Packaging production line used for multi-product collective packaging

A packaging production line and multi-product technology, applied in packaging, packaging machines, transportation packaging, etc., can solve the problems of restricting production efficiency, single work, heavy workload, etc., achieve rapid and non-destructive continuous separation, reduce labor intensity, and save production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

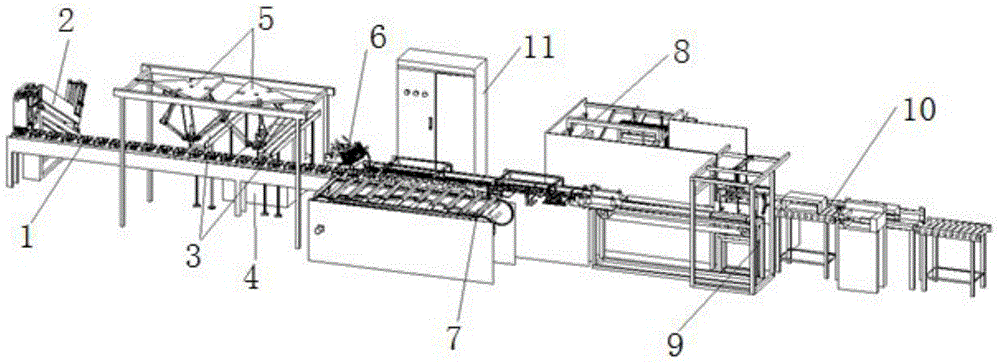

[0034] Design a shampoo product - a packaging production line for the combined packaging of two products of 500ml shampoo and 300ml hair conditioner (see figure 1 ).

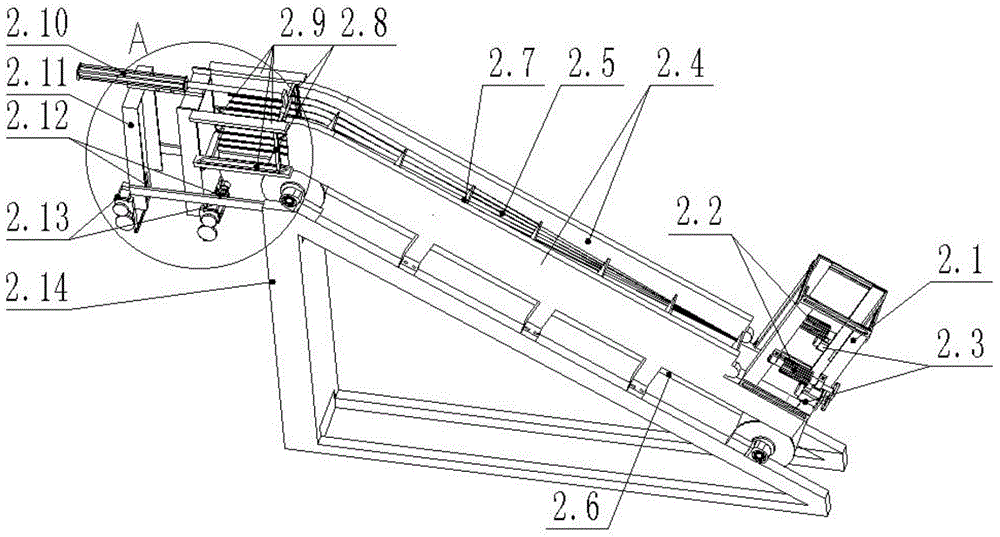

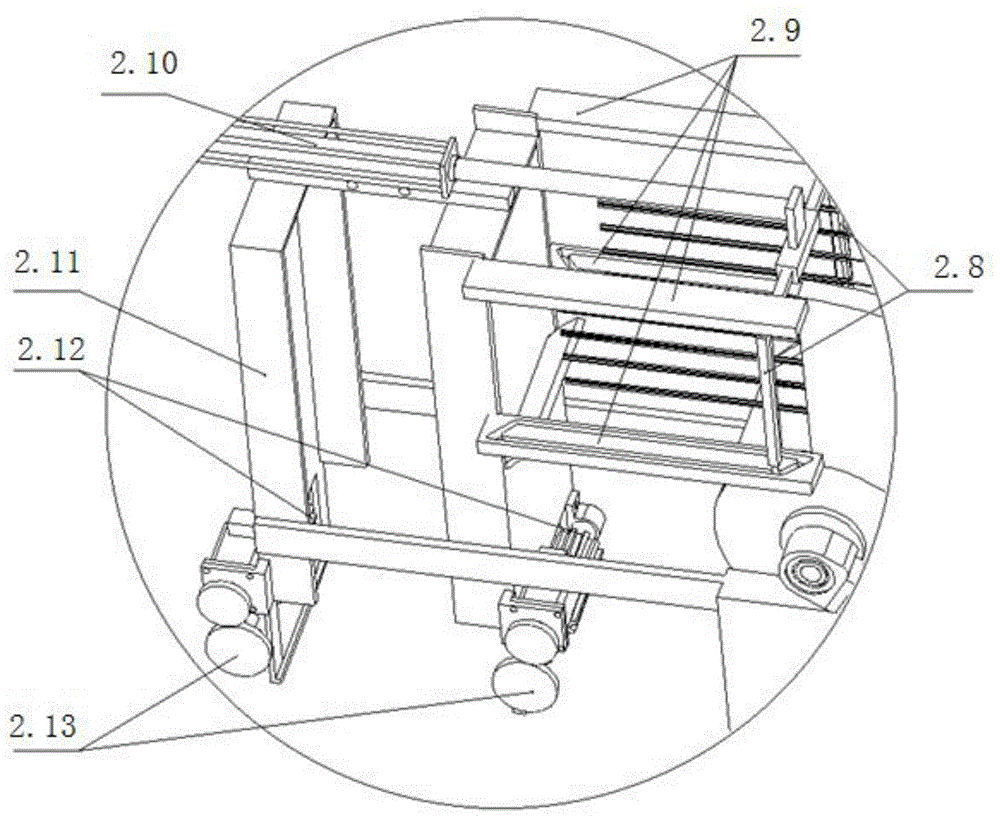

[0035] The packaging line (see figure 1 ) Including the main conveyor belt 1, plastic unloading machine 2, feeding conveyor belt 3, coding machine 4, feeding manipulator 5, box unpacking machine 6, continuous box packing and sealing machine 7, box unpacking machine 8, whole column code layer loading Box machine 9, box sealing machine 10 and control cabinet 11; described plastic support machine 2, feeding manipulator 5, box unpacking machine 6, box packing and sealing machine 7 are connected successively through the total conveyor belt 1; the total conveyor belt 1, Plastic unpacking machine 2, feeding conveyor belt 3, coding machine 4, feeding manipulator 5, box unpacking machine 6, box packing and sealing machine 7, box unpacking machine 8, whole column code layer box packing machine 9, box sealing machine 10 ...

Embodiment 2

[0044] Design a packaging production line for the combined packaging of 100ml lotion, 120ml toner and 100g facial cleanser. Compared with Example 1, the difference is that the number of feeding conveyor belt 3, coding machine 4 and feeding manipulator 5 in the production line is 3, and the two feeding manipulators 5 are fixed side by side along the total conveying direction of the conveyor belt. On the manipulator bracket, each coding machine is responsible for coding one product, one feeding conveyor belt 3 is responsible for loading one product, and one feeding manipulator 5 is responsible for grabbing one product and putting the product into the assembly line. In the corresponding positions of the plastic pallets on the conveyor belt 1, a feeding conveyor belt 3 corresponds to a coding machine 4 and a feeding manipulator 5 is jointly responsible for feeding a product. The number of individual plastic trays in each group of the grouped plastic trays to be separated in this e...

Embodiment 3

[0046] This embodiment designs a co-packaging production line for a cosmetic set. The cosmetic set includes four products: lotion, skin toner, facial cleanser and face cream. Structures are tightly packed together. The connection method of Embodiment 2 is adopted, the difference is that there are 4 feeding conveyor belts 3, coding machines 4 and feeding manipulators 5, and the four feeding manipulators are fixed side by side on the manipulator bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com