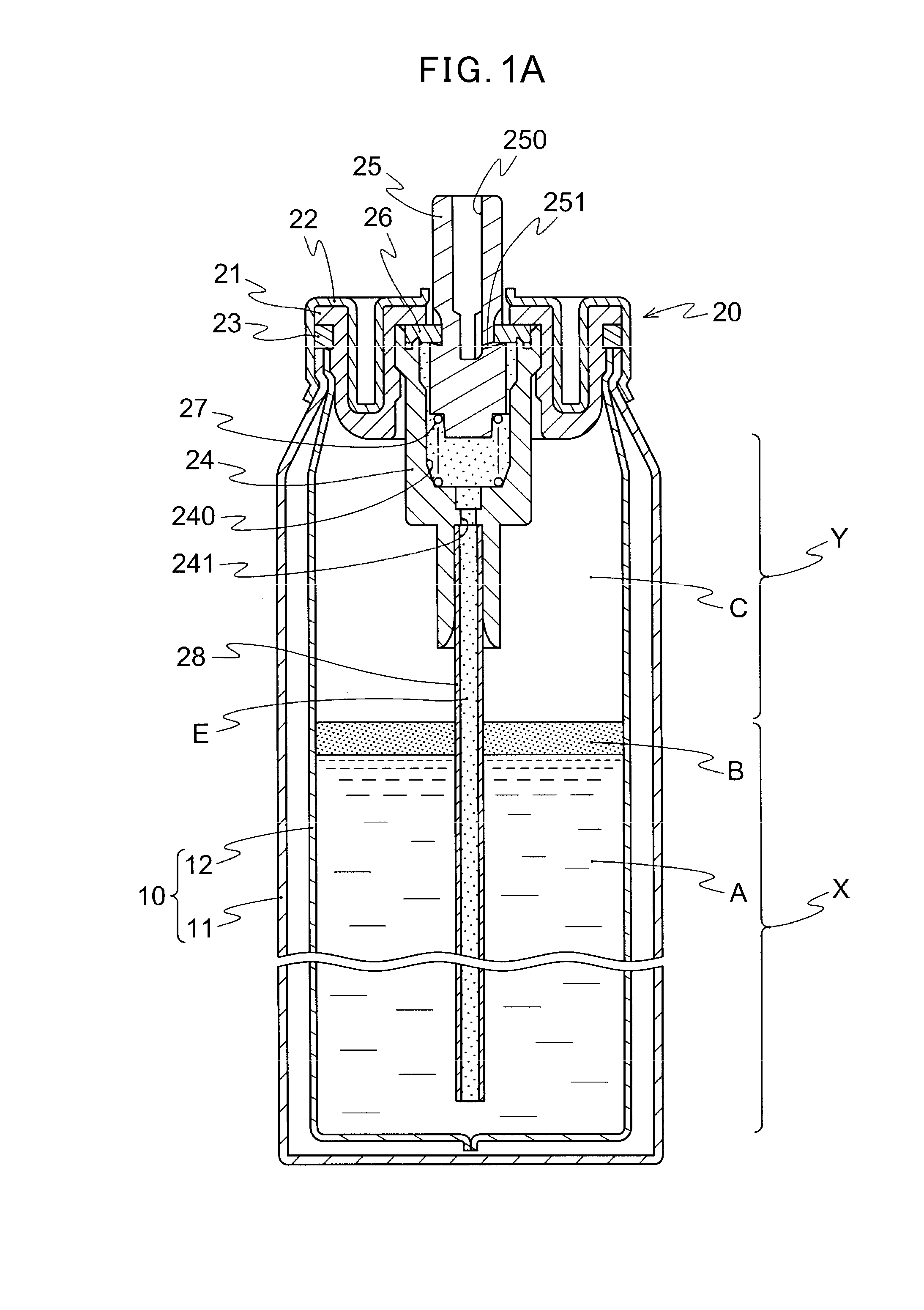

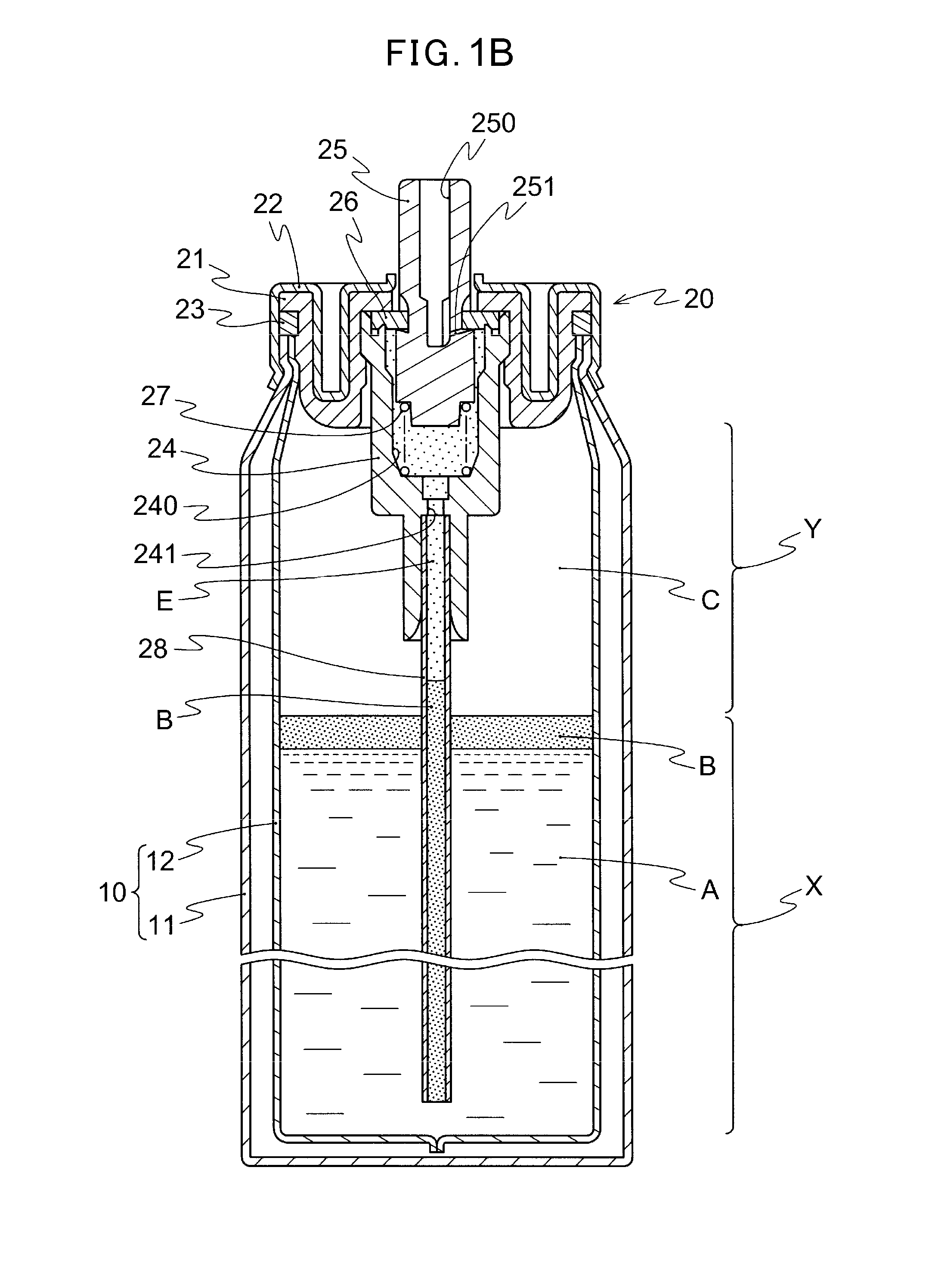

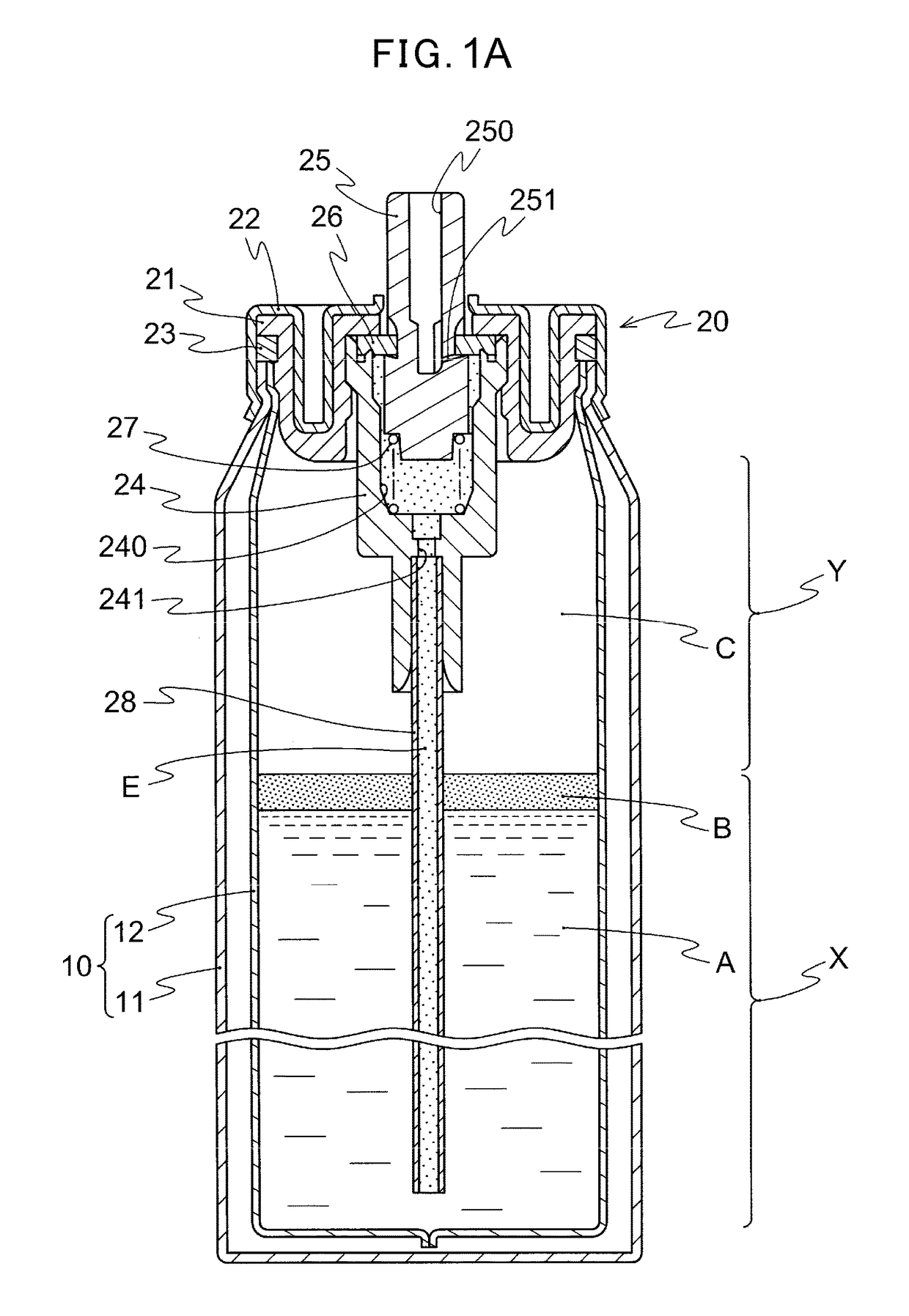

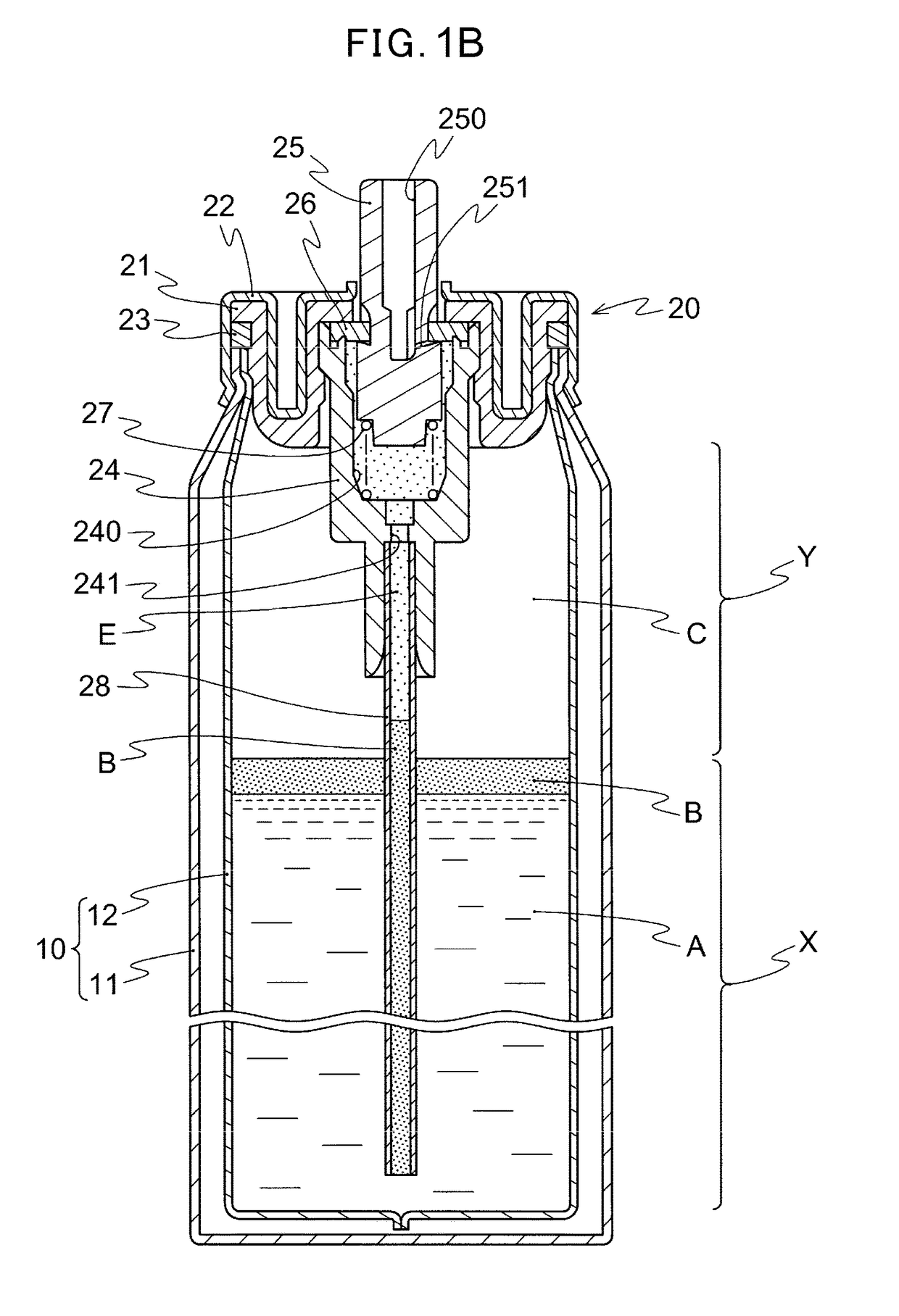

Aerosol product and method for manufacturing same

ActiveUS20150166253A1Long period of timePrevent oxidationCosmetic preparationsHair cosmeticsOxygenBULK ACTIVE INGREDIENT

An aerosol product comprising an aerosol container comprising a container body and an aerosol valve fixed to an opening of the container body, and an aqueous concentrate and a propellant being filled in the aerosol container, wherein the aqueous concentrate comprises an active ingredient having reactivity with oxygen, and an inert ingredient is present in at least a part of an injection passage of the aerosol valve, even though the aqueous concentrate comprising an active ingredient having reactivity with oxygen is filled, oxidation of the active ingredient is inhibited in the aerosol valve, and an aerosol product that can be stored stably for a long period of time and a method for manufacturing the same can be provided.

Owner:DAIZO

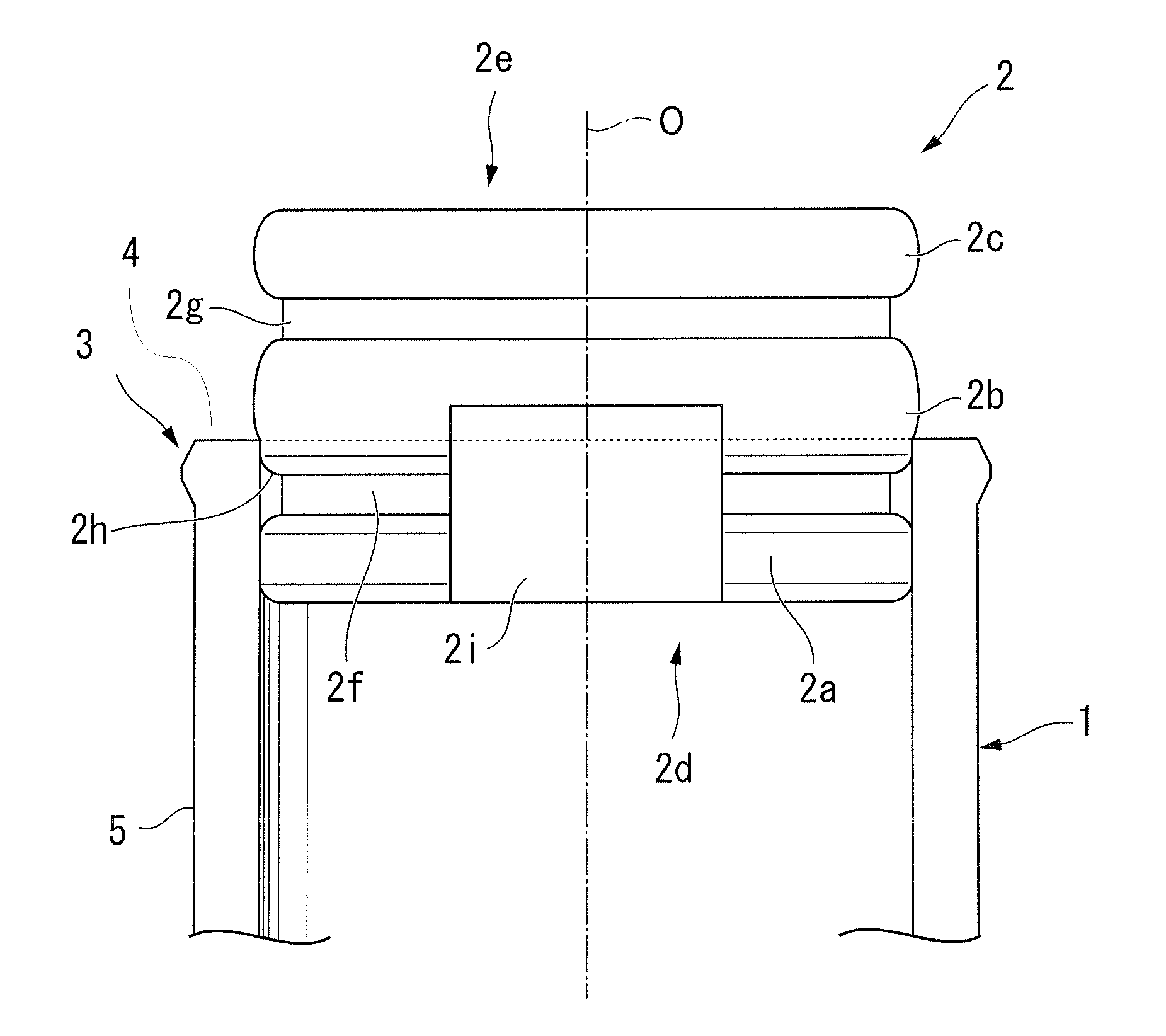

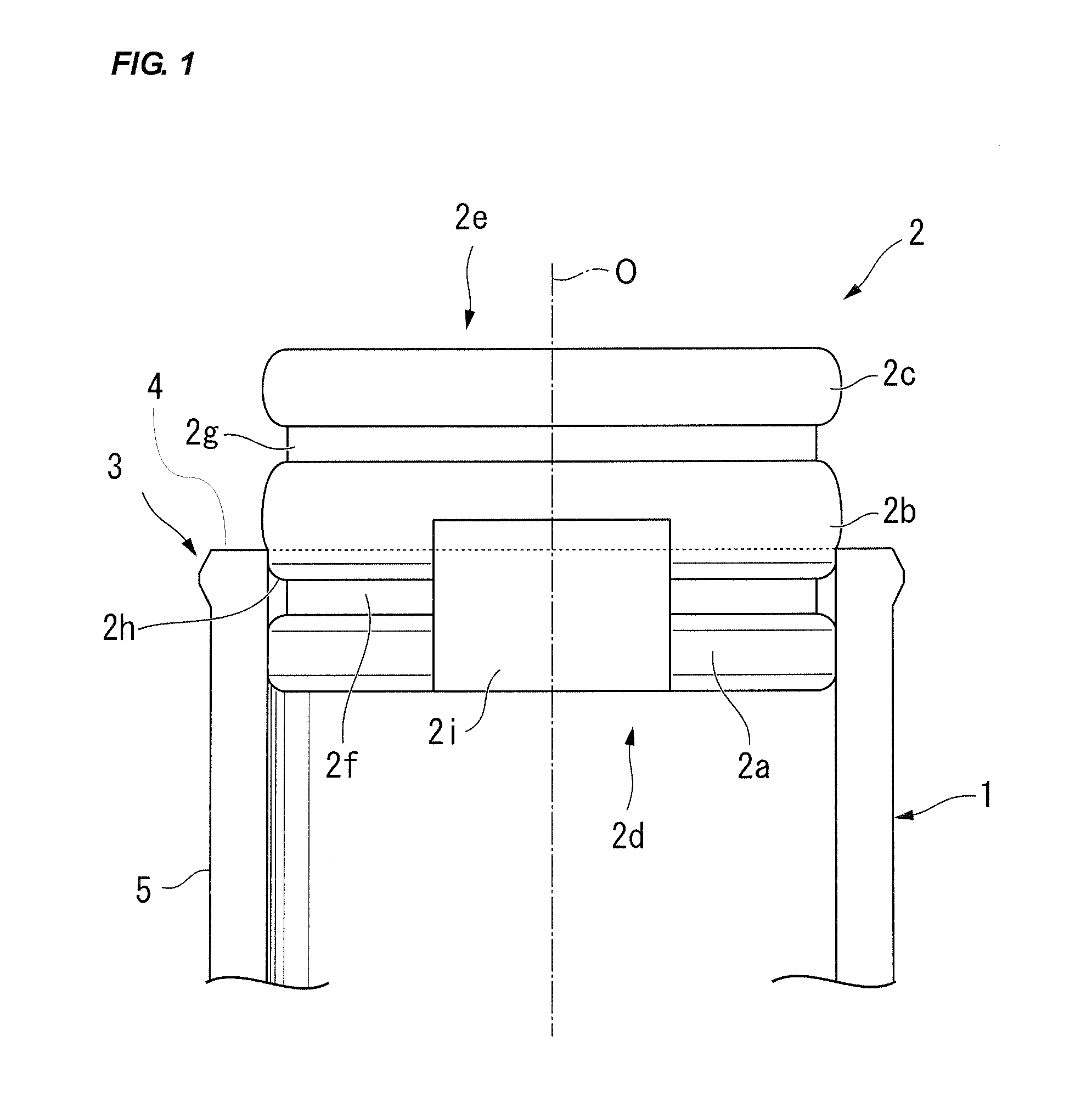

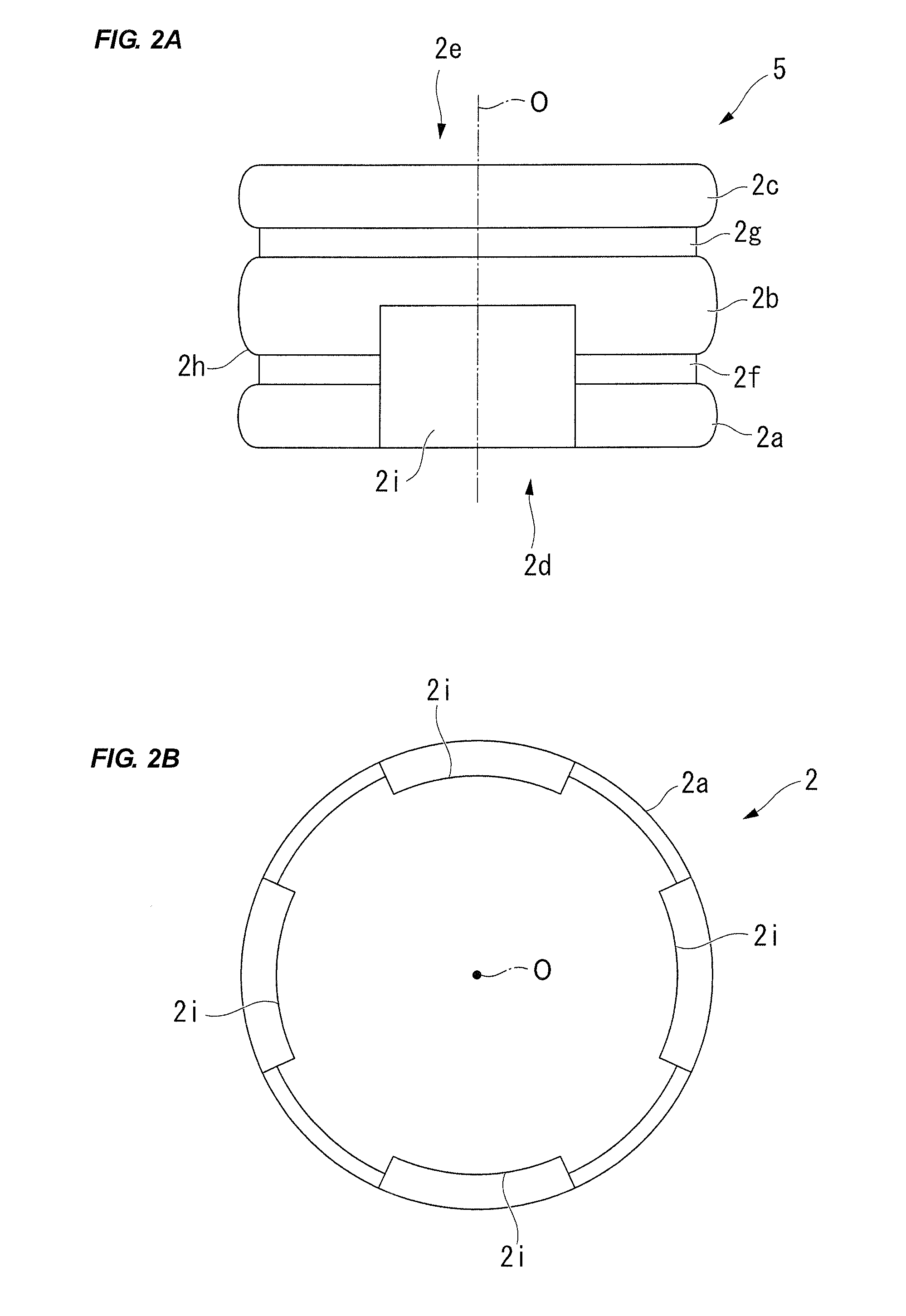

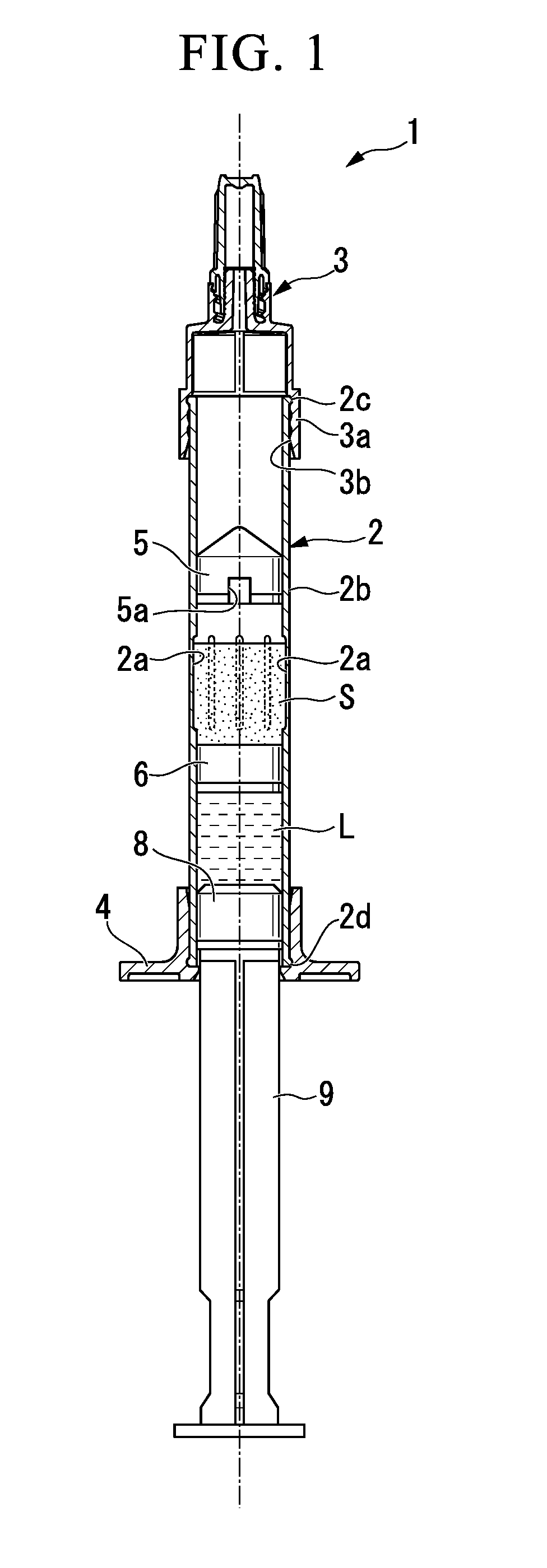

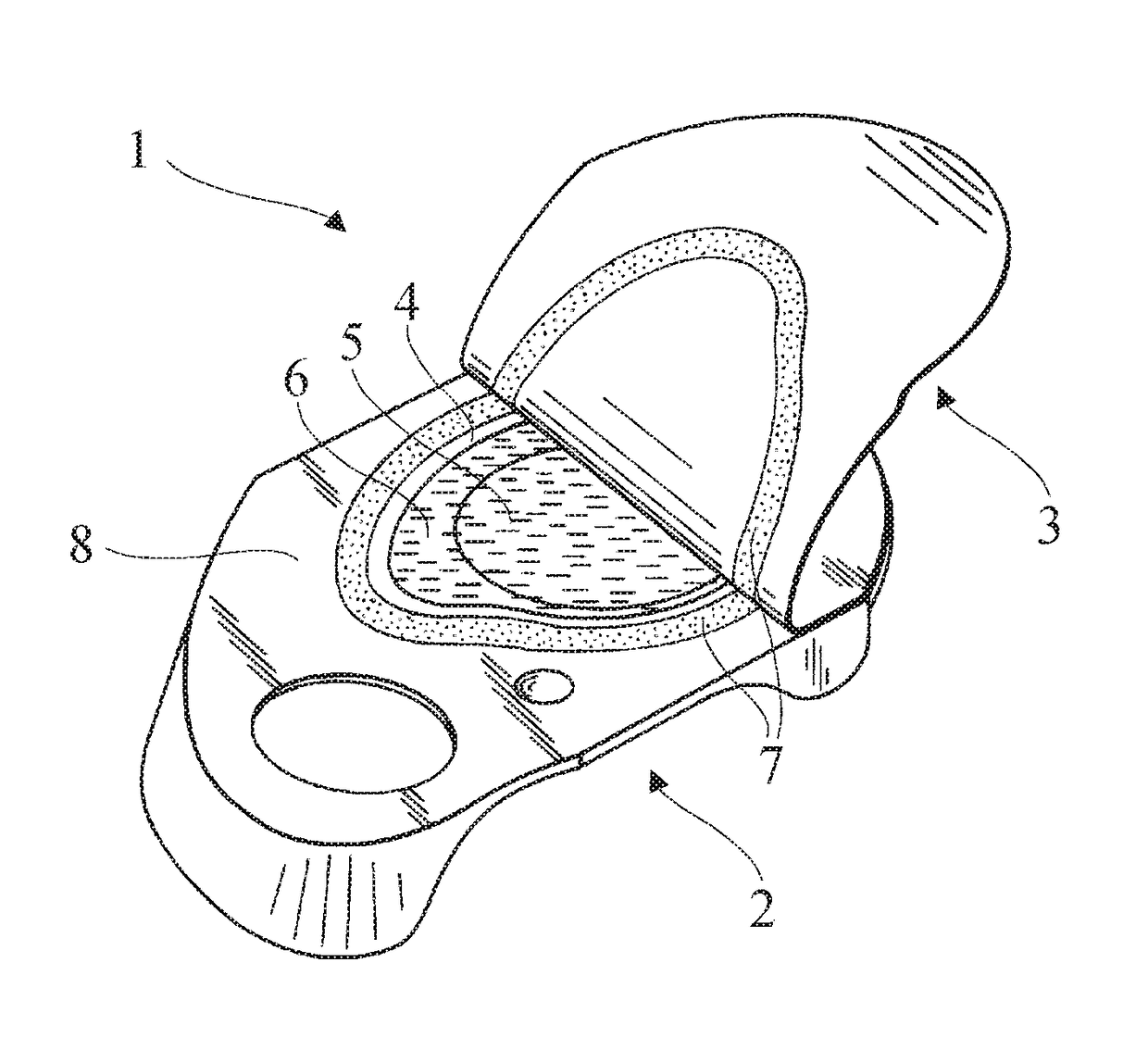

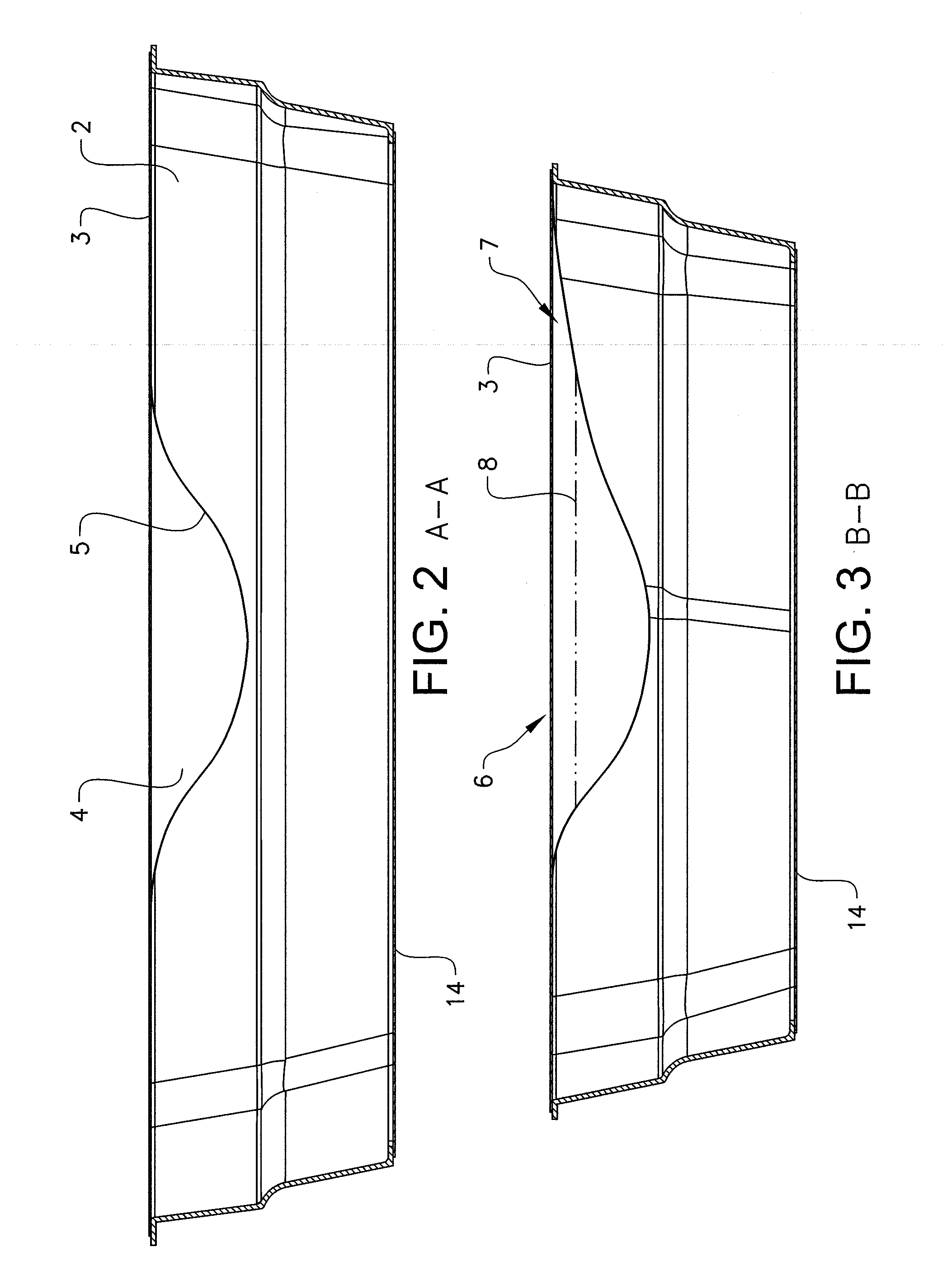

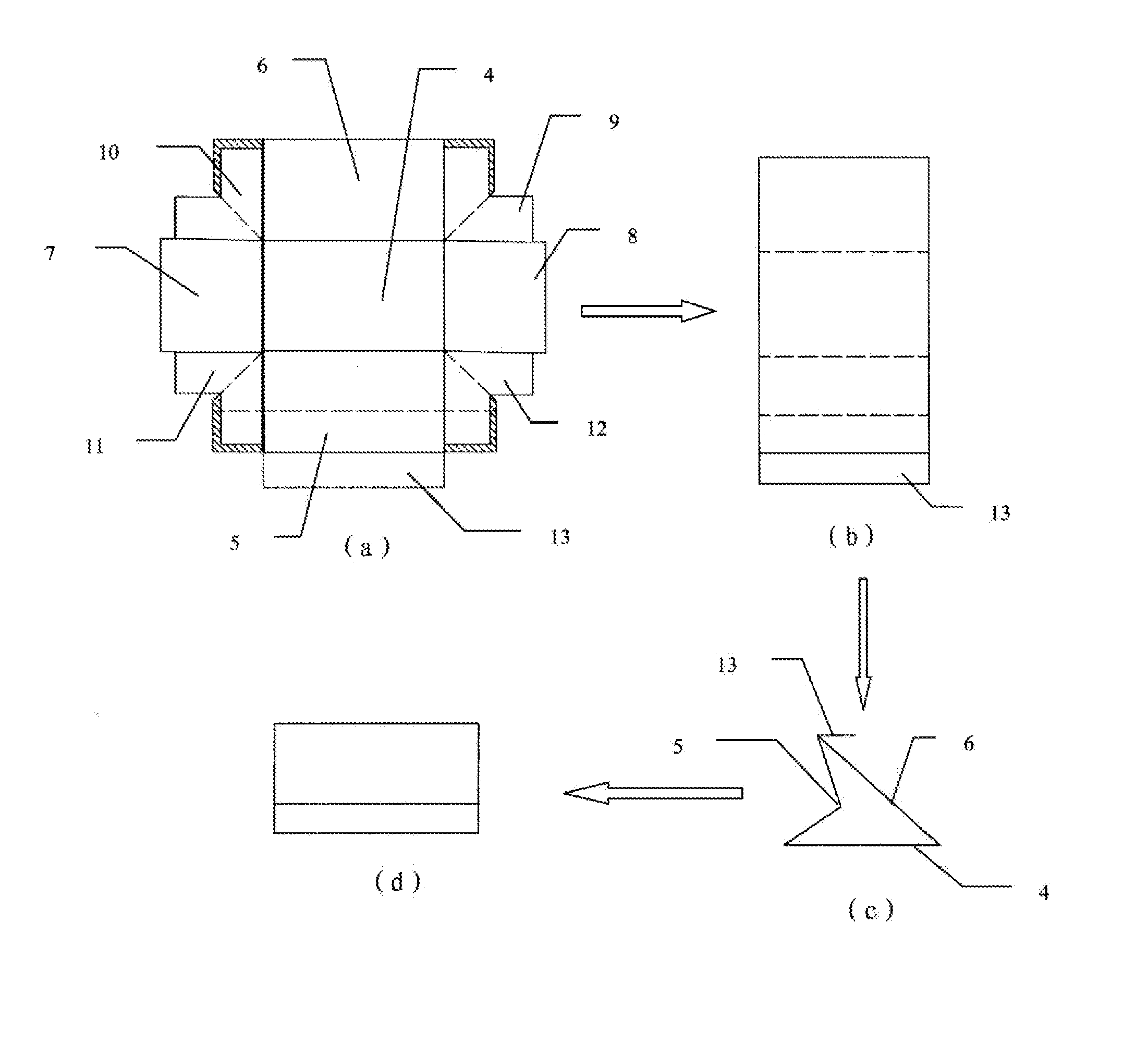

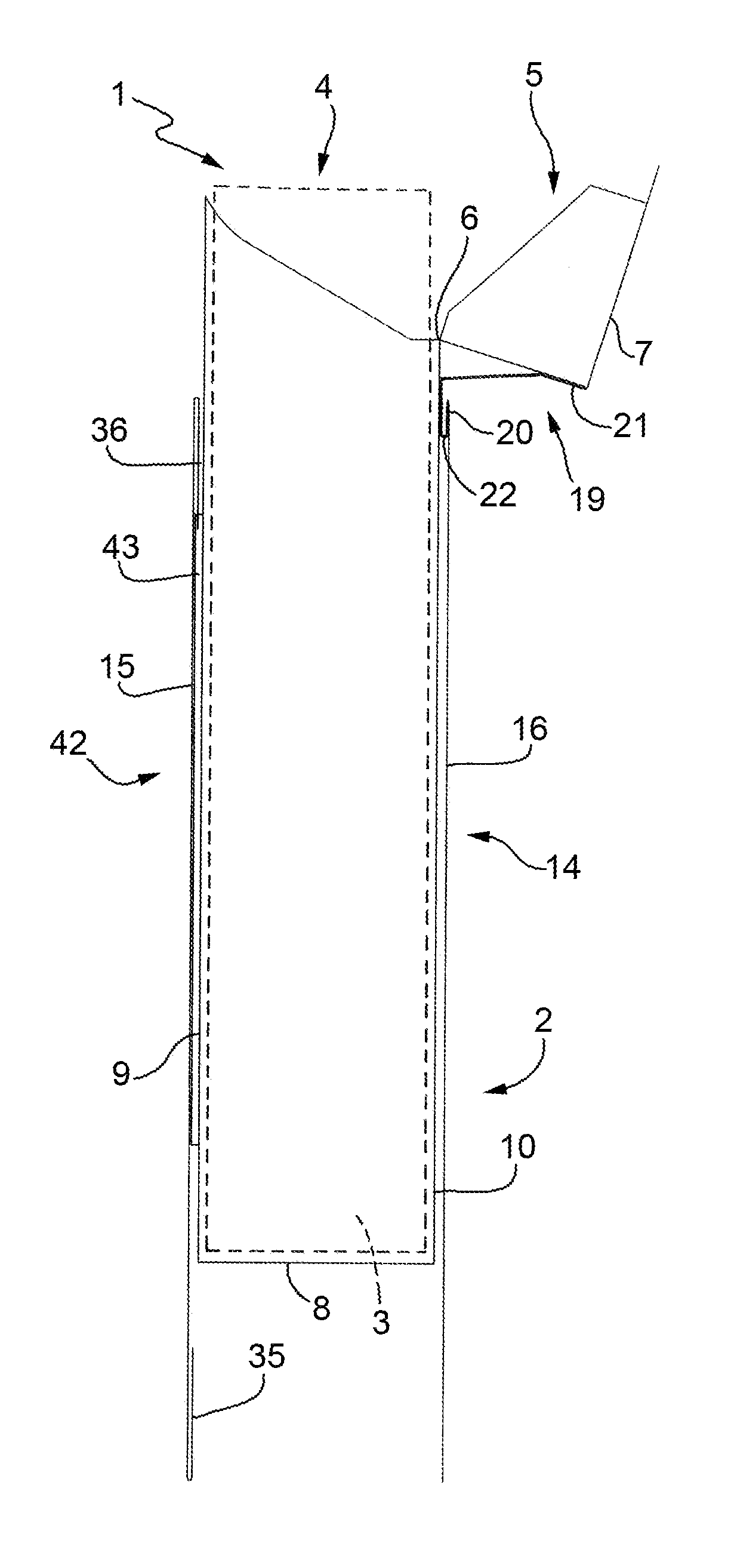

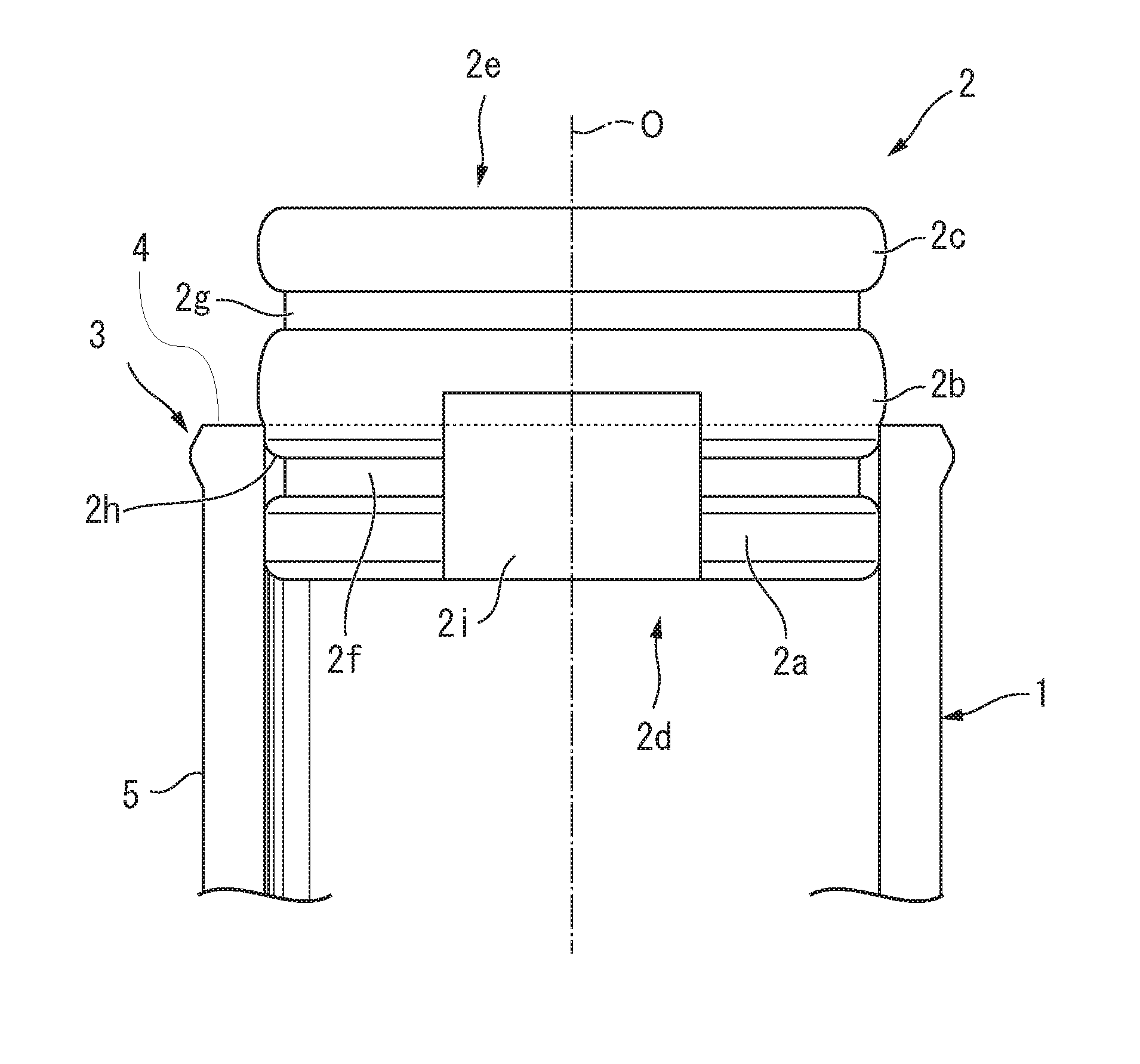

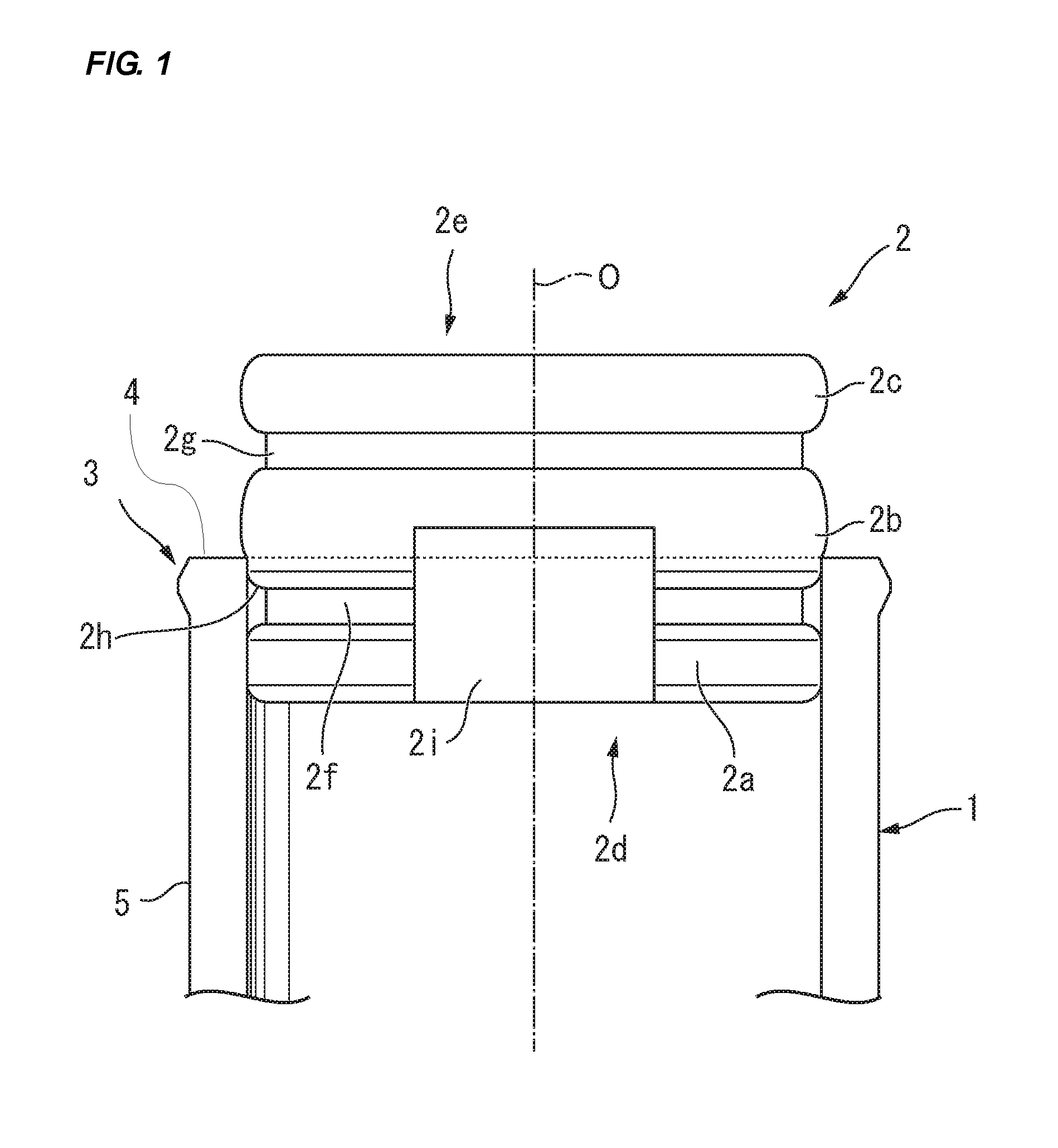

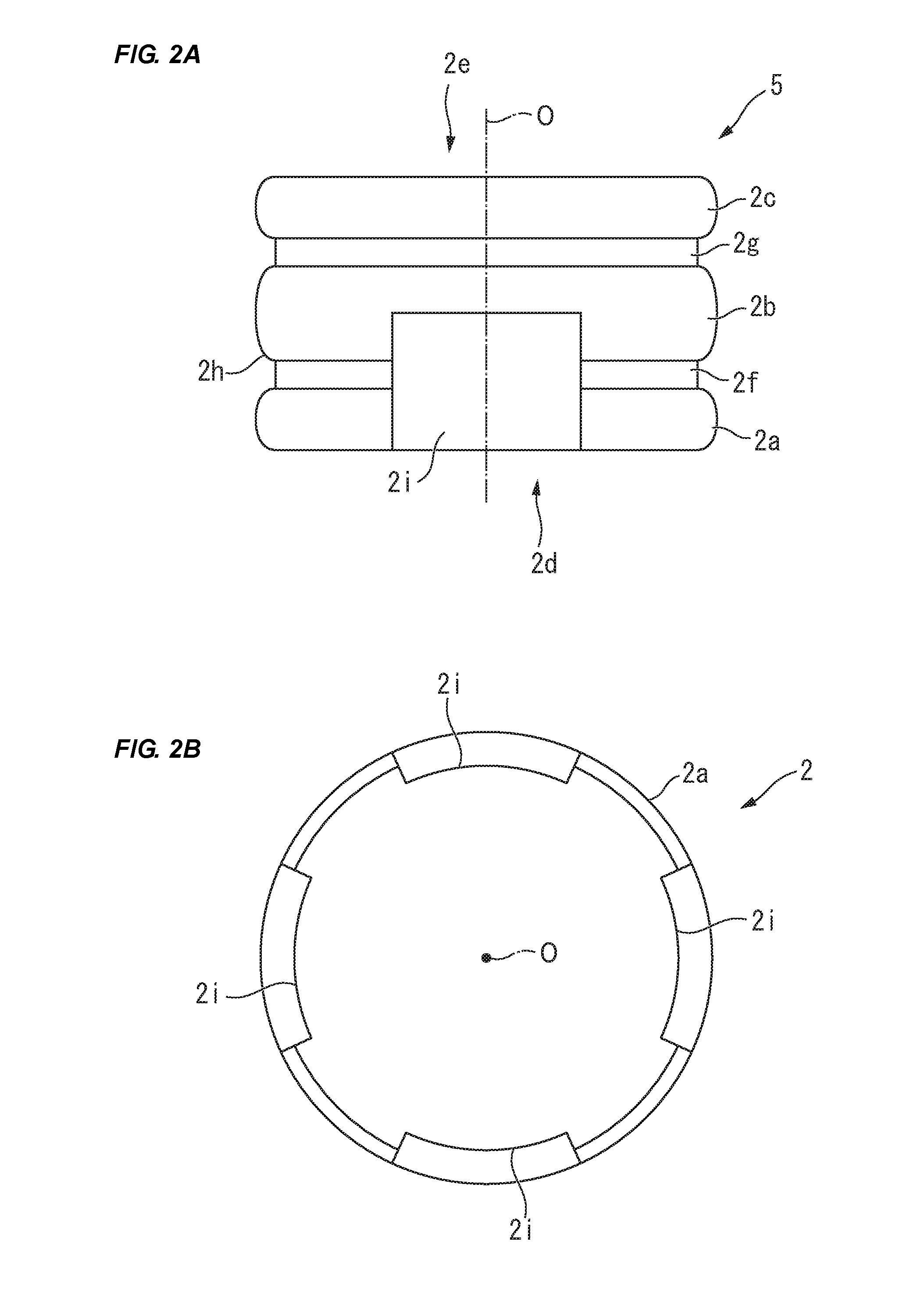

Device for accommodating a freeze-dried pharmaceutical product and method of manufacturing a sealed vessel accommodating a freeze-dried pharmaceutical product

InactiveUS20150041498A1High levelIncrease productivityCapsDecorative coversBiomedical engineeringPlunger

A device for accommodating a freeze-dried pharmaceutical product (S) for reconstitution, comprising: a vessel (1) having at its opening end (3) an opening edge (4) and an adjoining longitudinal portion (5) with an evenly formed inner cross section, a front plunger (2) to be positioned inside the vessel (1) at the longitudinal portion (5), wherein the front plunger (2) is configured to be positioned inside the vessel (1) in a sealing state, in which the front plunger (2) is fully inserted in the vessel (1), or in an exchange state, in which the front plunger (2) is inserted partly in the vessel (1) and partly protrudes over the opening edge (4) of the vessel (1), and wherein the front plunger (2) comprises sealing means that are configured to seal the inside of the vessel (1) against the outside when the front plunger (2) is positioned in the sealing state, and one or more communicating grooves (2i) that are configured to place the inside and outside of the vessel (1) in communication with each other when the front plunger (2) is positioned in the exchange state, is characterized in that the sealing means are dimensioned and / or structured in such a way that the front plunger (2), when an underpressure of predefined strength is applied to the outer environment of the vessel (1), is caused to move inside the vessel (1) toward its opening end (3). Furthermore, a method of manufacturing a sealed vessel (1) accommodating a freeze-dried pharmaceutical product (S) is disclosed.

Owner:ARTE

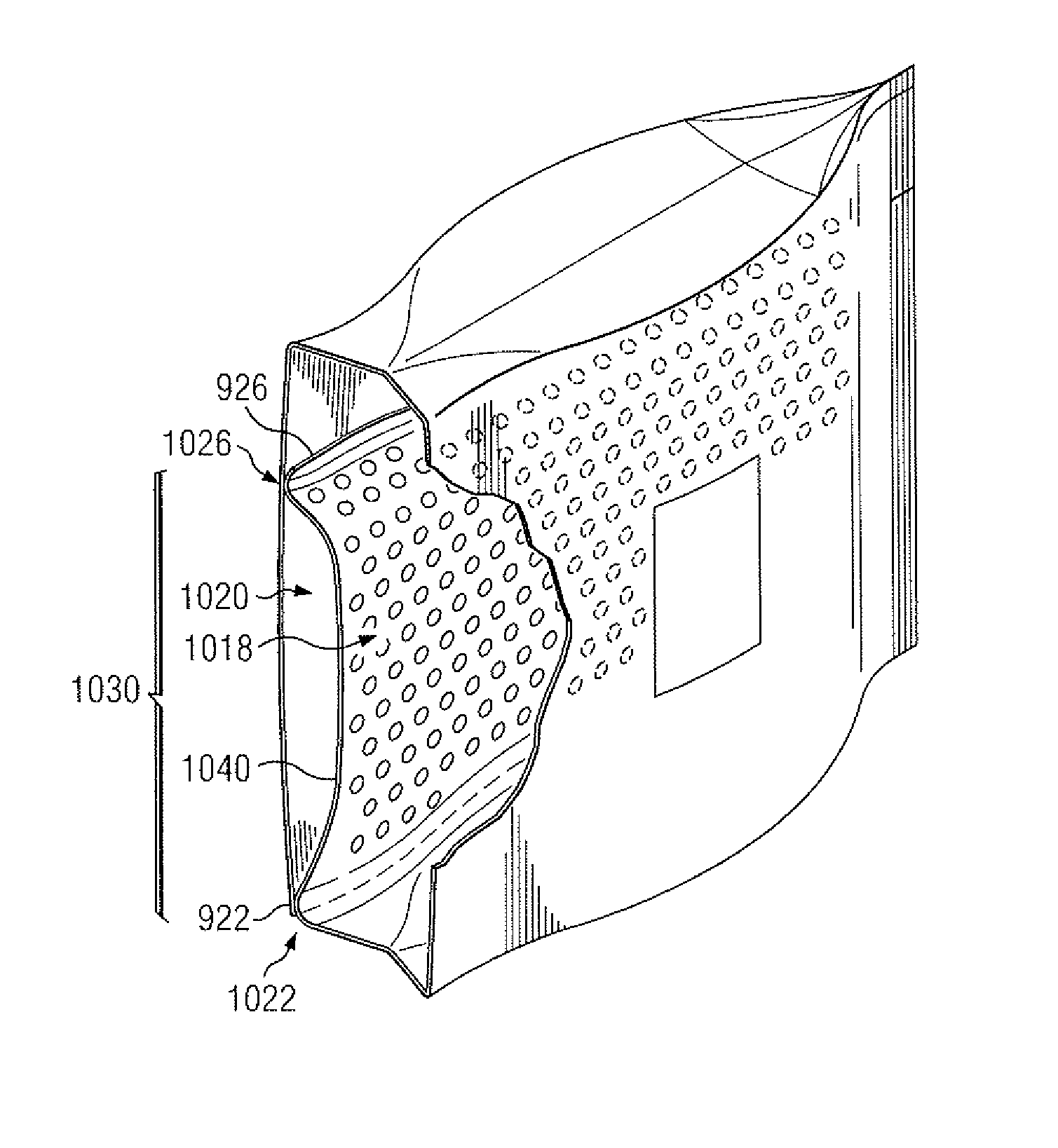

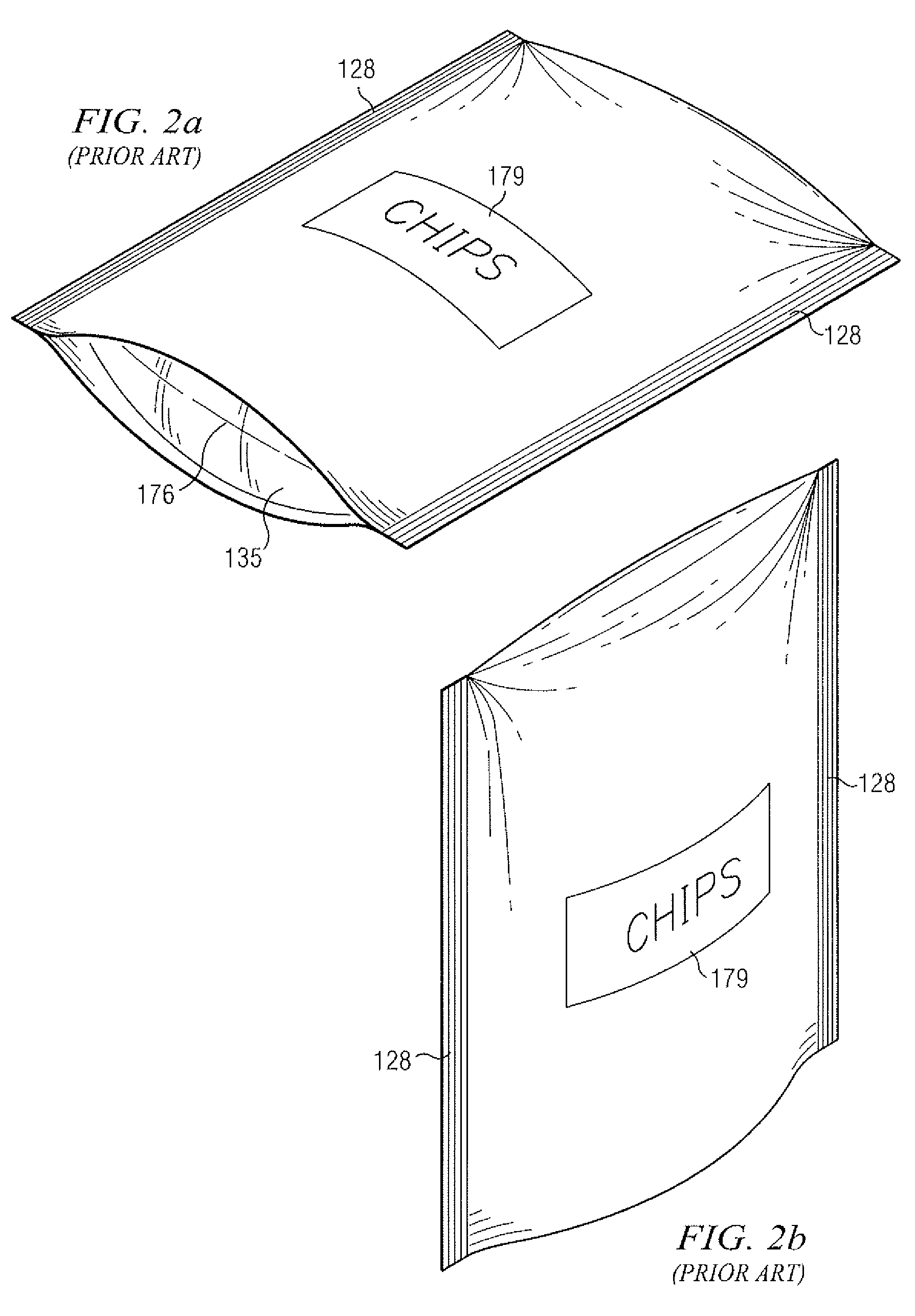

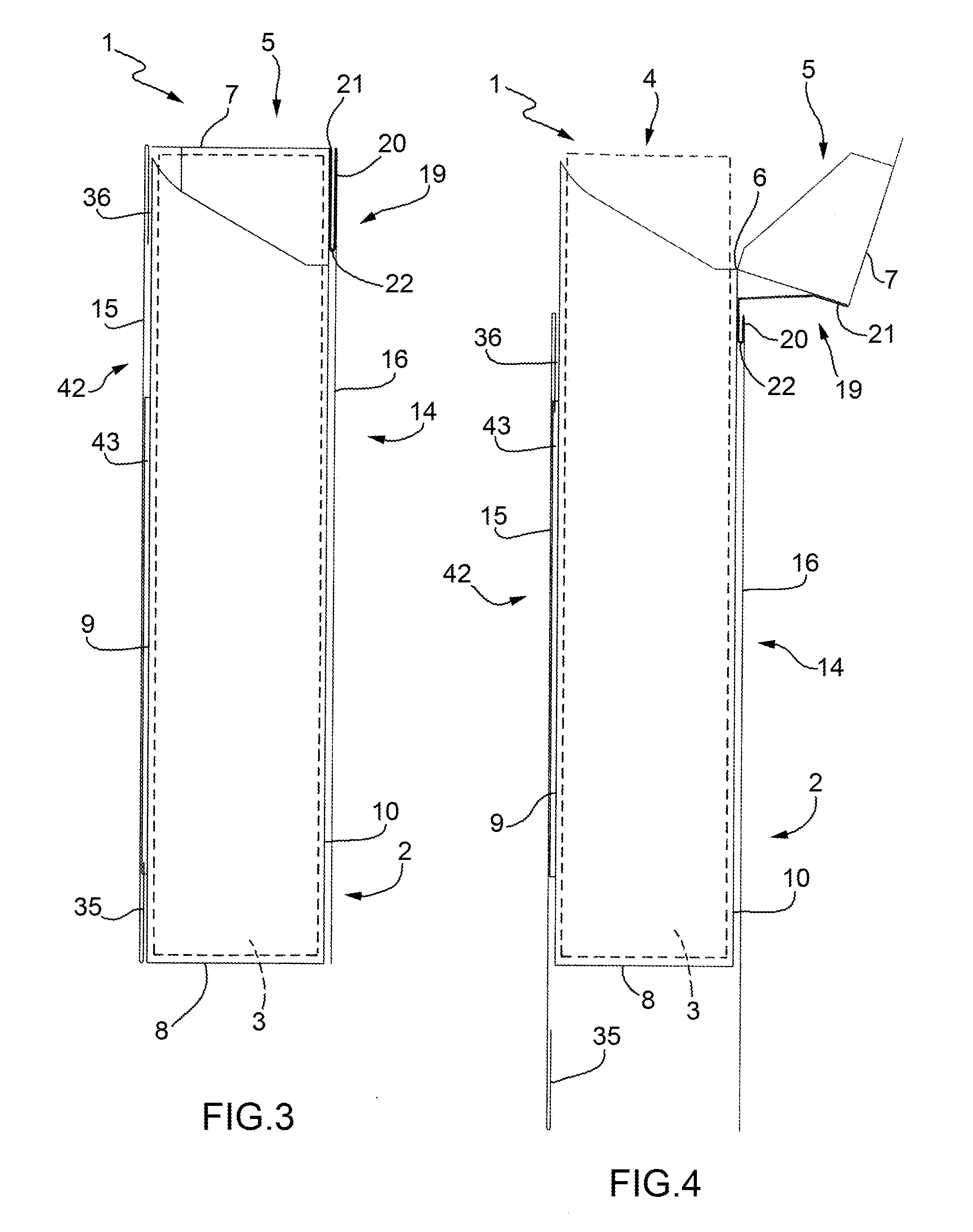

Method for Making a Multi-Compartment Microwavable Package Having a Permeable Wall Between Compartments

InactiveUS20070127853A1Easy to convertEasy to changeEnvelopes/bags making machineryBox making operationsMicrowaveHermetic packaging

A method for making a multi-compartment microwavable package having one or more open or closed compartments within the package, and method and apparatus for manufacturing the same, constructed by modification to existing vertical form, fill and seal packaging machines. The invention involves producing a multi-compartment bag having an internal permeable wall between compartments from a single sheet of flexible packaging film. A food product can be placed into the first compartment and steam pack can be placed into the second compartment.

Owner:FRITO LAY NORTH AMERICA INC

Container Filling Systems and Methods

A method of filling a cartridge having one or more pouches. The method may include the steps of placing the pouch on a support, placing a first cartridge half over the pouch and the support, placing the pouch and the first cartridge half on a second cartridge half to form the cartridge, maneuvering the cartridge to a filling unit, and filling the pouch within the cartridge.

Owner:THE COCA-COLA CO

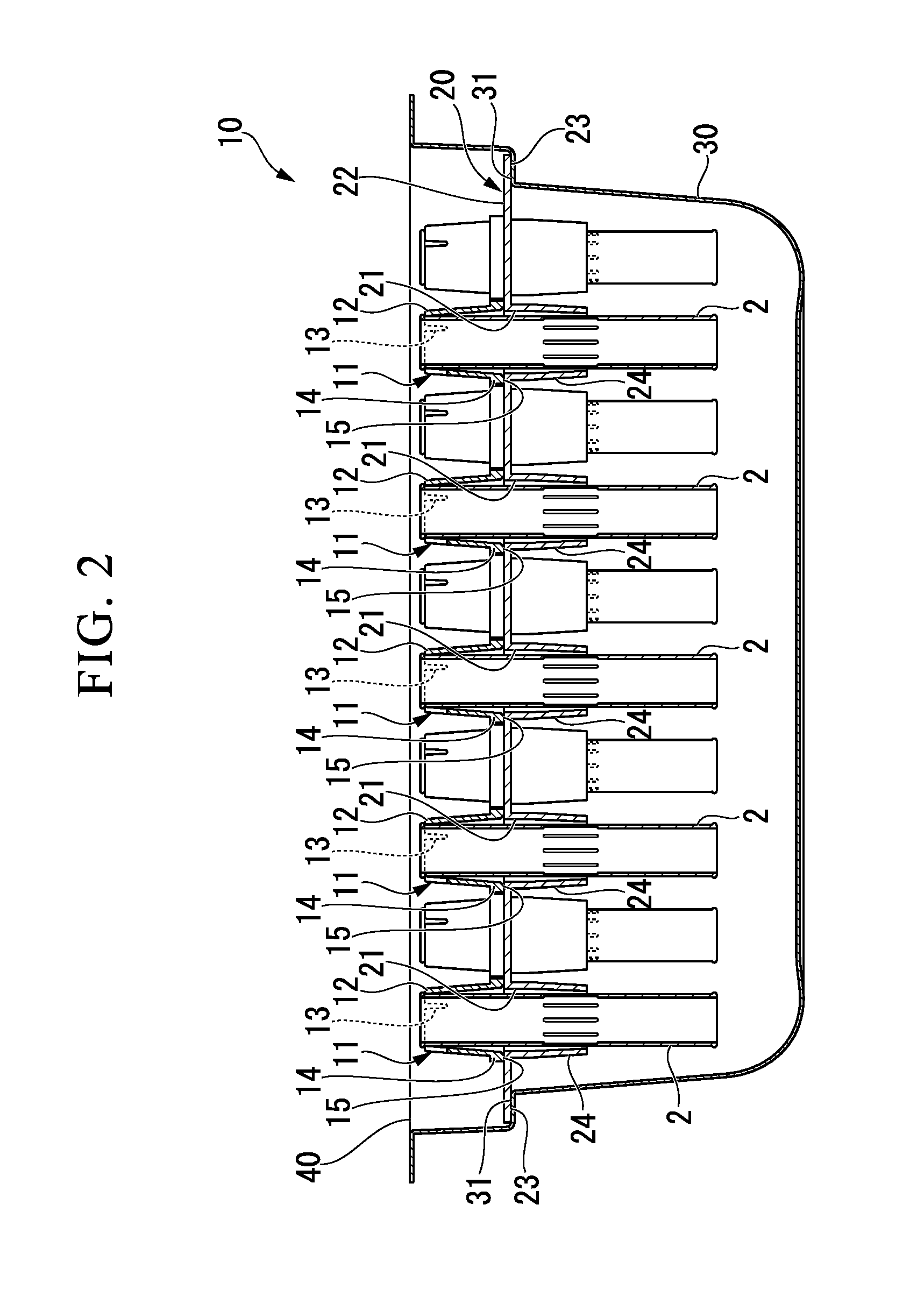

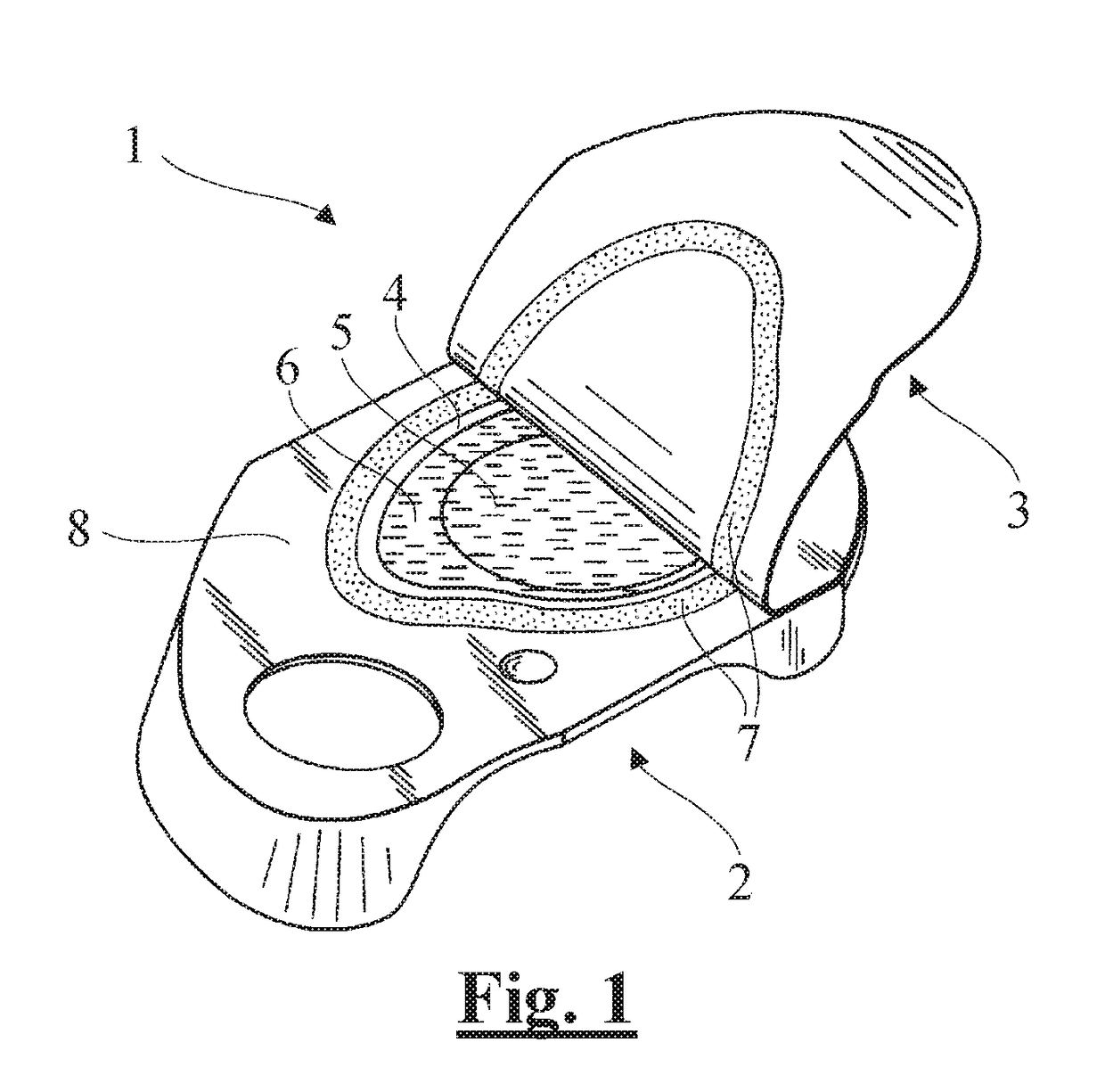

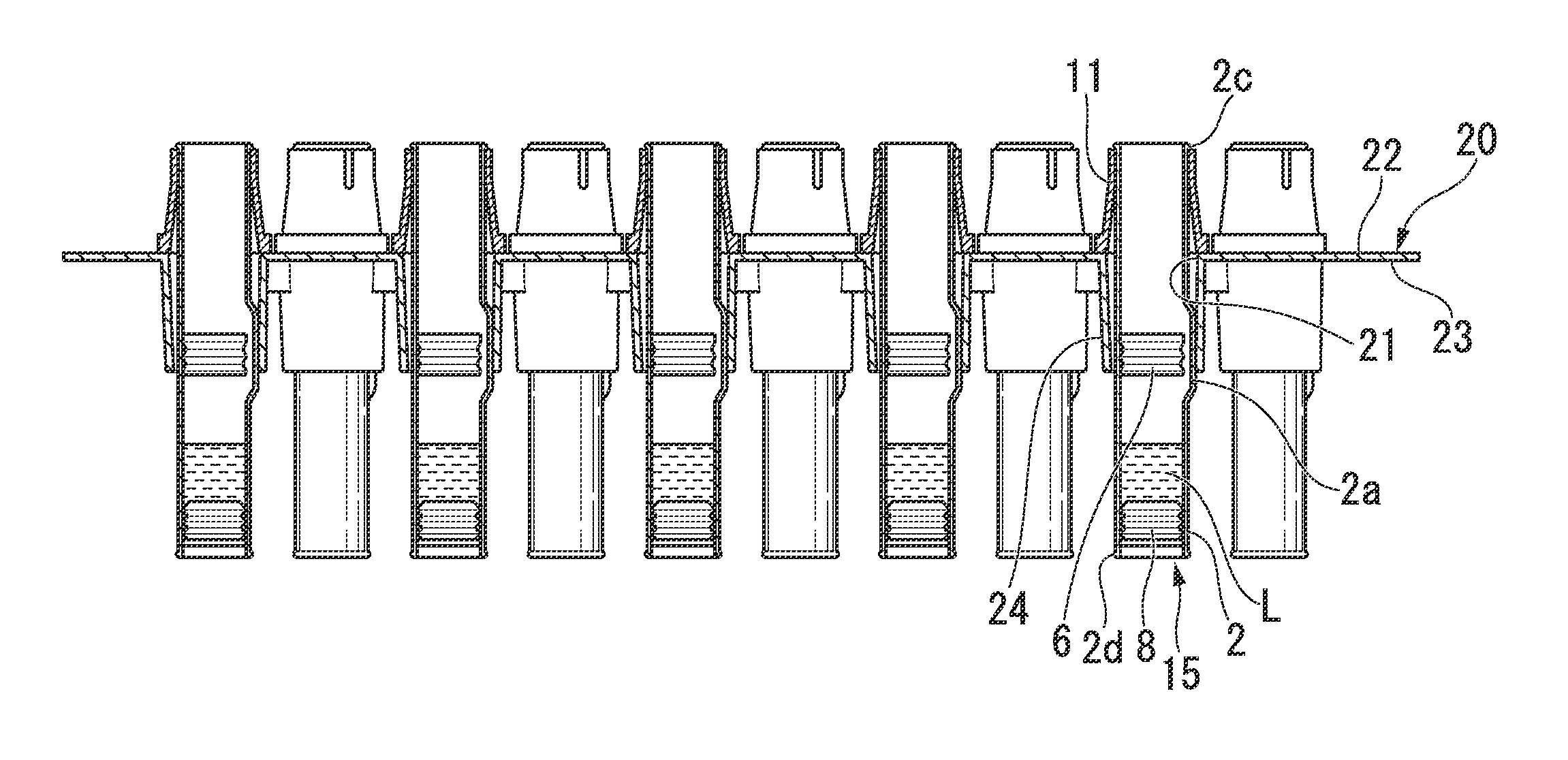

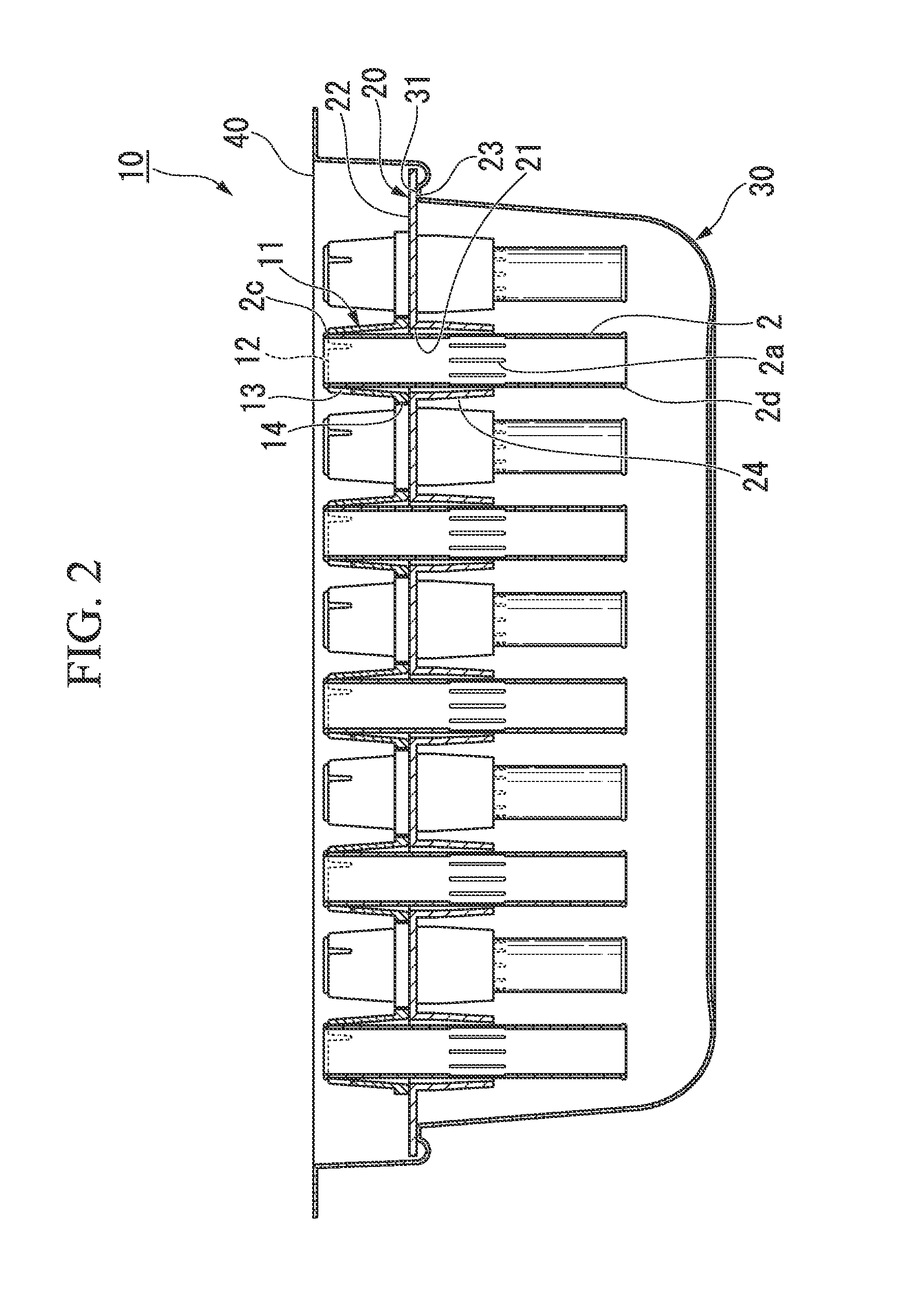

Cartridge set for manufacturing syringe and method for manufacturing dual-chamber type combined container-syringe

ActiveUS20130341849A1Easy to disassembleAdjustable positionDrying solid materials without heatInfusion syringesSyringe

A cartridge set including: a plurality of cartridges; a plurality of holders, each of which has an upper end externally fitted to the outer peripheral surface of each of the cartridges, and has a lower end face whose outer diameter is greater than the outer diameter of the outer peripheral surface of the cartridge; a supporting plate that has a plurality of through-holes, each of which has an inner diameter greater than the outer diameter of the outer peripheral surface of the cartridge and has each of the plurality of cartridges inserted therethrough; a storage box that stores the supporting plate therein; and a lid member that blocks an upper end opening of the storage box.

Owner:ARTE

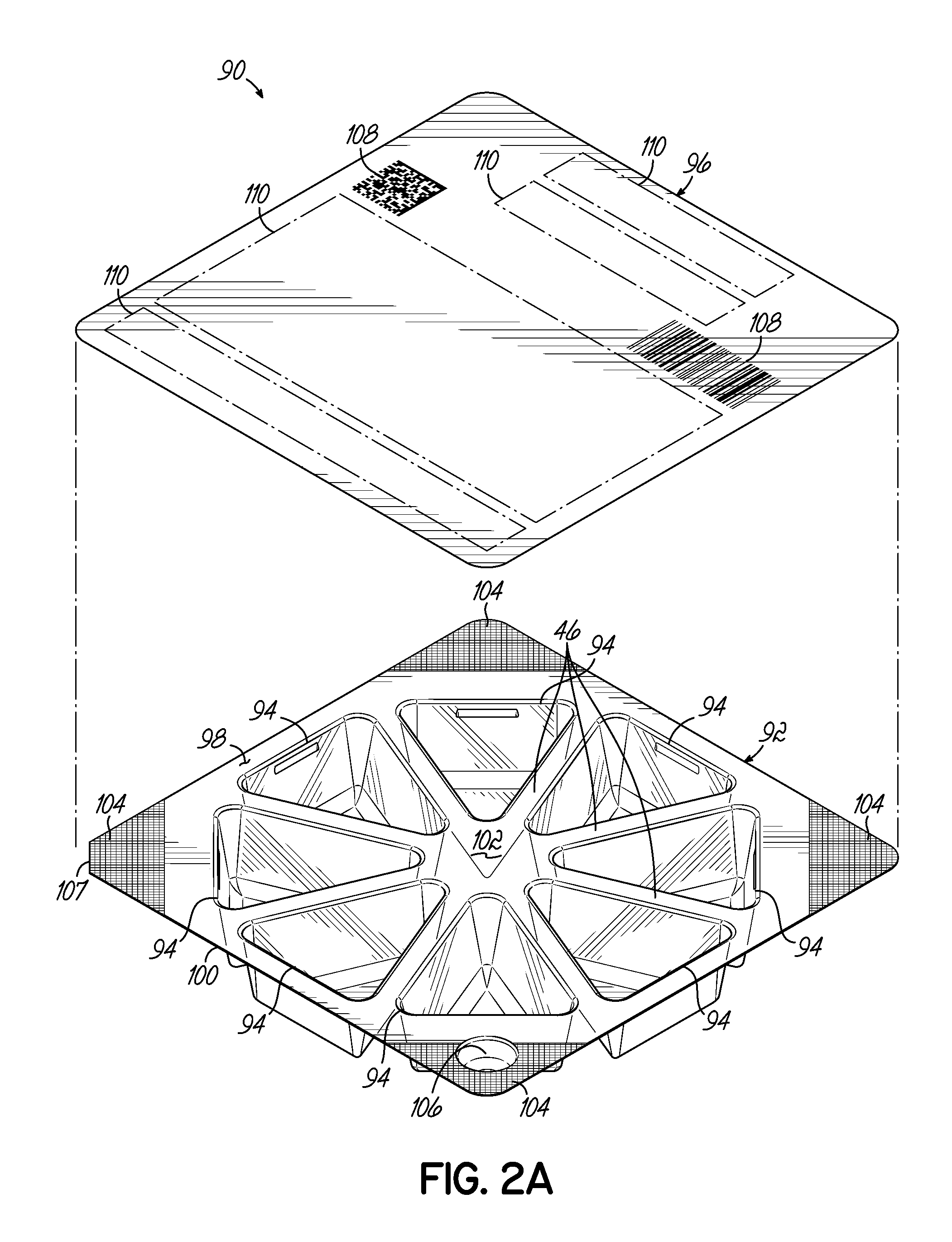

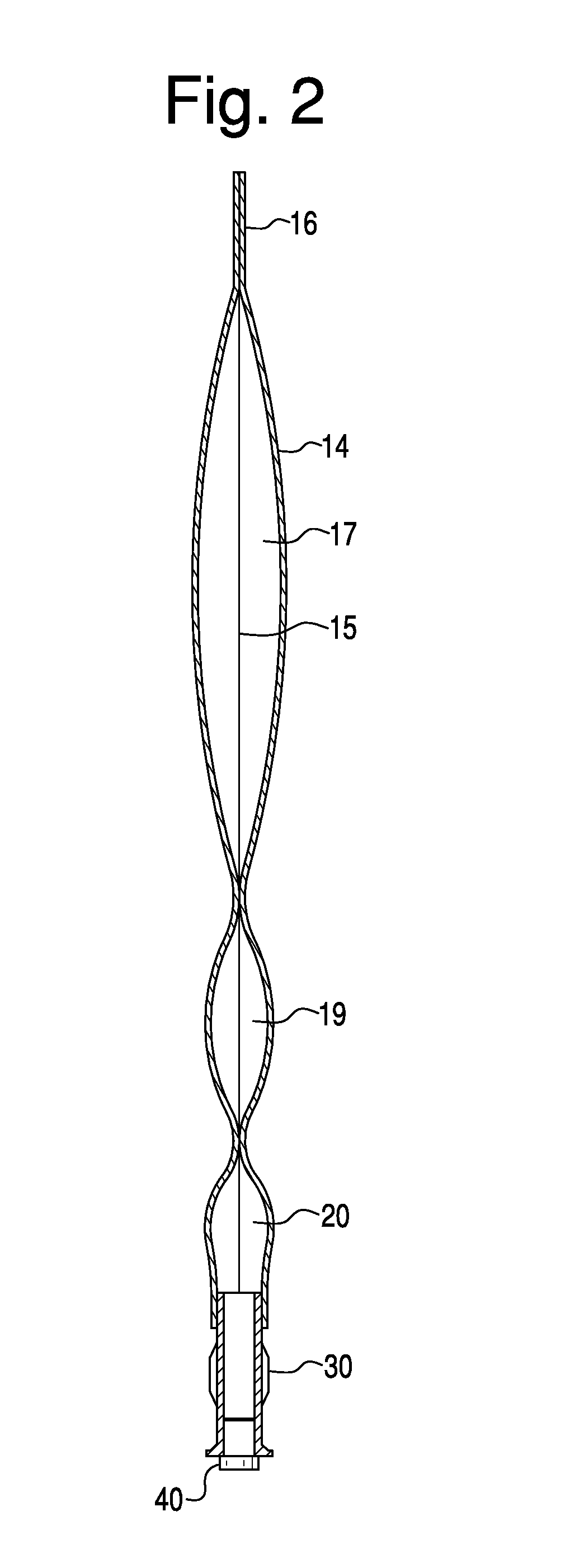

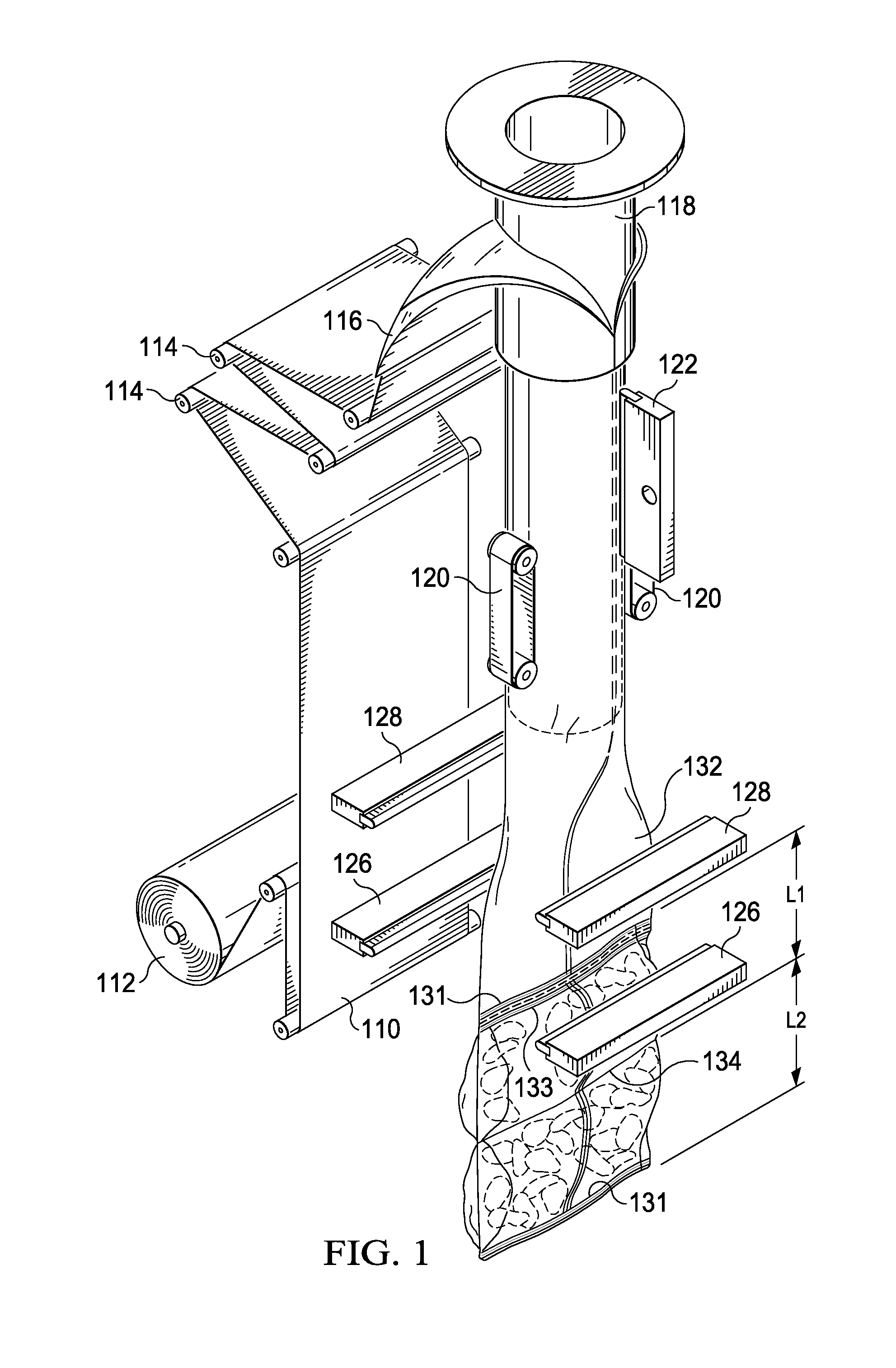

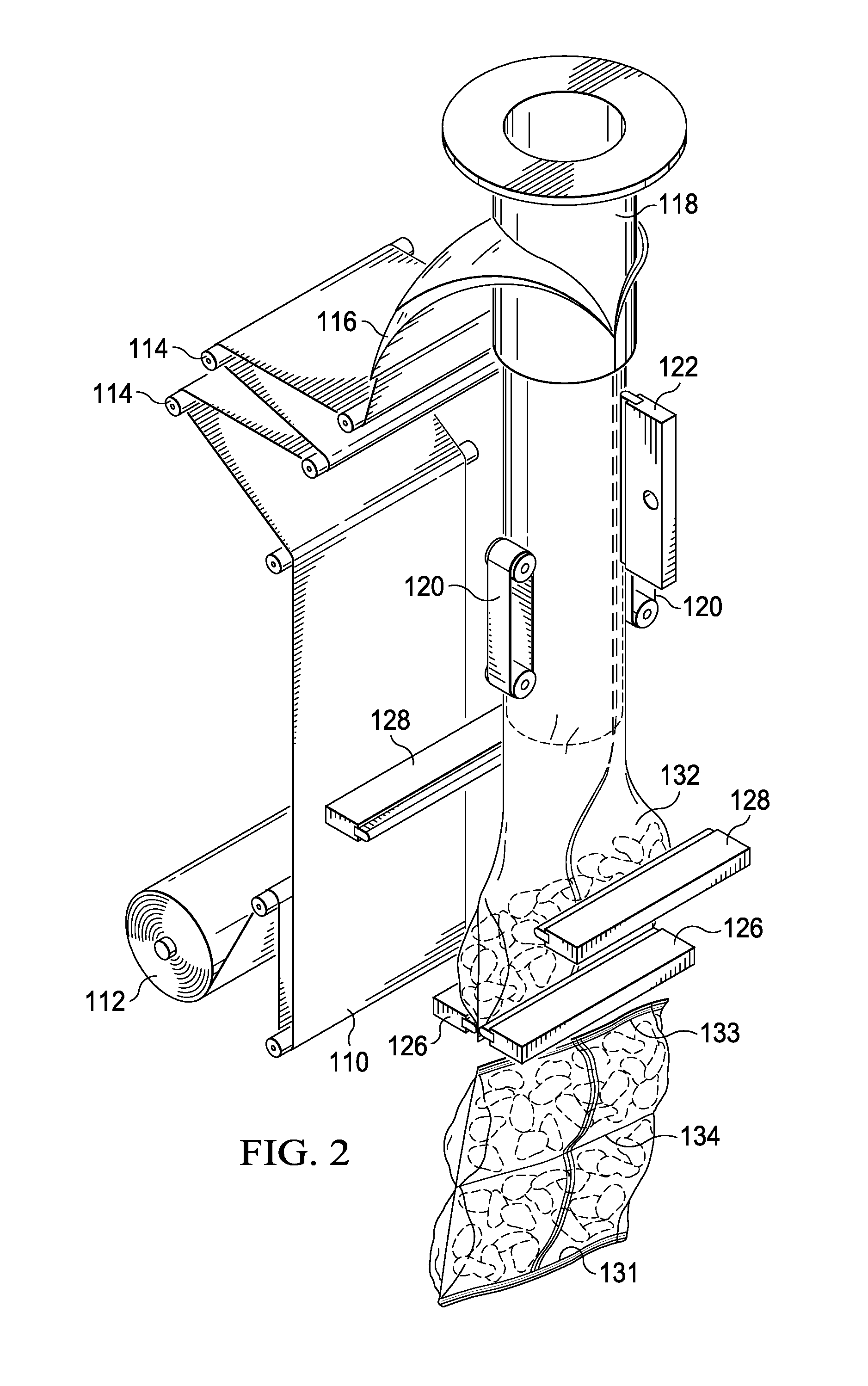

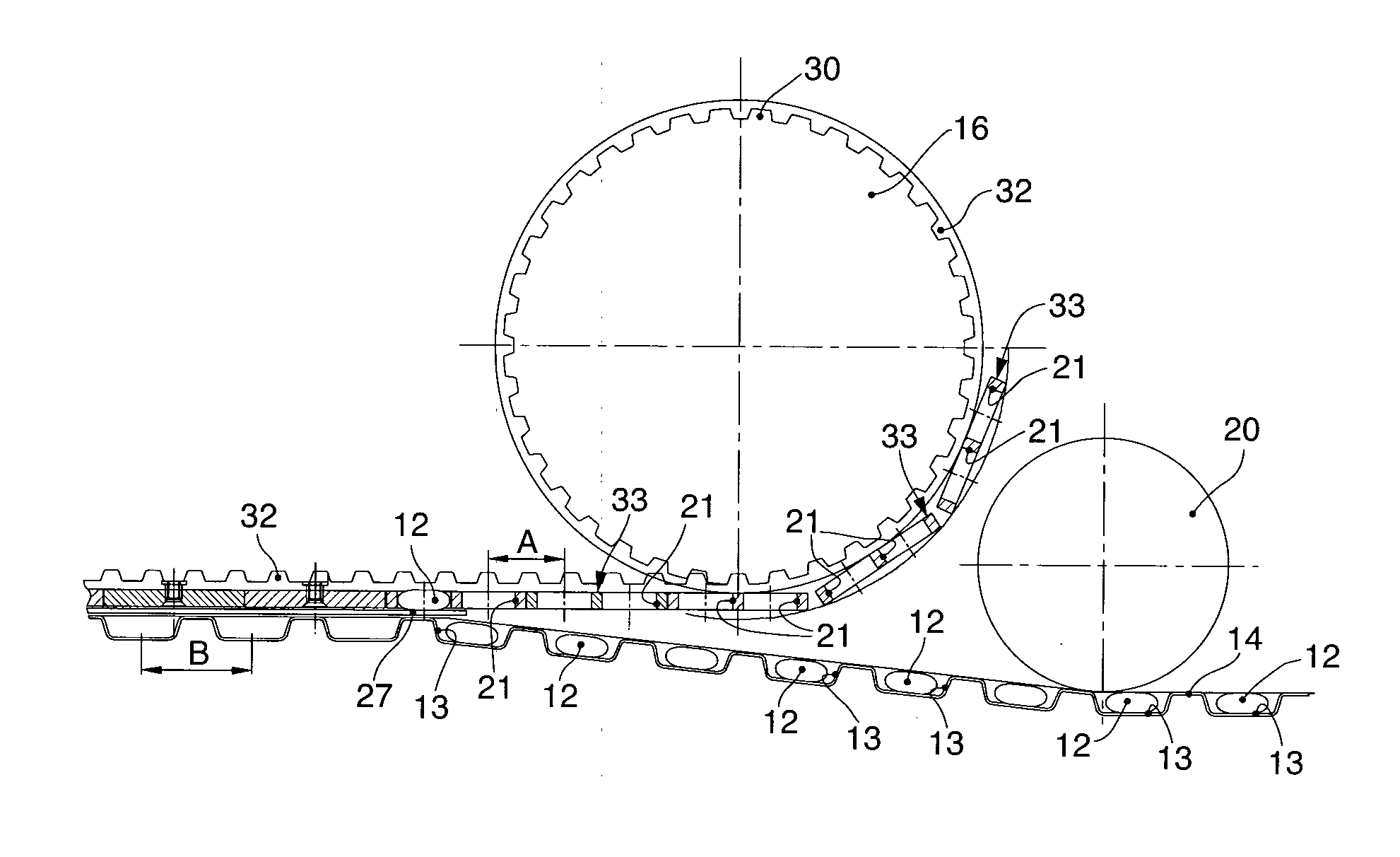

Device for forming partitioned film packages

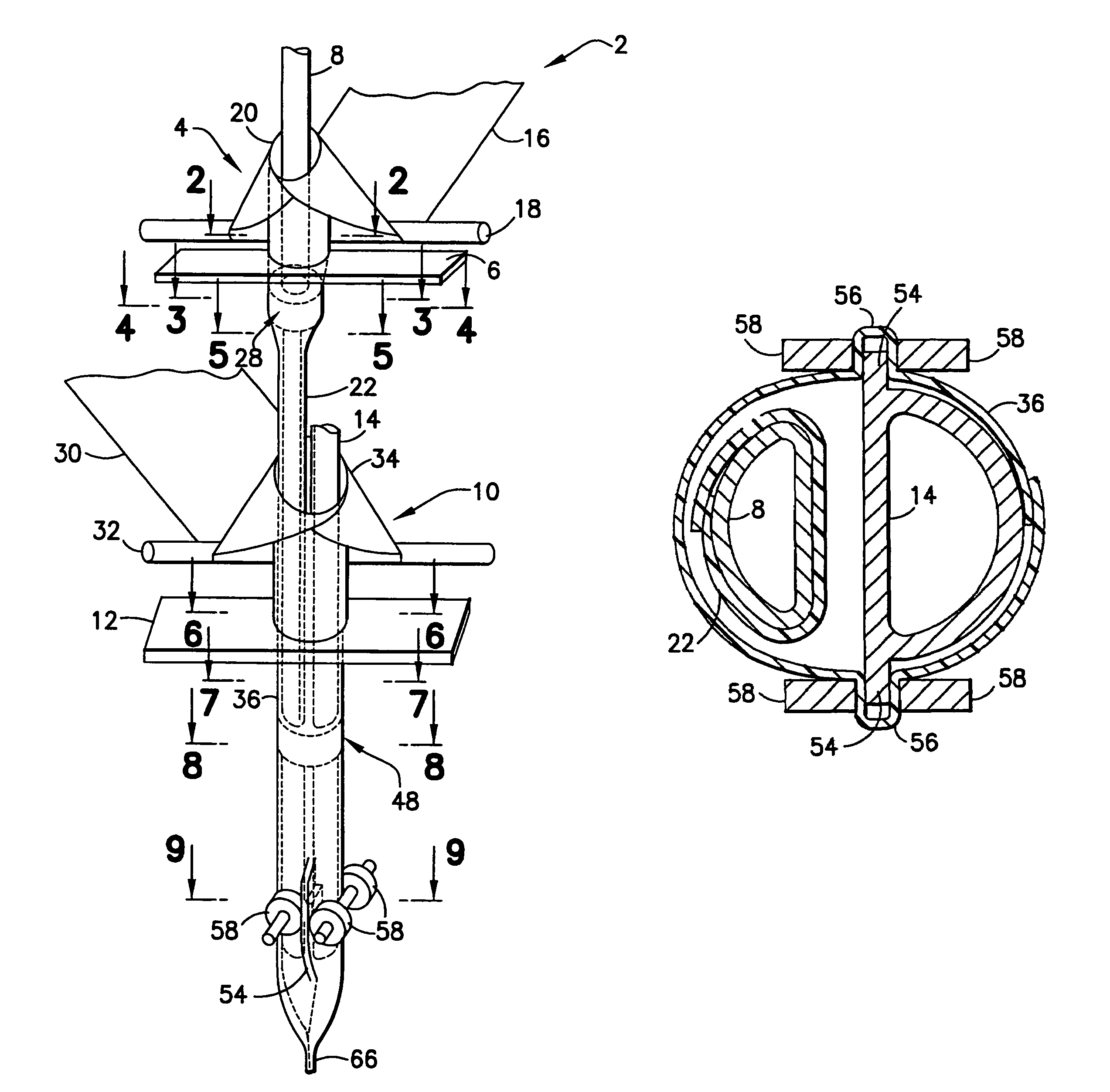

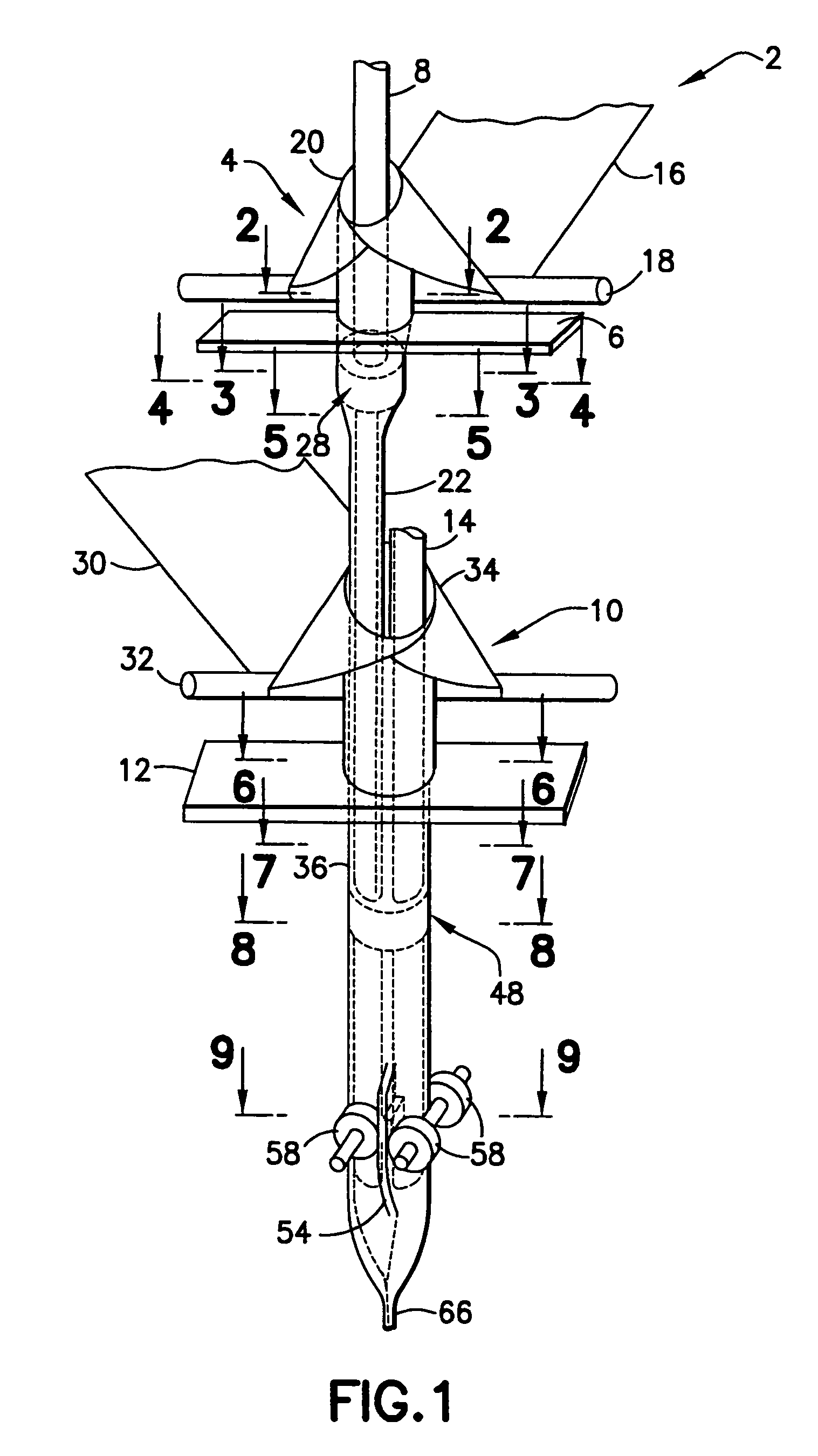

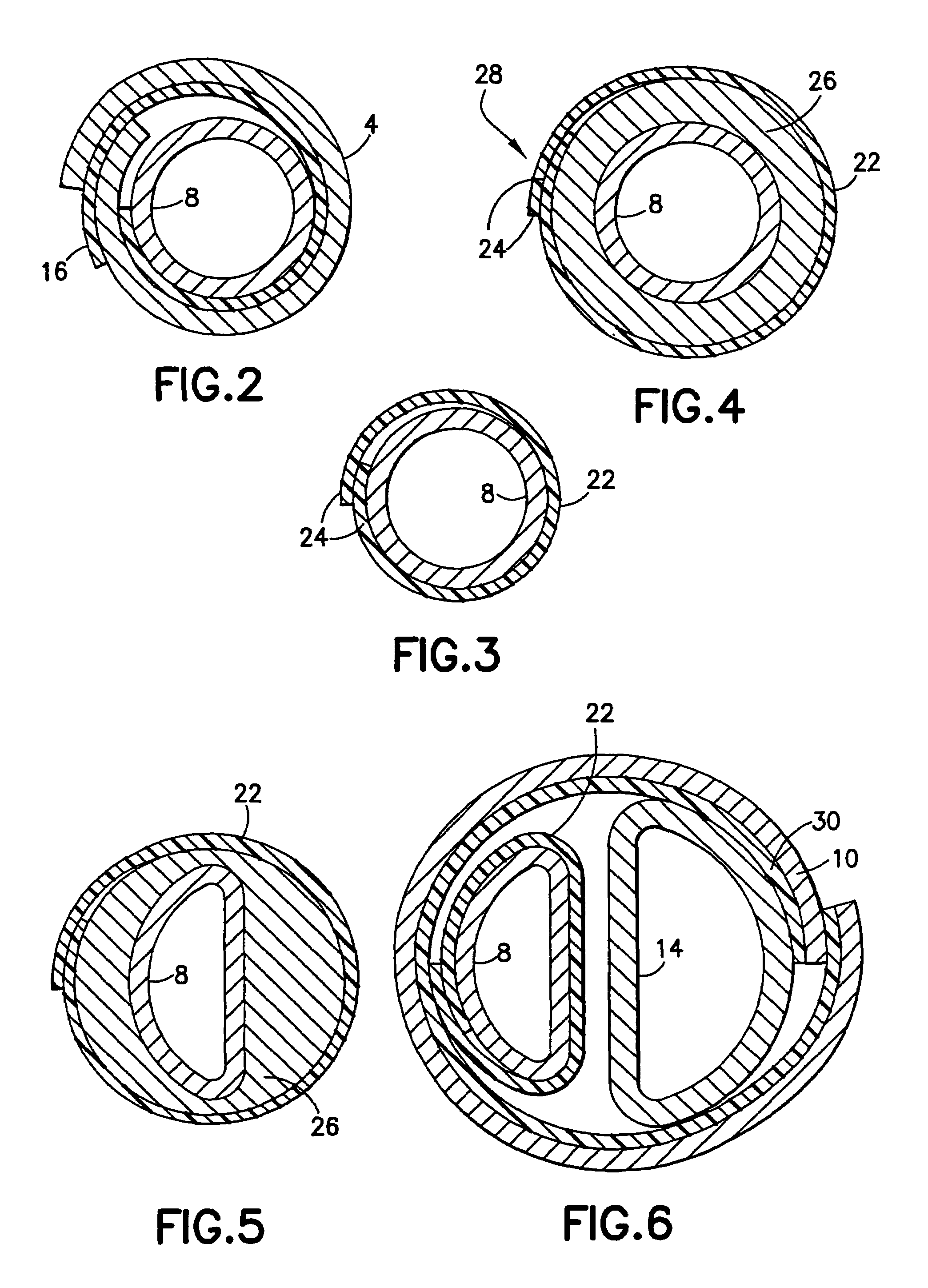

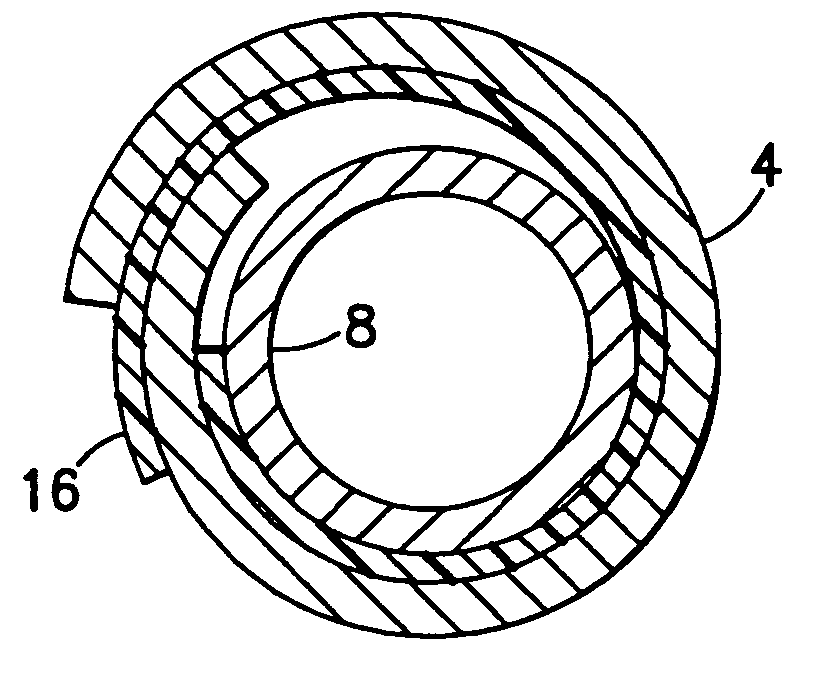

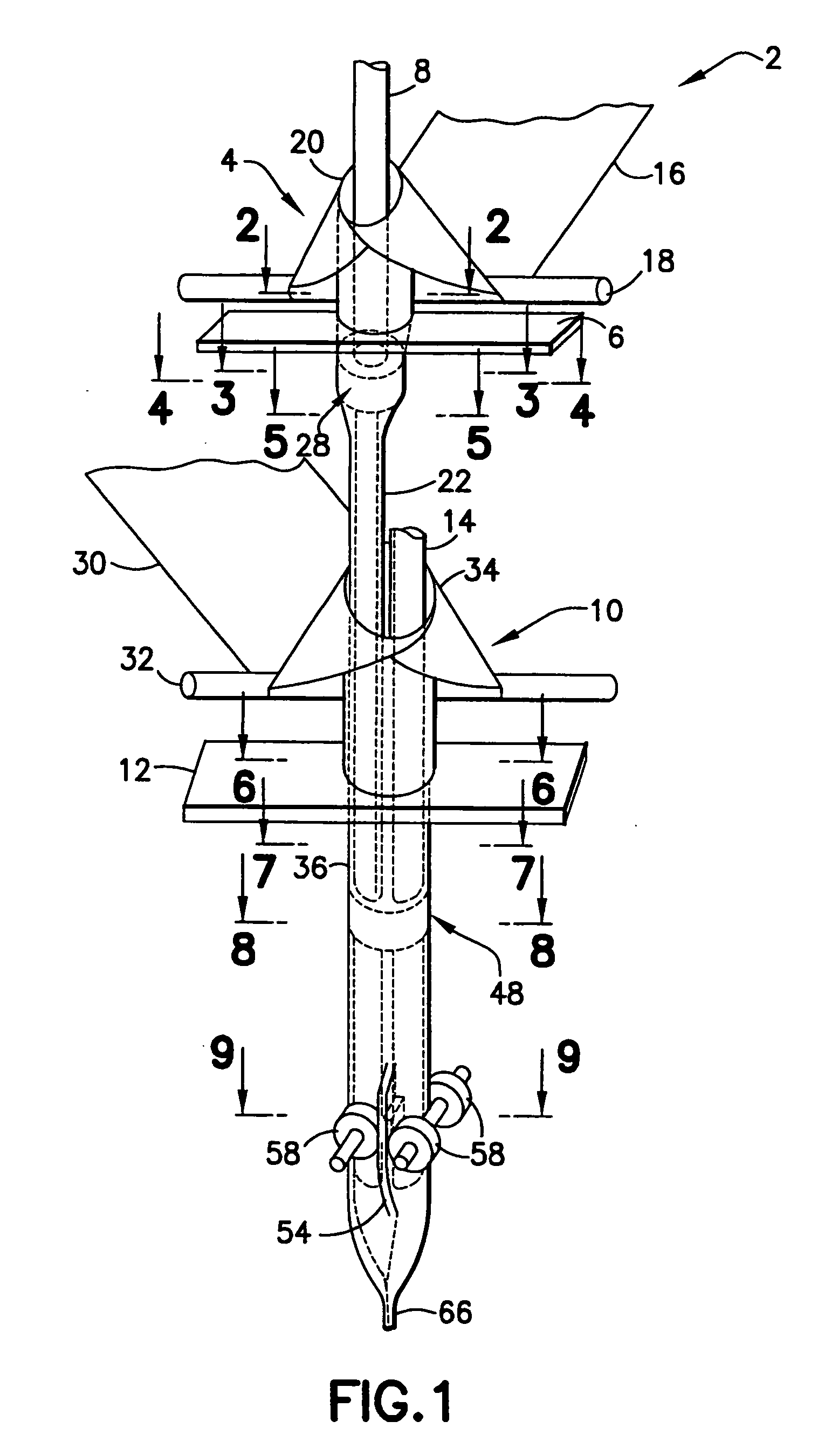

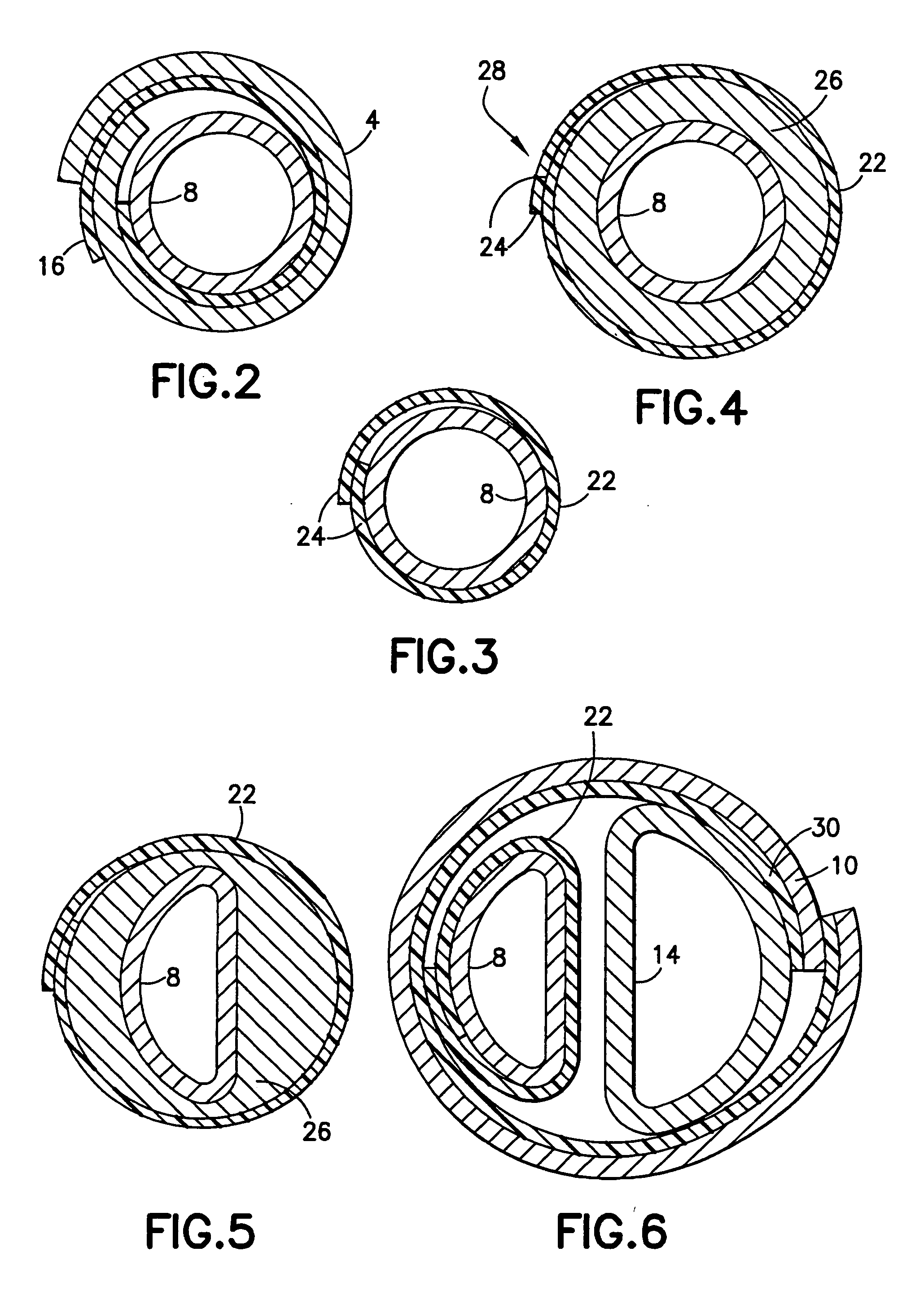

ActiveUS7681377B2Low costMinimize forcePaper/cardboard wound articlesFinal package aspectsThin membraneEngineering

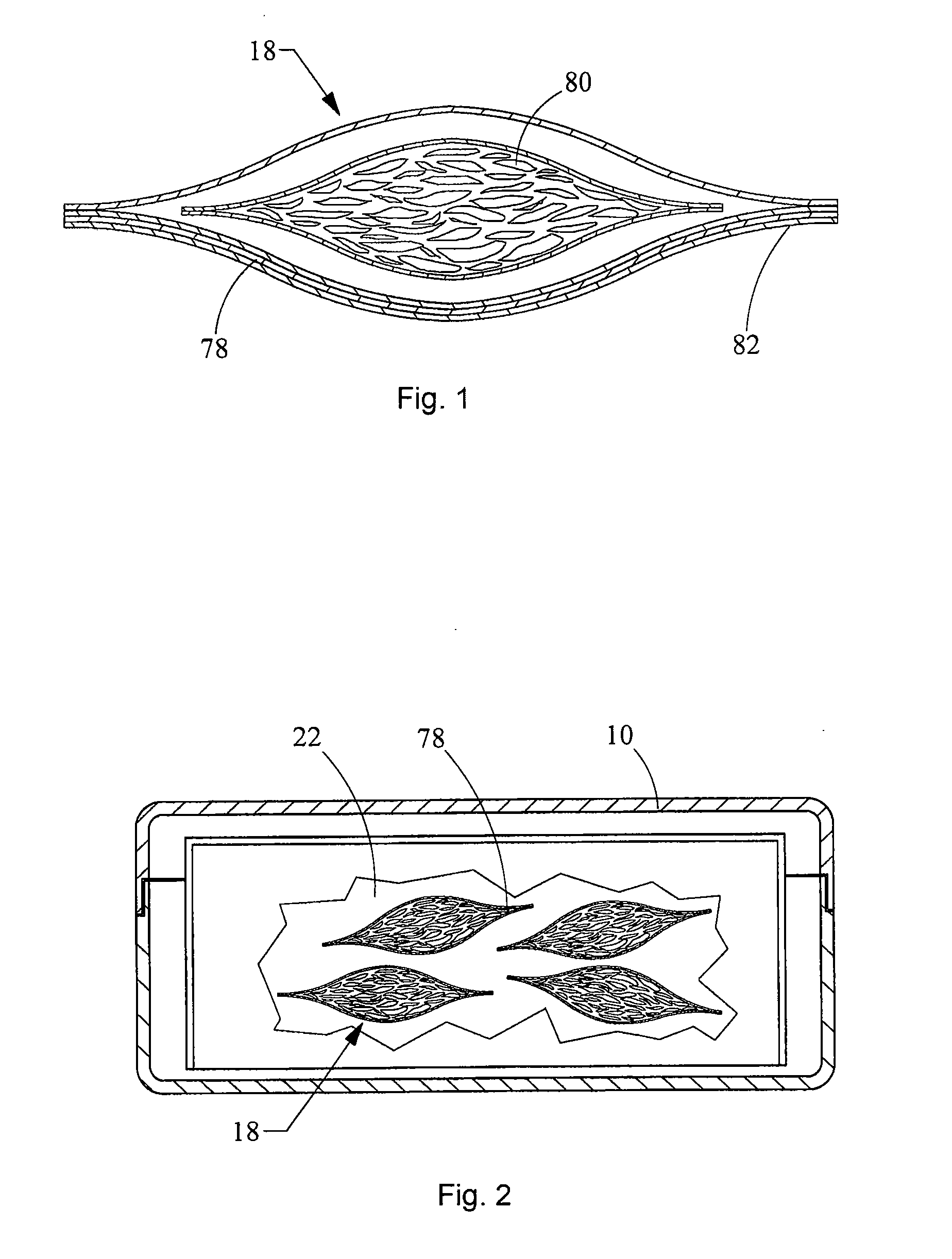

A process for producing partitioned packages by which a first film is formed into an elongated inner tube and a second film is formed into an elongated outer tube surrounding the inner tube. Reactive components are filled into the inner and outer tubes as the tubes are formed to maintain the reactive components separate from each other. Only the outer tube is actively engaged to advance the tube longitudinally. Frictional forces from the advancing outer tube are applied to the component within the outer tube and, in turn, are applied to the inner tube thereby advancing the inner tube at a rate substantially the same as the outer tube.

Owner:J LOK

Method for making a multi-compartment microwavable package having a permeable wall between compartments

InactiveUS7458195B2Easy to convertEasy to useEnvelopes/bags making machineryBox making operationsMicrowaveHermetic packaging

Owner:FRITO LAY NORTH AMERICA INC

Methods for manufacturing an aerosol product

ActiveUS9828170B2Stable storagePrevent oxidationCosmetic preparationsHair cosmeticsOxygenBULK ACTIVE INGREDIENT

An aerosol product comprising an aerosol container comprising a container body and an aerosol valve fixed to an opening of the container body, and an aqueous concentrate and a propellant being filled in the aerosol container, wherein the aqueous concentrate comprises an active ingredient having reactivity with oxygen, and an inert ingredient is present in at least a part of an injection passage of the aerosol valve, even though the aqueous concentrate comprising an active ingredient having reactivity with oxygen is filled, oxidation of the active ingredient is inhibited in the aerosol valve, and an aerosol product that can be stored stably for a long period of time and a method for manufacturing the same can be provided.

Owner:DAIZO

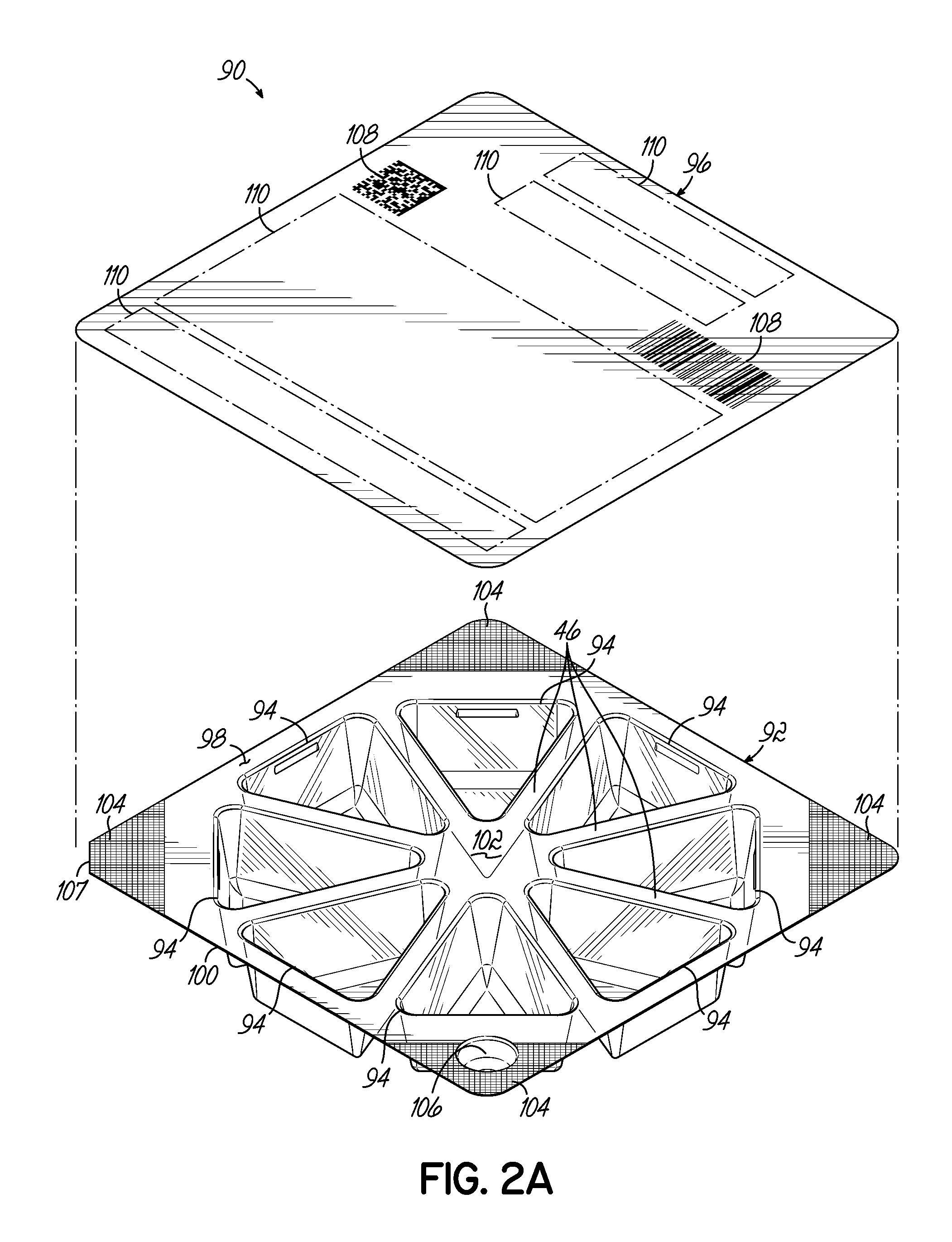

Methods and apparatus for automated filling of packagings with medications

ActiveUS9073206B2Rapidly and accurately placed into easy-to-use packagingsImprove complianceProgramme-controlled manipulatorDigital data processing detailsBiomedical engineering

Methods for filling packagings with at least one medication includes receiving filling instructions for an order and operating an automated packaging station to fill a plurality of packagings making up an order. Operating the automated packaging station includes positioning a plurality of cassettes containing the medications needed for the order onto a feeder base at a single filling location, and moving each of the plurality of packagings to the filling location. The operation also includes actuating at least one of the cassettes at the feeder base simultaneously and according to the filling instructions when each packaging is located at the filling location. Automated packaging stations operable to perform the above filling instructions are also provided.

Owner:OMNICARE INC

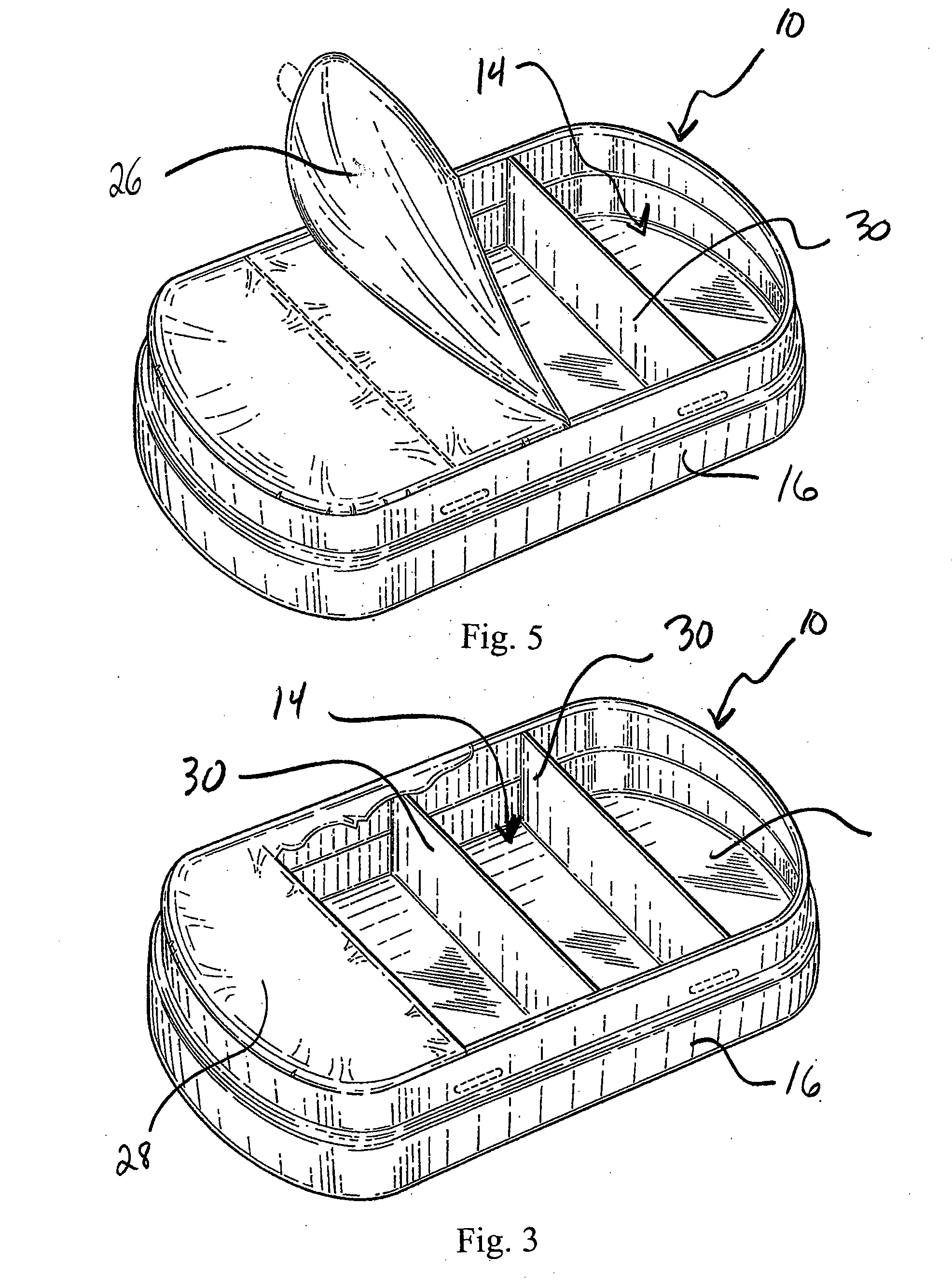

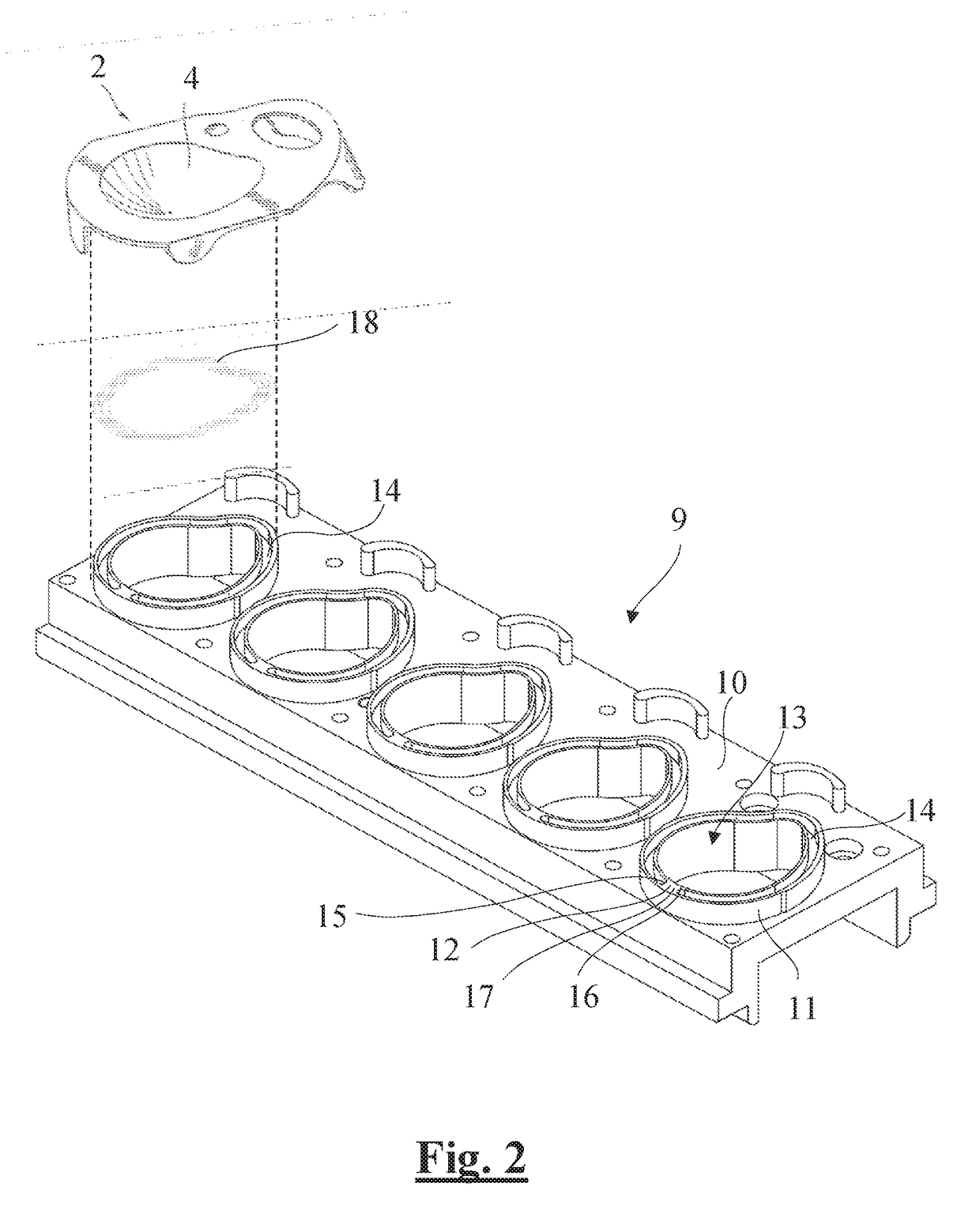

Method for thermally bonding together a cover film of an ophthalmic lens package and a base part of the ophthalmic lens package

A method for thermally bonding together a cover film (3) of an ophthalmic lens package (1) and a base part (2) of the ophthalmic lens package (1), such as a contact lens package, in particular a soft contact lens package, including the steps ofproviding a package holder (9) supporting a base part (2) and a cover film (3) arranged thereon, the base part (2) comprising a depression (4) containing an ophthalmic lens (5) immersed in a liquid (6);mechanically pressing the cover film (3) and the base part (2) together along a bonding area (7) having a shape completely enclosing the depression (4) while applying heat to the bonding area (7), thereby thermally bonding together the cover film (3) and the base part (2) along the bonding area (7);wherein the step of providing the package holder (9) includes arranging a flexible support element (18) on an upper surface (10) of the package holder (9) to form a support area (19) corresponding in shape to and being arranged in alignment with the bonding area (7), with the flexible support element (18) having a flexibility higher than the flexibility of the base part (2).

Owner:ALCON INC

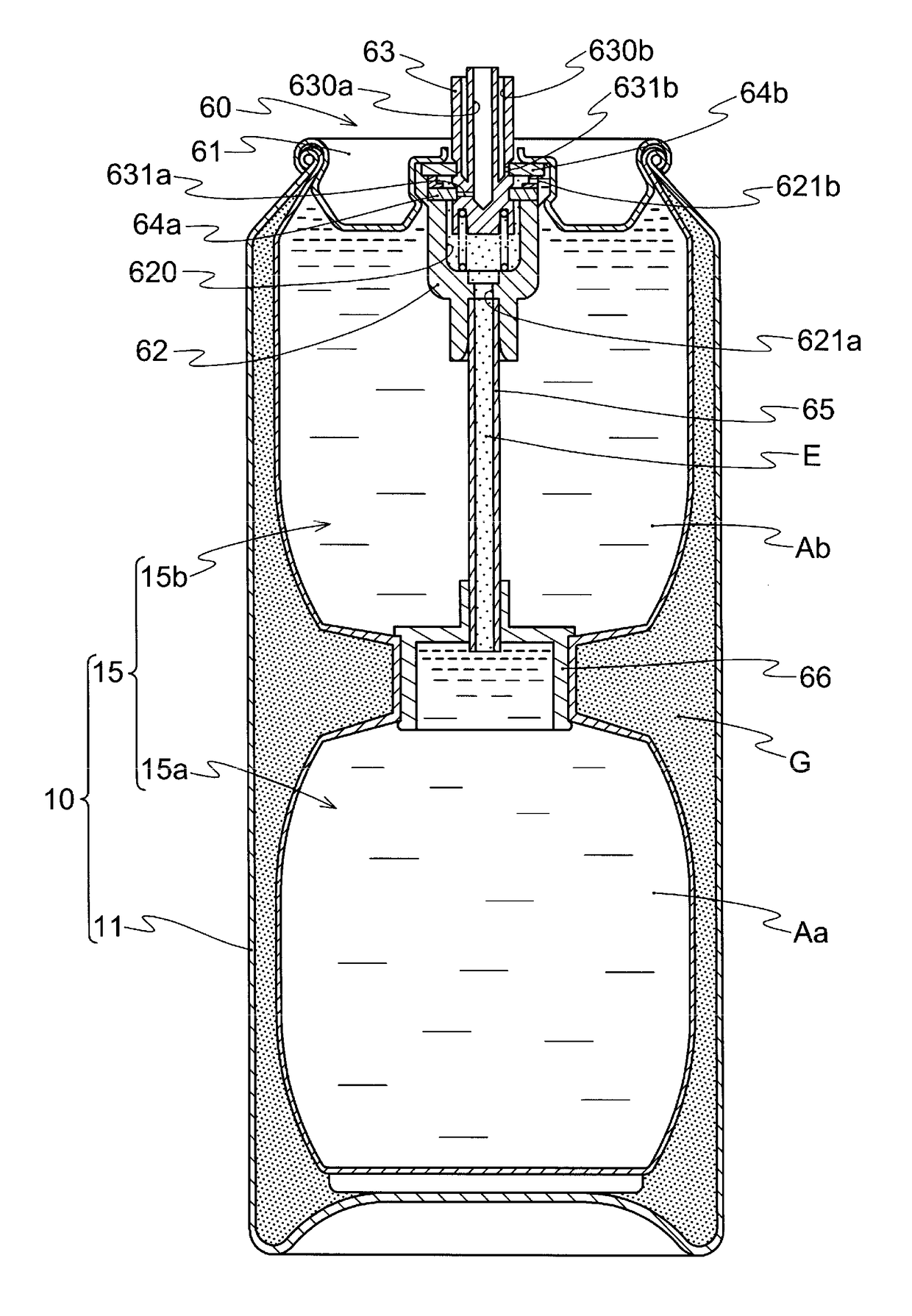

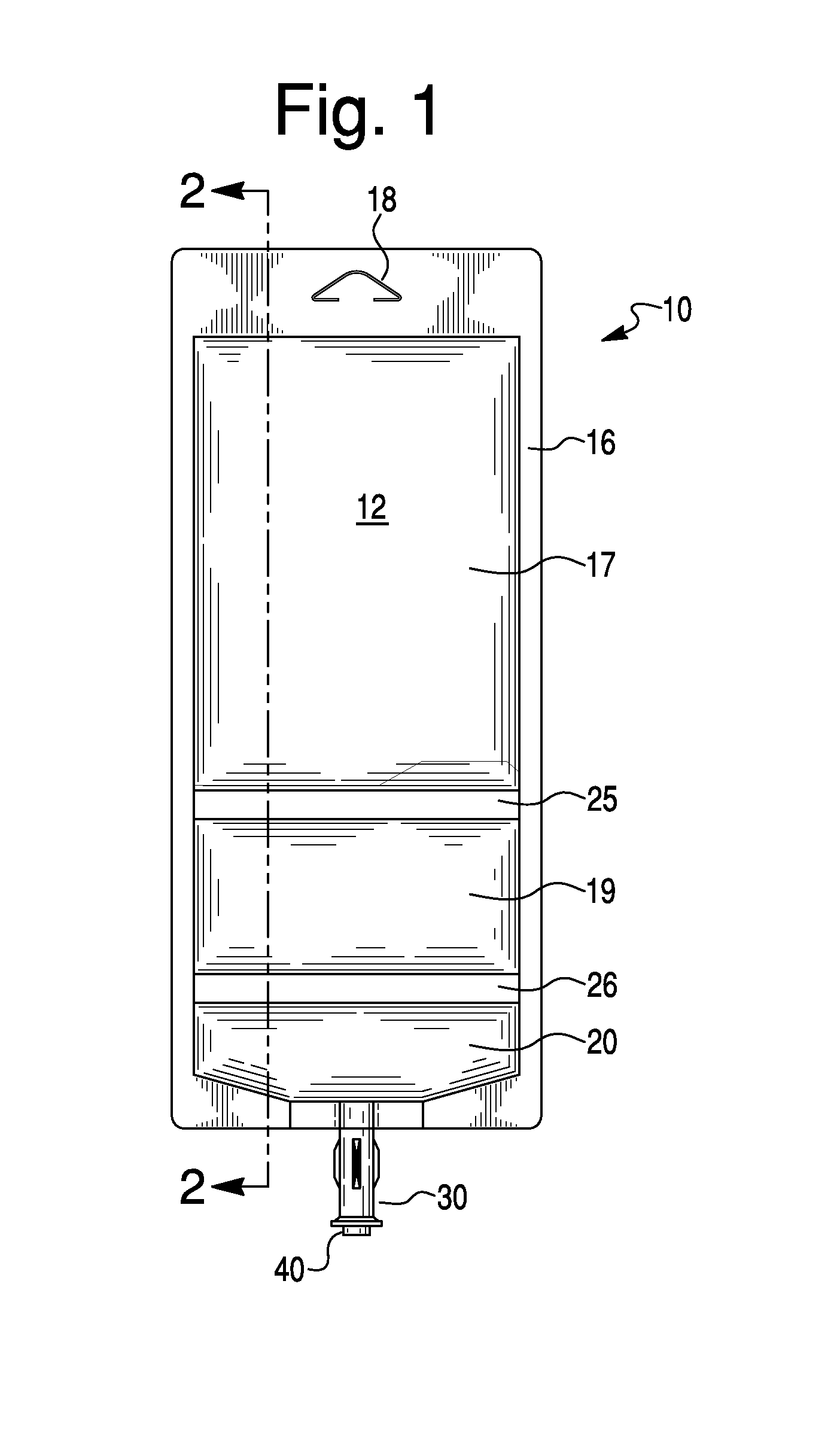

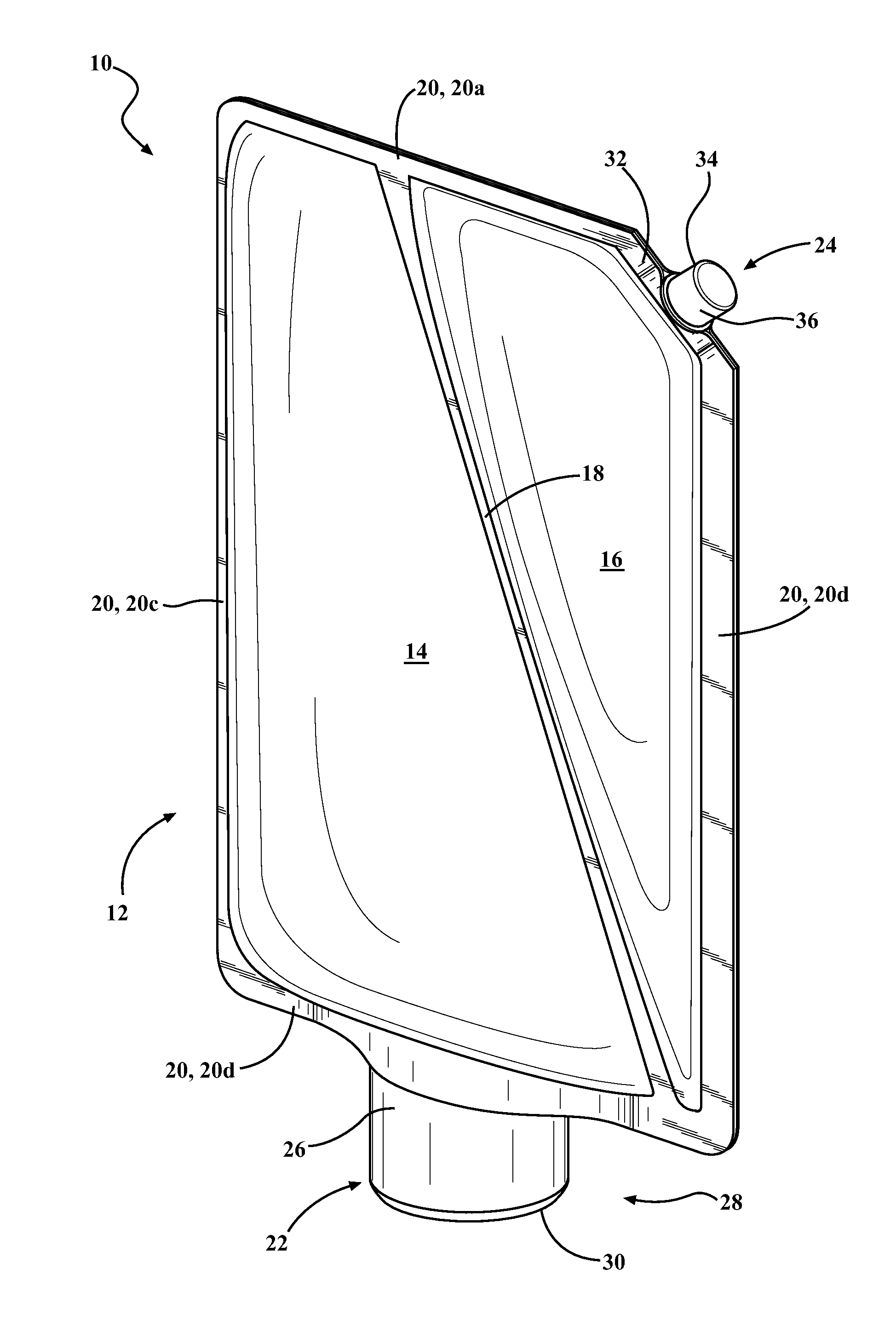

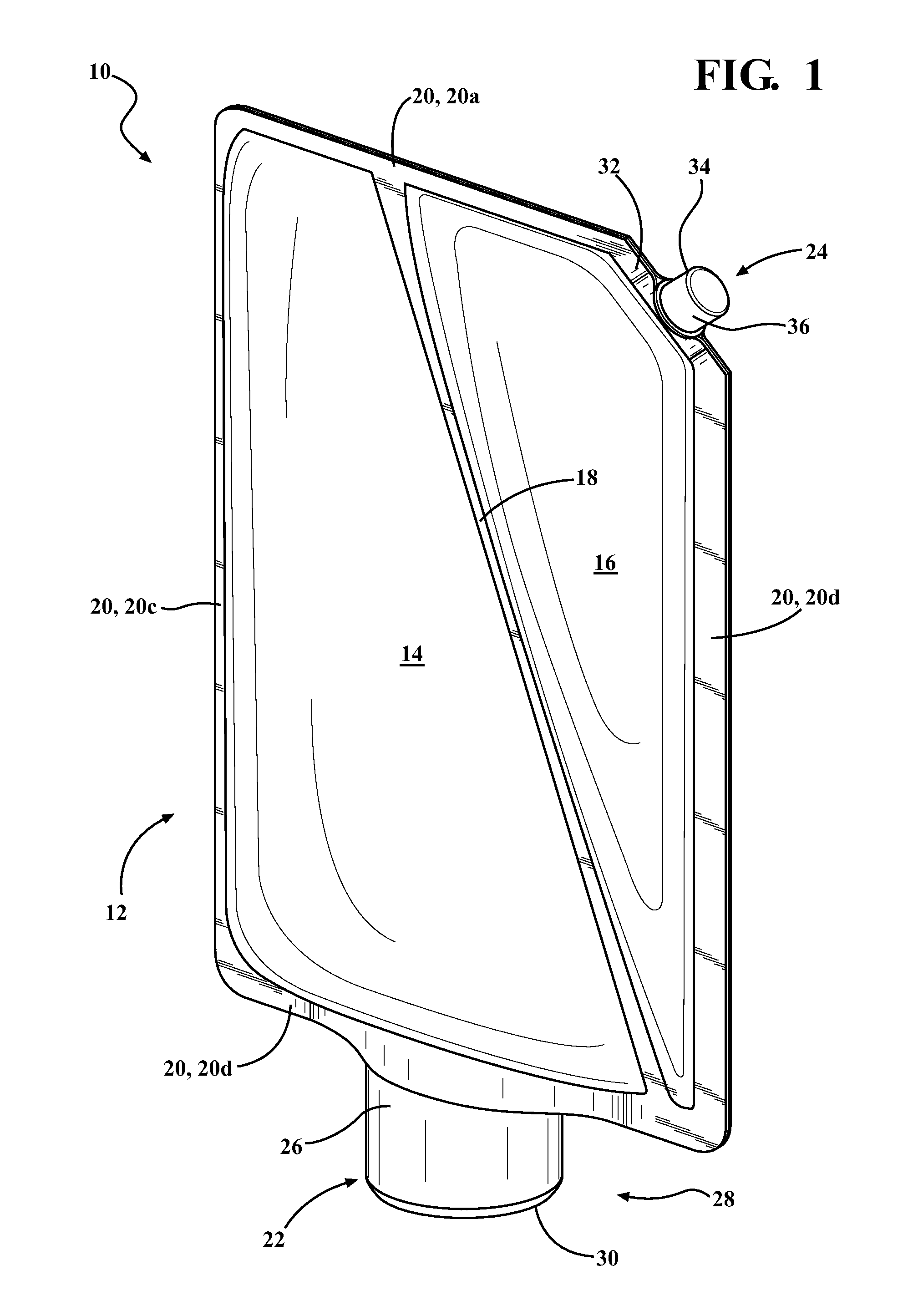

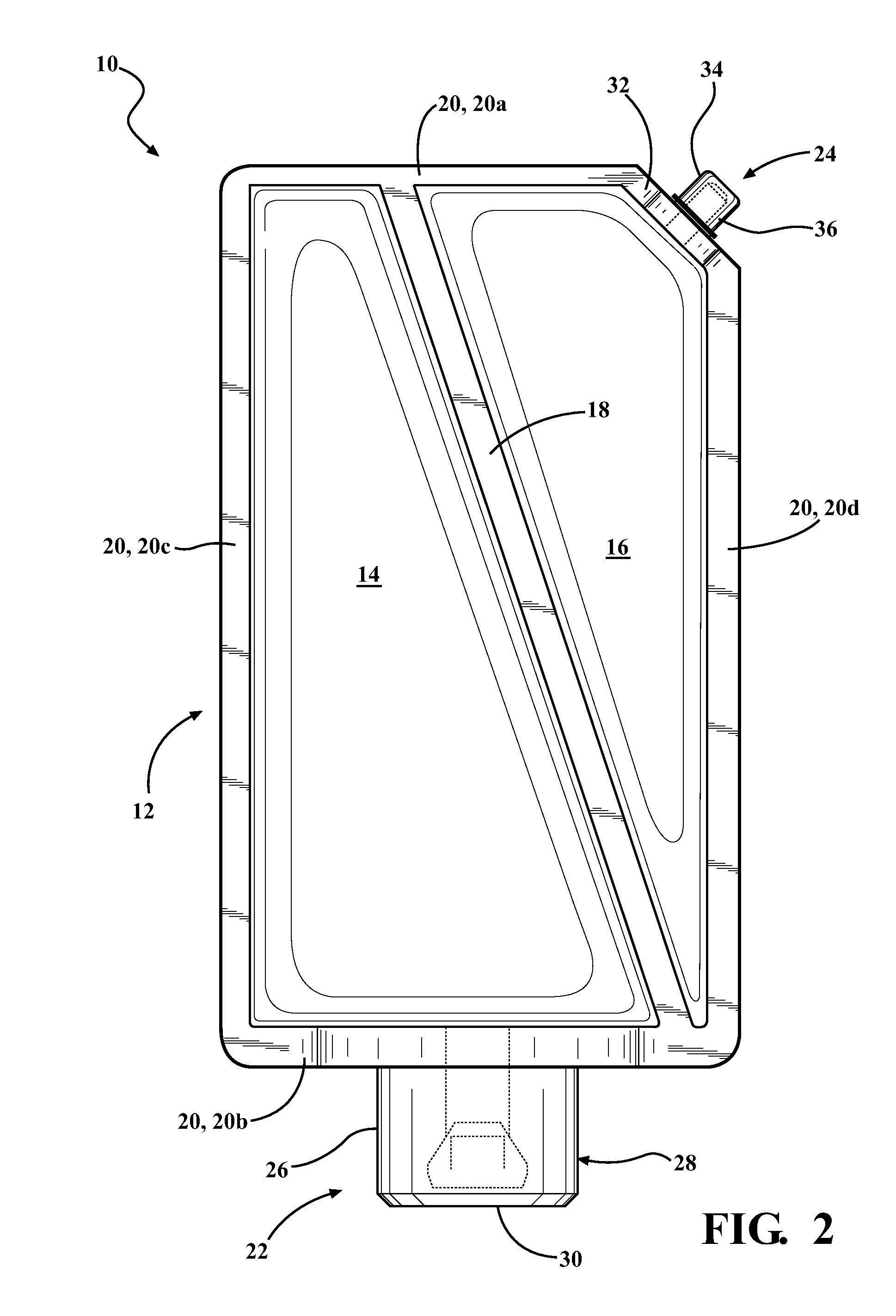

Flexible container, system and method of manufacture

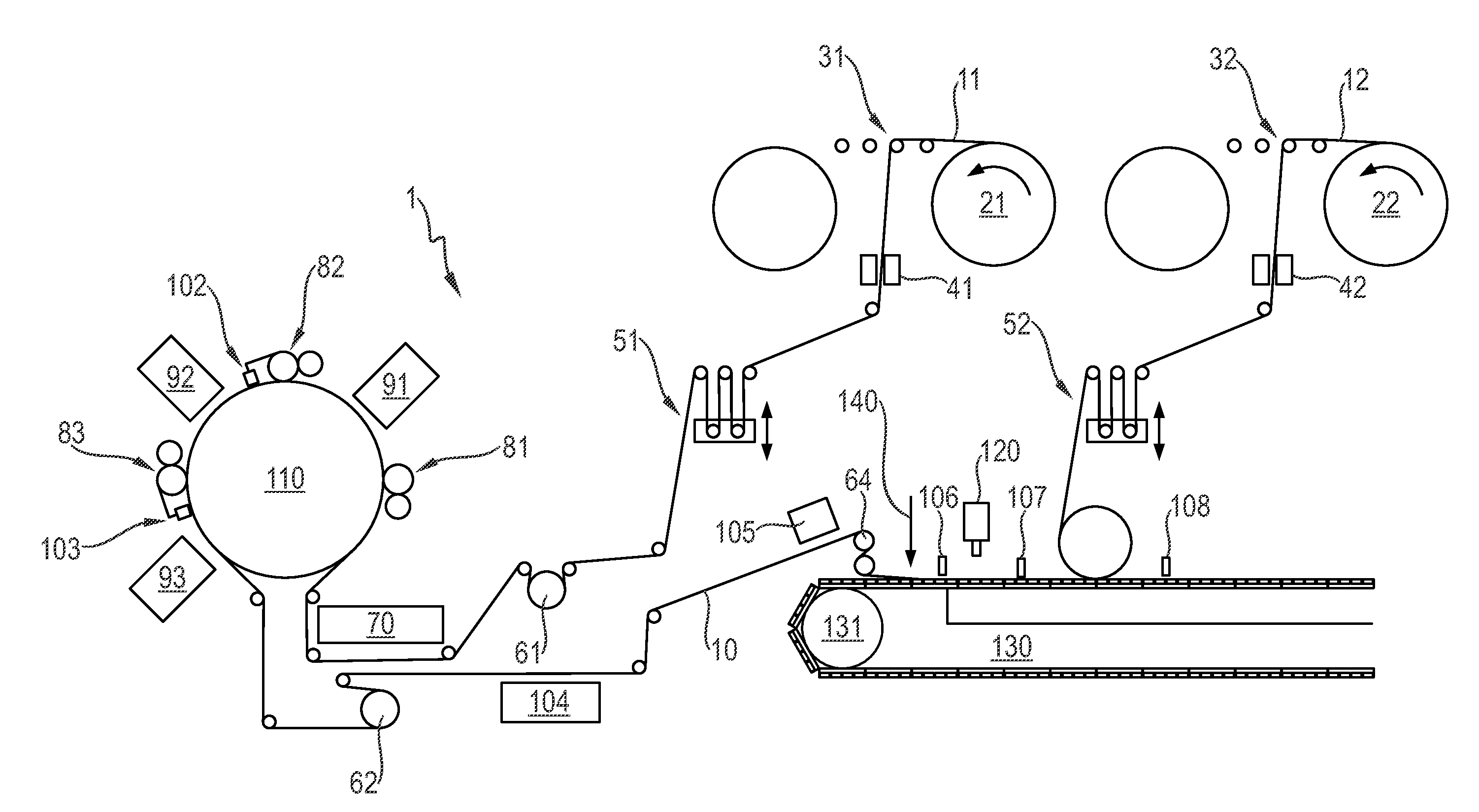

ActiveUS20150059288A1High oxygenHigh moisture barrier propertyPharmaceutical containersPackage sterilisationProduction lineEngineering

A flexible container, system and method of manufacture can include an in-line system that allows flexible containers of varying sizes to be manufactured in a single relatively high speed and efficient production line and in a single clean room through the use of transport and exchange equipment configured to adeptly handle flexible containers throughout the process.

Owner:B BRAUN MEDICAL

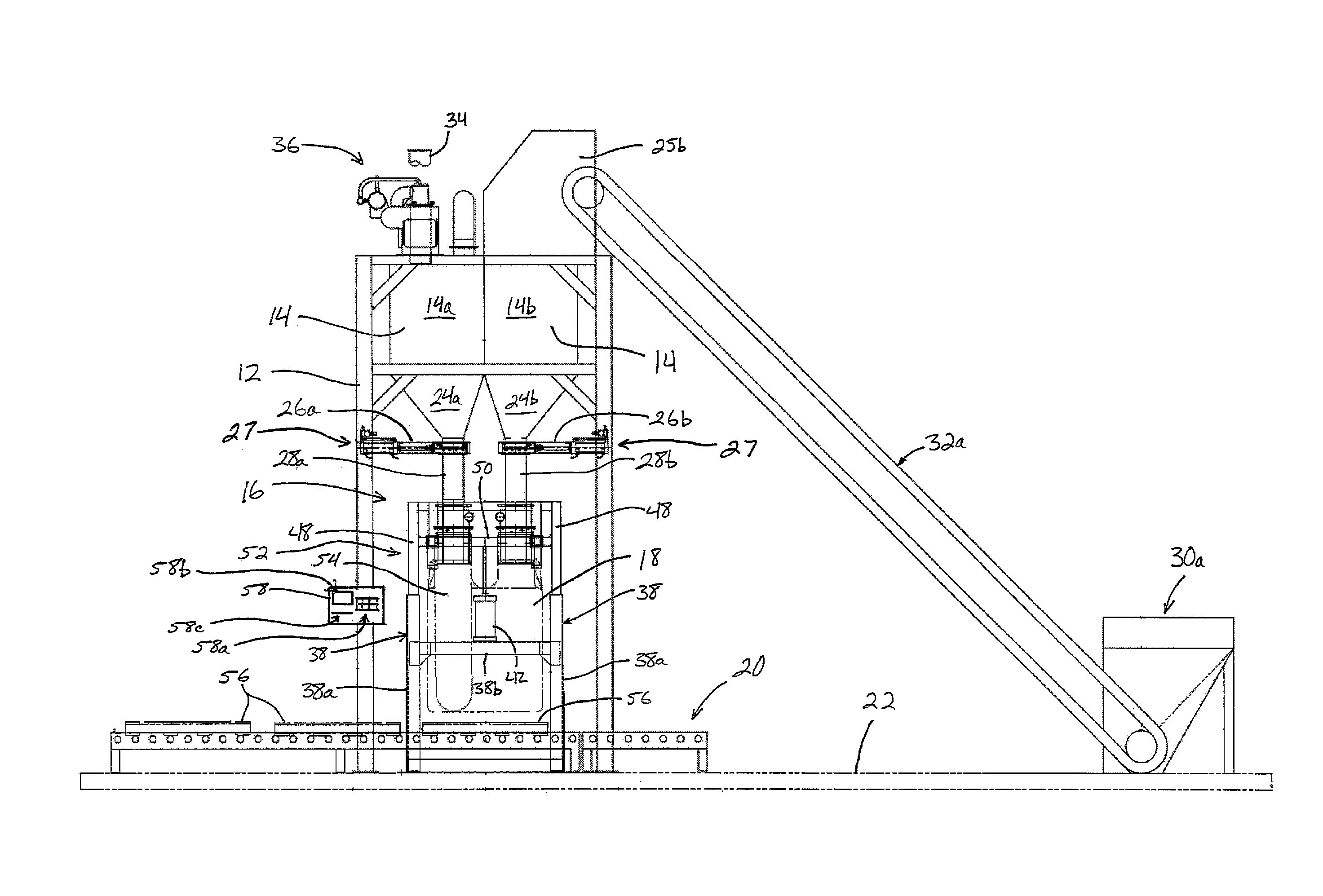

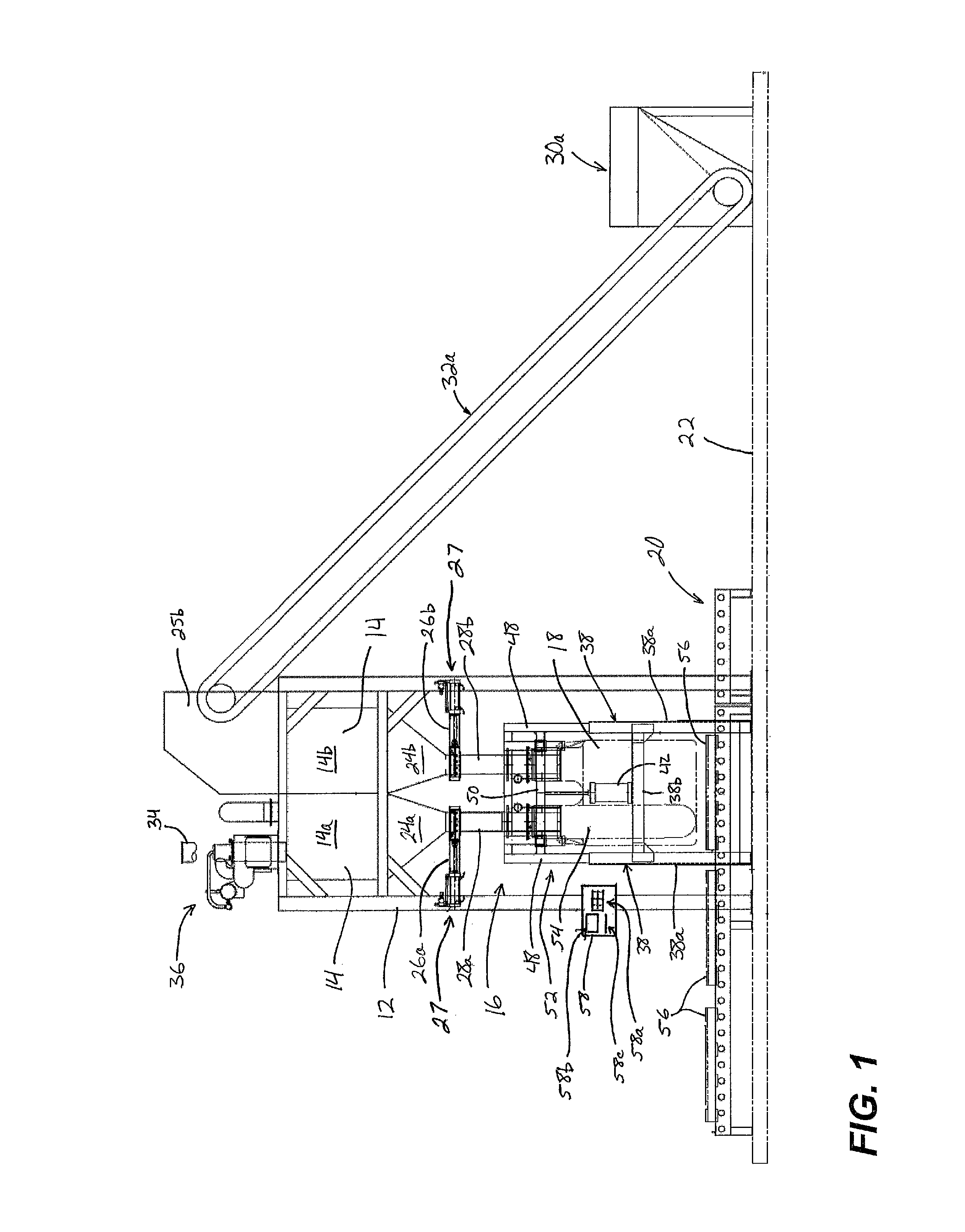

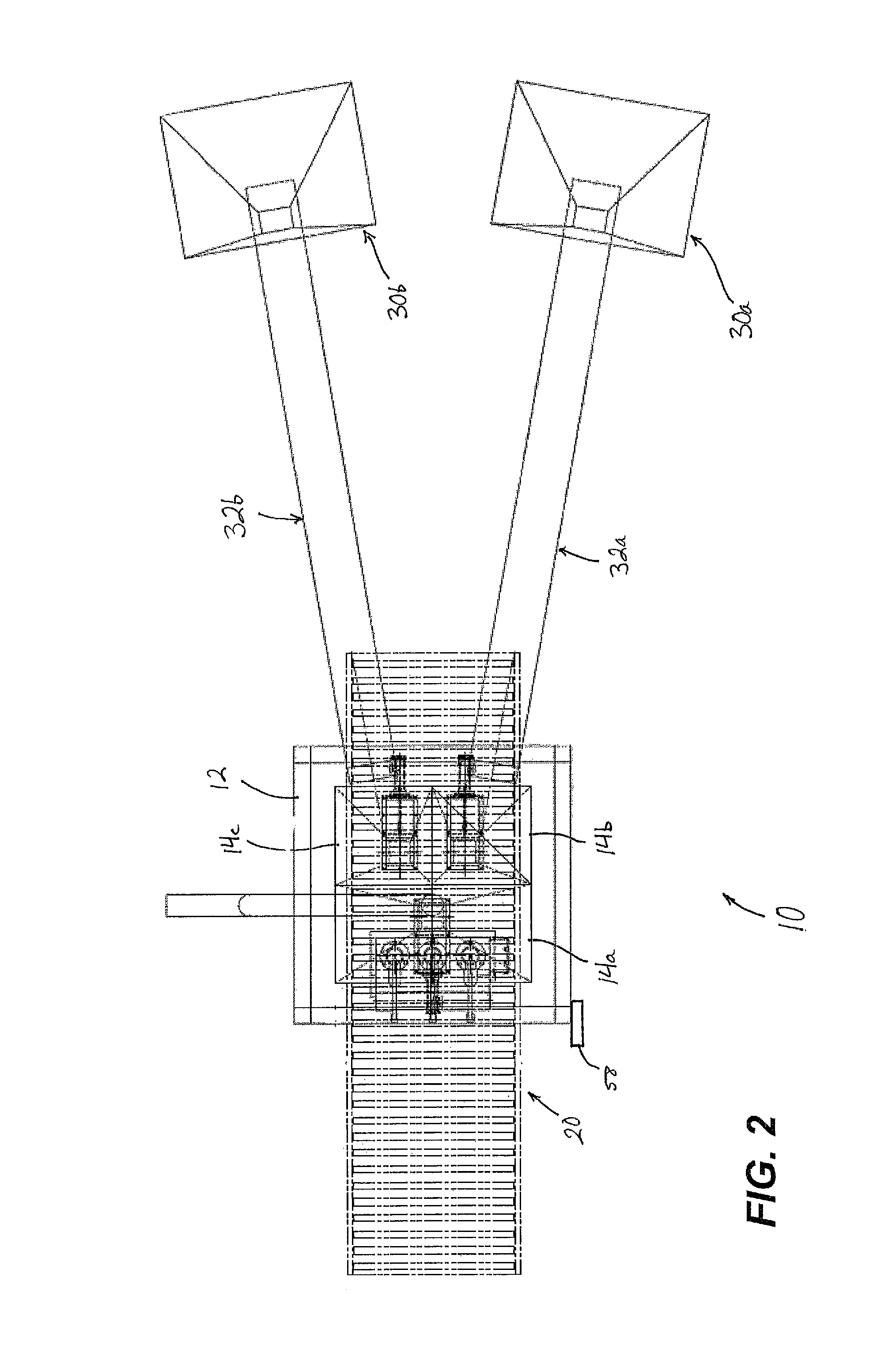

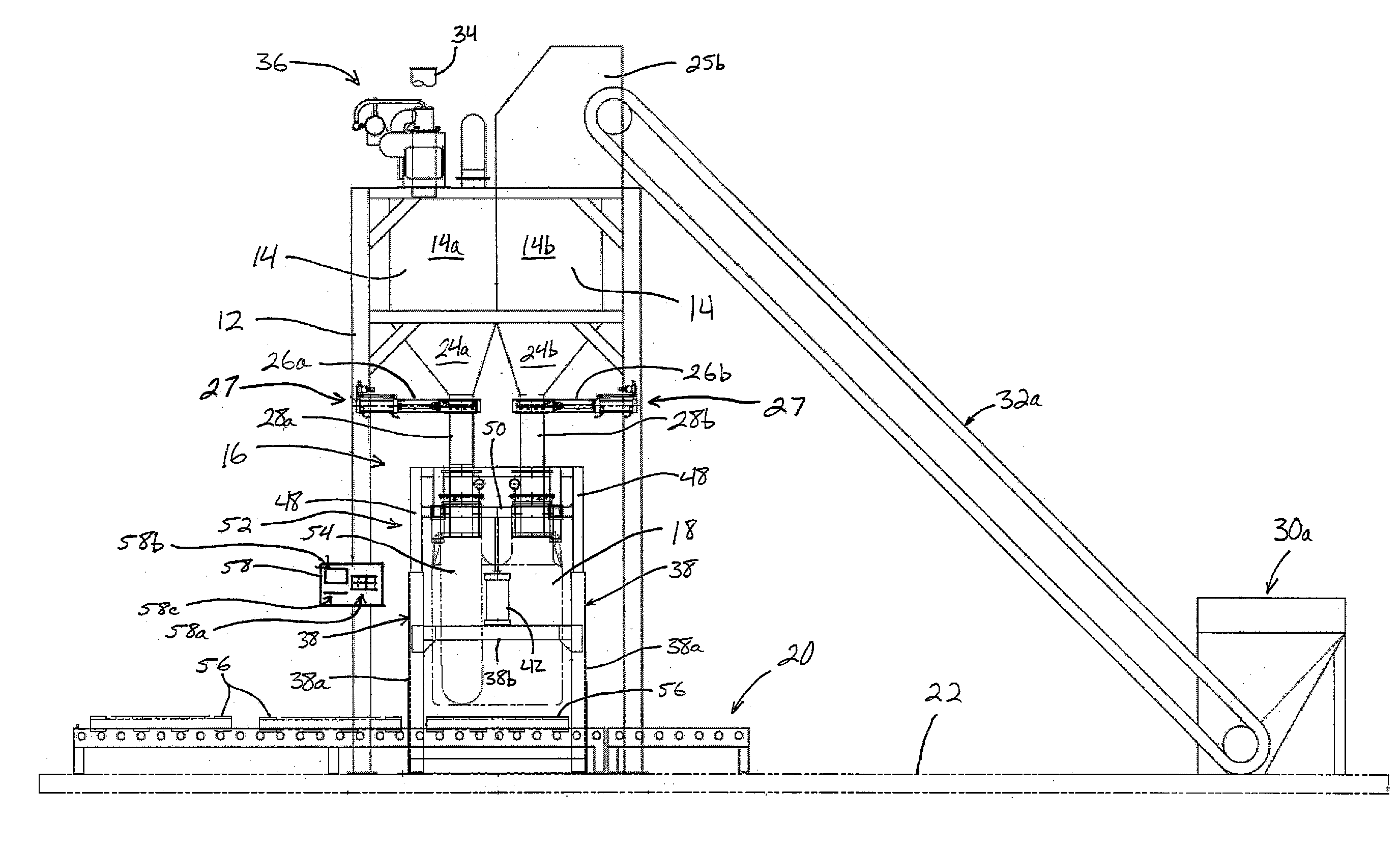

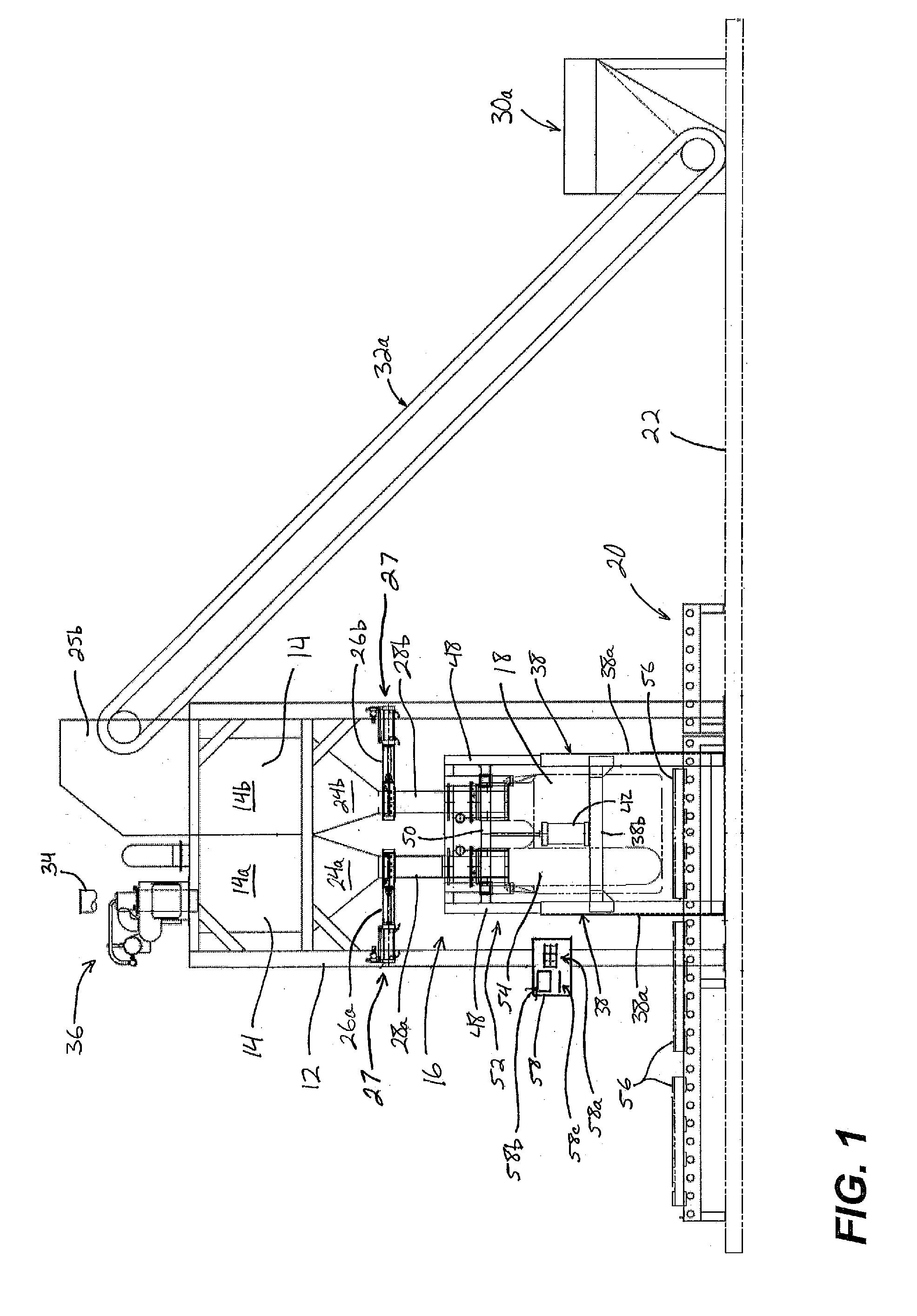

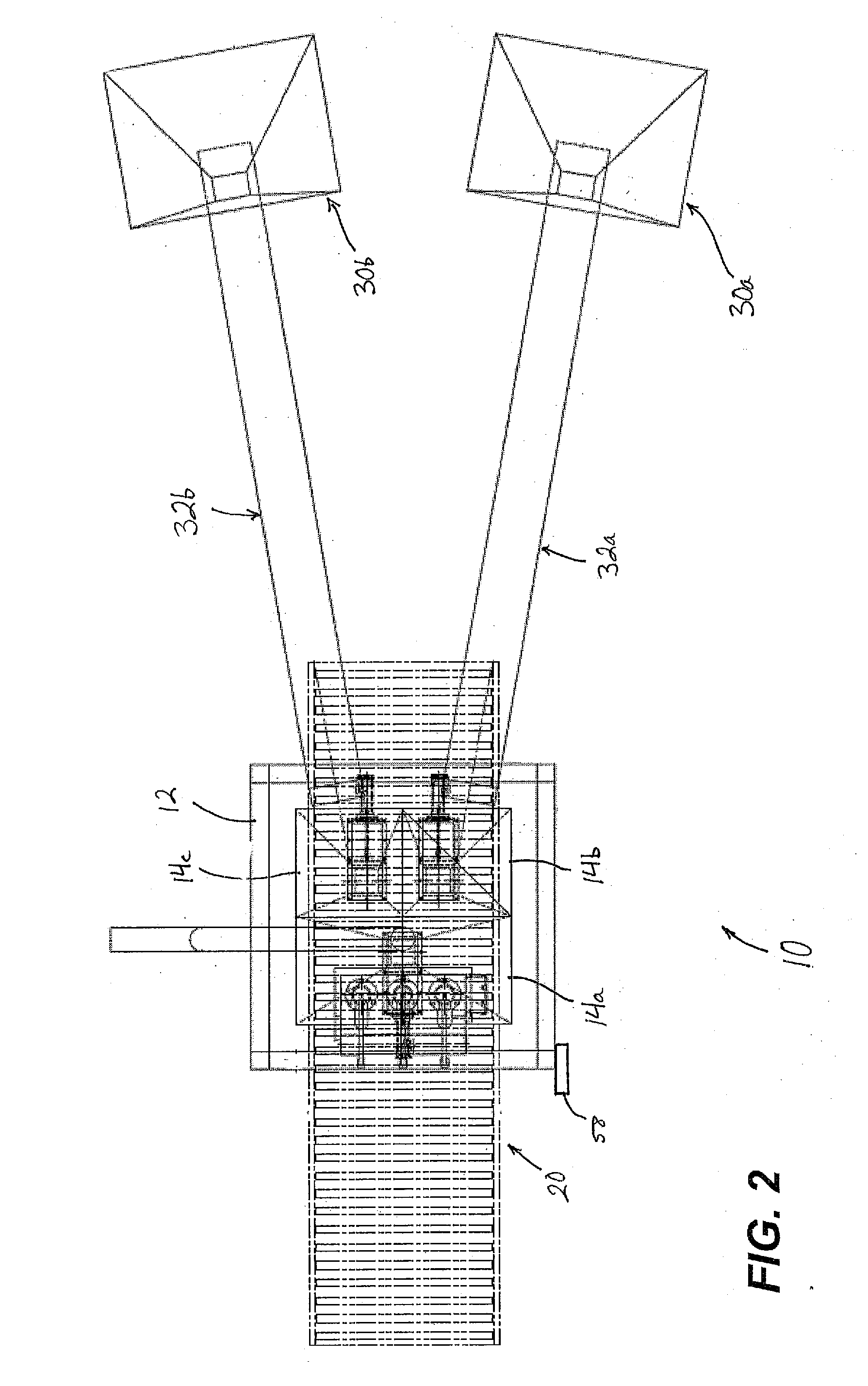

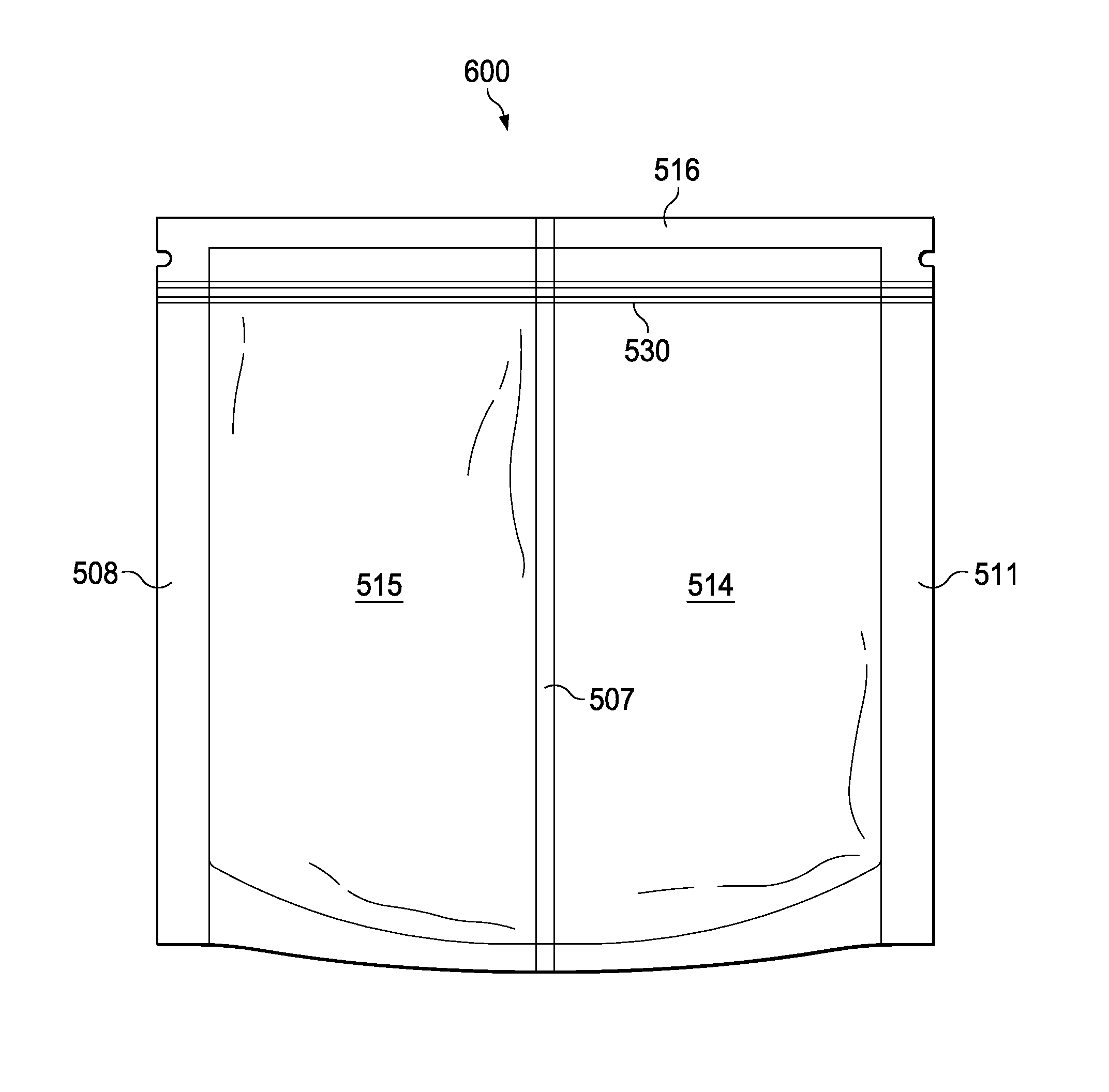

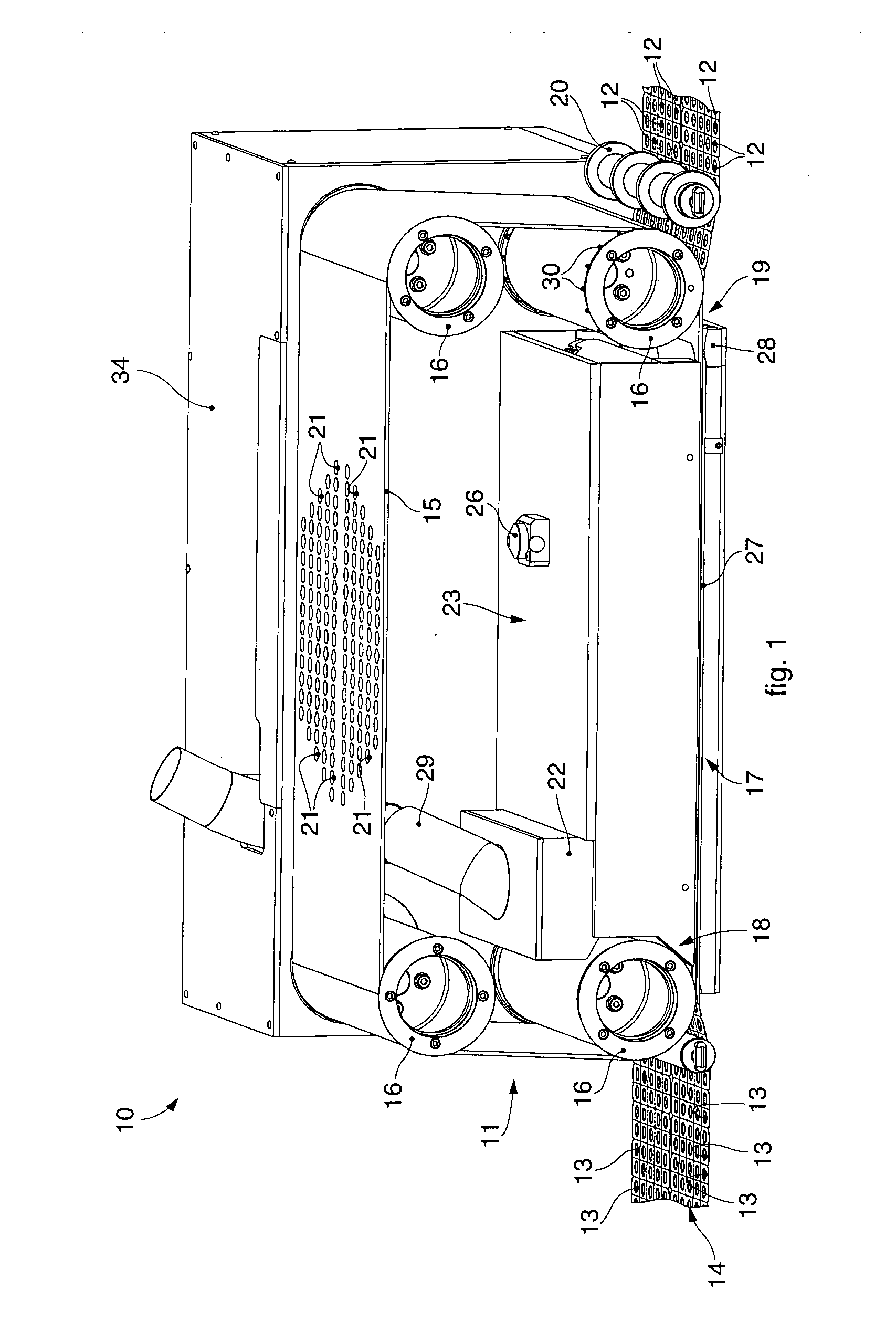

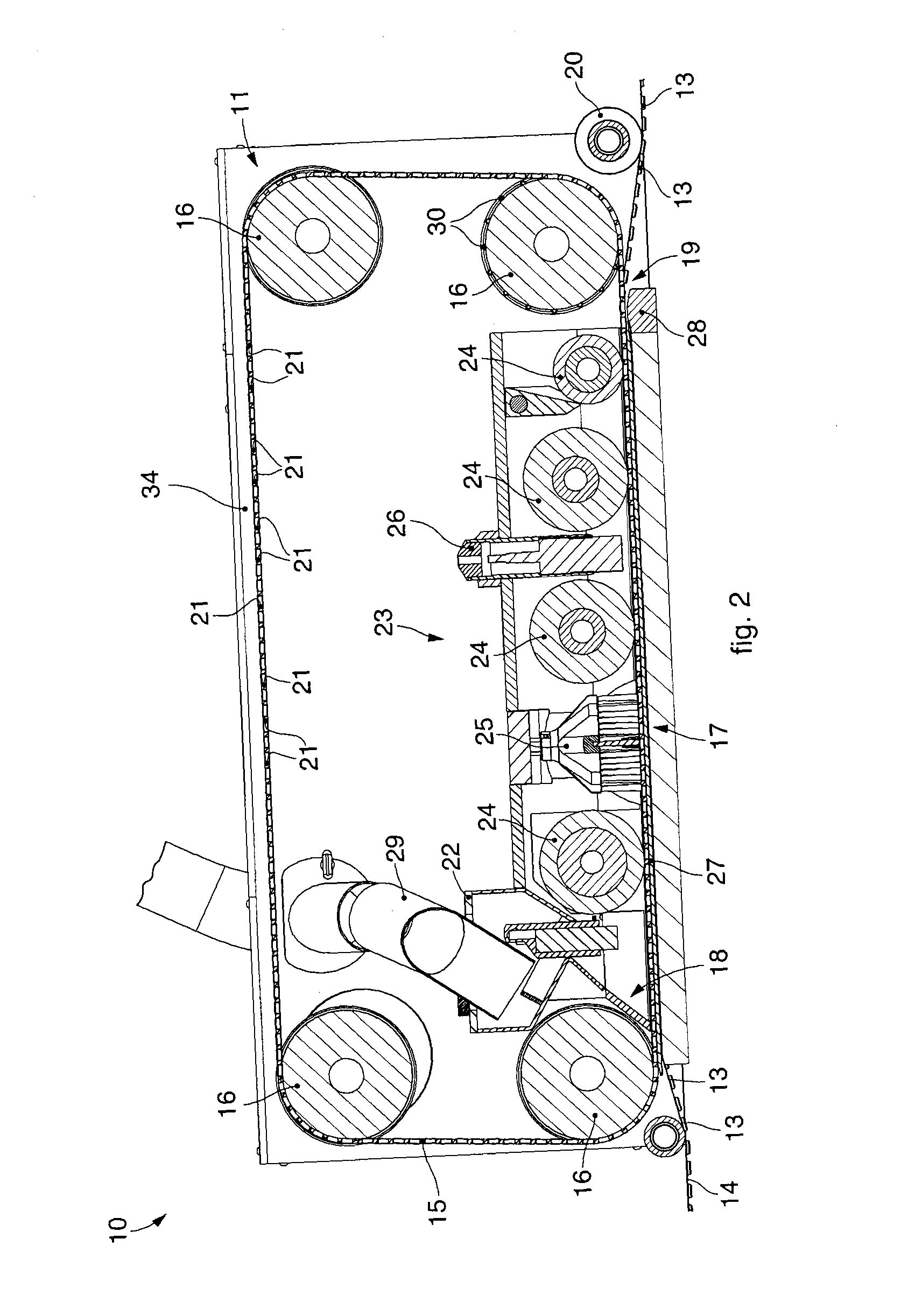

Apparatus and method for filling multi-chamber containers with bulk materials

An apparatus and method are provided for filling multi-chamber containers with different loose bulk materials. The apparatus and method may be particularly well-suited to packaging at least one bulk material, which is susceptible to water, chemicals, or other contaminants, with at least one other bulk material. The apparatus is a machine that includes separate hoppers for handling the separate bulk materials, and directs the separate bulk materials into different chambers of a multi-chamber container, which is then transported away from the machine for storage or use. The machine may include one or more movable hoppers supported on tracks, for moving the bulk materials to the hoppers that direct the bulk materials into different chambers of the multi-chamber container. A controller and data logger may be provided to control the apparatus and record the quantity and / or weight of the contents of each multi-chamber container.

Owner:MATYE REINHARD

Package having vacuum packed absorbent article and methods thereof

InactiveUS20080140039A1Consumes small amountAmount of spaceFinal package aspectsBaby linensProcess engineeringVacuum packing

Vacuum packed absorbent articles including diapers, kits thereof, and retail packages including vacuum packed and non vacuum packed absorbent articles are disclosed.

Owner:KDS DEVING LLC

Device for forming partitioned film packages

ActiveUS20070017832A1Low costMinimize forcePaper/cardboard wound articlesFinal package aspectsEngineeringReactive components

A process for producing partitioned packages by which a first film is formed into an elongated inner tube and a second film is formed into an elongated outer tube surrounding the inner tube. Reactive components are filled into the inner and outer tubes as the tubes are formed to maintain the reactive components separate from each other. Only the outer tube is actively engaged to advance the tube longitudinally. Frictional forces from the advancing outer tube are applied to the component within the outer tube and, in turn, are applied to the inner tube thereby advancing the inner tube at a rate substantially the same as the outer tube.

Owner:J LOK

Apparatus for producing pouches

InactiveUS20150291300A1Wrapping material feeding apparatusSynthetic resin layered productsControl systemEngineering

Apparatus for producing pouches including a source of printed water-soluble PVOH film, a second source of film, a source of composition, a pouch making unit comprising a filing system to form pouches from the first film, the second film, and the composition, a control system for monitoring and adjusting the position of the pattern onto the pouches. Pouches made by the apparatus.

Owner:THE PROCTER & GAMBLE COMPANY

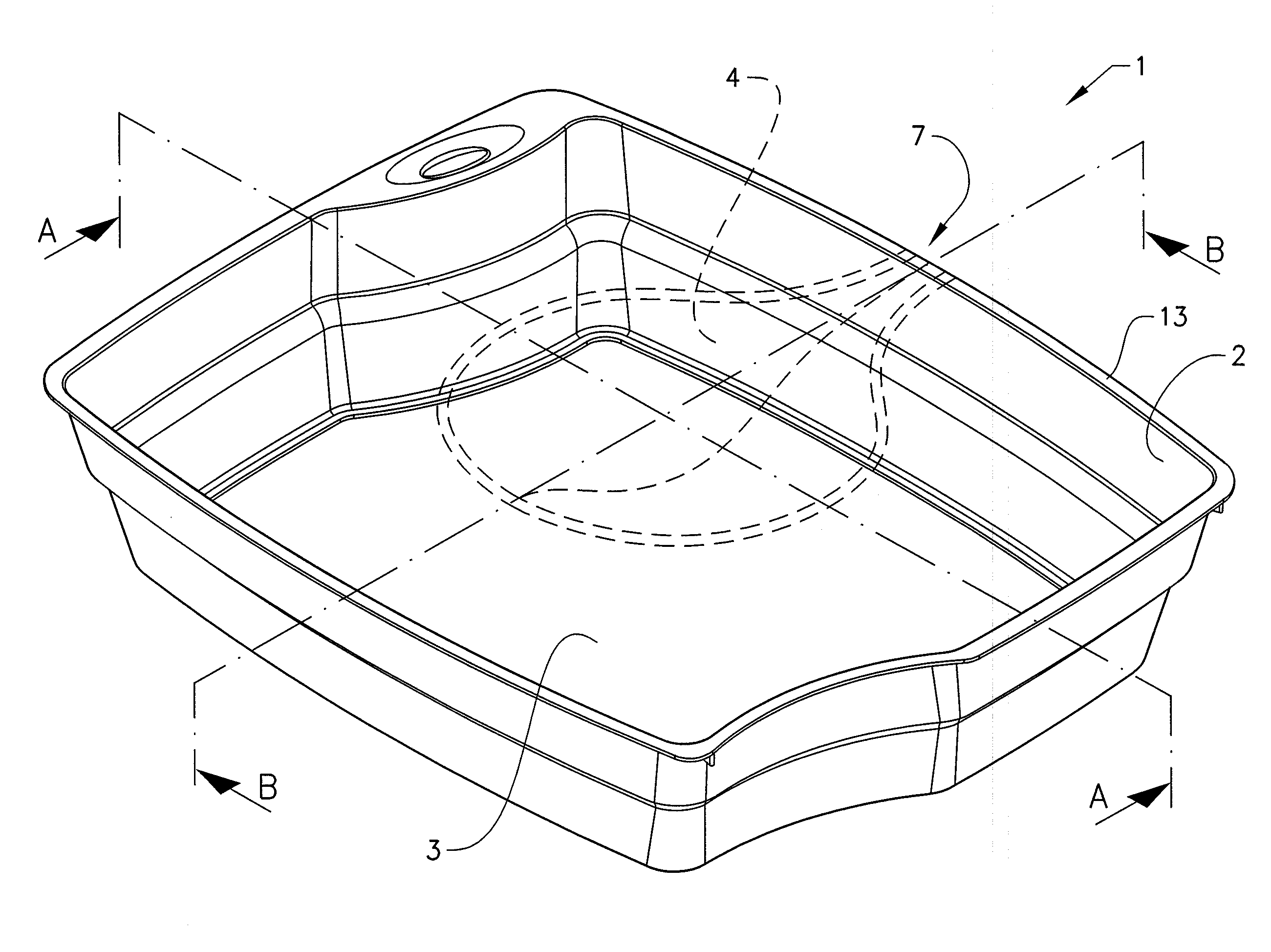

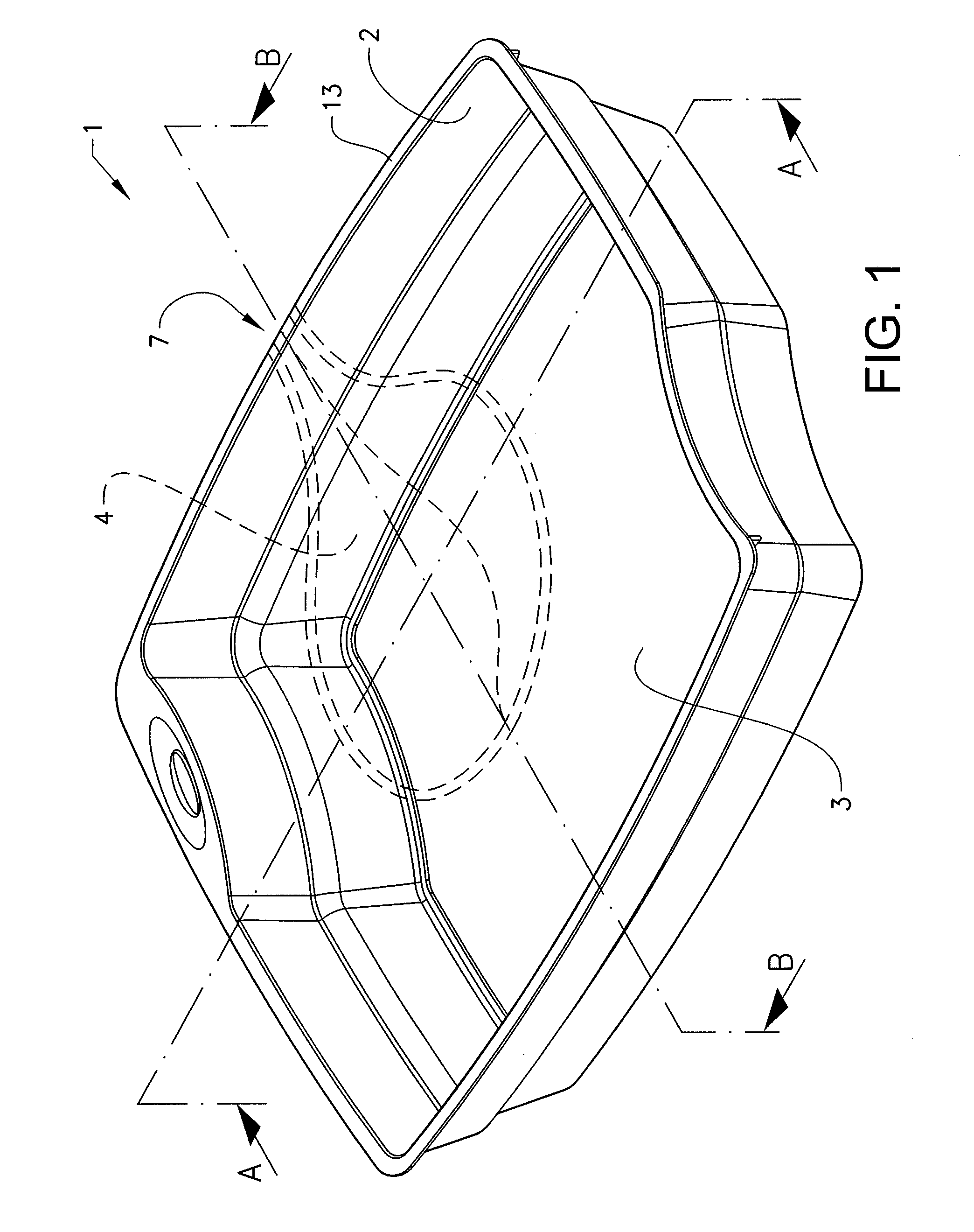

Food package with additional food container and foil comprising an additional food container and a method for filling and sealing an additional food container comprised in a lid of a food tray

InactiveUS20130074455A1Radiation shieldingLess heatVenting meansClosure with auxillary devicesEngineeringFood packaging

A food package comprising a food tray and a lid, where the food package comprises an additional food container comprised in the lid of the food package. The invention further relates to a food package foil for a food package, where the foil comprises lid portions and intermediate foil portions, where the food package foil further comprises an additional food container comprised in the lid portion of the foil. The advantage of the invention is that an additional food can be held separated from the rest of the food but can be prepared at the same time. The invention also relates to a method for filling and sealing an additional food container comprised in a lid of a food tray.

Owner:TORUS PAK RES & DEV SARL

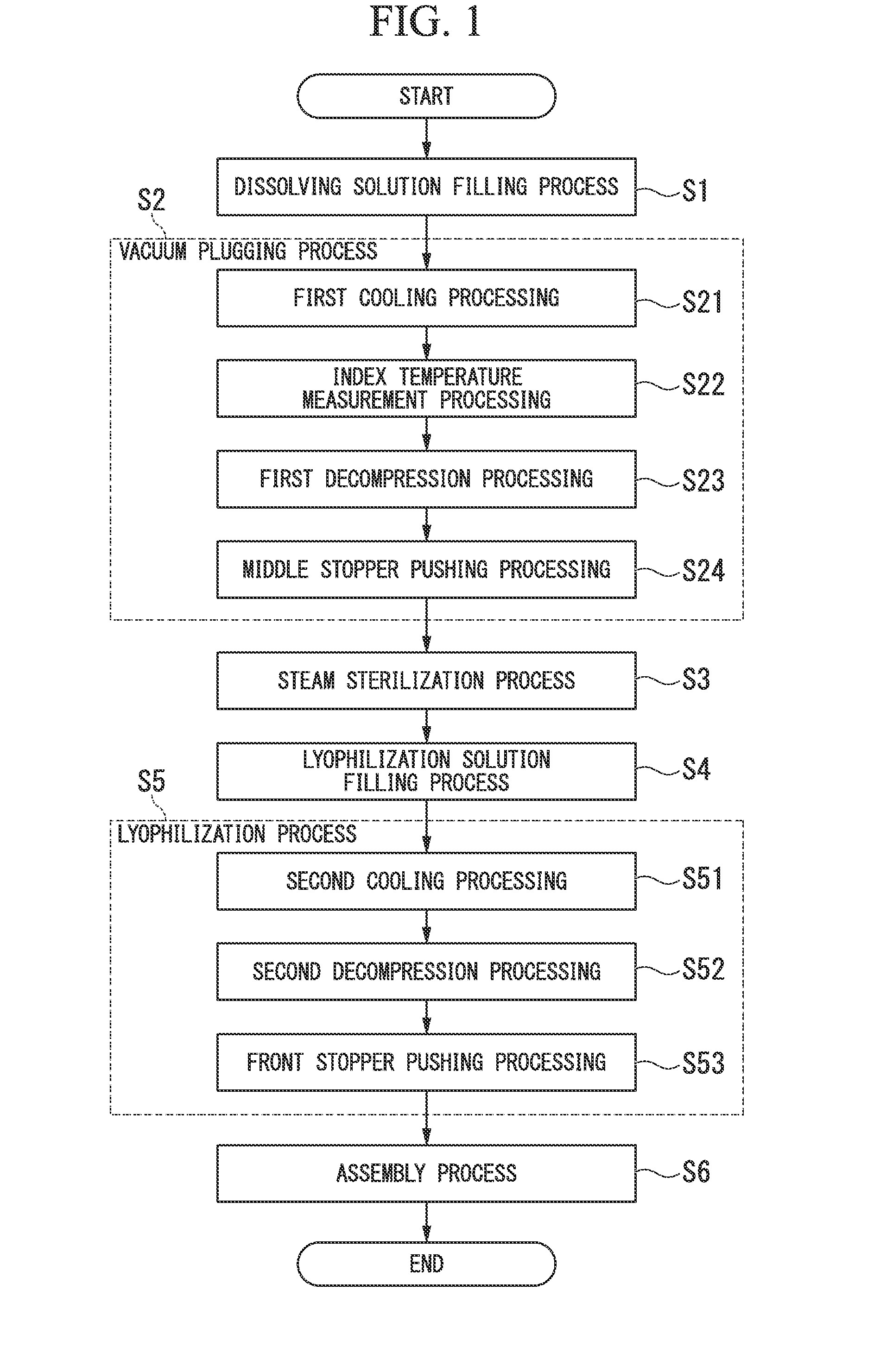

Manufacturing Method Of Two-Chamber Type Combined Container-Syringe

ActiveUS20150013276A1Easy to fillEfficient executionCapsAmpoule syringesFree statePulp and paper industry

A manufacturing method of two-chamber type combined container-syringe including: a vacuum plugging process (S2) of eliminating air bubbles from the dissolving solution of the dissolving solution-filled cartridge and sealing the dissolving solution with a middle stopper after the dissolving solution filling process (S1); a vacuum plugging process (S2) has a first cooling processing (S21) of cooling the inside of a vacuum plugging equipment in which a dissolving solution-filled cartridge is disposed to a cooling temperature that does not freeze the dissolving solution, a first decompression processing (S23) of decreasing a pressure inside the vacuum plugging equipment while the vacuum plugging equipment maintains the cooling temperature after the first cooling processing (S21), and a middle stopper pushing processing (S24) of pushing the middle stopper downward and bringing the middle stopper into contact with the dissolving solution after the first decompression processing (S23). The dissolving solution can be easily filled in a bubble-free state in the two-chamber type combined container-syringe.

Owner:ARTE

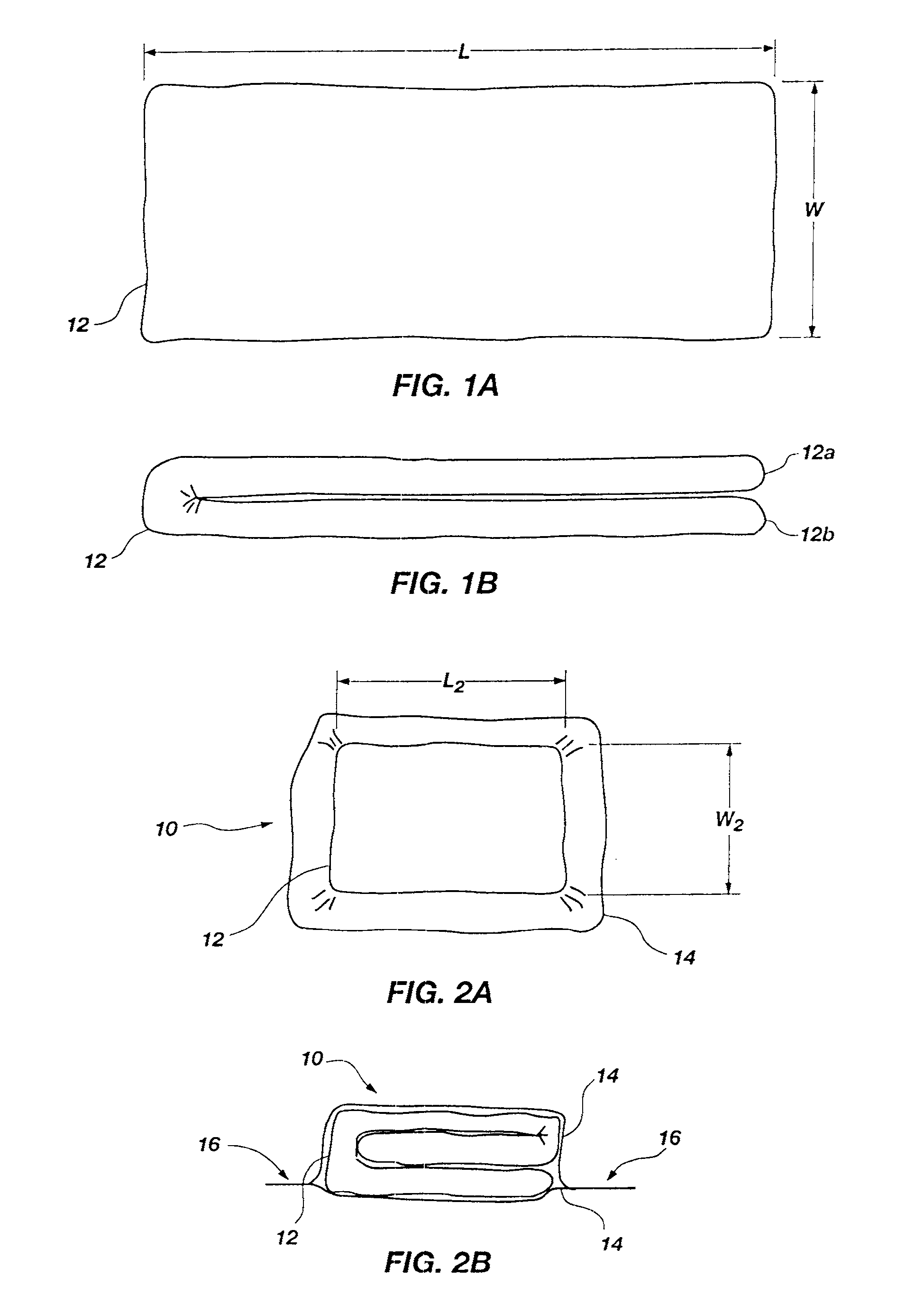

Dual compartmented pouch and method for making the same

A flexible pouch and a method for making a flexible pouch is provided. The pouch includes a pouch body defined by a peripheral edge. A dividing seal is disposed between opposite ends of the flexible pouch so as to define two pouch spaces. The pouch includes two fitments are mounted to a respective pouch space. One of the fitments is configured to support the pouch body in an upright manner. A method for making said flexible includes forming a flexible pouch having an open top. A dividing seal extends from the open top to the bottom of the pouch so as to define two pouch openings and two pouch spaces. Substances are introduced into the pouch spaces by a first nozzle and a second nozzle inserted into a respective first space and second space and filling the pouch body through the first and second nozzle.

Owner:POUCH PAC INNOVATIONS

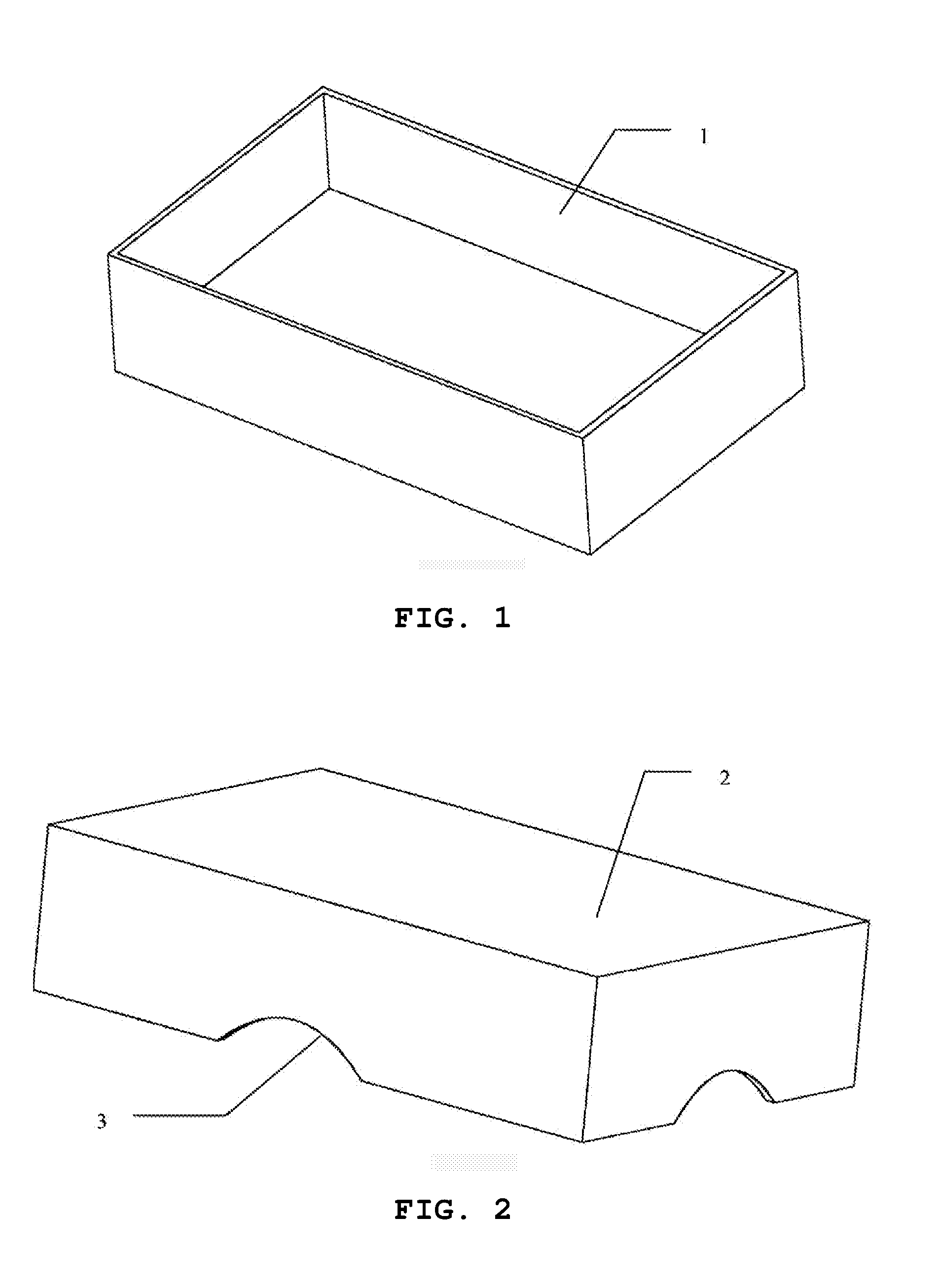

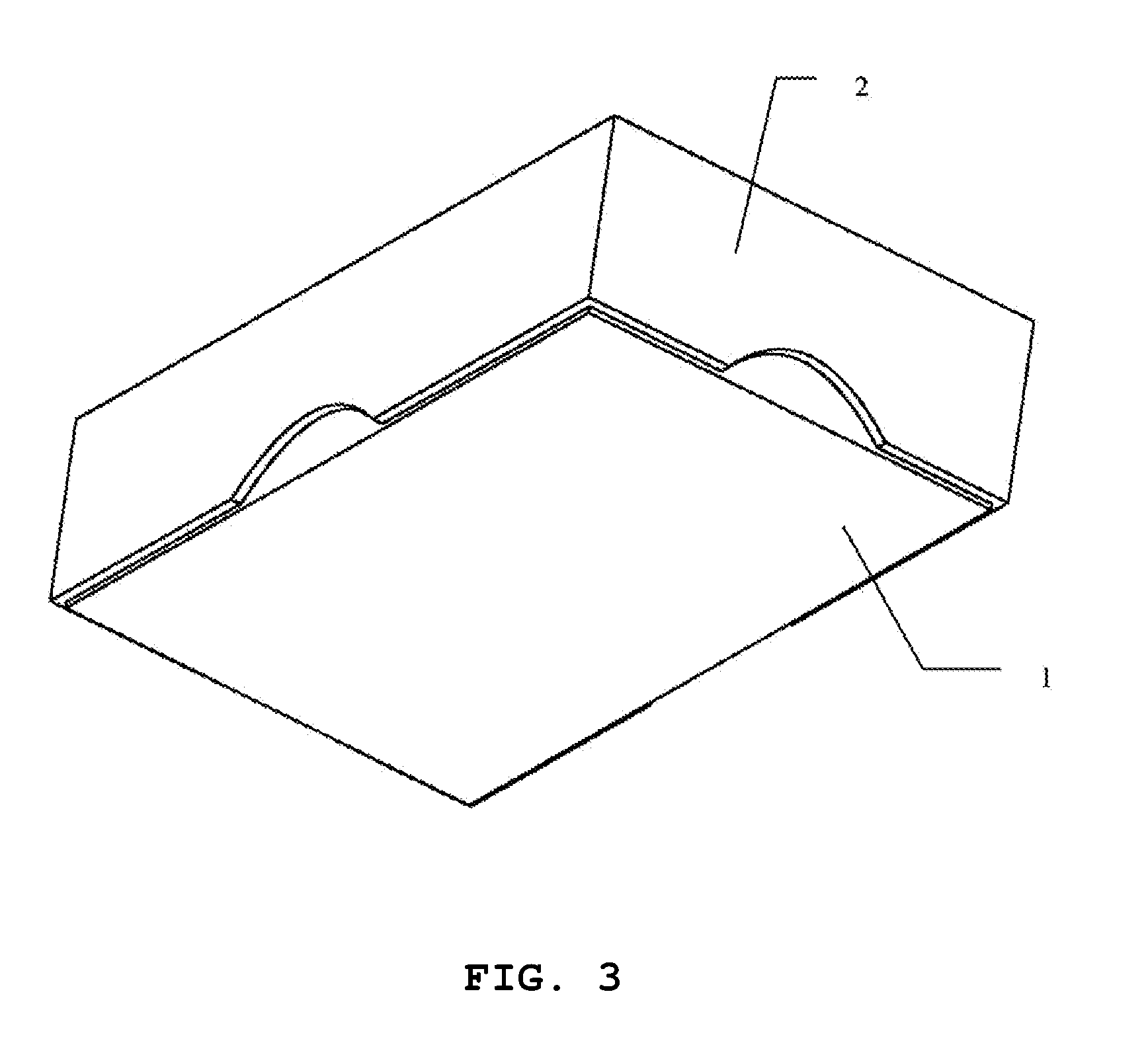

Compressed-type instance noodle packaging box and method of manufacturing the same

ActiveUS20170043928A1Easy to separatePrevent leakageWrappers shrinkageFinal package aspectsInstant noodleBiomedical engineering

Disclosed are a compressed-type instant noodle packaging box and a method of manufacturing the same. The packaging box comprises a cuboid packaging box main body (1) of a volume slightly larger than that of the instant noddle block and a box cover (2) covering the packaging box main body, and further comprises a folding container of which a bottom face (4) is adhered together with a bottom face inside the packaging box main body, wherein after opening out in the packaging box main body, the folding container is a cuboid barrel body (14) higher than the packaging box main body; a separately packaged instant noodle bag, seasoning bag and cutlery bag are placed on an upper face of the folding container, and after the box cover covers the packaging box main body, the whole is provided on the outside thereof with a layer of heat-shrinkable film for sealing. The instant noodle packaging box has a small volume, occupies little space, and is convenient for transporting and carrying, the folding and opening methods for the folding container are simple, and the packaging box main body also plays the role of heat insulation.

Owner:PIAO CHANGJIN

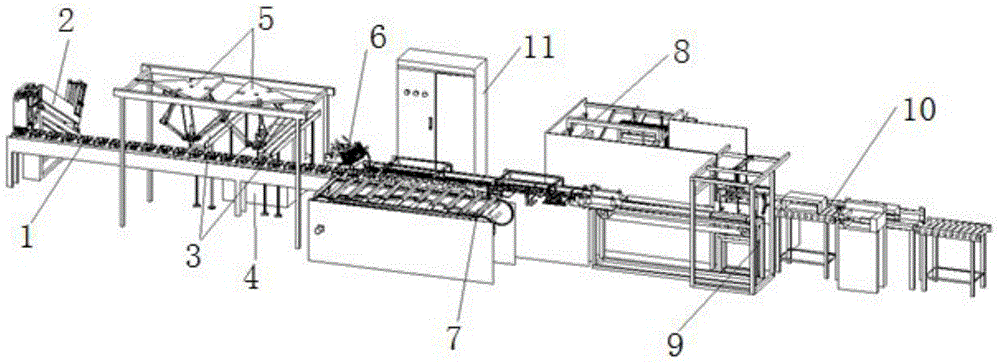

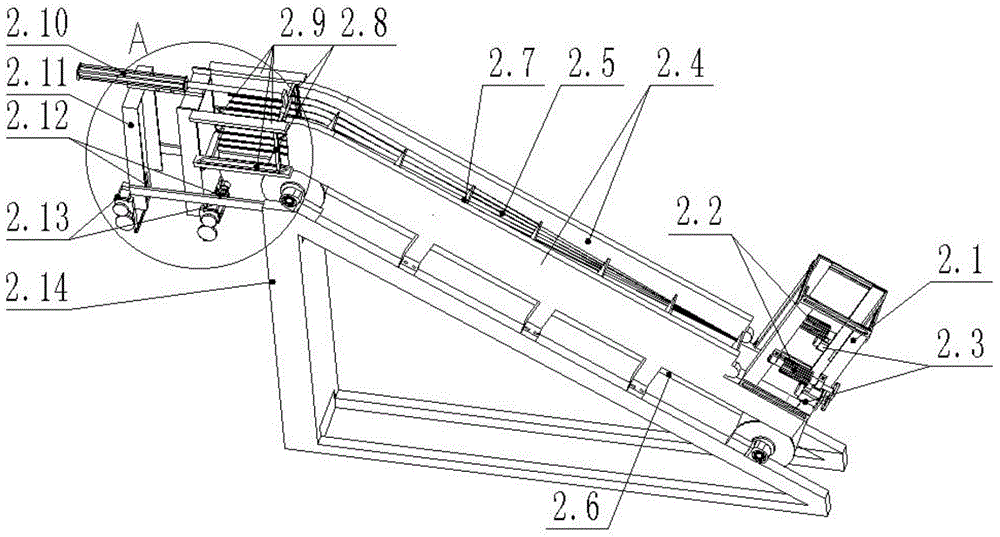

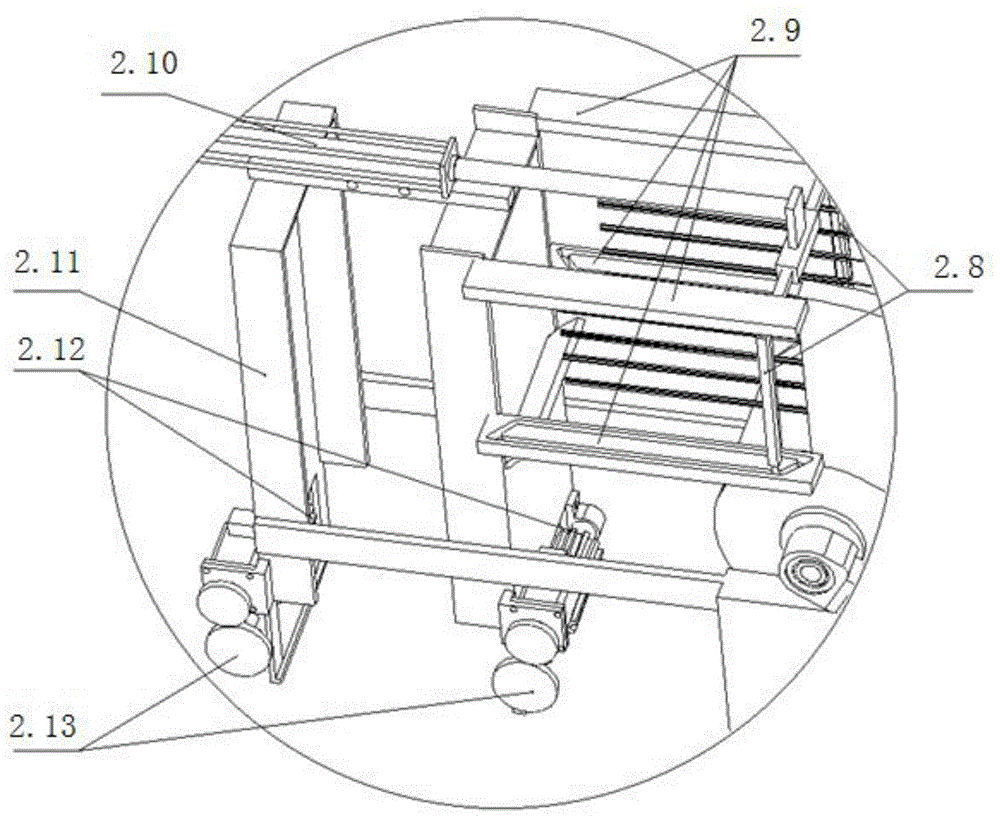

Packaging production line used for multi-product collective packaging

InactiveCN104875912AReferred to separation efficiencyFully automatedFinal package aspectsIndividual articlesProduction lineControl system

The invention relates to a packaging production line used for multi-product collective packaging. The packaging production line comprises a main conveying belt, a plastic demounting support machine, a feeding conveying belt, a coding machine, a feeding manipulator, a box demounting machine, a box packing and sealing machine, a box unpacking machine, an integral code layer box filling machine, a box sealing machine and a control cabinet. The packaging production line is characterized in that the plastic demounting support machine, the feeding manipulator, the box unpacking machine and the box packing and sealing machine are sequentially connected via the main conveying belt, the coding machine is mounted on the lower portion of the feeding conveying belt, the feeding manipulator is arranged right above the main conveying belt and higher than the feeding conveying belt, and the main conveying belt, the plastic demounting support machine, the feeding conveying belt, the coding machine, the feeding manipulator, the box demounting machine, the box packing and sealing machine, the box unpacking machine, the integral code layer box filling machine and the box sealing machine are electrically connected with a control system in the control cabinet.

Owner:HEBEI UNIV OF TECH

Apparatus and method for filling multi-chamber containers with bulk materials

An apparatus and method are provided for filling multi-chamber containers with different loose bulk materials. The apparatus and method may be particularly well-suited to packaging at least one bulk material, which is susceptible to water, chemicals, or other contaminants, with at least one other bulk material. The apparatus is a machine that includes separate hoppers for handling the separate bulk materials, and directs the separate bulk materials into different chambers of a multi-chamber container, which is then transported away from the machine for storage or use. The machine may include one or more movable hoppers supported on tracks, for moving the bulk materials to the hoppers that direct the bulk materials into different chambers of the multi-chamber container. A controller and data logger may be provided to control the apparatus and record the quantity and / or weight of the contents of each multi-chamber container.

Owner:MATYE REINHARD

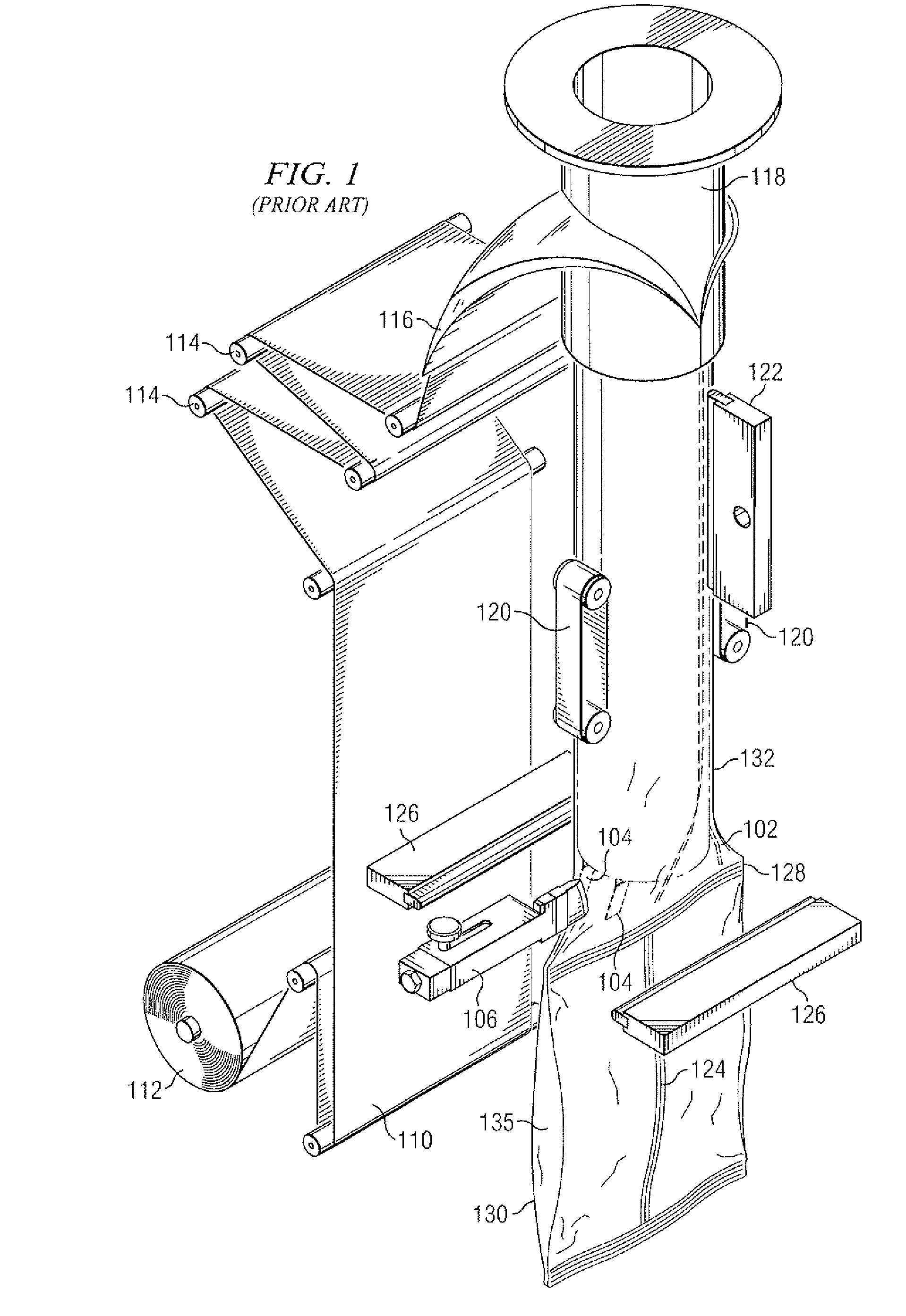

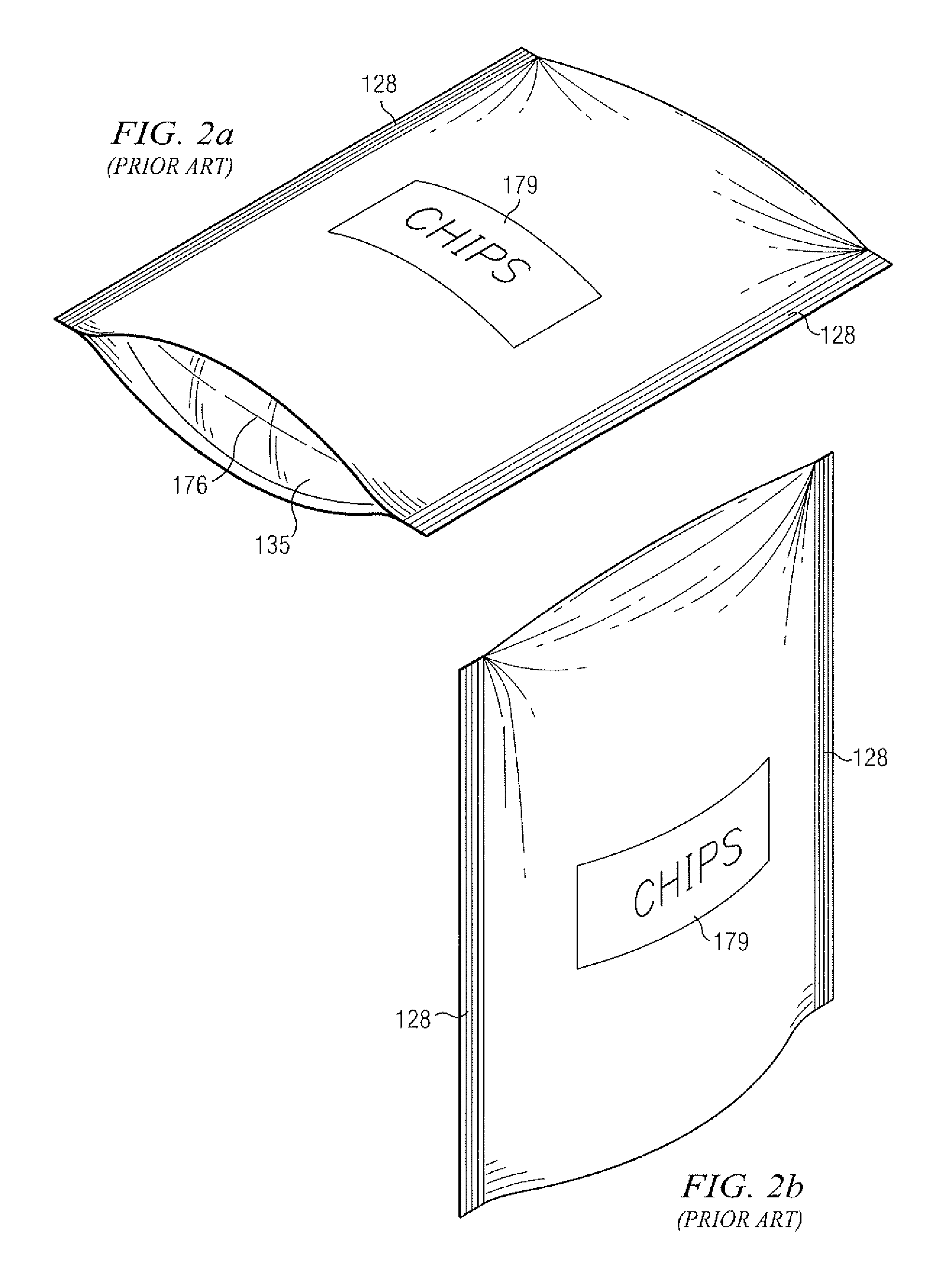

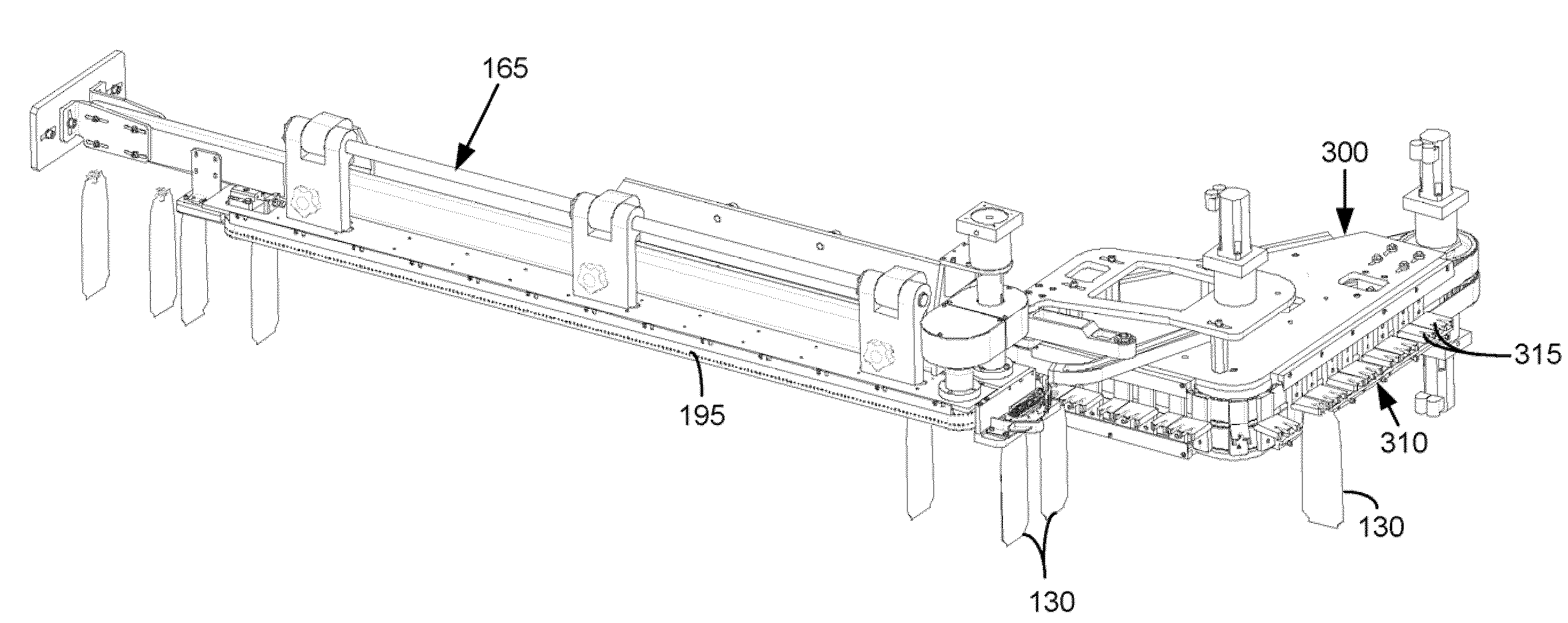

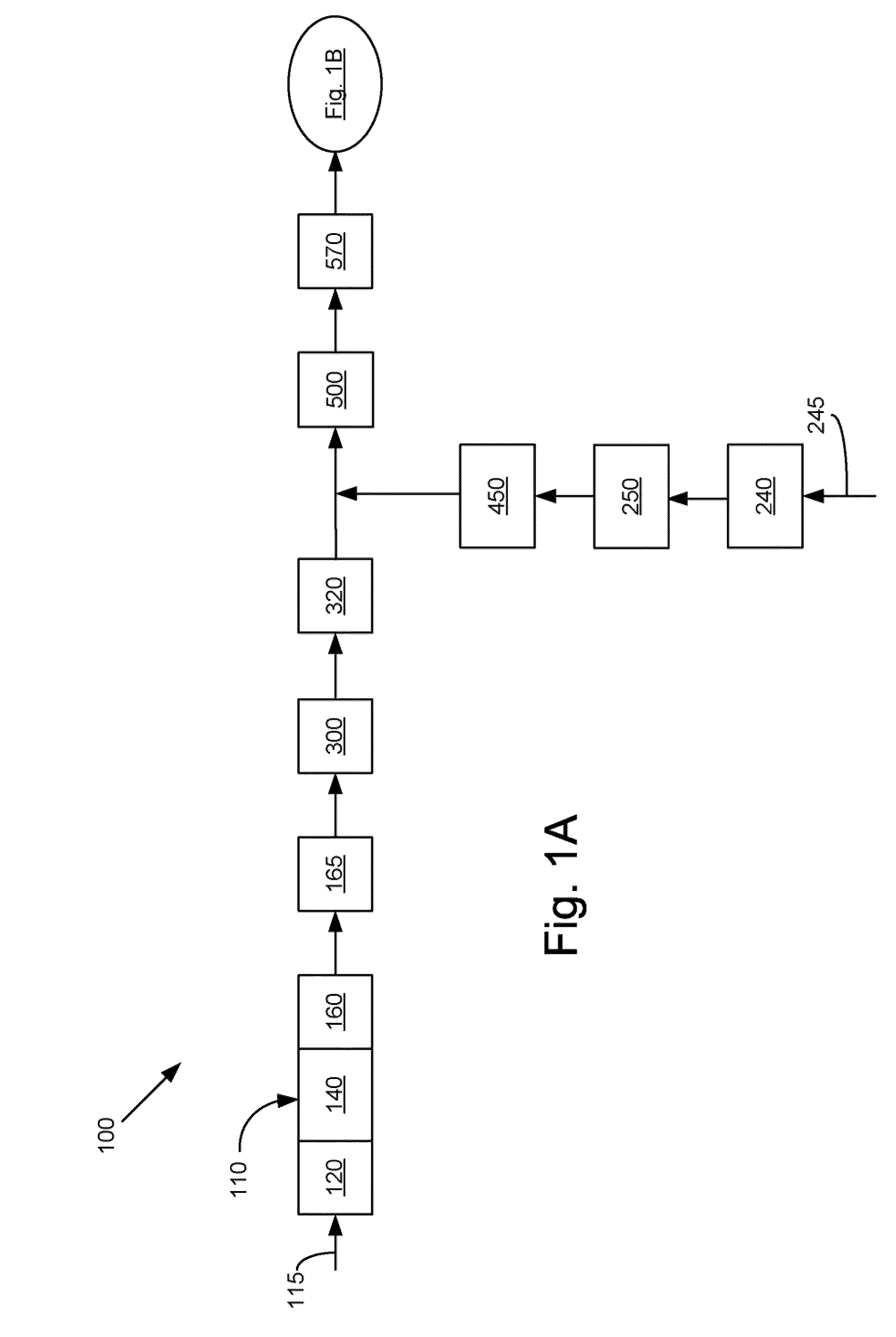

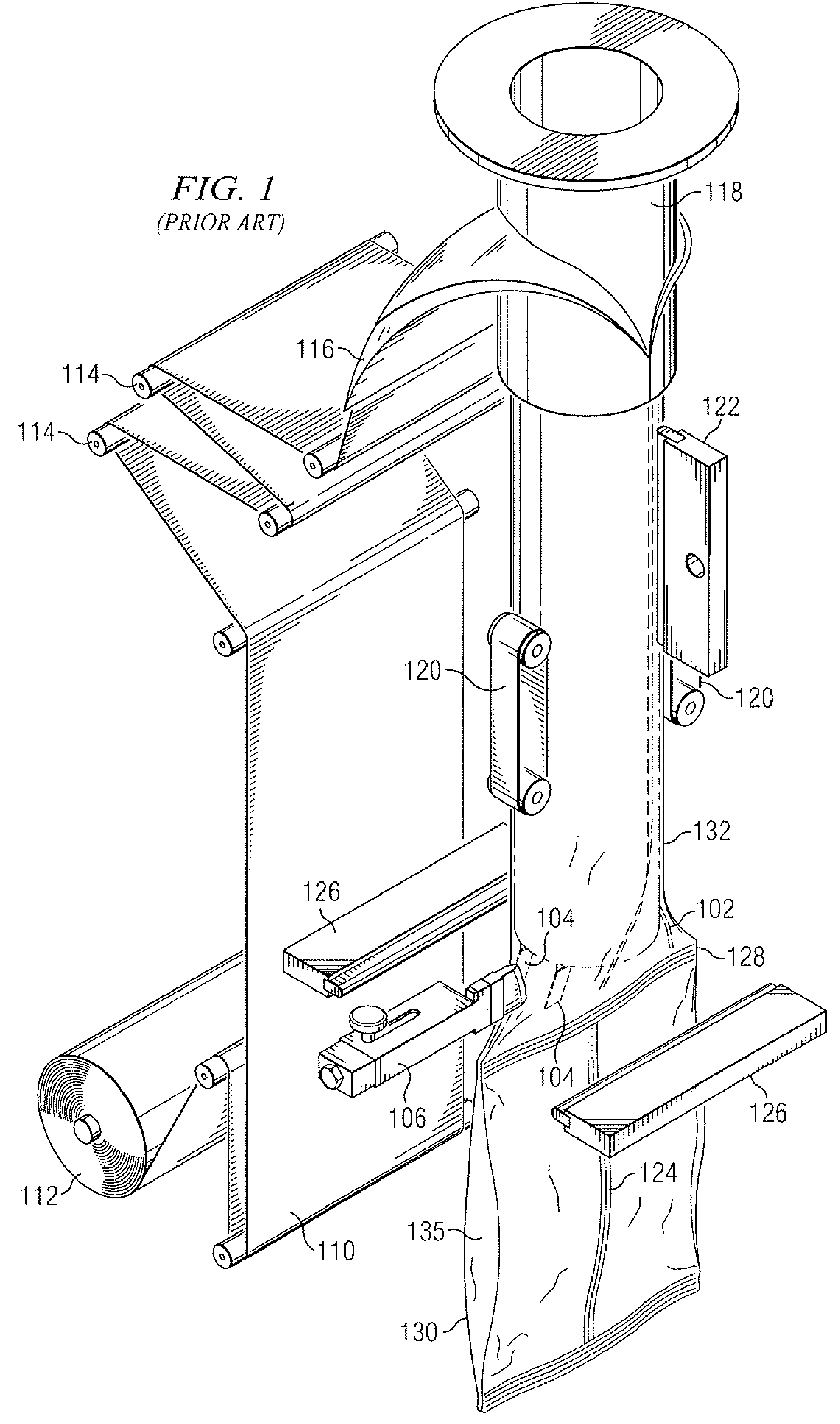

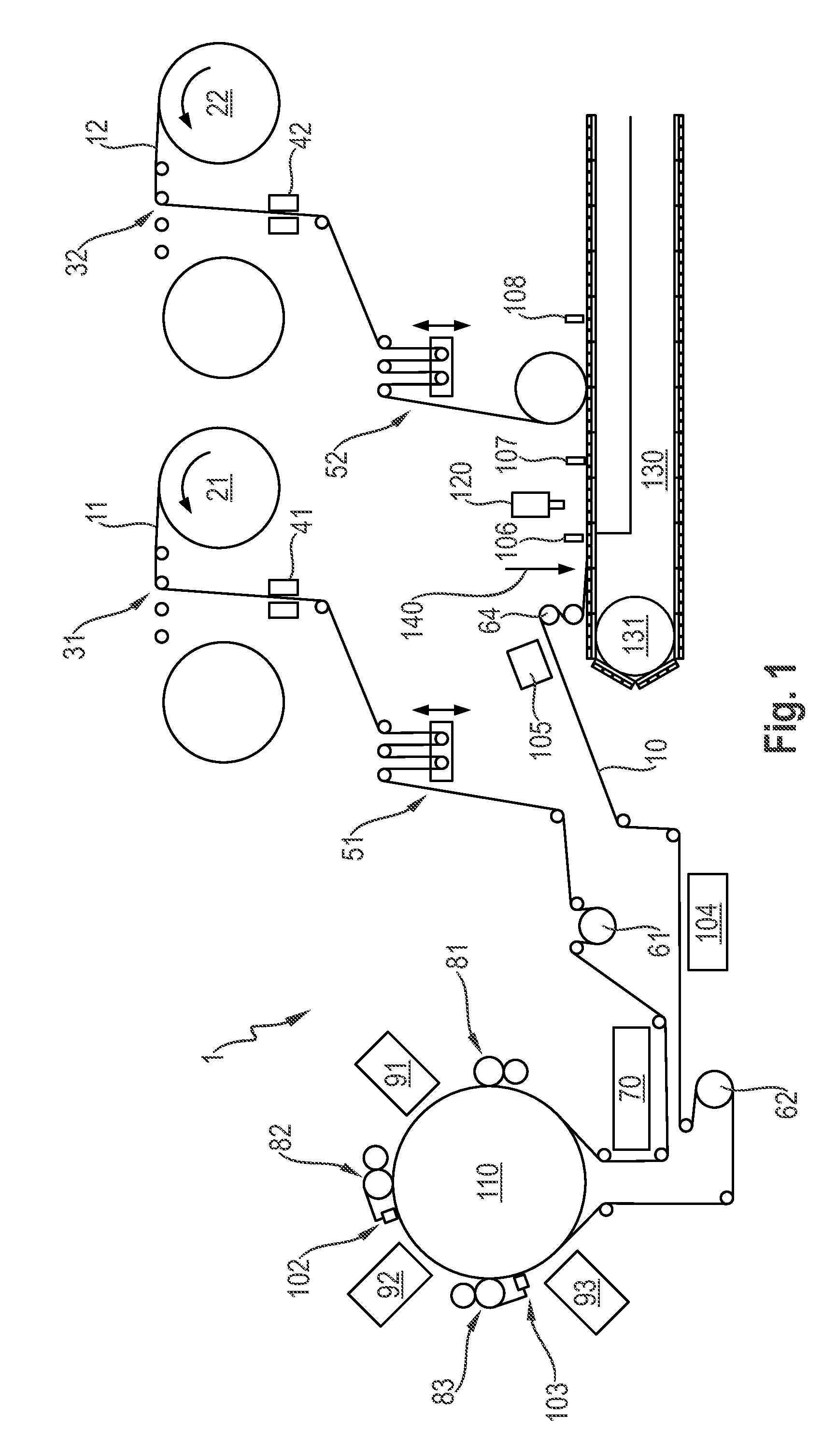

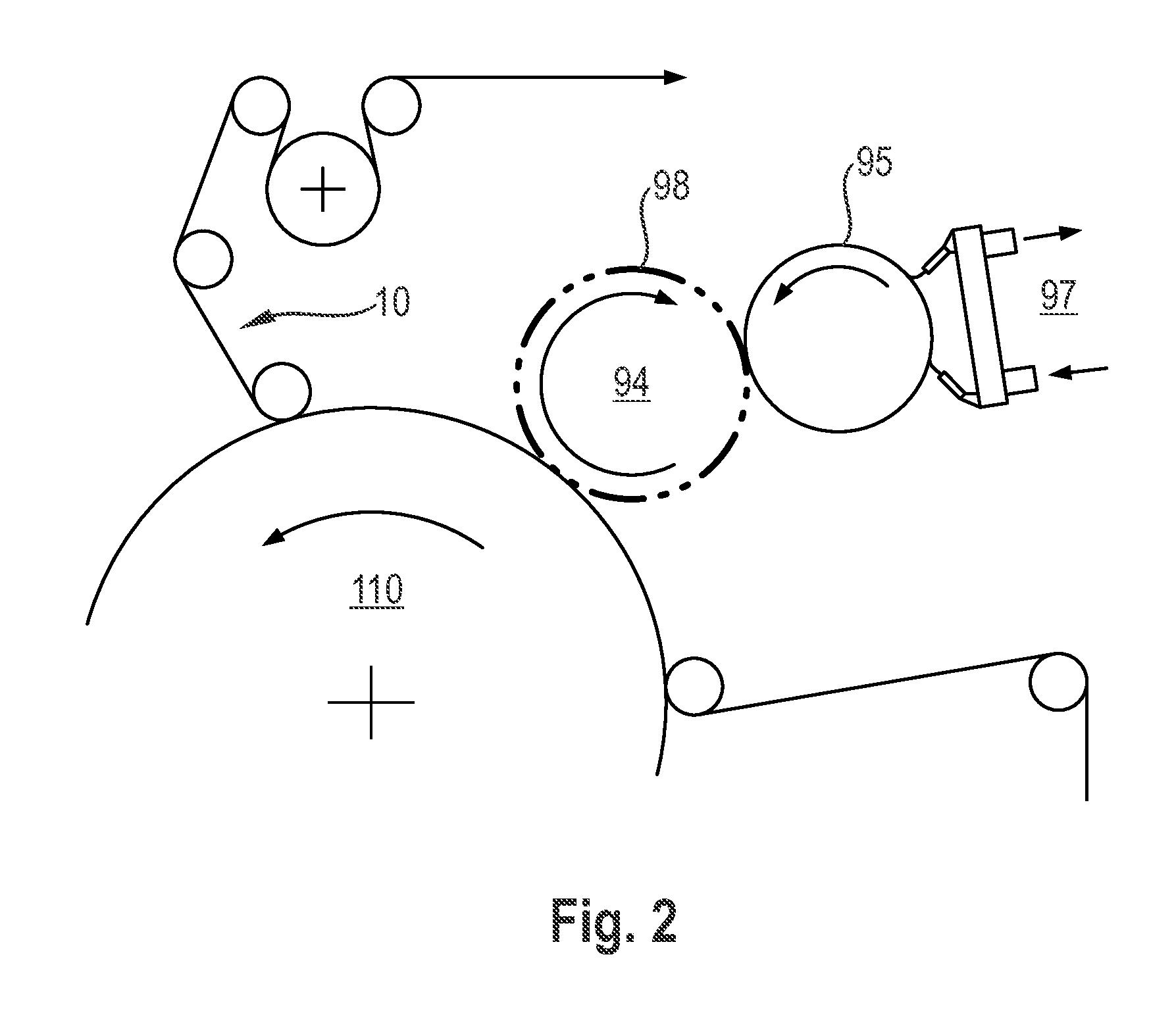

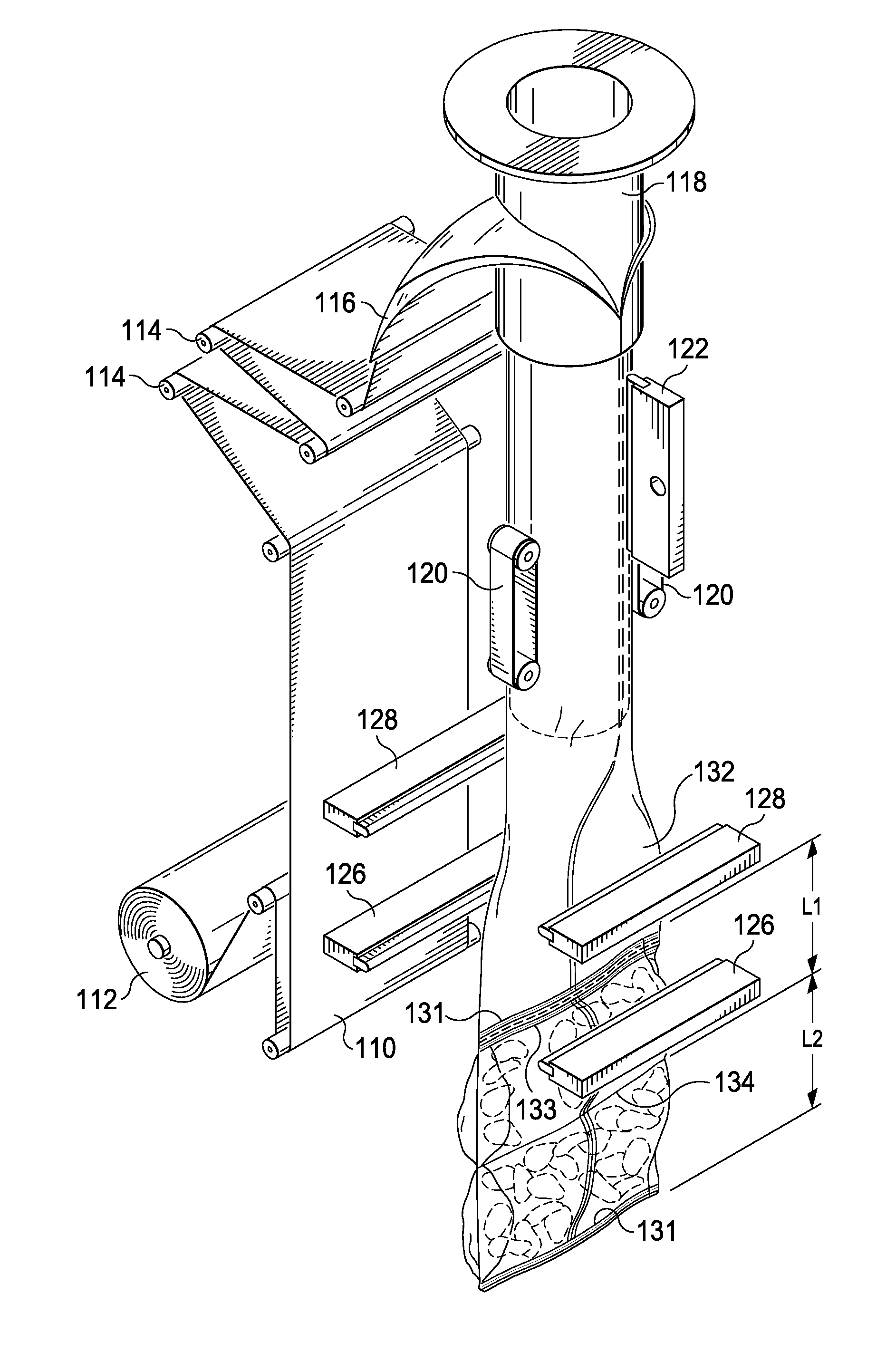

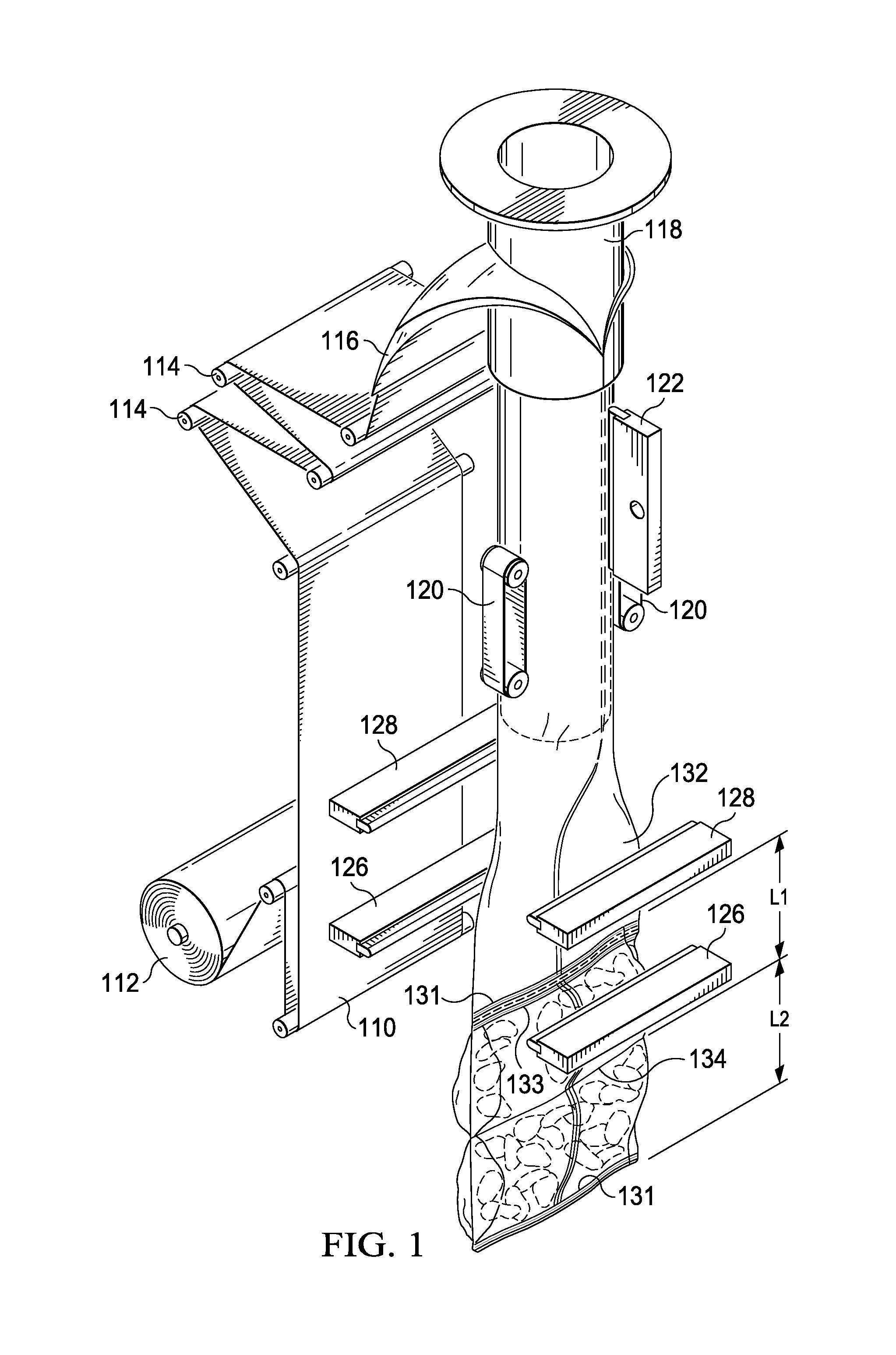

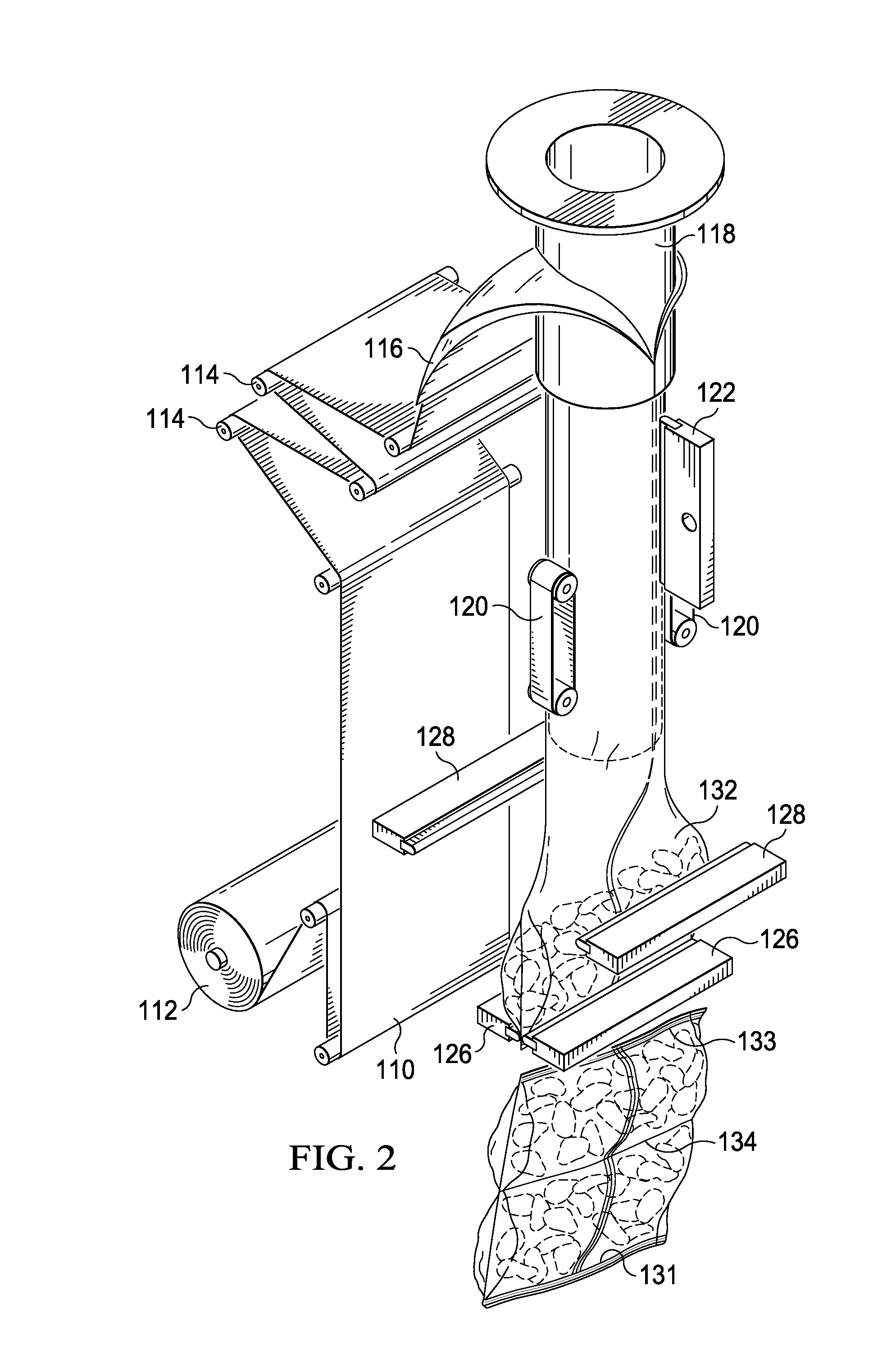

Method and apparatus for producing multi-compartment packages

An improved method and apparatus for making a multi-compartment package on a form, fill, and seal machine. Two pairs of heat sealing jaws are provided below a product delivery tube.

Owner:FRITO LAY NORTH AMERICA INC

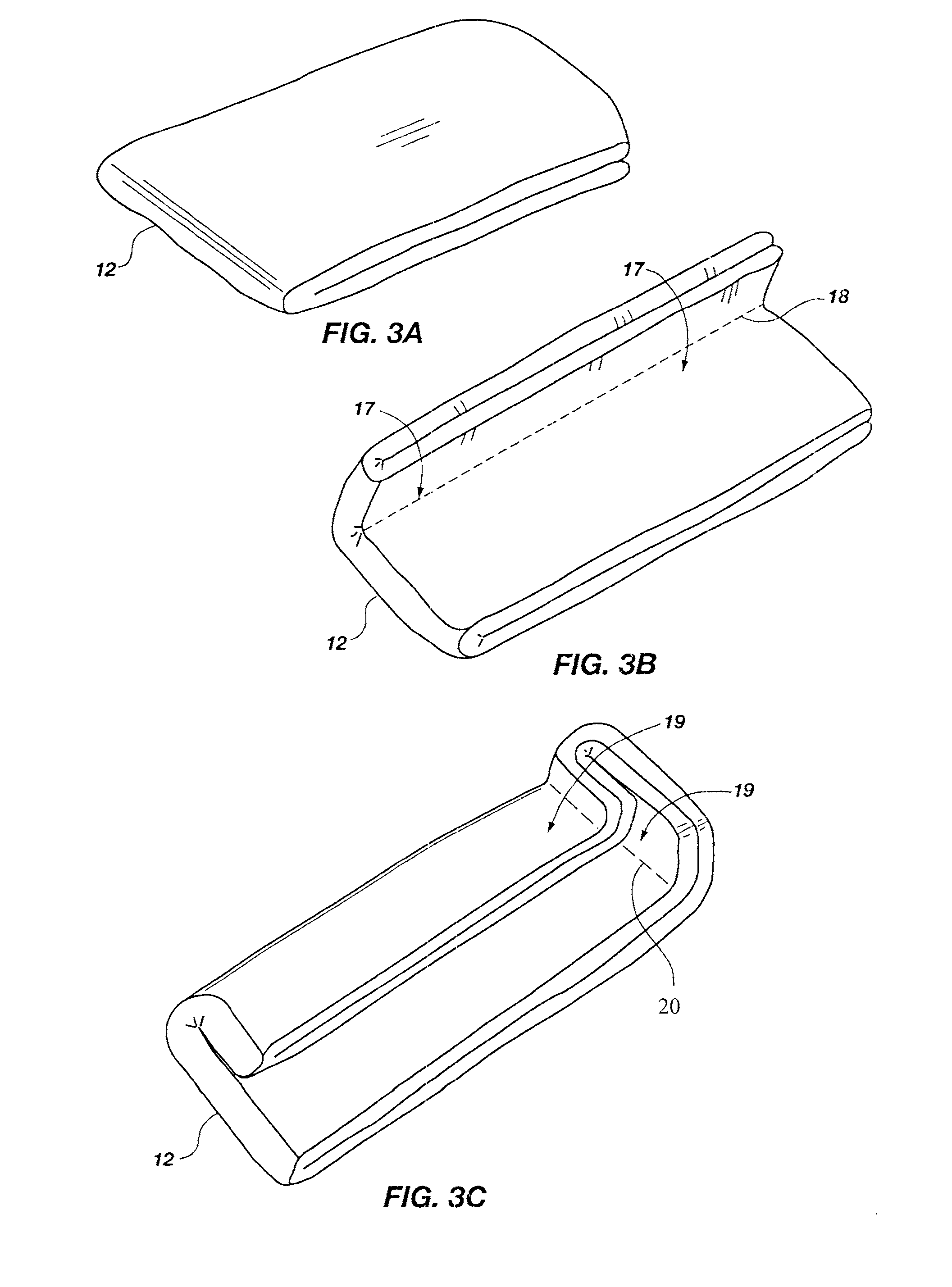

Cigarette packing machine for producing a rigid, hinged-lid packet

InactiveUS8745962B2Easy and relatively cheap to implementWrapping material feeding apparatusPackaging cigaretteEngineeringCigarette pack

A cigarette packing machine for producing a rigid packet a hinged lid has a first packing unit which folds a first blank about a group of cigarettes to form an outer container with a hinged lid; and a second packing unit which folds a second blank about the outer container to form a tubular slide surrounding the outer container to slide axially with respect to the outer container; the tubular slide has a transmission member, in turn having a first end integral with the lid, a second end opposite the first end and integral with the slide, and a deformable intermediate portion having a U-shaped fold between the outer container and the slide.

Owner:GD SPA

Method and apparatus for producing multi-compartment packages

An improved method and apparatus for making a multi-compartment package on a form, fill, and seal machine. Two pairs of heat sealing jaws are provided which produce seals having different sealing strengths.

Owner:FRITO LAY NORTH AMERICA INC

Device for sealing a vessel and method of manufacturing a sealed vessel

ActiveUS20130197467A1Reliably savedHigh levelAmpoule syringesDiagnosticsMarine engineeringFreeze-drying

A device for sealing a vessel, in particular a cartridge (7) or a test-tube for accommodating a freeze-dried pharmaceutical product (S), wherein the vessel (1) comprises at its opening end (3) an opening edge (4) and an adjoining longitudinal portion (5) with an evenly formed inner cross section, including a front plunger (2) to be positioned inside the vessel (1) at the longitudinal portion (5), is characterized in that the front plunger (2) is configured to be positioned in the vessel (1) in a sealing state, in which the front plunger (2) is fully inserted in the vessel (1), or in an exchange state, in which the front plunger (2) is inserted partly in the vessel (1) and partly protrudes over the opening edge (4) of the vessel (1), wherein the front plunger (2) comprises sealing means that are configured to seal the inside of the vessel (1) against the outside when the front plunger (2) is positioned in the sealing state, and one or more communicating grooves (2i) that are configured to place the inside and outside of the vessel (1) in communication with each other when the front plunger (2) is positioned in the exchange state. Furthermore, a method of manufacturing a sealed vessel (1) is disclosed.

Owner:ARTE

Processing method and unit for automatically opening a hinged-lid slide-open package of tobacco products

A processing method for automatically opening a slide-open package of tobacco articles with a hinged lid; the processing method including the steps of: mechanically clamping an outer container of the package; exerting pull on the lid to rotate the lid into an open position by means of a first actuator, which contacts a top wall of the lid, and has a suction head which engages the top wall by suction; and, simultaneously and in coordination with the step of exerting pull on the lid, exerting thrust on an inner container of the package, to slide the inner container axially with respect to the outer container, by means of a second actuator, which contacts a wall of the inner container through a window formed through a corresponding wall of the outer container.

Owner:GD SPA

Distributor unit for tablets or capsules

ActiveUS20150203226A1Improve translation speedRapid and efficient and reliable distributionCoin-freed apparatus detailsFinal package aspectsControl mannerDistributor

Distributor unit for transferring tablets and putting them in order, from a loading zone to an unloading zone, and for distributing the tablets in an orderly and controlled manner in organized blisters present in a blister strip. The distributor unit comprises belt-type feed means in which a feed belt is provided, along at least part of its length, and along at least part of its width, with a plurality of open through seatings each having at different times sizes coordinated with those of the tablets to be distributed, said open through seatings having a transverse interaxis about equal to, and a longitudinal interaxis equal to or less than, that of the blisters in the blister strip.

Owner:IMA IND MASCH AUTOMATICHE SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com