Punching and binding integrative machine

An all-in-one machine and punching device technology, applied in binding and other directions, can solve the problems of messing up the order of paper, taking a lot of time, and low binding efficiency, and achieve the effects of ensuring binding quality, convenient operation, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

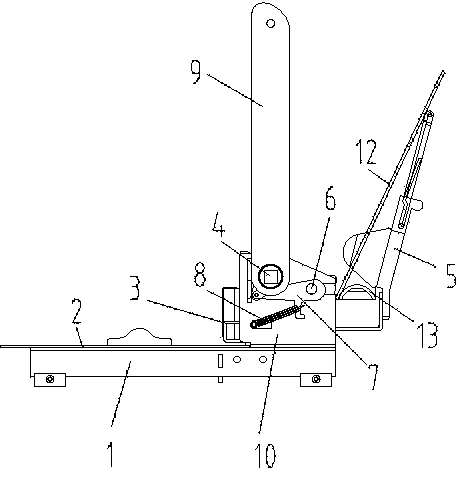

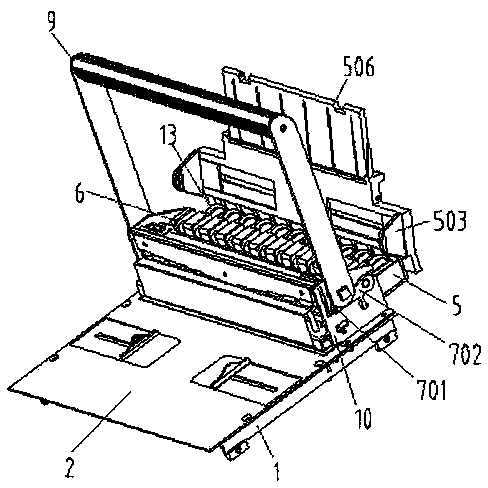

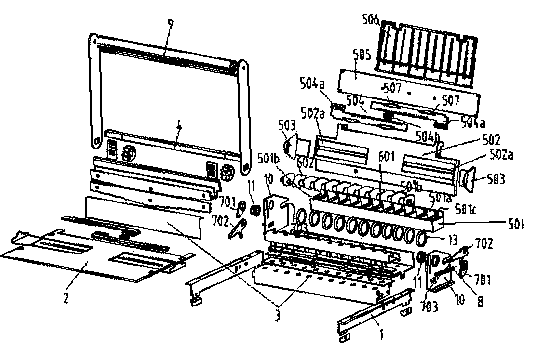

[0042] Embodiment 1, see attached figure 1 , 2, 3, 4, punching and binding all-in-one machine, including a base 1, a punching table 2 arranged on the base 1, a punching device 3 arranged on the base 1, and a rotatable mounting on the base 1 The rotating shaft 4 is fixed with a moving handle 9 on the rotating shaft 4, and the rotating shaft 4 is rotated by moving the handle 9 so that the punching device 3 completes the punching of the binding hole. The rotating shaft 4 is hinged on two brackets 10 Above, the rotating shaft 4 can be a polygonal prism shaft body or a cylinder. In this embodiment, it is a regular quadrangular prism with bushings 11 at both ends. The base 1 rotates to complete the punching of the paper, and the punched binding hole is mushroom-shaped, which is used to match the binding ring. In addition, it also includes the paper for placing the binding hole that has been punched and the binding hole that matches the binding hole. The placement device 5 of the r...

Embodiment 2

[0047] Embodiment 2, see attached Figure 5 , in this embodiment, the rotating part 701 includes a driving gear, the transition connecting part 702 includes a driven rack meshed with the driving gear, the driven rack is fixedly connected to the press-fit device 6, Drive the press-in device 6 to move linearly away from the rotation direction of the carrying handle 9 in the horizontal direction; the elastic return device can be a compression spring or a tension spring.

Embodiment 3

[0048] Embodiment 3, see attached Image 6 , the rotating part 701 includes a cam fixedly connected with the rotating shaft 4, the transition connecting part 702 includes a driven plate connected with the press-in device 6 for cooperating with the cam, and the guide The device 703 is a guide sleeve set on the driven plate, which acts as a guide for the driven plate, and the elastic return device can be a compression spring for pressing the driven plate or a tension spring for pulling the driven plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com