Reinforcing steel bar banding mechanical arm

A technology for tying steel bars and manipulators, which is applied in construction, building construction, and processing of building materials, etc., can solve the problems of high intensity of manual labor, large workload, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

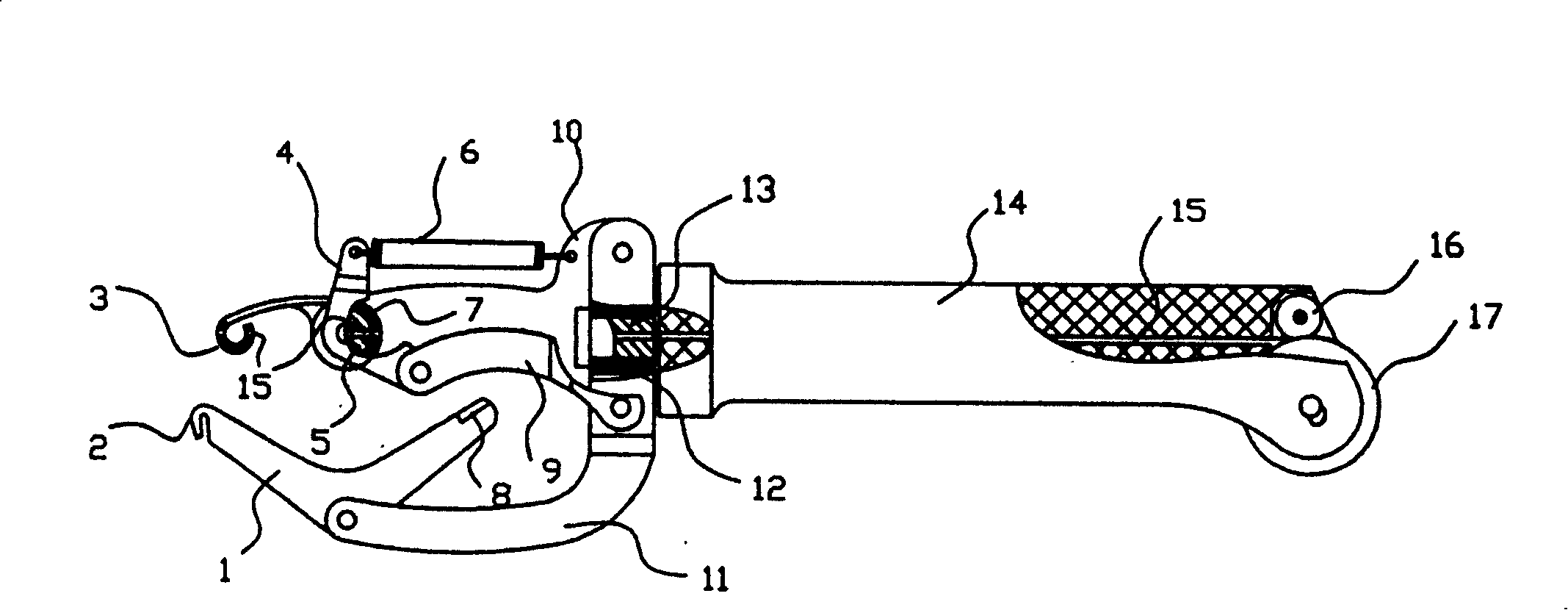

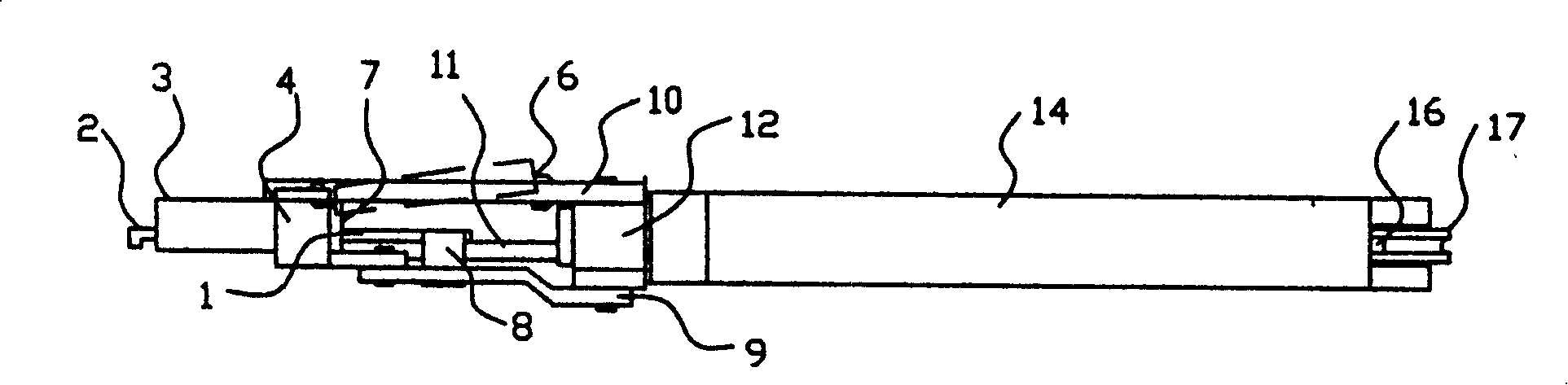

[0009] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0010] As can be seen from the accompanying drawings, the steel bar binding manipulator of this program has a handle (14) with a wire guide hole (15), and there are pressure wheels (16) on both sides of the wire guide hole (15) at one end of the handle (14). ) and wire walking wheel (17), the bottom of this wire walking wheel (17) protrudes outside the handle (14). The other end of the handle (14) is fixedly connected with the rotating shaft (13) with the guide wire hole (15) with the handle (14), and the shaft seat (13) that can rotate around the rotating shaft (13) is covered with the rotating shaft (13). 12), a crank arm (11) is fixed on one side of the shaft seat (12), the top of the crank arm (11) is hinged with a V-shaped broken wire swing bar (1), and the broken wire swing bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com