Apparatus for producing pouches

a pouch and pouch technology, applied in the field of pouch production apparatus, can solve the problems of undesired distortion of the shape difficulty in obtaining the correct position of the printed pattern on the pouch, and difficulty in maintaining the registration or phasing of the printed pattern with the pouch, etc., to achieve the effect of improving the position of the printed pattern

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

The Apparatus

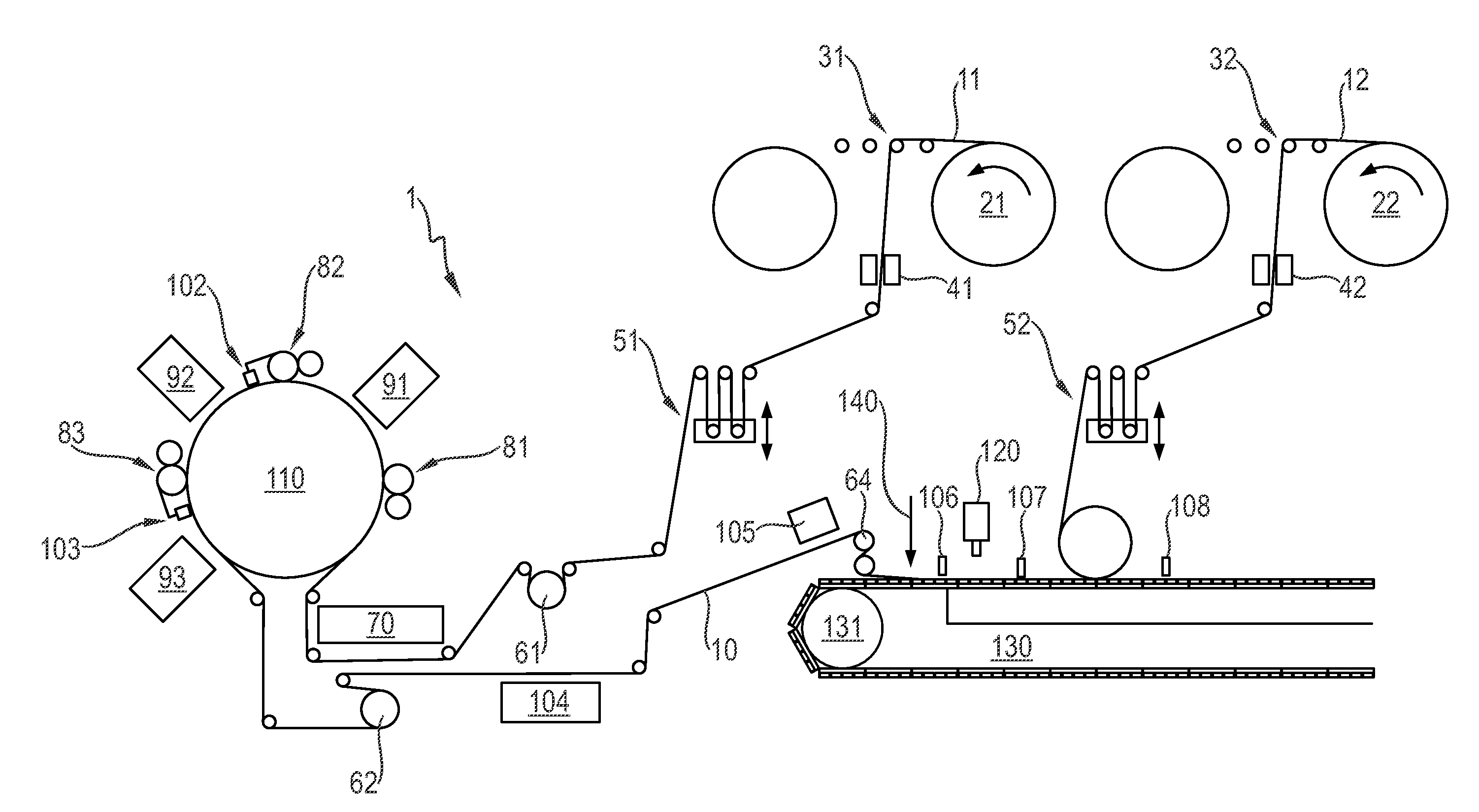

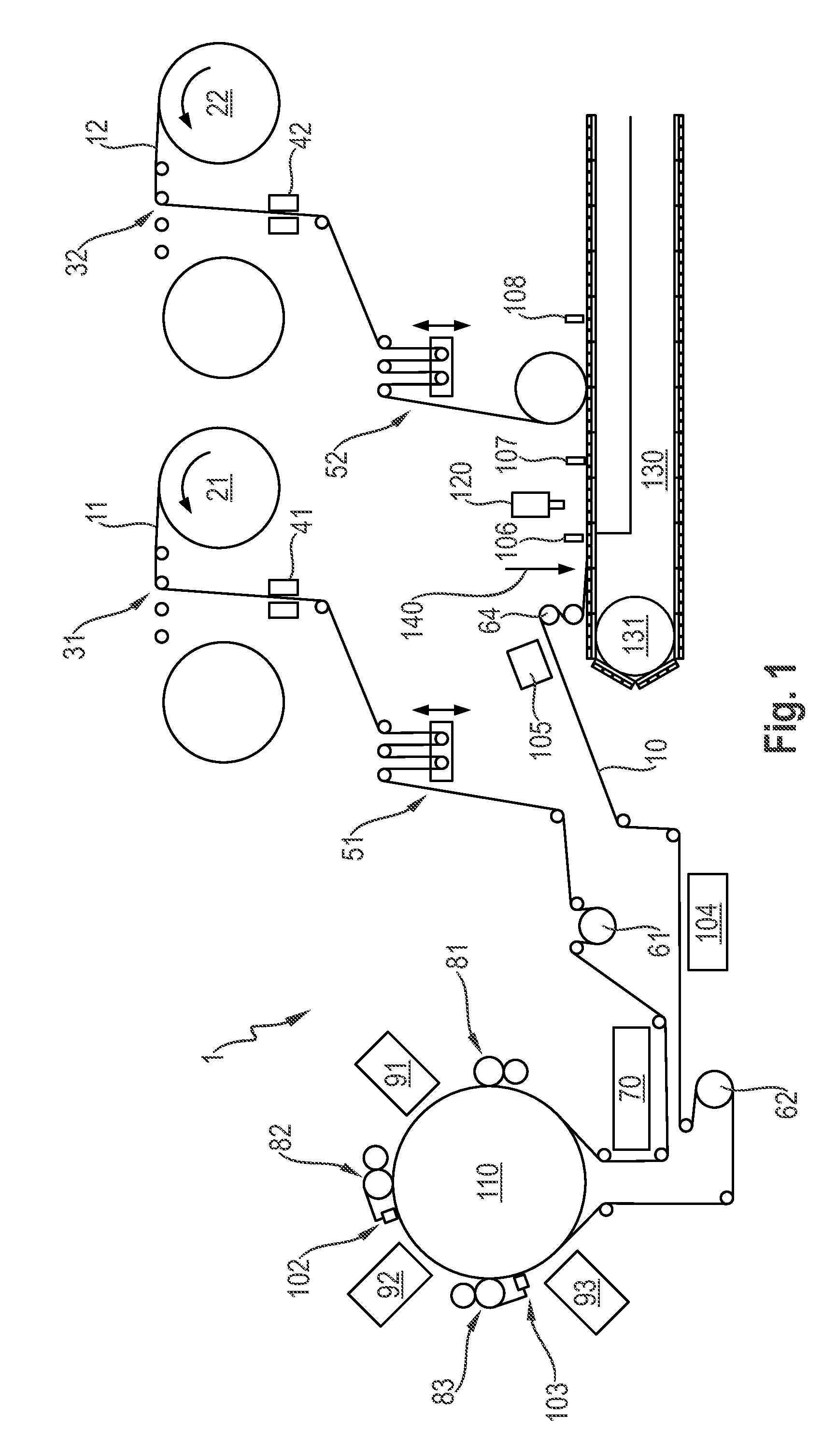

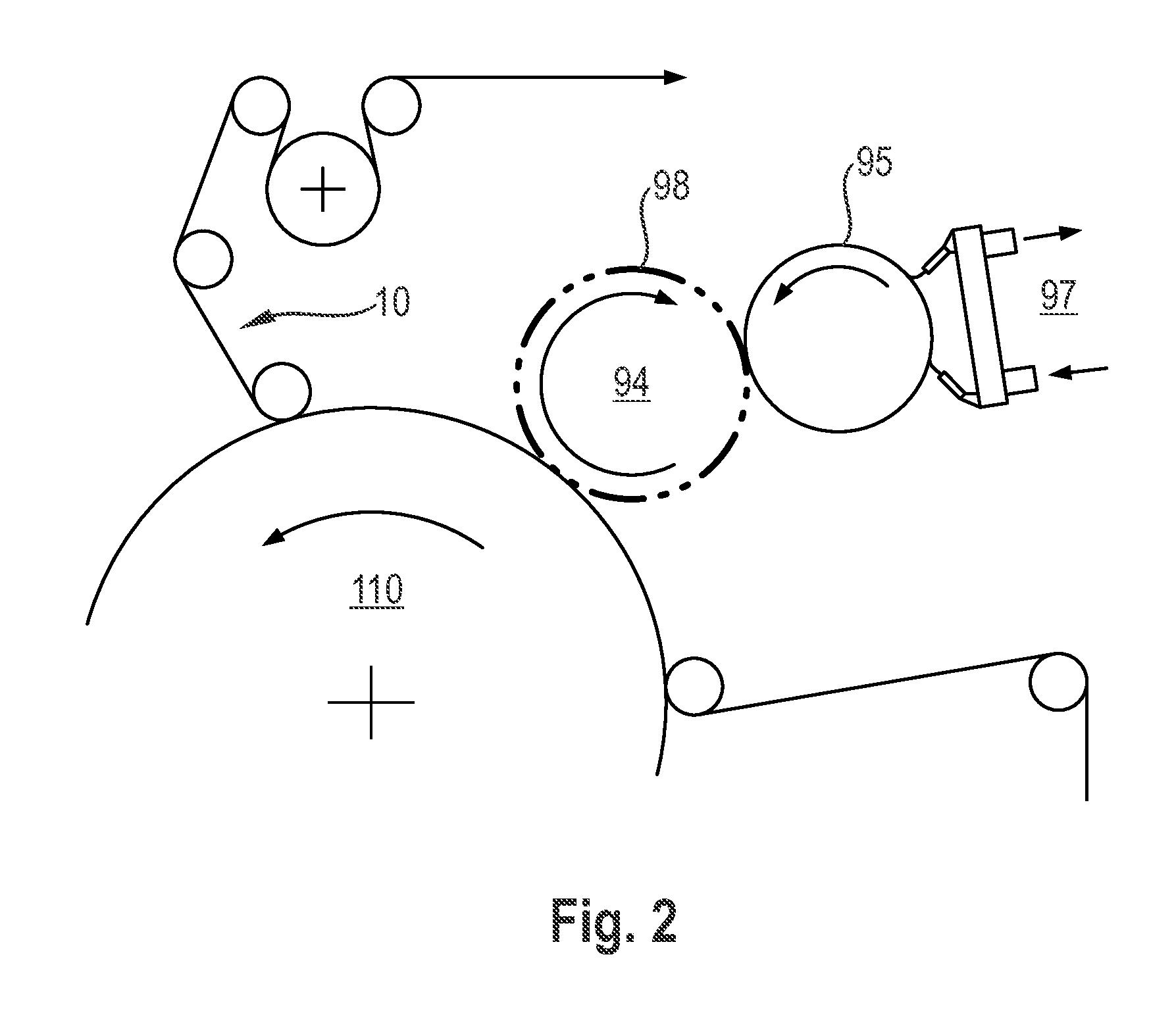

[0014]As shown on FIG. 1, the apparatus (1) comprises a first source of film (21) and a second source of film (22). The apparatus (1) may comprise a roll (21) of film to be printed. The film (11) comprises a copolymer of polyvinylalcohol. The film may be unwound from a spindle or a reel. The apparatus may comprise a film unwinder (31). The apparatus may comprise an automatic splicer (41). The apparatus may comprise an accumulator / dancer system (51) for control of the unwind tension and speed. The tension and / or the metering velocity may be controlled on the in-feed of the printing unit by utilizing an in-feed driven roller (61) which may or may not be coupled with tension measurement load cells. The apparatus may comprise a film pre-treatment station (70). The film pre-treatment station may provide corona treatment for increased spreadability and / or deposition of the compound to be printed (e.g. dye or ink). The apparatus may comprise an endless rotating system such as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com