Patents

Literature

40 results about "Binding iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

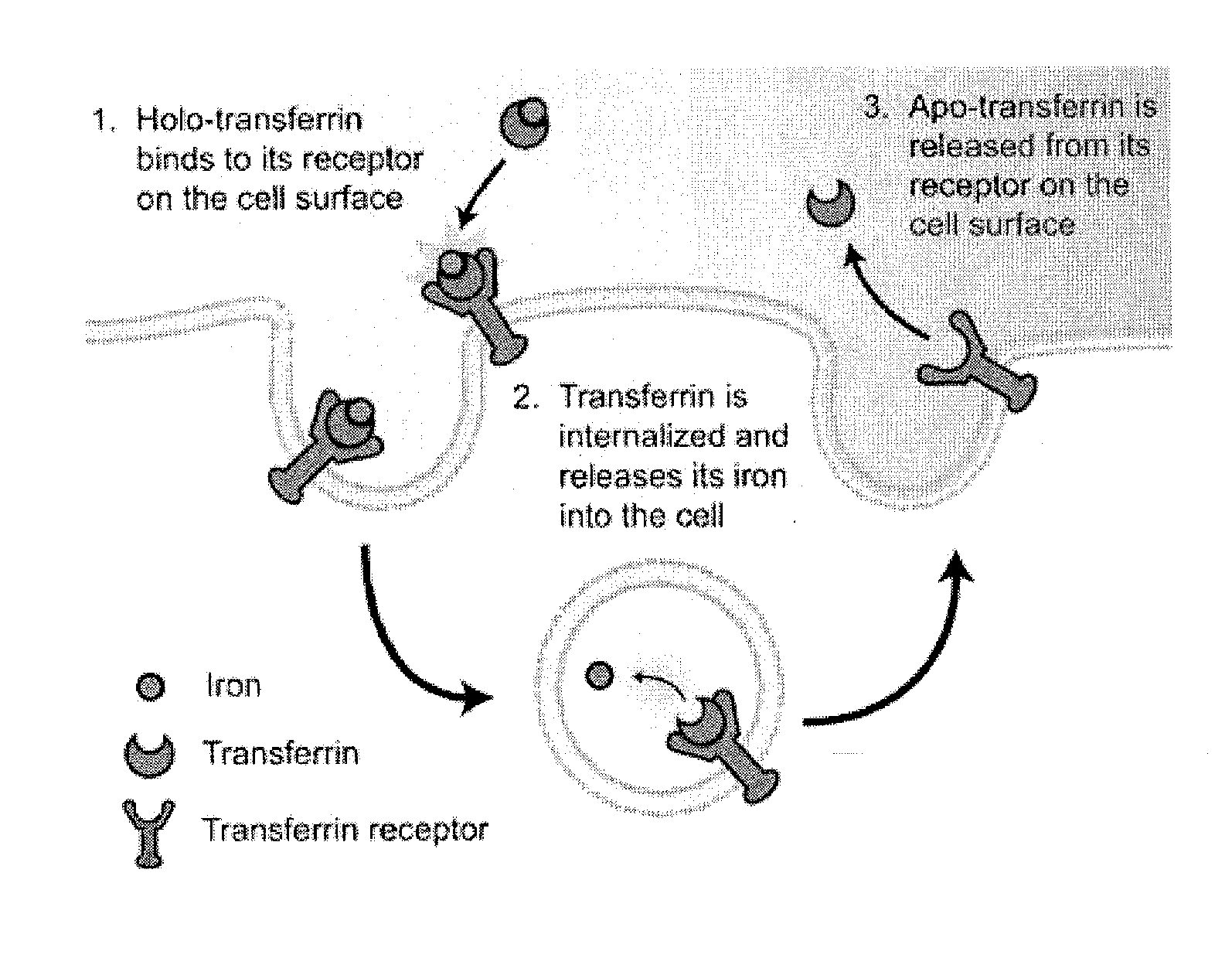

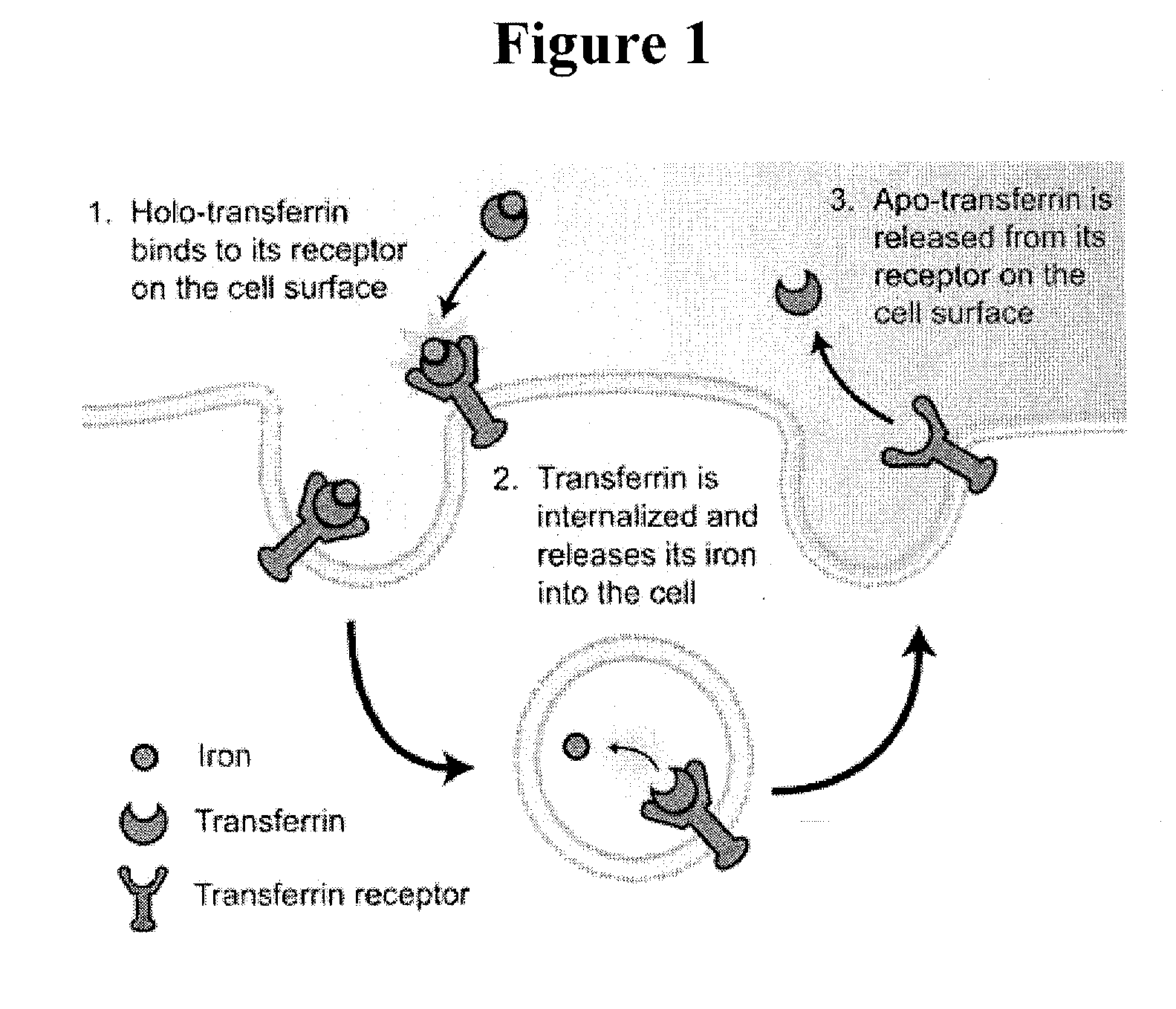

Total iron binding capacity. Total iron binding capacity (TIBC) is a blood test to see if you have too much or too little iron in your blood. Iron moves through the blood attached to a protein called transferrin.

Iron-Containing Human Milk Fortifier With Improved Antimicrobial Properties

InactiveUS20080274230A1Reducing and eliminating inherent activityHigh iron concentrationNervous disorderAntipyreticHuman milk fortifierMicroorganism

Disclosed are human milk fortifier compositions, in either powder or liquid forms, comprising nutrients and selected iron-containing materials, wherein the fortifiers when added to human milk do not significantly inhibit or otherwise eliminate the inherent, in-vitro antimicrobial properties of the milk. This is accomplished by formulating the compositions with iron-containing insoluble iron, soluble bound iron, or combinations thereof, with little or no soluble unbound iron. Also disclosed are methods of providing nutrition to infants, especially preterm infants, by adding the human milk fortifier described herein with human milk to form a fortified human milk, and then administering the fortified human milk to the infant. The fortifier can also be used to fortify other infant formulas.

Owner:JOHNS PAUL W +2

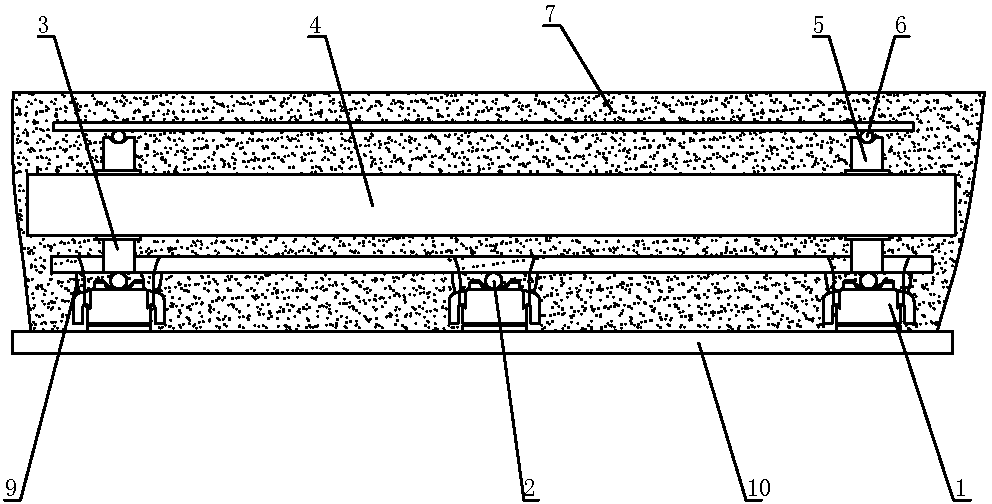

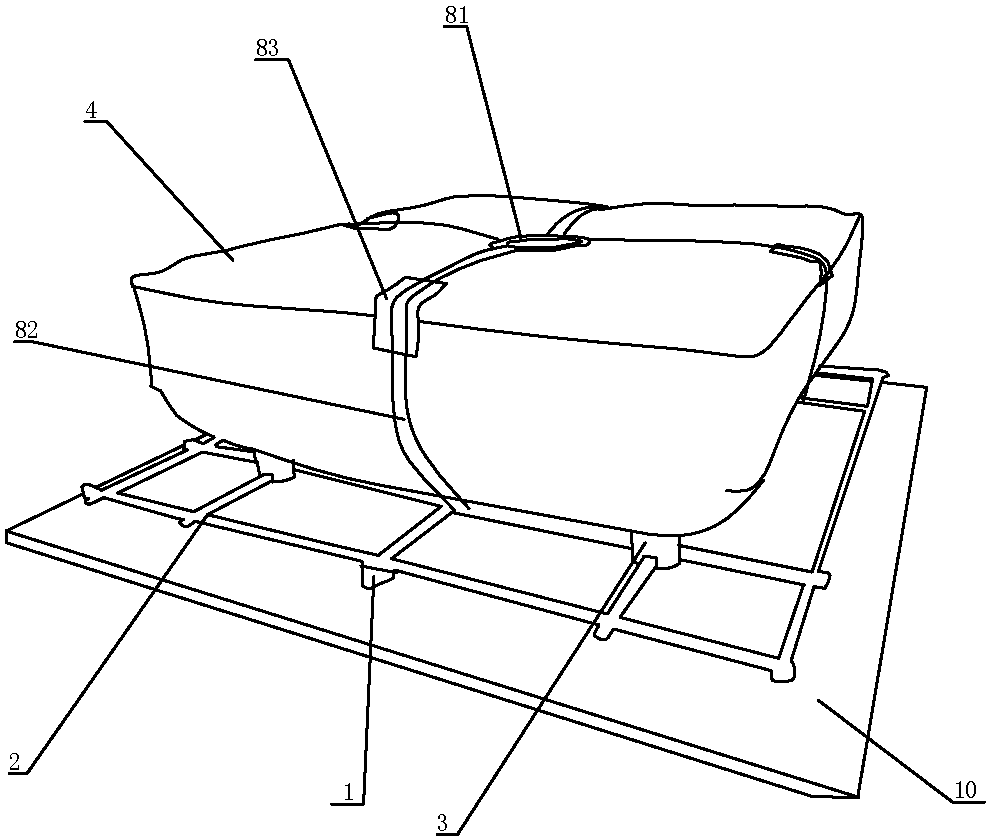

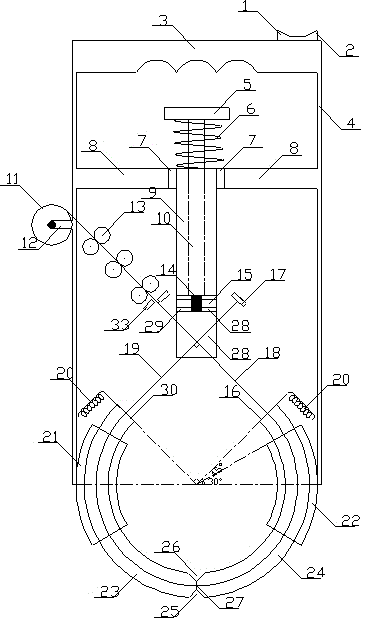

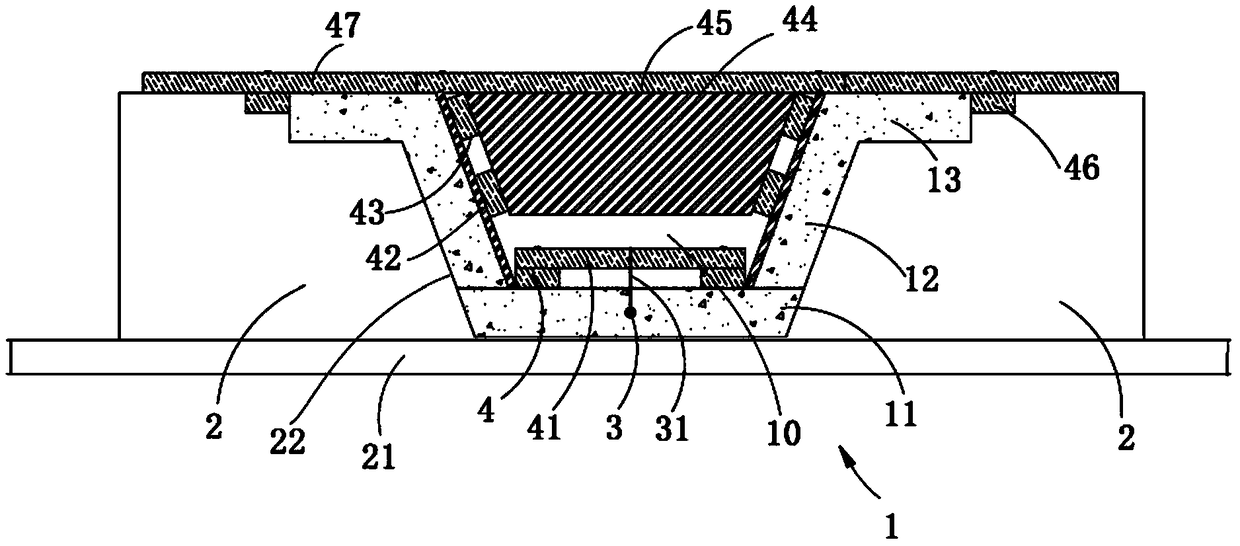

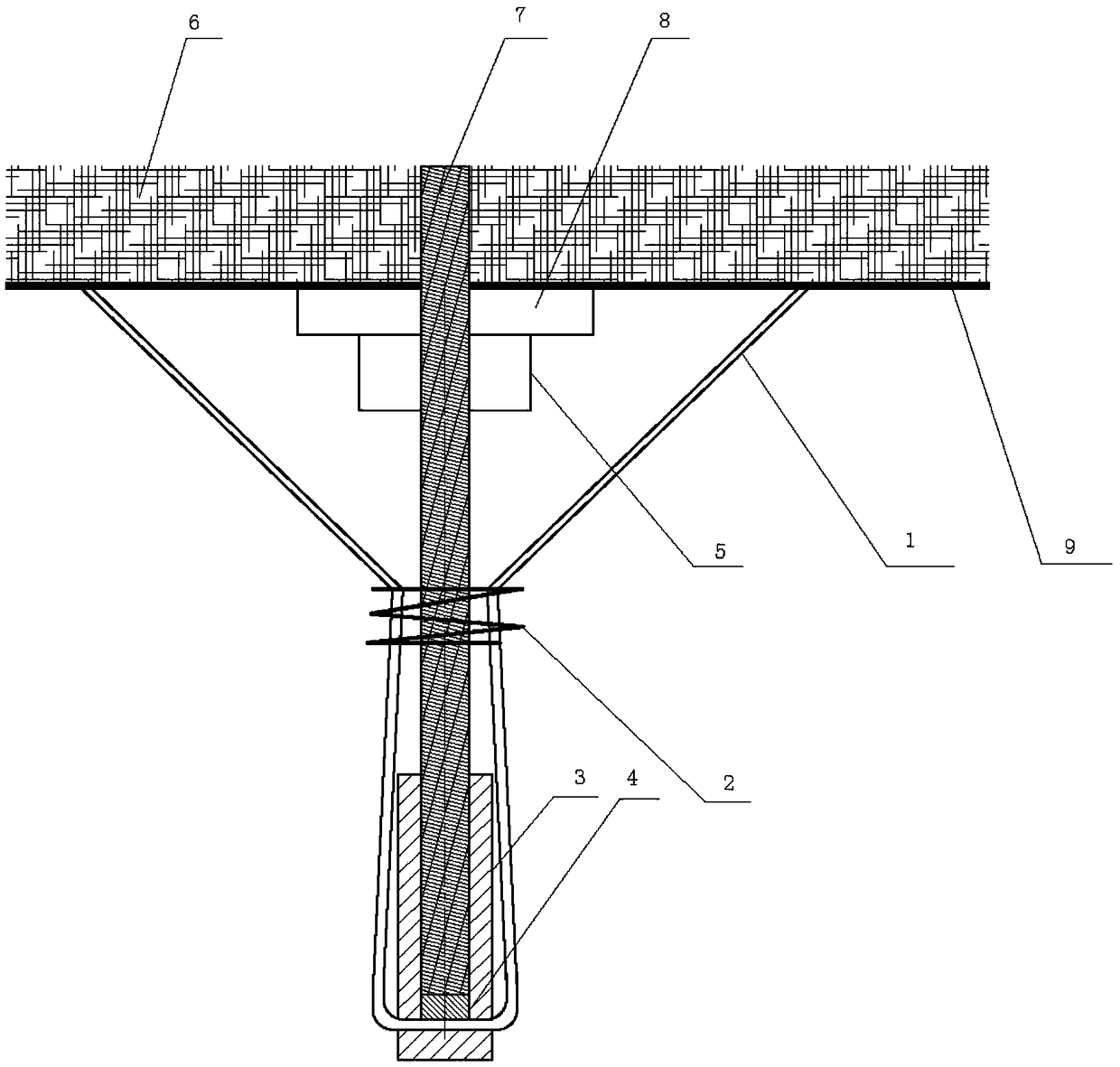

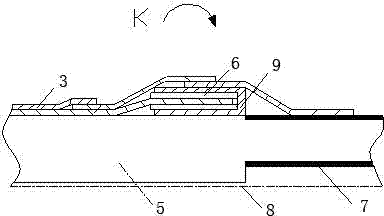

Hollow floor slab and construction method thereof

The invention discloses a hollow floor slab and a construction method of the hollow floor slab. The hollow floor slab comprises an anti-floating component, a protecting layer steel bar, a lower supporting fixing member, a core die, an upper supporting fixing member, an upper layer steel bar, a fixing structure and concrete. The construction method comprises the steps of setting up a formwork, mounting the anti-floating component, laying the protecting layer steel bar, arranging the lower supporting fixing member, mounting the core die, mounting the upper supporting fixing member, laying the upper layer steel bar, pouring the concrete and disassembling the formwork. The hollow floor slab structure is free of the phenomenon that binding iron wires are exposed outwards, and the position of the core die is determined so that the distance among the steel bars and the core die can be limited. The construction method can prevent the steel bars and the core die from floating upwards, the distance among the steel bars and the core die can be limited, the fact that the thickness of the floor slab reaches design requirements is ensured, and meanwhile the binding iron wires can be prevented from being exposed outwards under the premise that the formwork is convenient to disassemble.

Owner:广东班高得绿色建工科技有限公司

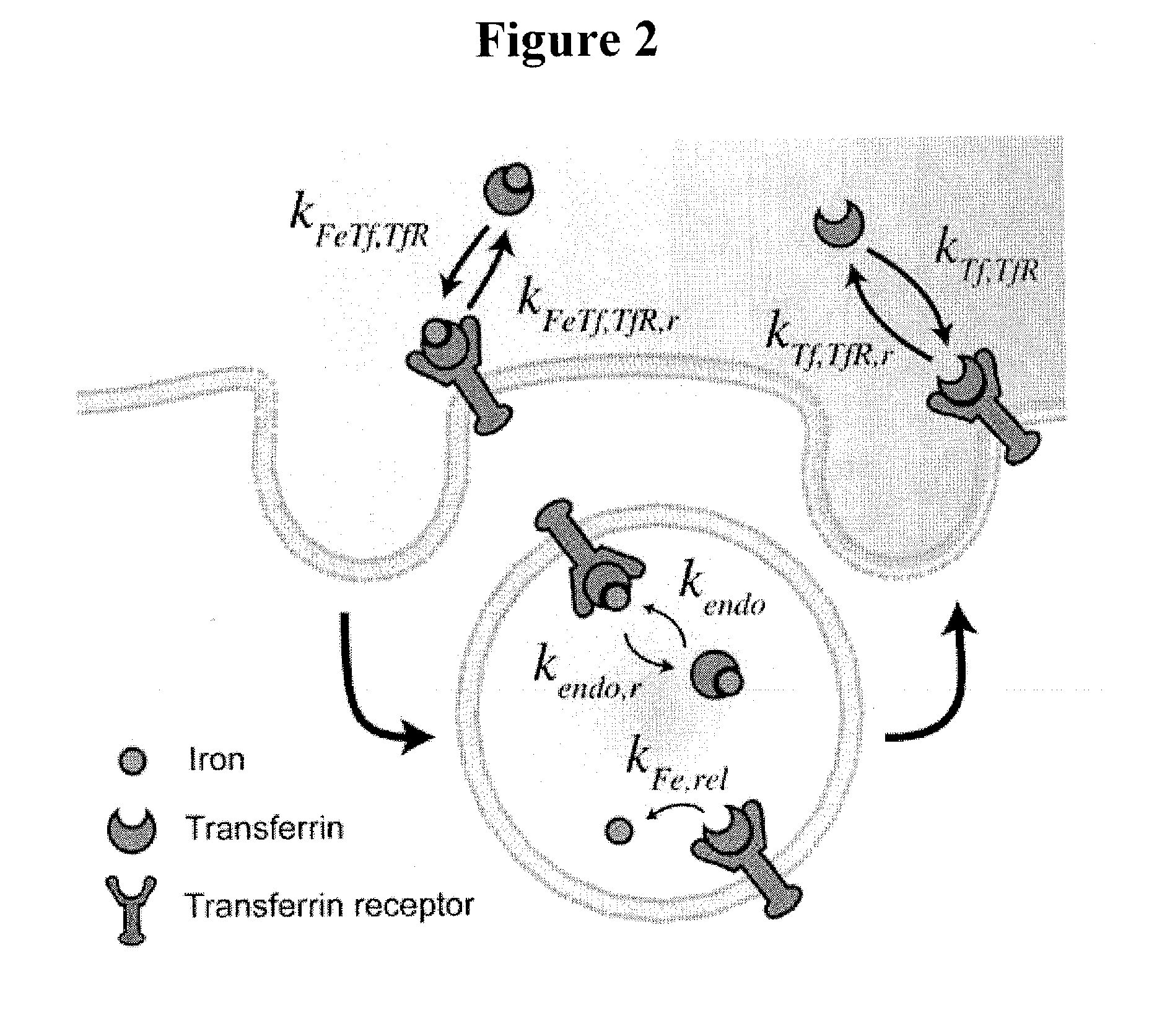

Cancer drug delivery using modified transferrin

The invention provides modified Transferrin (Tf) molecules and conjugates of the Tf molecules with a therapeutic agent. The invention also provides methods of treating cancer wherein the therapeutic agents are chemotherapeutic agents. The modified Tf molecules improve the delivery of the conjugated agent to a target tissue. In some embodiments, the modified Tf molecule has a mutation which decreases the release of bound iron from a Tf complex. The complex can also contain, for instance, a carbonate, oxalate, or other anion to stabilize the Tf iron complex.

Owner:RGT UNIV OF CALIFORNIA +1

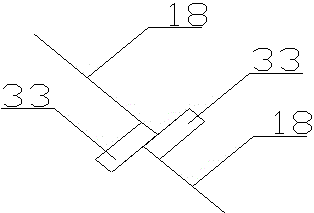

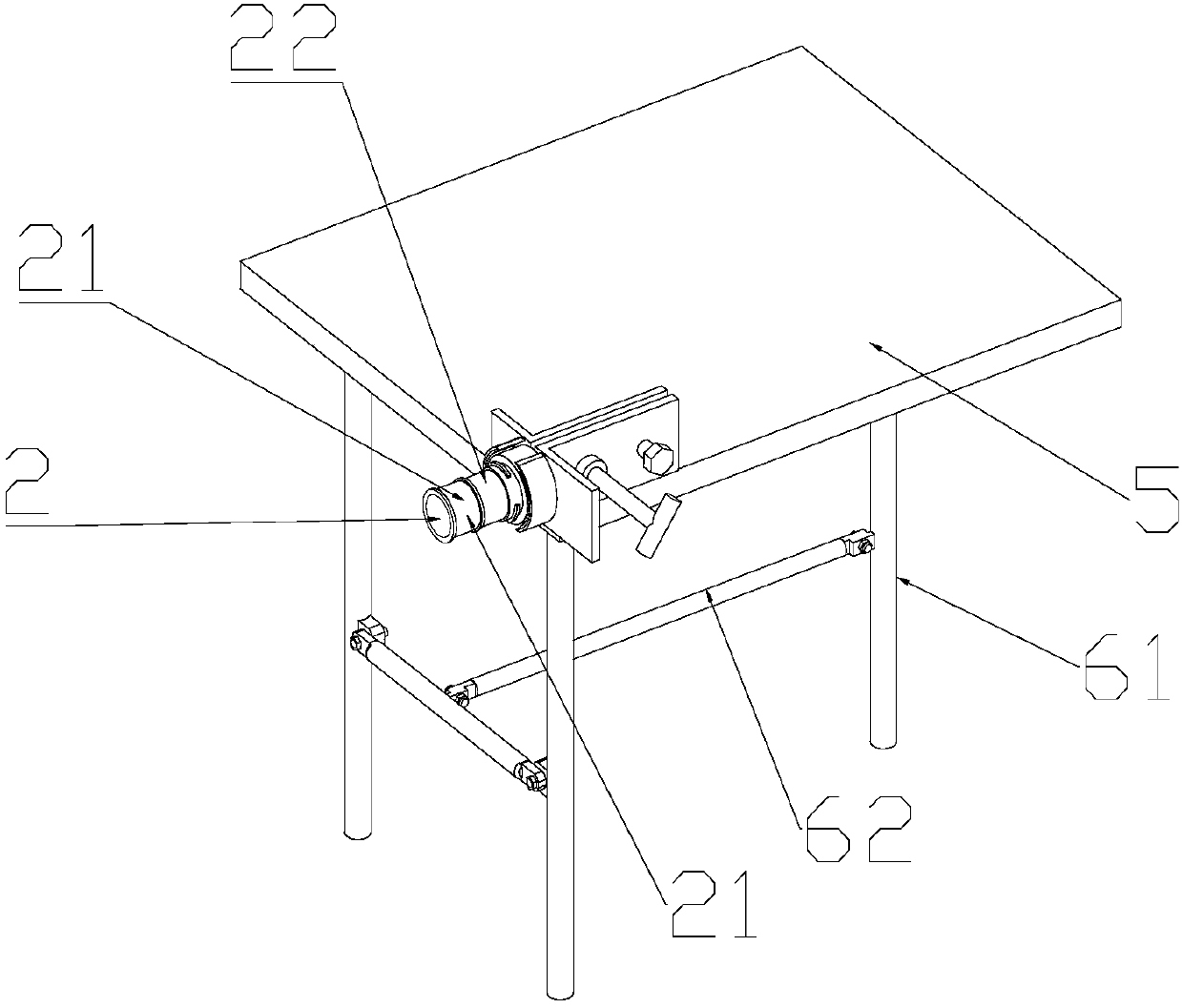

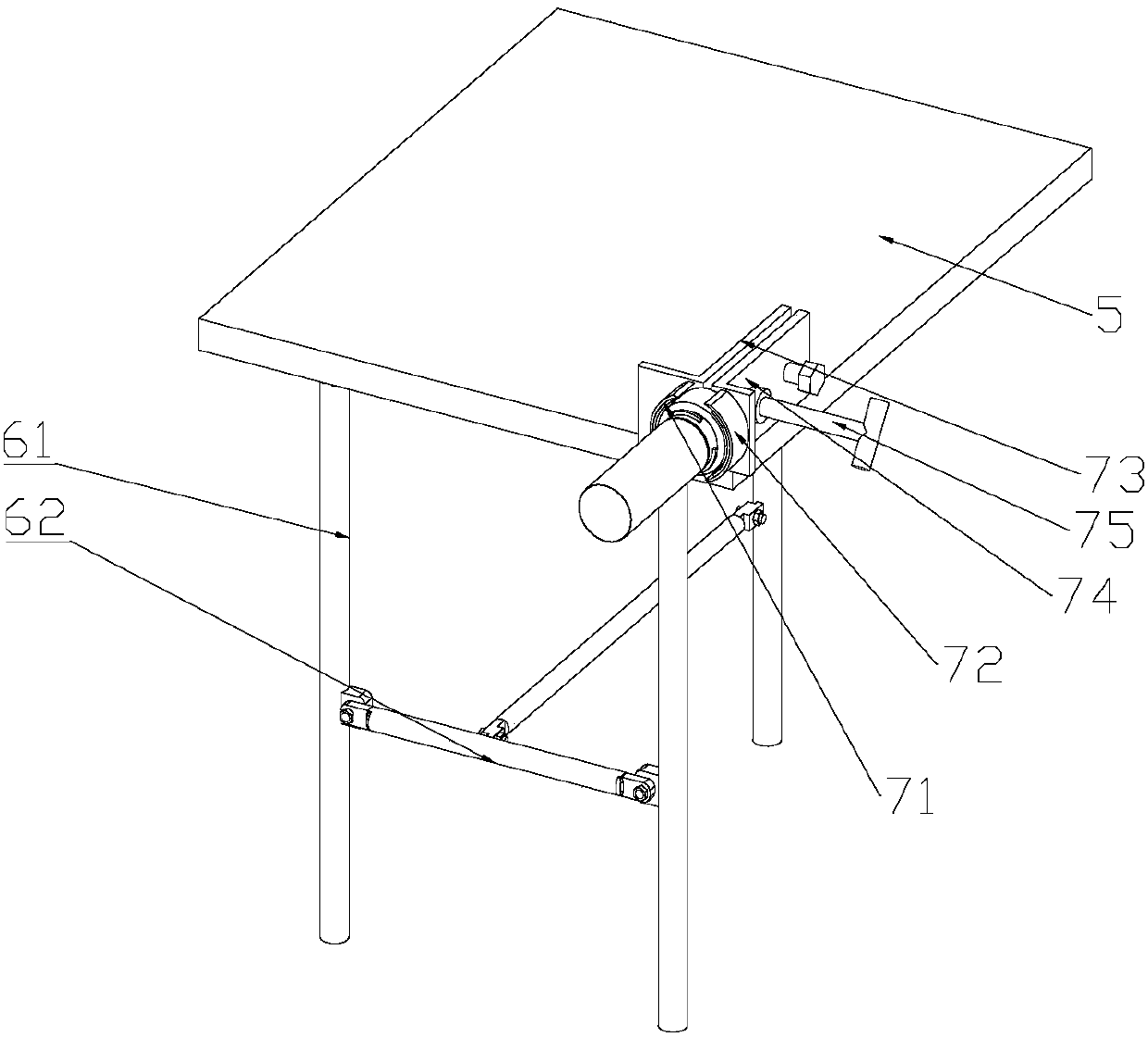

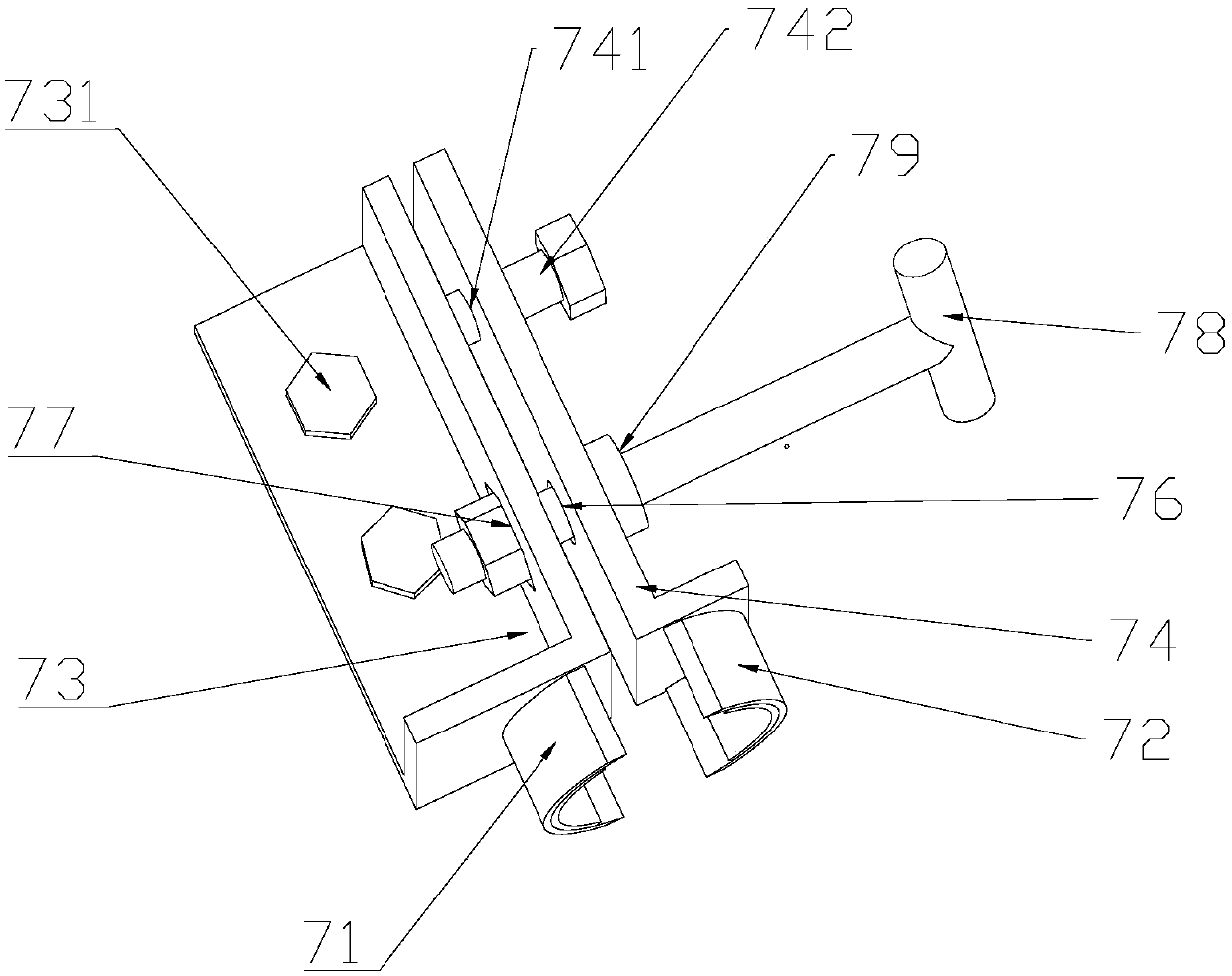

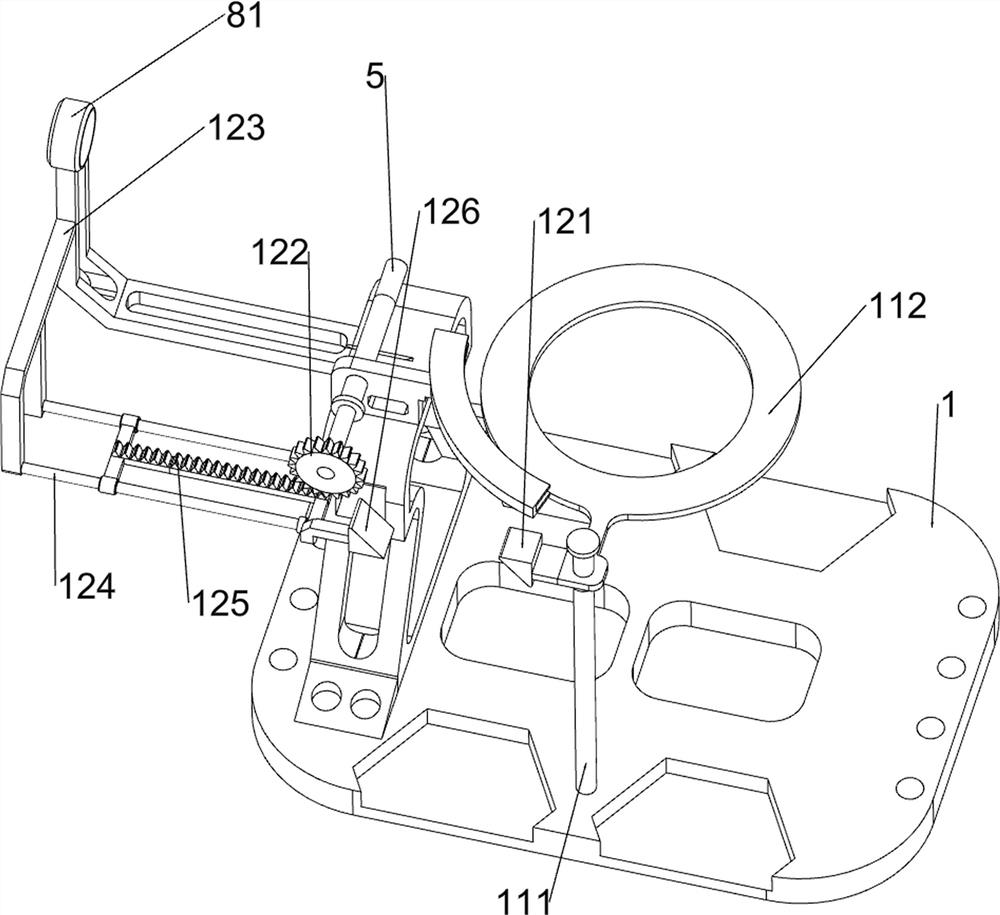

Novel reinforcing steel bar binding device

InactiveCN104818854AEasy to useThe principle is simpleBuilding material handlingWire cuttingEngineering

The invention relates to a reinforcing steel bar binding device which comprises an outer shell, a handle, a wire feeding wheel, an iron wire cutting knife, an iron wire sliding chute, an outer sleeve, a clamp A, a clamp B, a center shaft, an inner shaft, an iron wire coil support base, a torsion spring, a compression spring, a tension spring, a wire feeding wheel switch, an outer sleeve switch and the like; the wire feeding wheel transmits an iron wire to the iron wire sliding chute; the clamps A and B clamp the cross point of iron wires guided in and out when a pressing plate is pressed down; the outer sleeve rotates in a rolling bearing to drive a center shaft to rotate; the center shaft drives the clamps A and B to rotate so as to screw the iron wire tightly. The invention provides a special reinforcing steel bar binding tool which is simple in structure, rational in design, convenient to use, good in binding quality, high in efficiency, time-saving, force-saving, and capable of saving binding iron wire and realizing continuous binding process of the reinforcing steel bar.

Owner:SHANDONG UNIV OF SCI & TECH

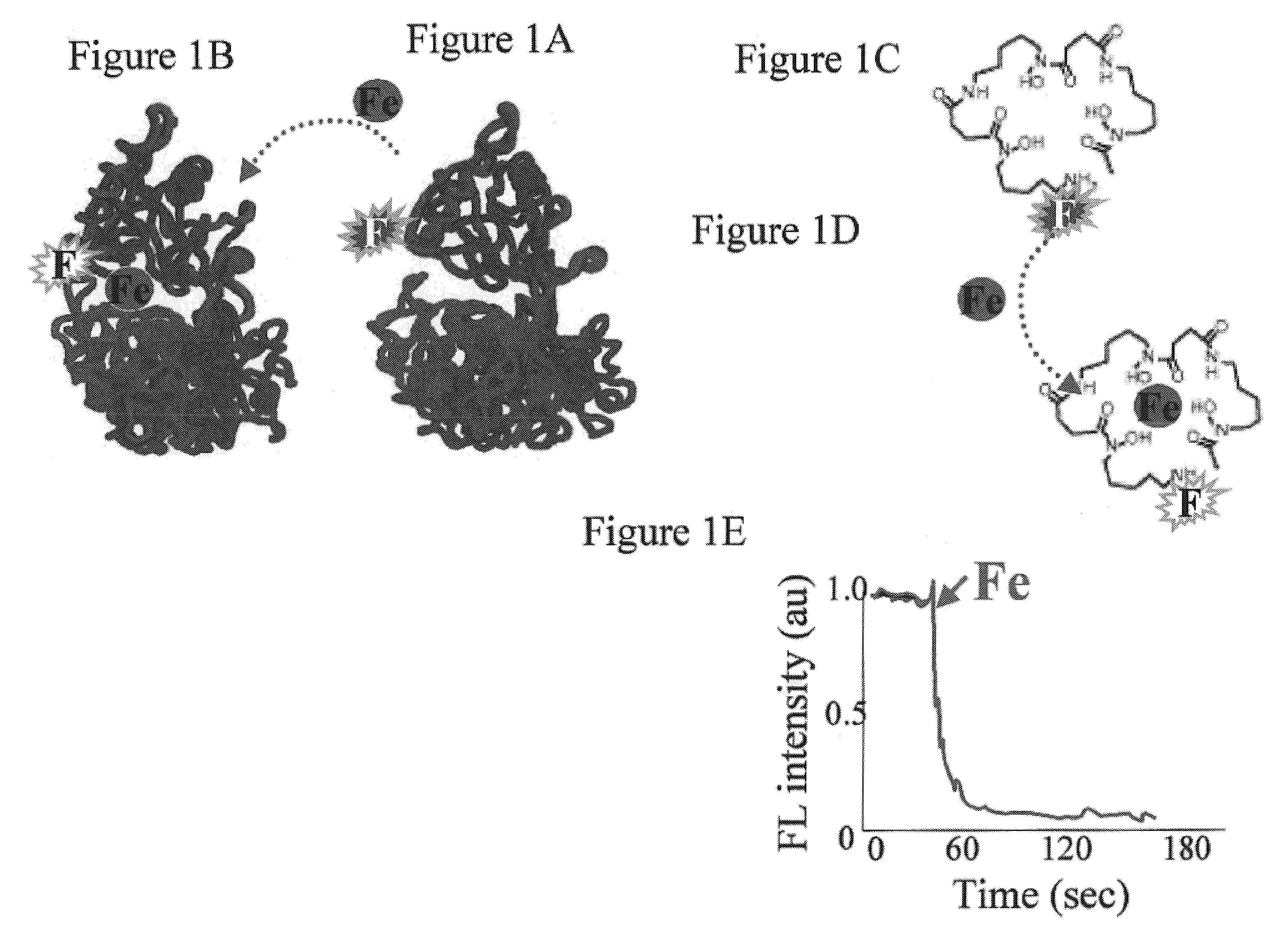

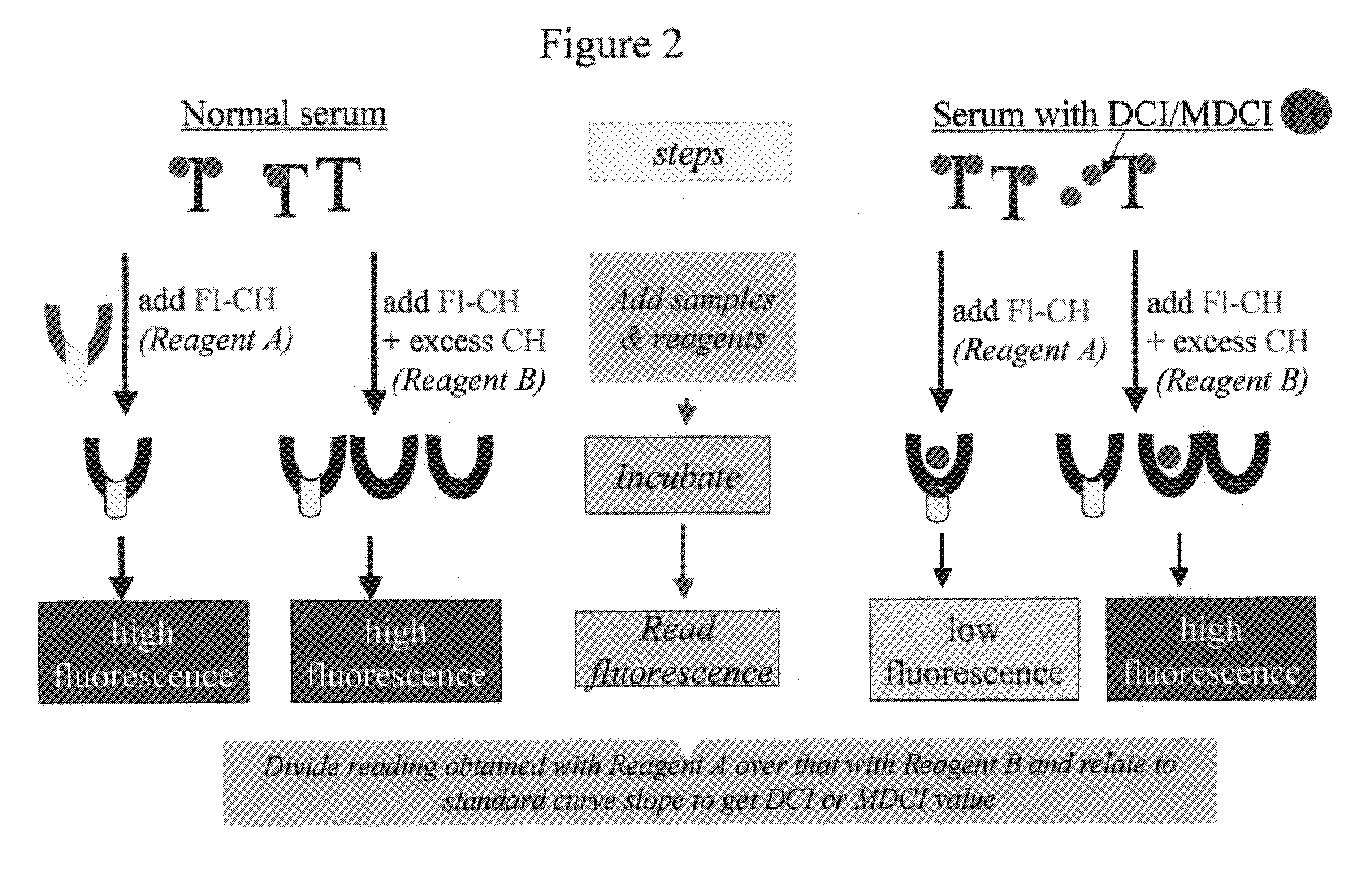

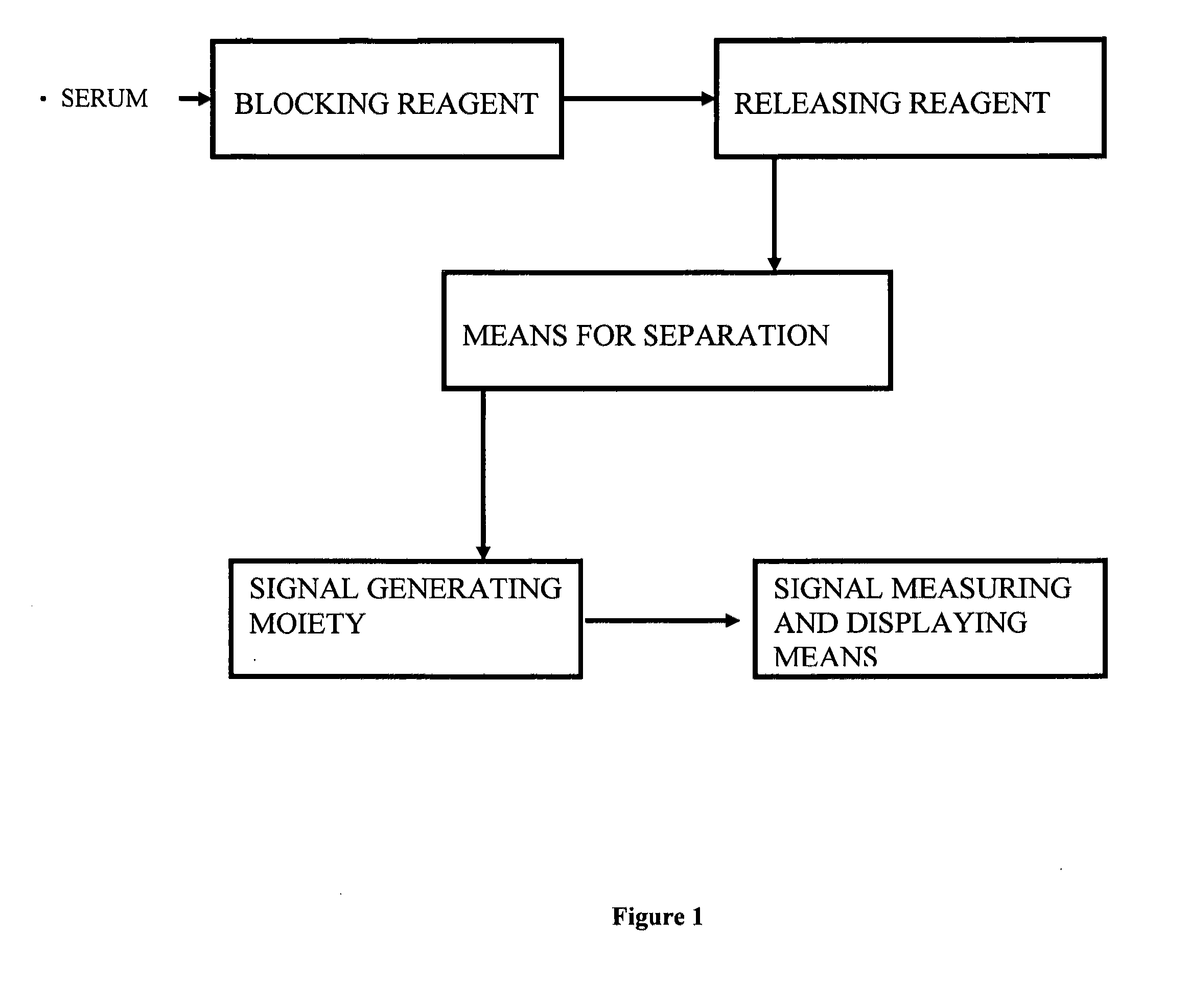

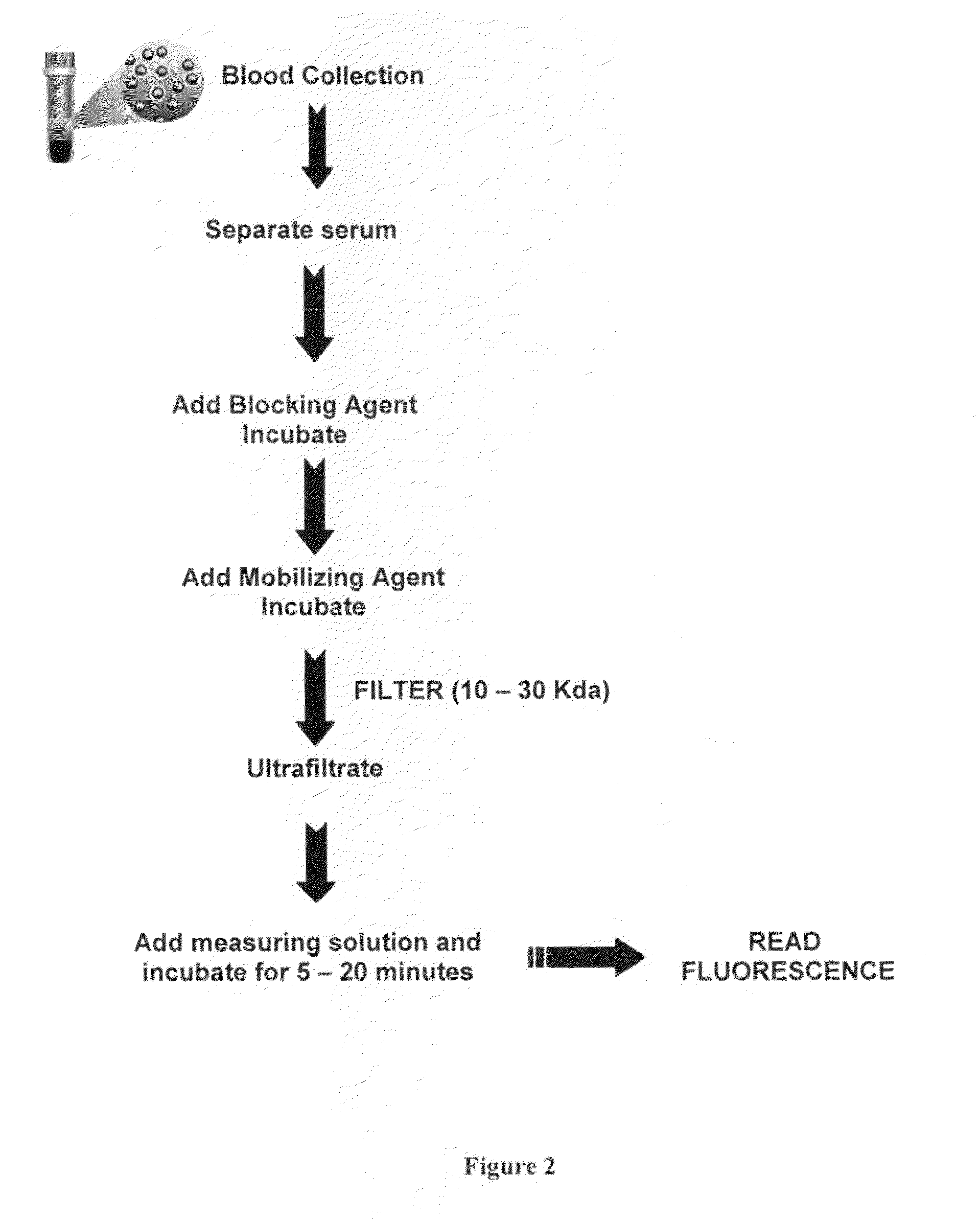

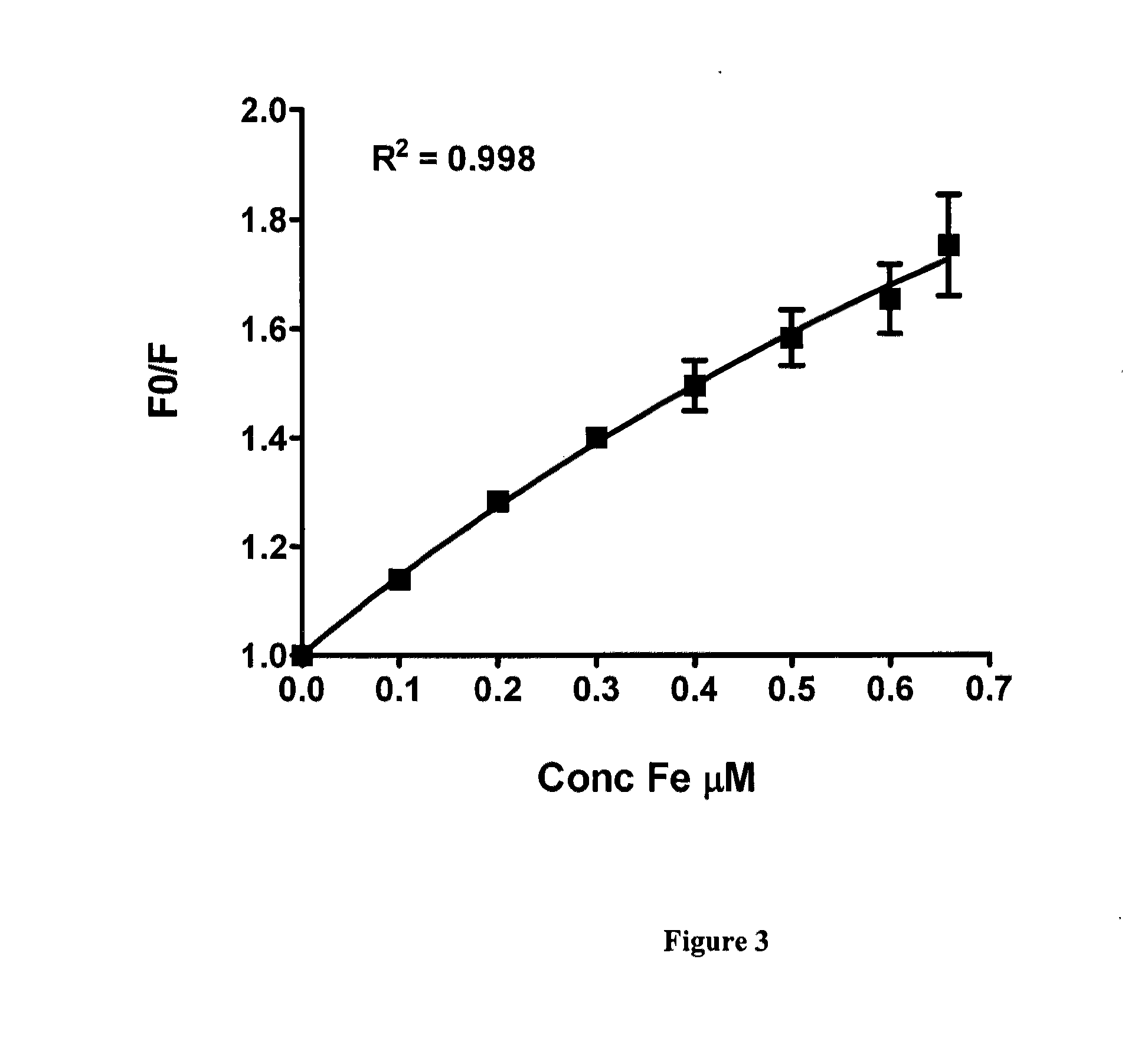

Molecules and methods using same for measuring non-transferrin bound iron

InactiveUS7090995B2Straightforward and accurate and sensitive identificationMicrobiological testing/measurementTesting metalsIron levelsUltimate tensile strength

A molecule suitable for use as an indicator of free iron levels in a biological sample, the molecule including an iron binding moeity and a signal generating moeity, wherein an intensity of the signal generated by the signal generating moeity is related to an amount of the iron bound by the iron binding moeity.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

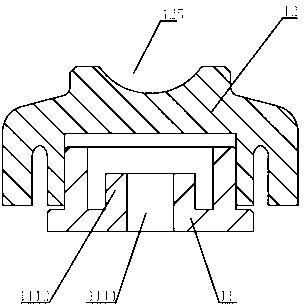

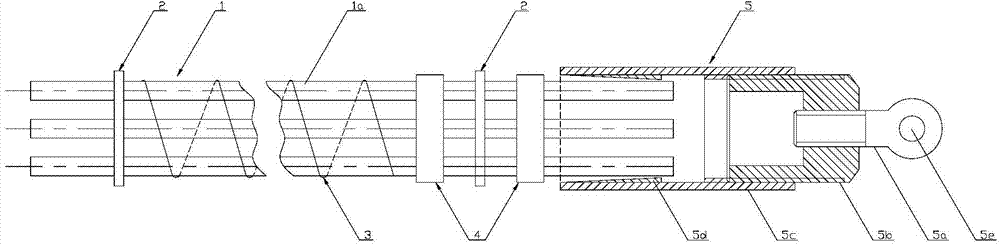

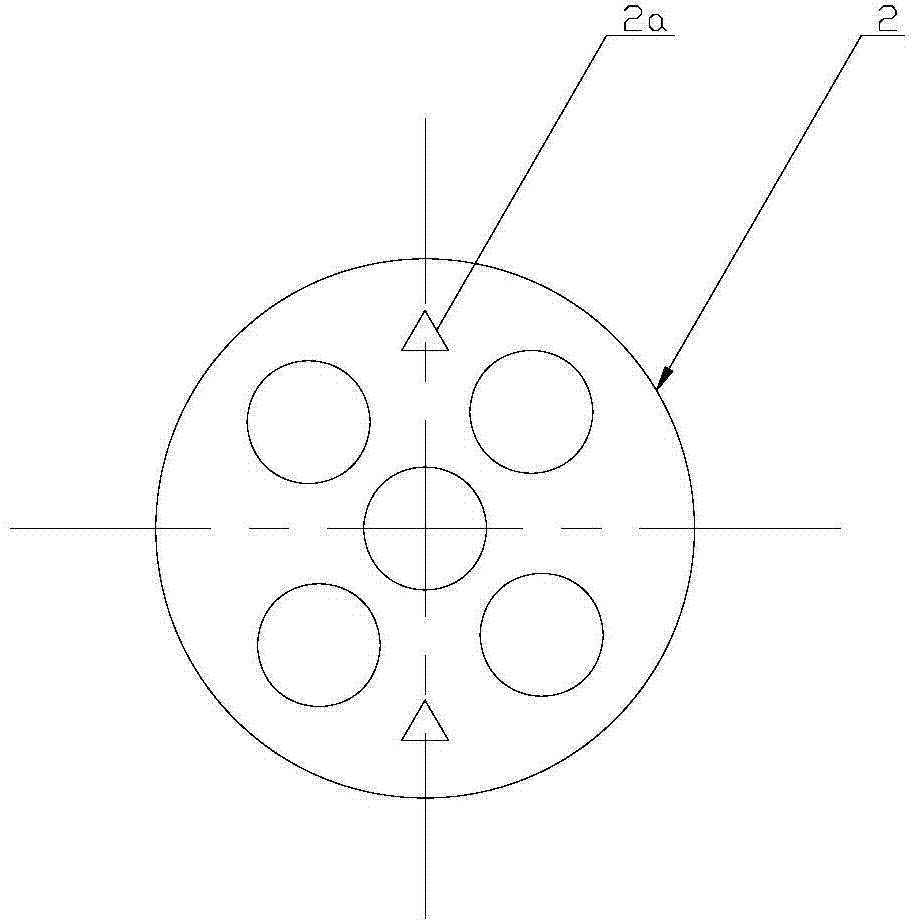

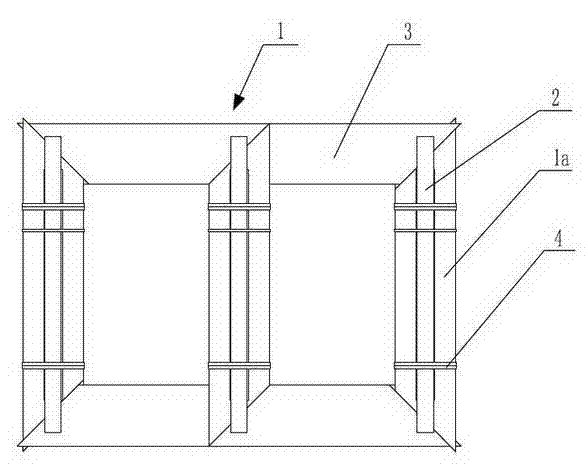

Finished steel strand bundle

The invention discloses a finished steel strand bundle. The finished steel strand bundle structurally comprises a steel strand bundle, marking plates, a binding iron wire, bundling steel belts and a tractor, wherein the tractor comprises a sleeve; a taper hole is formed in one end of the sleeve; three clamping sheets with the same structure are assembled in the taper hole in one end of the sleeve; the outer diameters of the three clamping sheets are in a taper ring shape; the inner rings of the three clamping sheets are sleeved on the steel strand bundle; an internal thread hole in the other end of the sleeve is connected with one end of a traction head; a hanging ring is arranged at the other end of the traction head; the size of the outer contour of the tractor is smaller than the inner diameter of a construction pore channel through which the finished steel strand bundle penetrates by subsequent traction. The finished steel strand bundle has the beneficial effects that the traction end of the finished steel strand bundle is gradually clamped through the tractor under the action of taper fit between the sleeve and the three clamping sheets; the tractor and the finished steel strand bundle can be firmly locked into a whole body through the hanging ring; meanwhile, the clamping sheets effectively prevent the traction head from slipping in a traction process; the marking plates display the position of each single steel strand, and the pre-stress tension effect is good.

Owner:TIANJIN SHINKUNTAI ADVANCED PRESTRESSING TECH

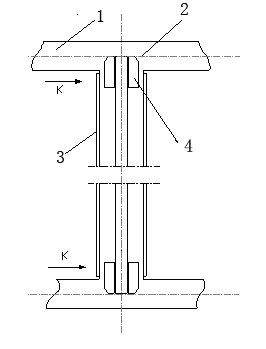

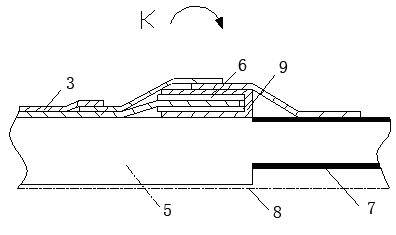

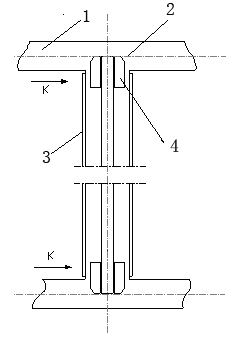

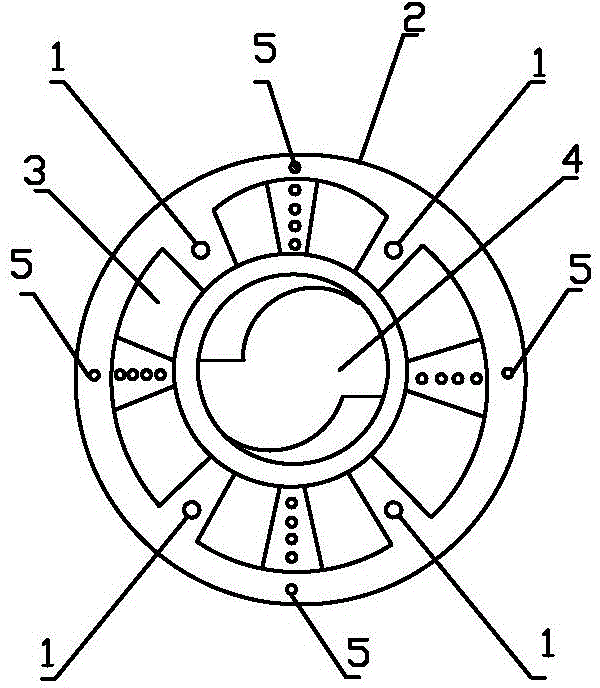

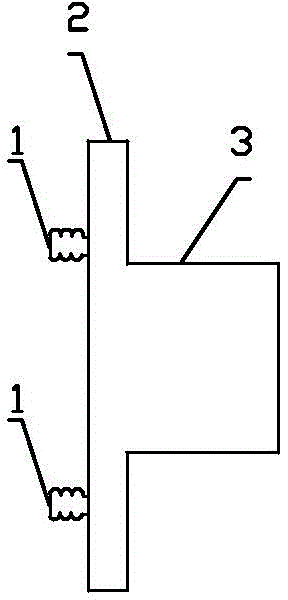

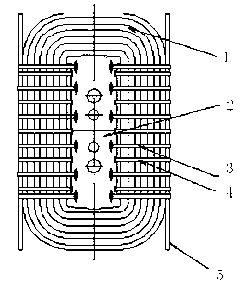

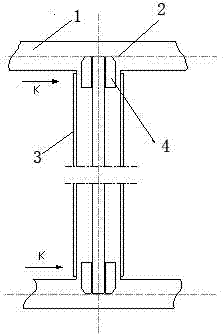

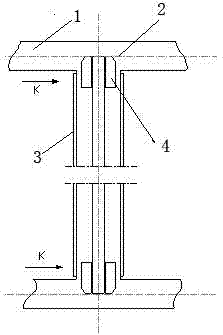

Method for binding iron core of transformer

ActiveCN101944423AImprove shielding effectReduce manufacturing costTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerInner bound

The invention relates to a method for binding an iron core of a transformer, which belongs to the technical field of transformer manufacturing processes. The method adopts a technical scheme that: the iron core is bound by a binding machine; an inner binding band of the iron core is a semiconductor electric band (6), and an outer binding band is a special weftless band (3) for iron core binding; packing wood (4) is arranged on the end part of the an exposed head of a coil, and semiconductor electric vanish (7) is coated on the packing wood for shielding the iron core; the semiconductor electric varnish is reliably connected with the semiconductor electric band; and the binding is carried out in a way of combining the iron core binding and the iron core shielding together. When the method is used, the iron core is bounded by the binding machine, the inner binding band of the iron core is the semiconductor electric band, and the outer binding band is the special weftless band for the iron core binding. In the invention, the iron core is bound by the binding machine, the inner binding band of the iron core is the semiconductor electric band, and the outer binding band the special weftless band for the iron core binding. The technology combines the regular iron core binding and an iron core shielding barrel together, and the binding bands have the double function of iron core binding and iron core shielding, so that binding time is shortened and the manufacturing cost of the transformer can be reduced; and using effects are good, binding requirements are met, the iron core is well shielded, and requirements on product quality are met.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

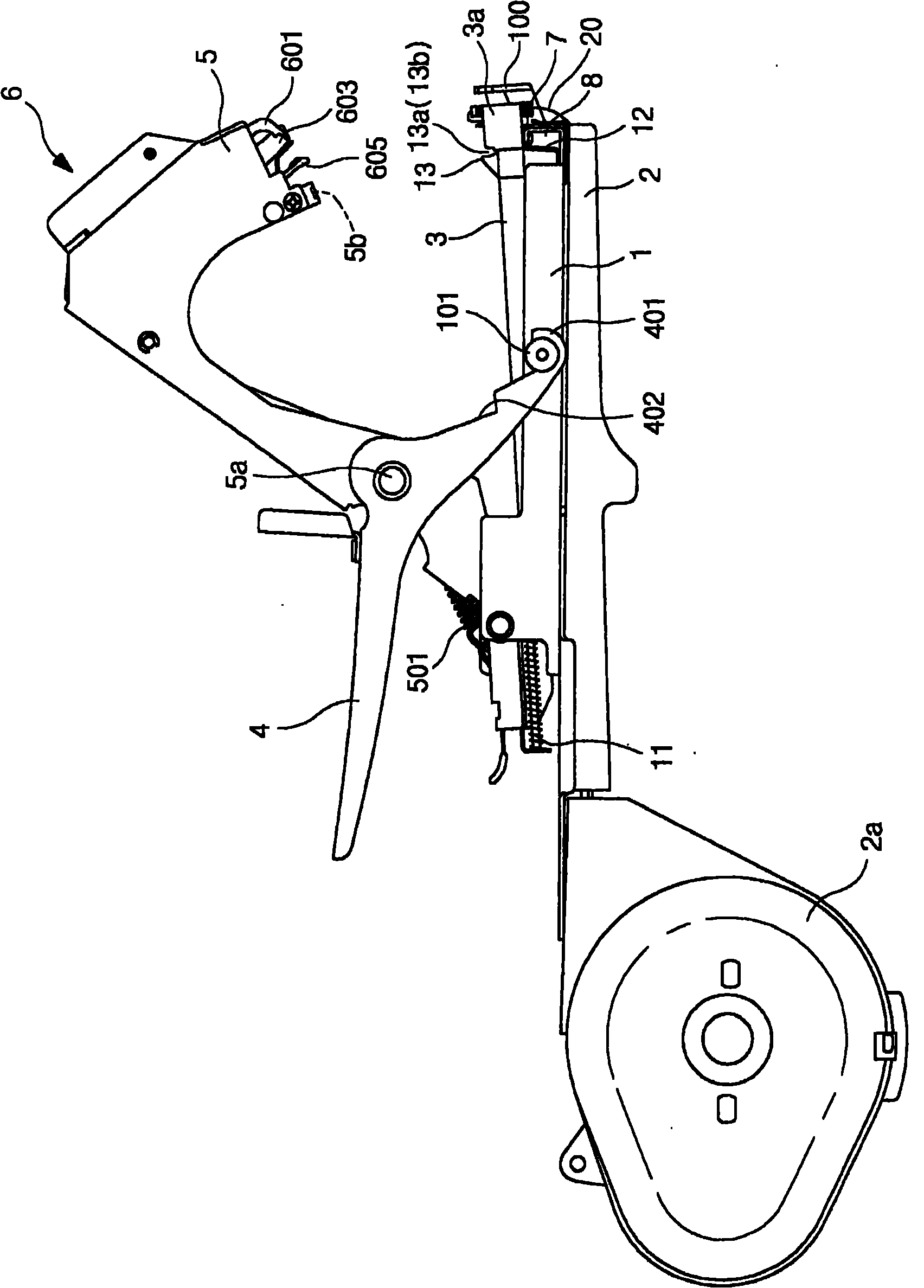

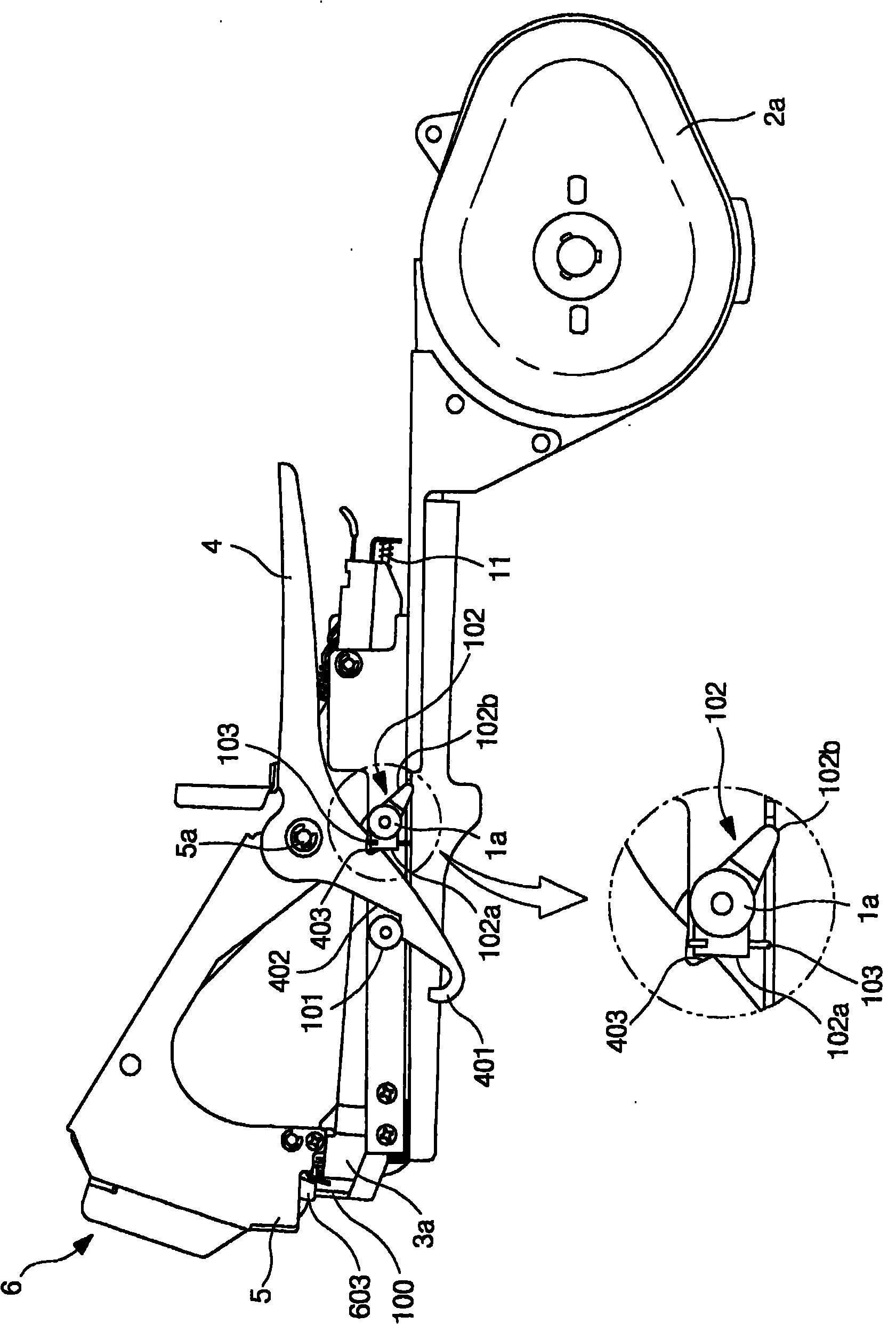

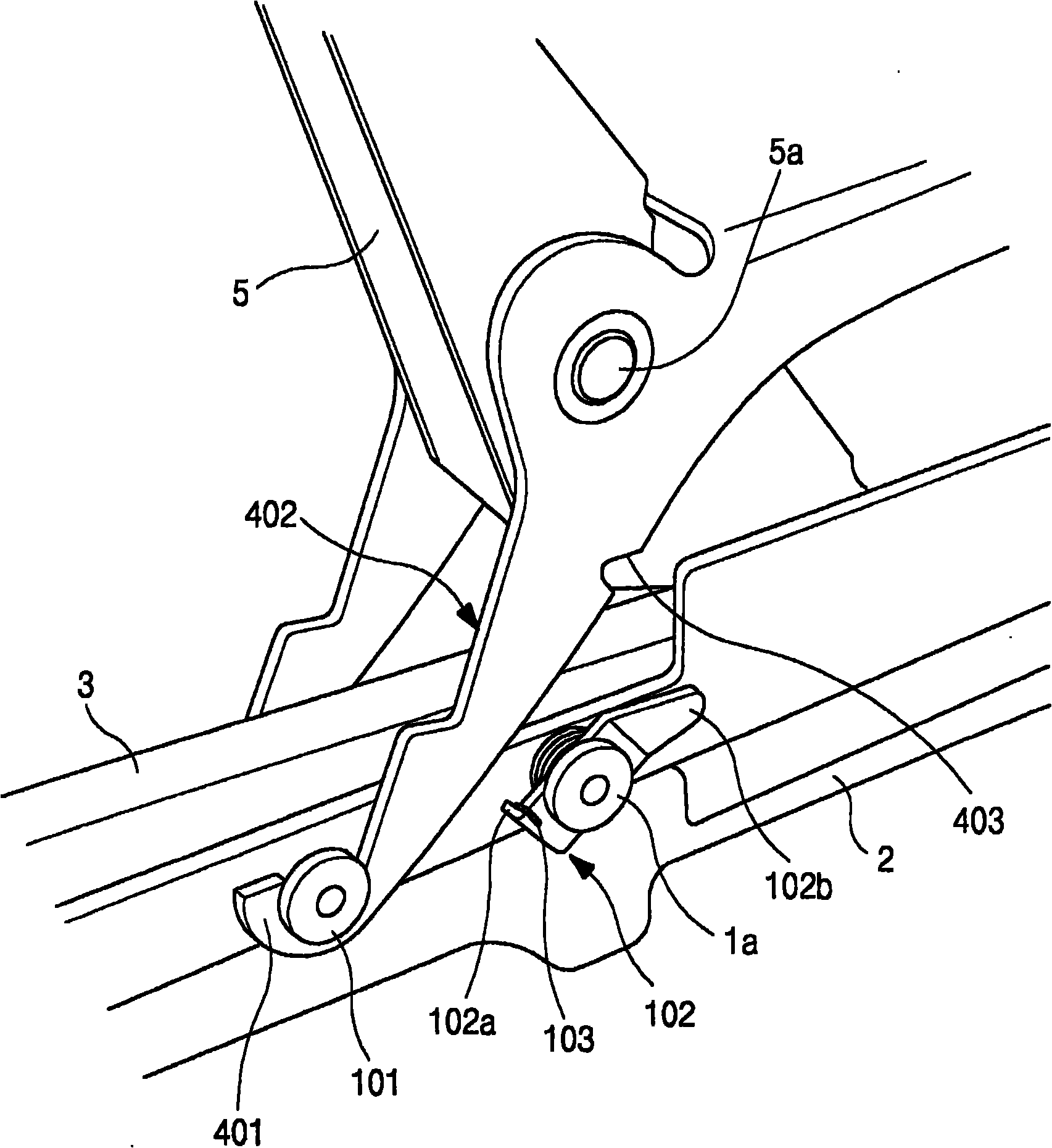

Agricultural binding device

The invention relates to an agricultural binding device, in particular to the agricultural binding device used for binding vine shoots or crop straws and the like on a strut or a support rope. The binding device is characterized in that a clamping groove (403) is formed on the lateral surface of an operating rod (4) and a locking plate (102) is arranged on a main body (1) corresponding to the clamping groove (403) to form a locking device to make a bayonet part (102a) of the locking plate be combined with the clamping groove (403) of the operating rod; a support rope guiding groove is formed on the outer wall on both sides of a binding iron nail extrusion port to make the support rope passing through the upper surface of the binding iron nail extrusion port pass through when being clung to the upper surface of the binding iron nail extrusion port; and the elasticity of a traction needle is softer so as to prevent the clamped position from cracking when the traction needle clamps the tail end of a binding band for drawing the binding band.

Owner:赵南善

Wire-pulling iron wire binding machine

The invention relates to an electric pole wire pulling tool, in particular relates to a wire-pulling iron wire binding machine. A wire puller body is provided with a front idler wheel, a middle idler wheel and a rear idler wheel through rivets, wherein the upper part of the front idler wheel is provided with positioning clips; a gap is reserved in the positioning clips; the gap of the positioning clips is in the same center line with the position of the idler wheel groove of the front idler wheel; the middle idler wheel is arranged between the front and rear idler wheels; a wire passage is arranged on the wire puller body between the middle and rear idler wheels; a handheld steel pipe is welded with the tail end of the wire puller body. According to the wire-pulling iron wire binding machine, high expert skill is not needed, the bound iron wire is tight and order, and meanwhile, the galvanized protection layer on the surface of the iron wire is protected.

Owner:MEISHAN POWER SUPPLY CO STATE GRID SICHUAN ELECTRIC POWER CO +1

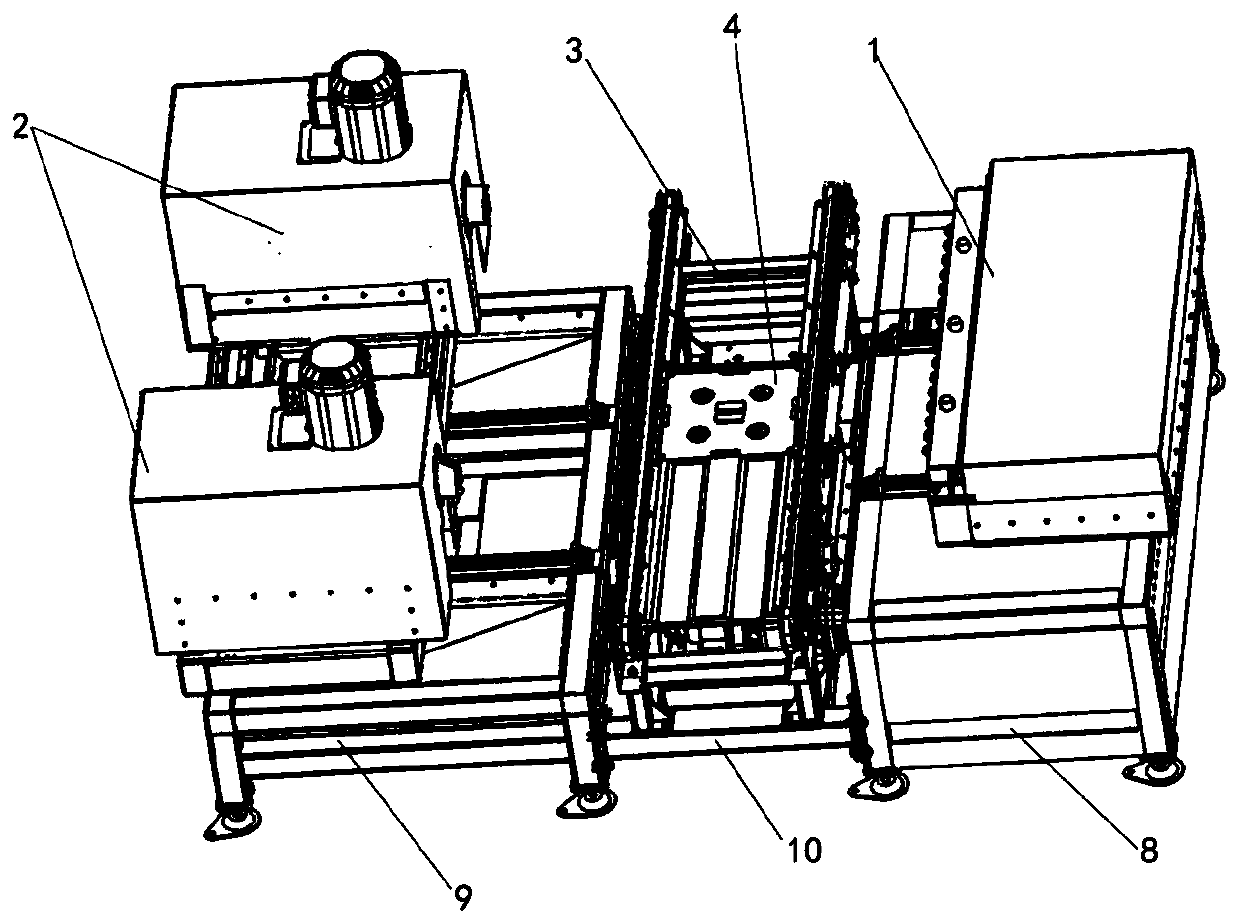

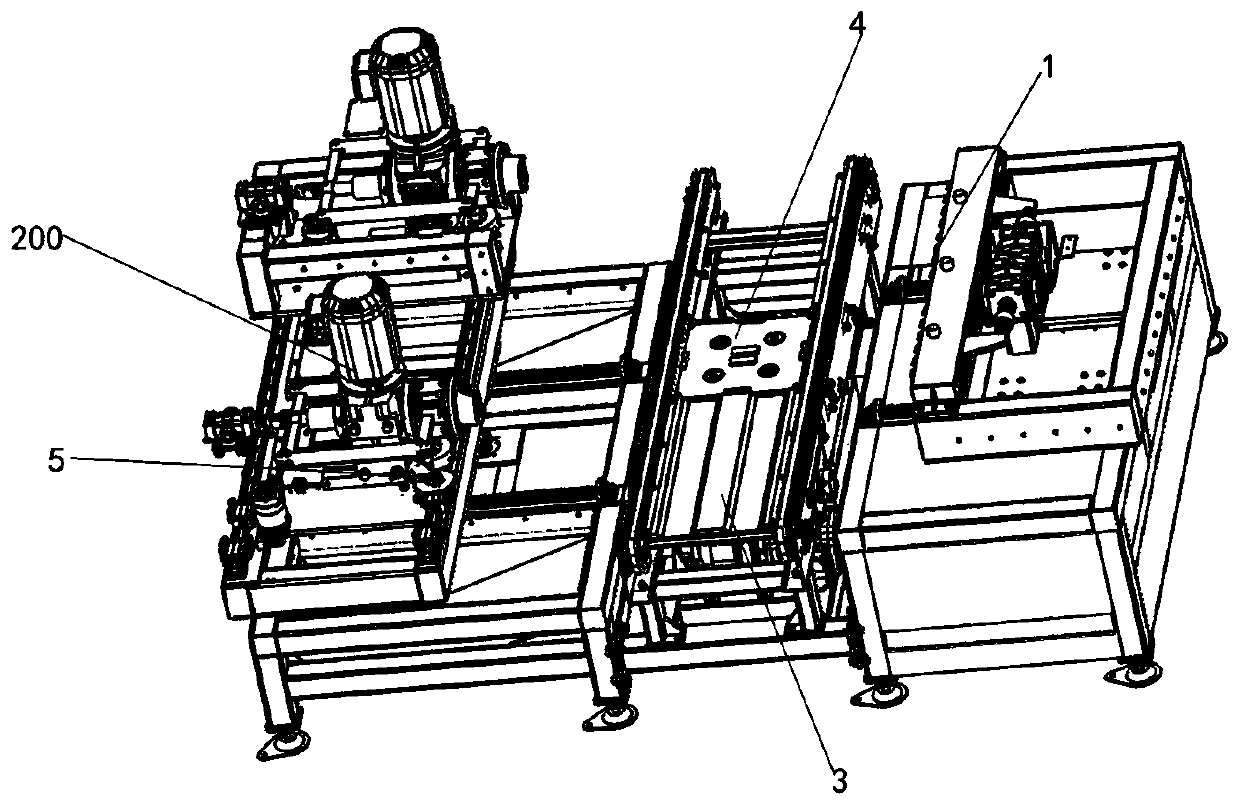

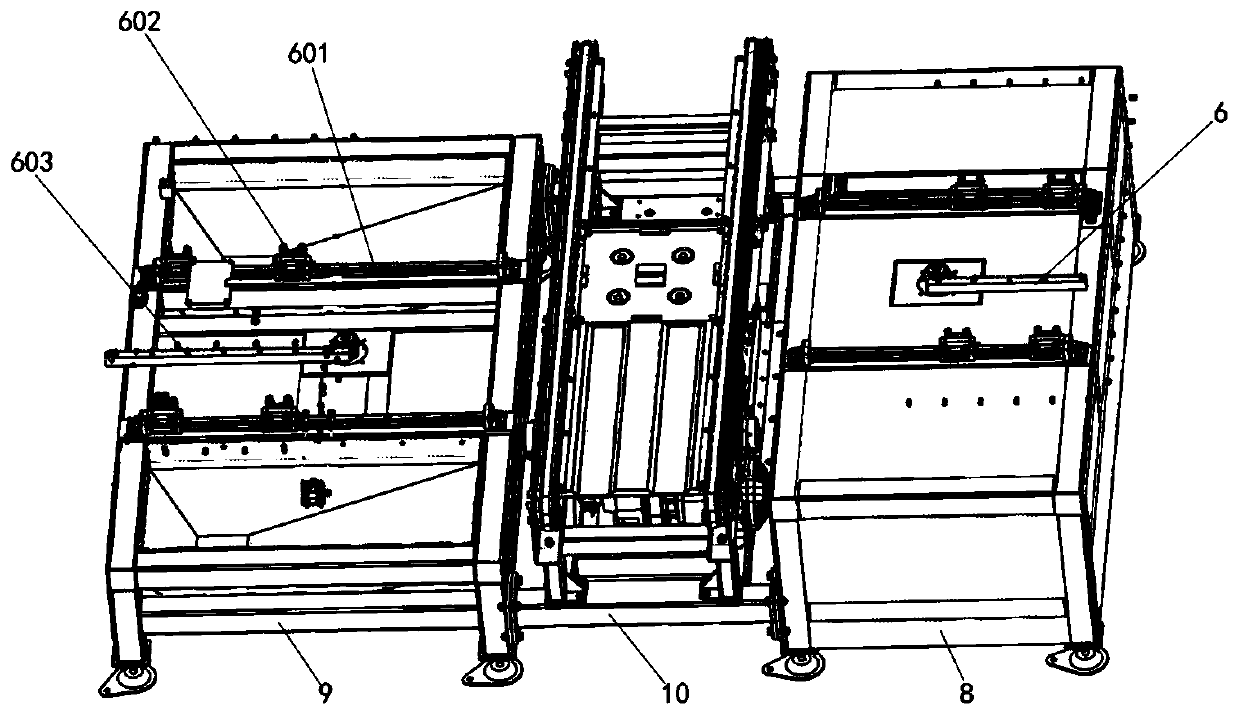

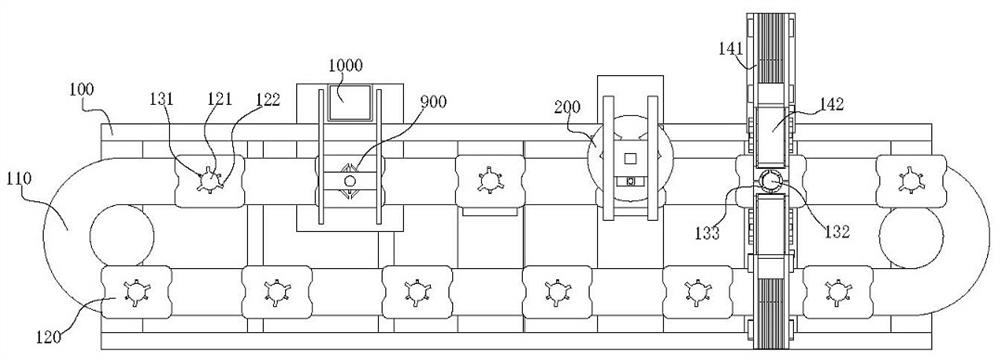

Device for automatically shearing and drawing binding iron wires

PendingCN110775377AIncrease productivityCompact structureFilament handlingPackagingMechanical equipmentTransfer line

The invention belongs to the technical field of mechanical equipment for packaging, and particularly relates to device for automatically shearing and drawing binding iron wires. The device for automatically shearing and drawing the binding iron wires comprises a shearing device, a wire drawing device and a conveying line arranged between the shearing device and the wire drawing device. A rotary lifting device is arranged on the conveying line. A bound package is placed on the conveying line and conveyed to the rotary lifting device. The shearing device on one side of the conveying line shearsan iron wire of the bound package. The wire drawing device on the other side of the conveying line draws the sheared iron wire from the surface of the bound package and strips the iron wire into a discharge hopper to be collected. The shearing device is movably installed on a shearing device supporting frame, and the wire drawing device is movably installed on a wire drawing device supporting frame so that the shearing device and the wire drawing device can be move away from or close to the conveying line in the horizontal direction. Through the shearing device, the wire drawing device and theconveying line, the iron wire of the bound package is sheared and drawn from the package and then is coiled to be discarded at a fixed position, so that the production efficiency is improved.

Owner:深圳市天和双力物流自动化设备有限公司

Construction method of inverted trapezoidal open channel

The invention provides a construction method of an inverted trapezoidal open channel, wherein the open channel comprises a channel and a channel bottom wall and a second channel side wall which are encircled to form the channel, wherein the construction method comprises the following steps of implementing an unprotected open cut excavation to form a groove bottom wall and a second groove side wallarranged at both sides of the groove bottom wall; embedding reinforcing steel bars, and binding iron wires on the reinforcing steel bars; pouring a concrete cushion to form the channel bottom wall; laying two opposite connecting rods and reinforcing transverse rods on the concrete cushion, wherein the plurality of transverse rods are connected with the reinforcing steel bars through the iron wires; installing a second lateral template, and the second lateral template is respectively defined between the two adjacent side walls of the two grooves to form a pouring space of the channel side wall; installing an inverted trapezoidal plate; casting the concrete into the first concrete space to form the channel side wall; curing the concrete and removing the template.

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

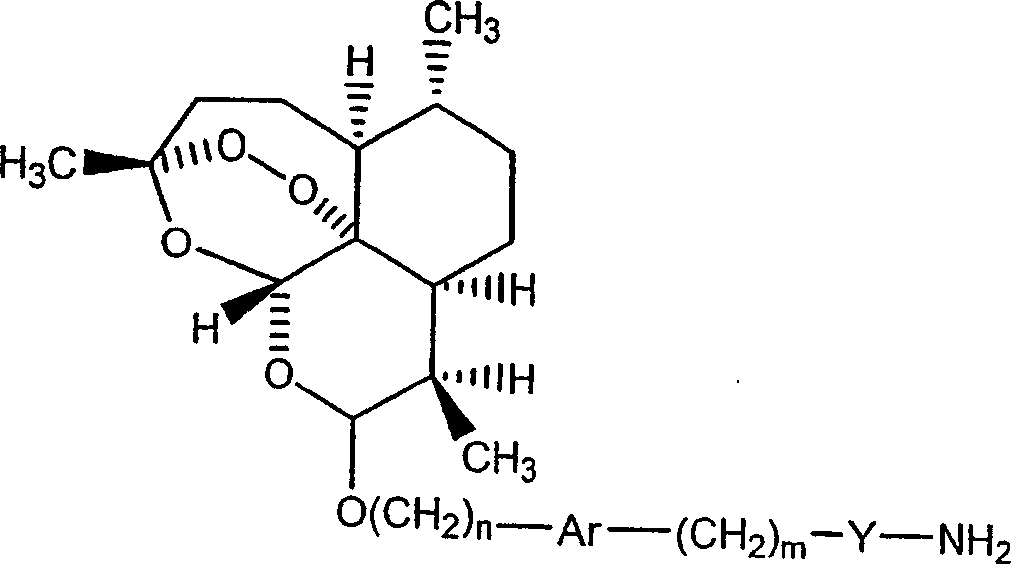

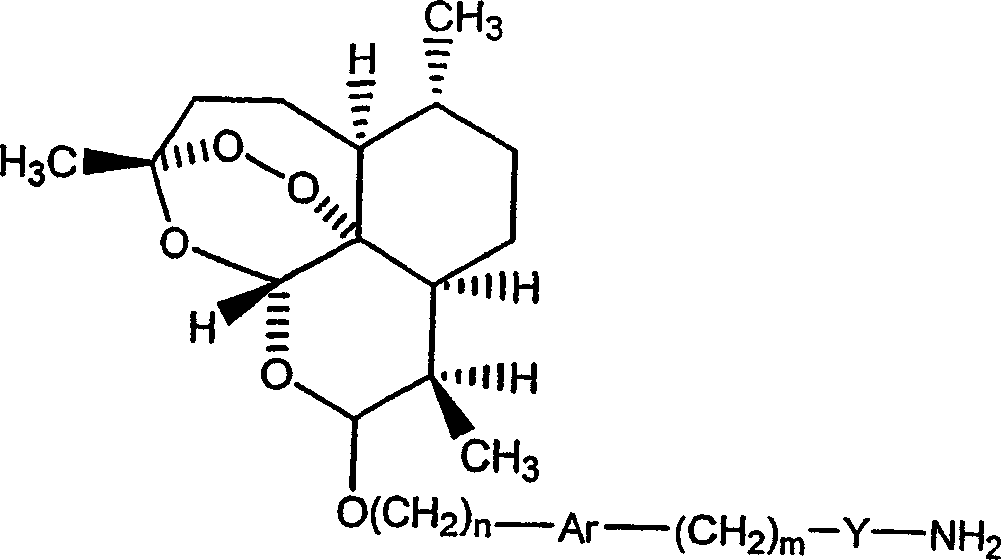

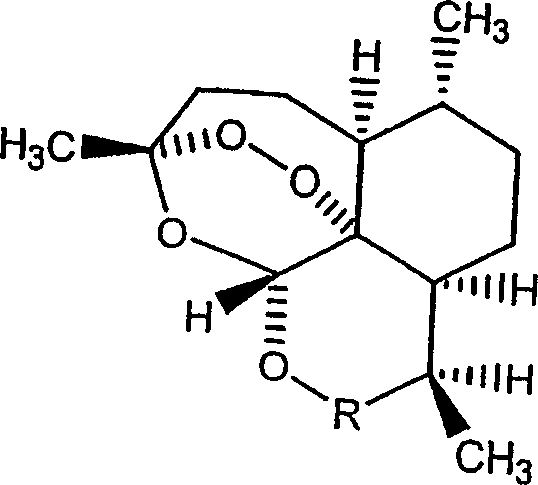

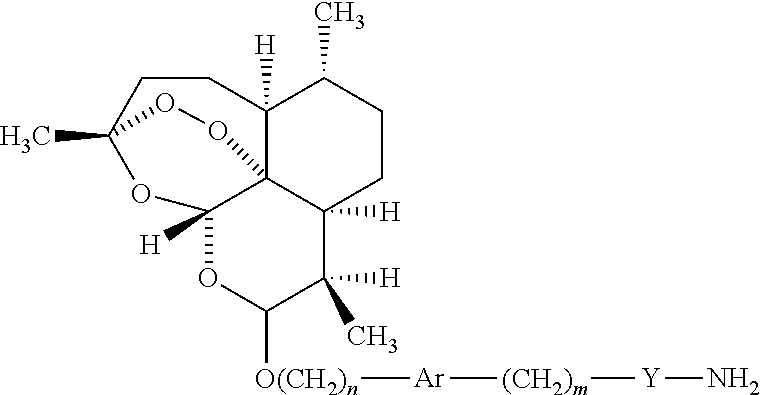

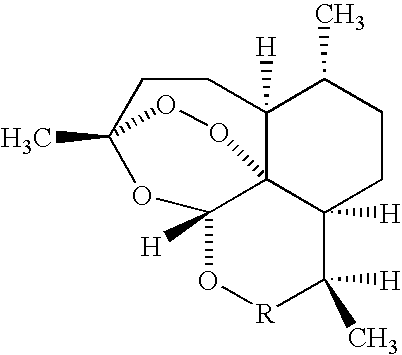

Covalent conjugates between artemisinin-related endoperoxides and iron-carrying proteins and methods of use

Owner:UNIV OF WASHINGTON

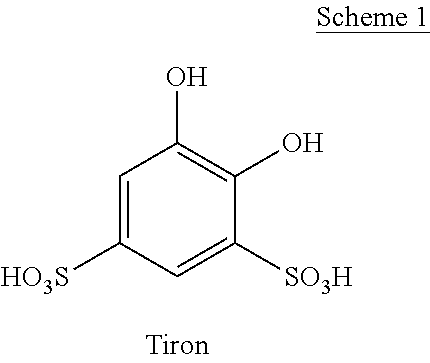

Detergents having acceptable color

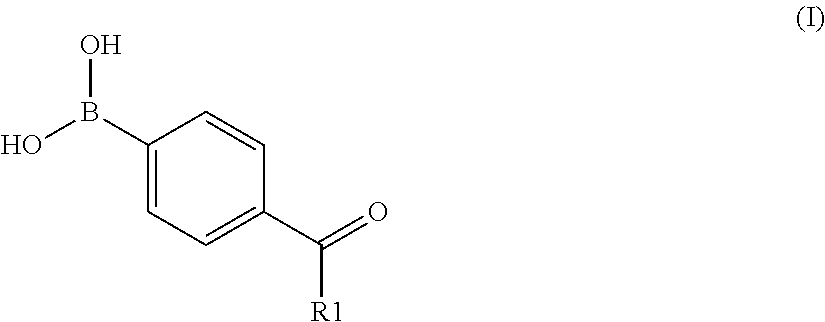

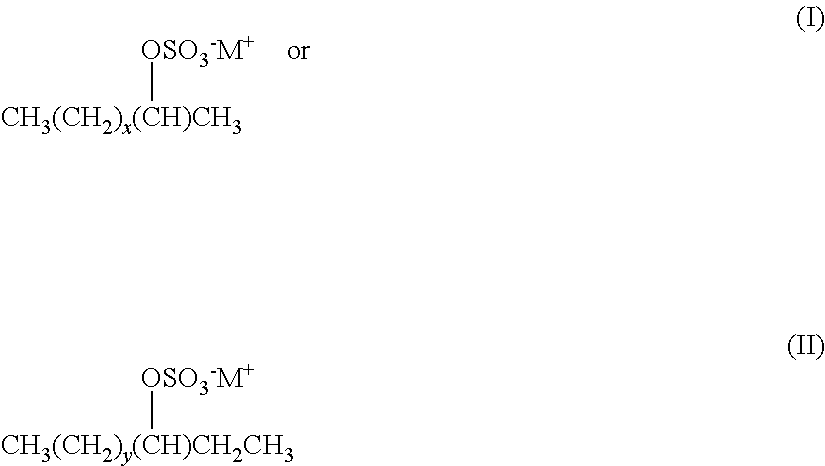

ActiveUS20130029896A1Reduce intensityOrganic detergent compounding agentsNon-surface-active detergent compositionsTitaniumFerric

This disclosure relates to detergent compositions containing tiron, a ligand capable of binding iron, an iron-displacing species, and iron. Methods for altering the color in a tiron-containing detergent composition are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

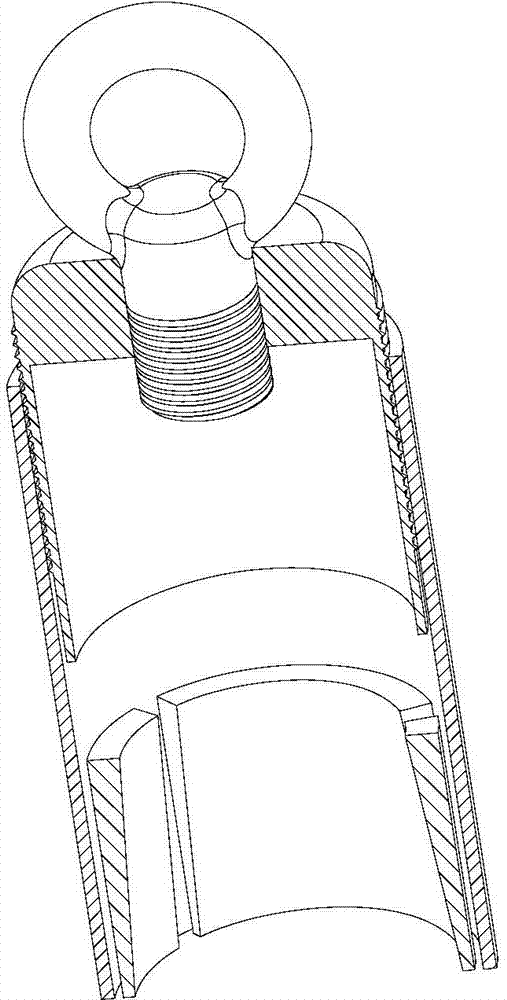

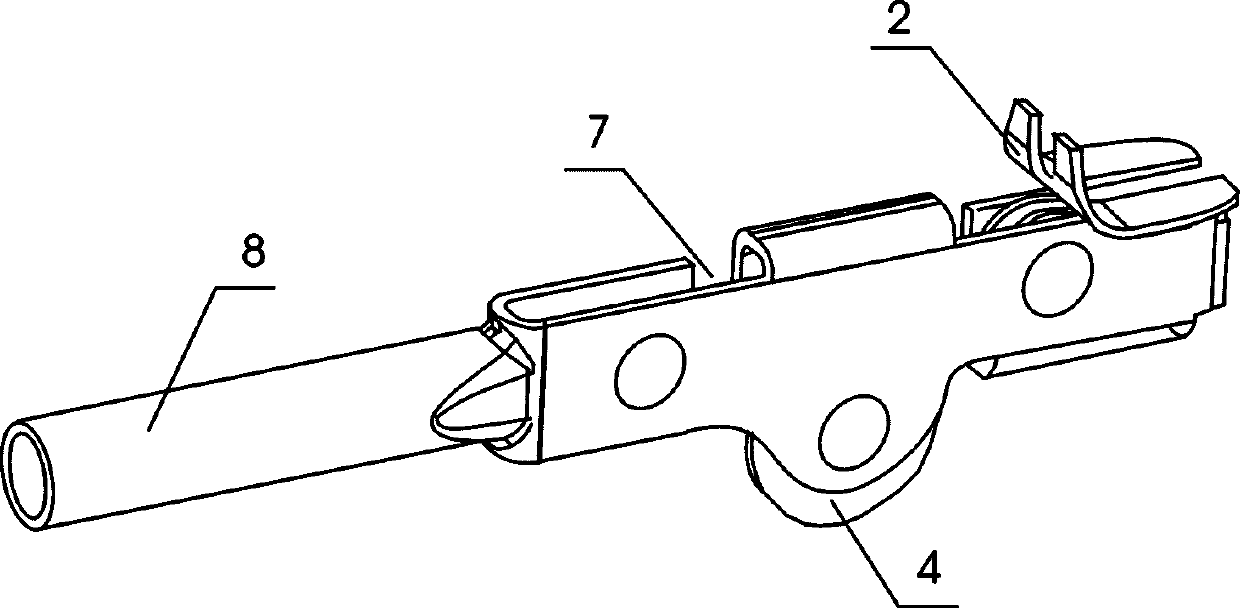

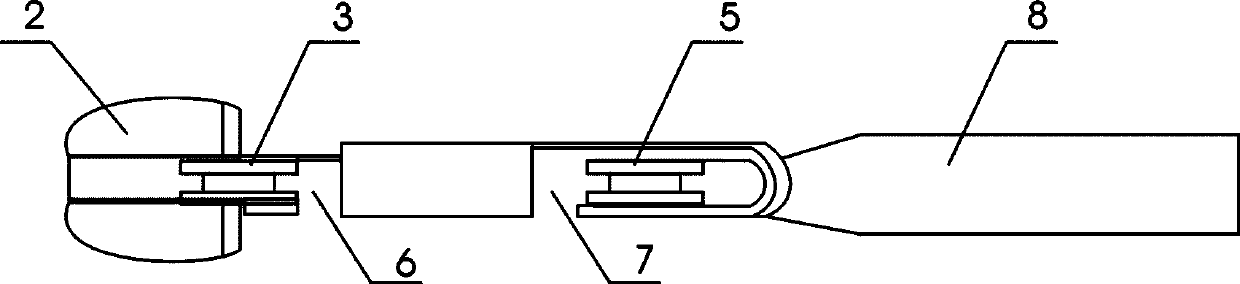

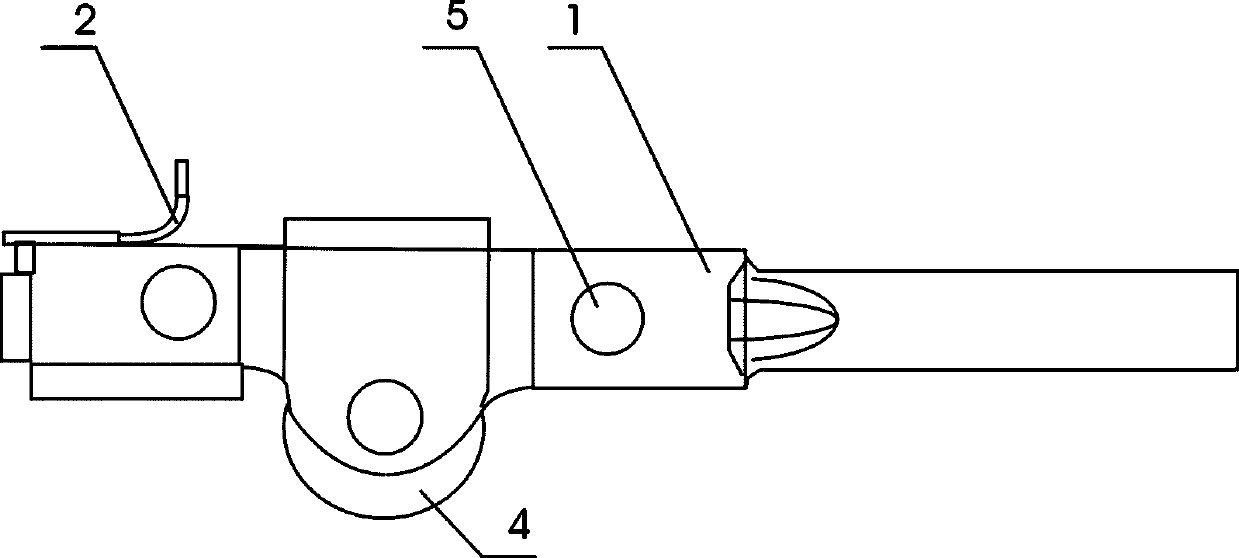

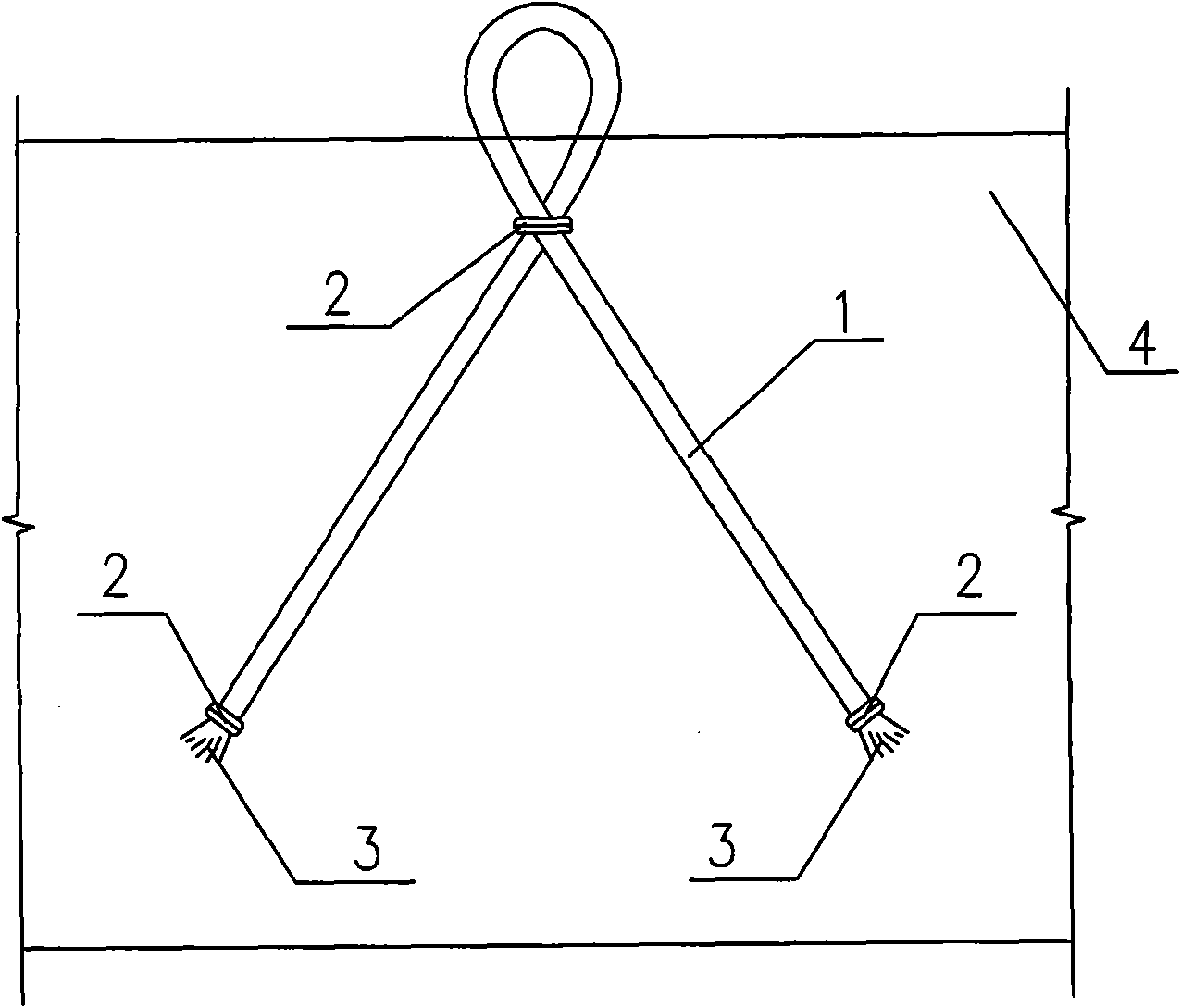

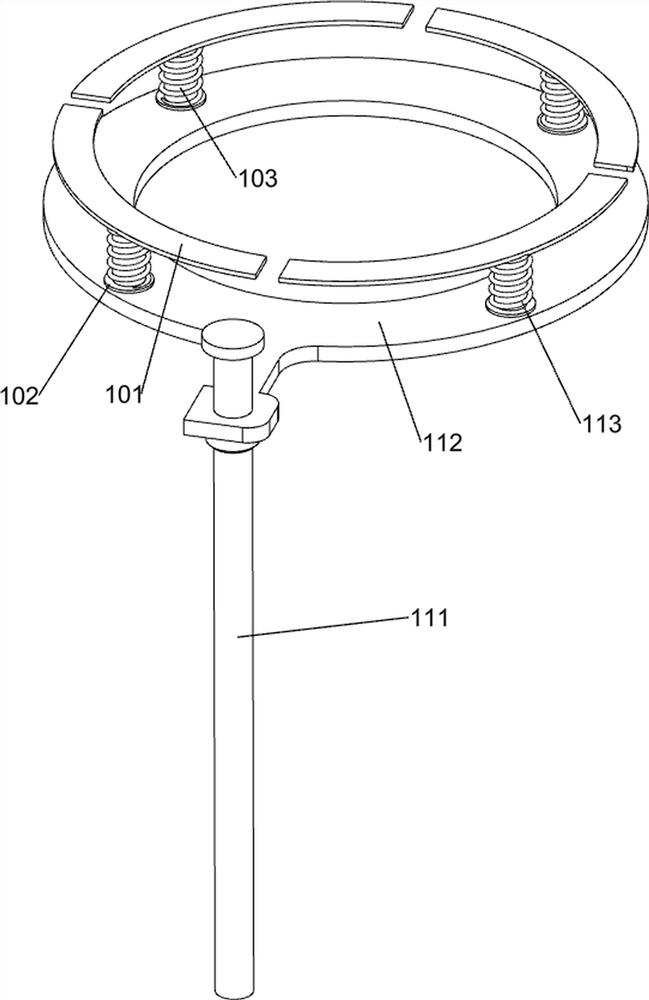

Hoisting ring manufactured by using prestressed concrete steel strand tailings

The invention discloses a hoisting ring manufactured by using prestressed concrete steel strand tailings, which relates to a constructional engineering component. The hoisting ring consists of the steel strand tailings, hydraulically upset anchoring ends, steel wire circular rings which bind the tailings and a precast member, and is characterized in that: the hoisting ring of a concrete precast member (4) is manufactured by upsetting the end parts of the prestressed concrete steel strand tailings (1), binding iron wire circular rings (3) with the hydraulically upset anchoring ends (2) and binding the iron wire circular rings (3) at an intersection (5) of the steel strand tailings (1). In the invention, the hoisting ring for hoisting and mounting various concrete precast members is manufactured by utilizing the high mechanical properties of the prestressed steel strand tailings, such as high strength, high flexibility, no brittle failure and the like, so waste materials are changed into valuable materials and useful steel products can be greatly saved.

Owner:中国建筑东北设计研究院有限公司

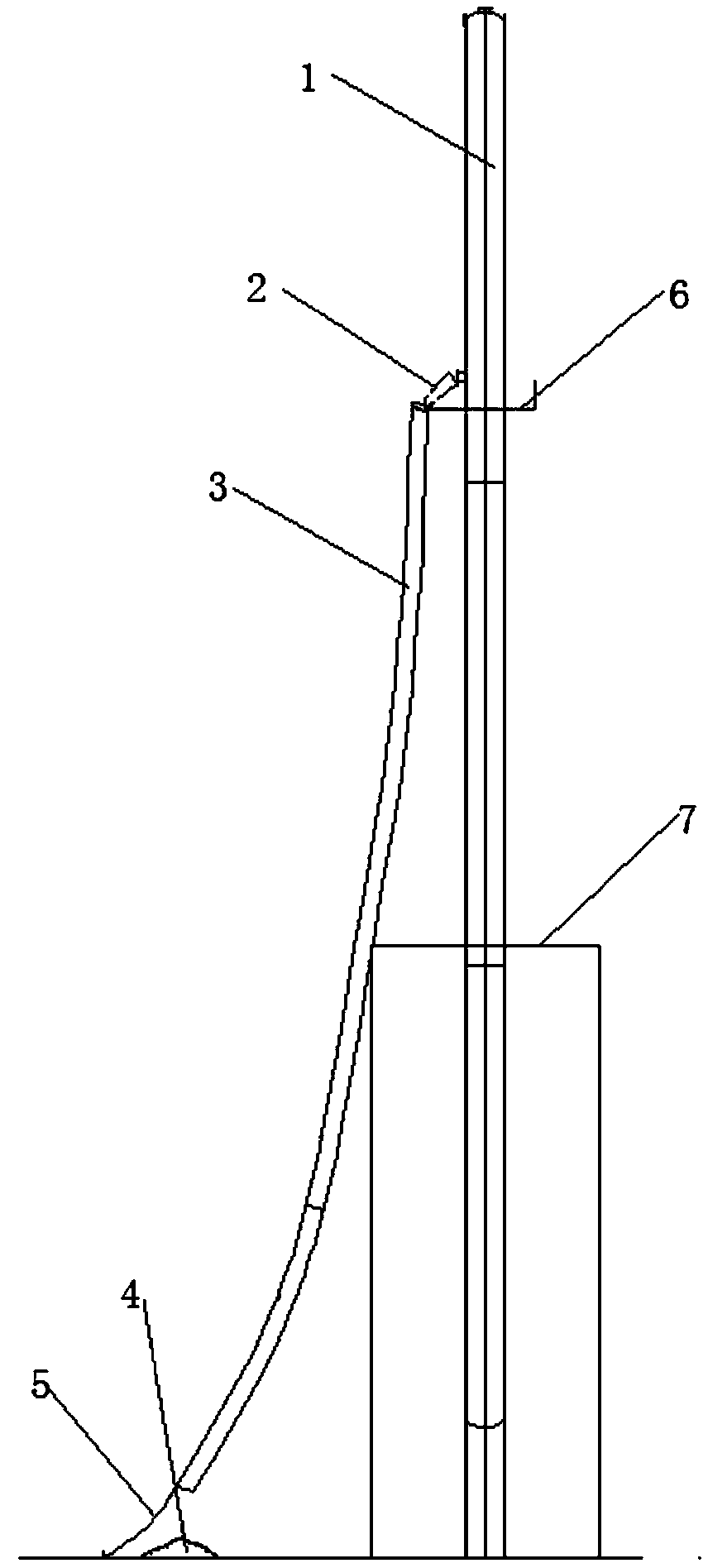

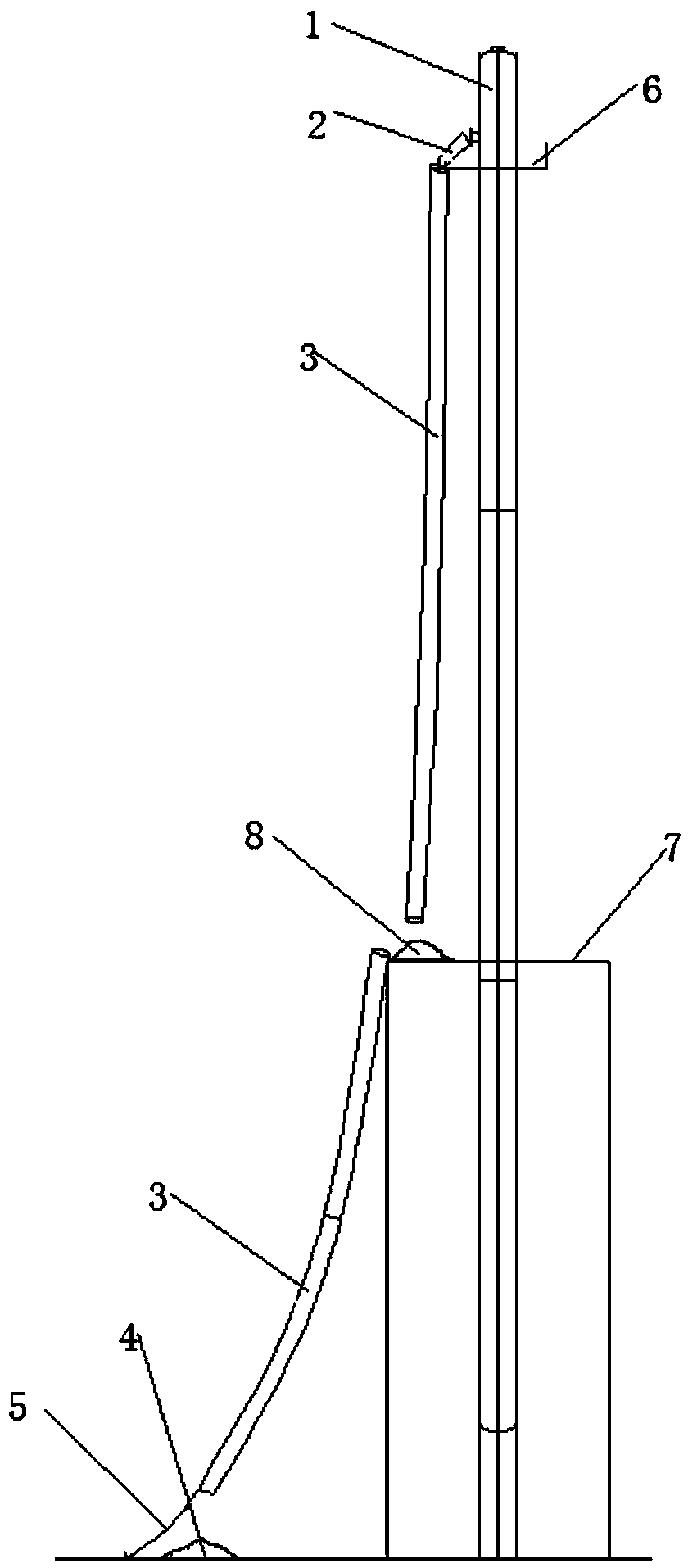

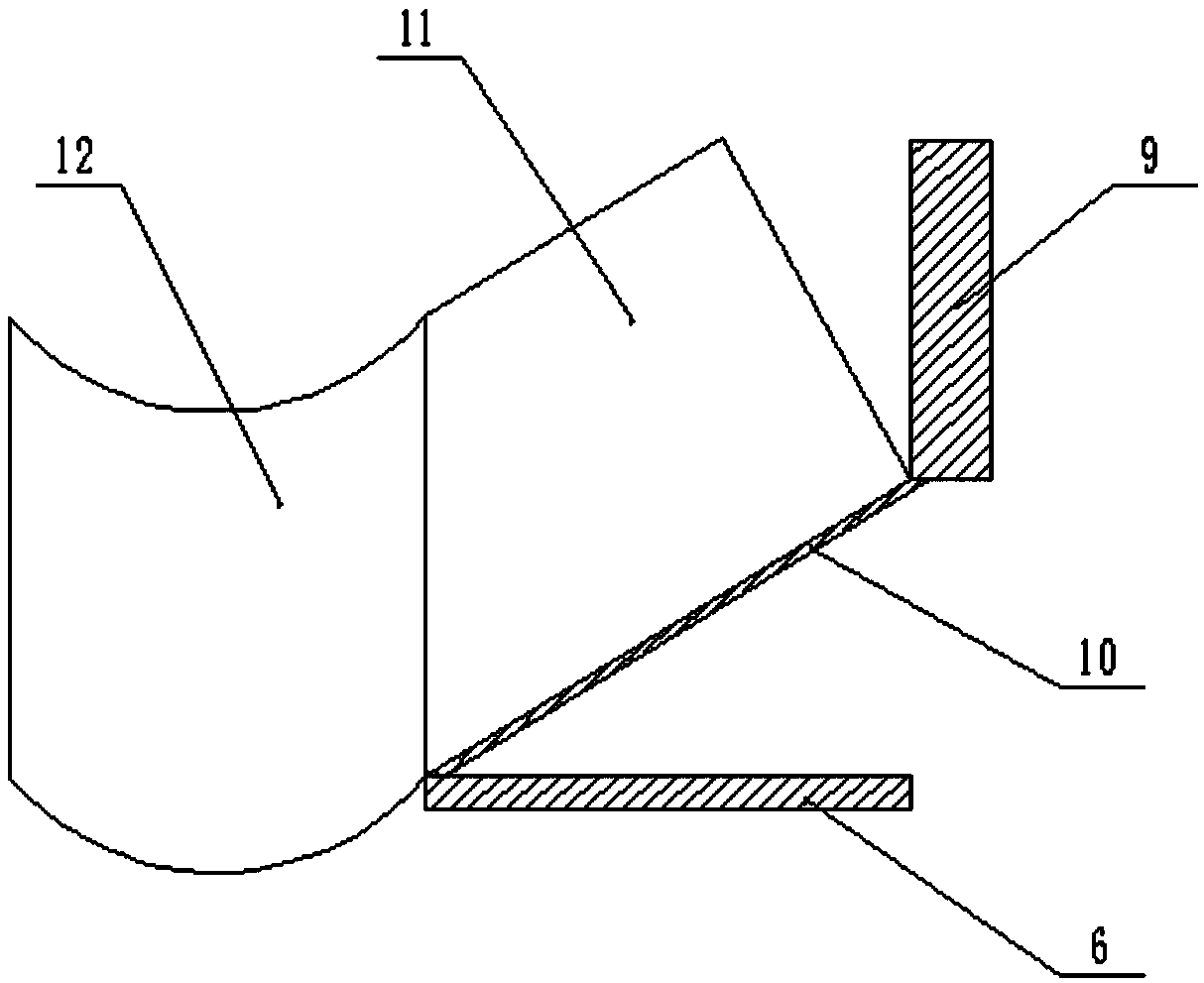

OPGW (optical fiber composite overhead ground wire) terminal reserved cable device of ultra-high voltage transformer substation

ActiveCN104678524AAvoid the problem of electric erosion and broken strands caused by inter-turn dischargeAvoid the problem of corrosion and broken strandsOptical fibre/cable installationElectric dischargeUltra high voltage

This application discloses an OPGW (optical fiber composite overhead ground wire) terminal reserved cable device of an ultra-high voltage transformer substation, which avoids the problem of strand breakage due to interturn electric discharge erosion of an optical cable caused by interturn induced voltage existing in the wound optical cable, and the problem of the strand breakage due to galvanic corrosion generated due to contact between the optical cable and a binding iron wire, and is safe, reliable and attractive. The device comprises a nonmetal seat disk and a nonmetal cover disk, wherein the nonmetal seat disk comprises an inner disk and a winding post that are formed integrally; the inner disk is located on the front surface of the nonmetal seat disk; the winding post is erected in the center of the inner disk; an OPGW terminal reserved cable is wound on the winding post; four cable limiting distance adjustment holes are uniformly formed on the edge of the inner disk; the nonmetal cover disk comprises an outer disk; four cable limiting distance adjustment holes corresponding to the four cable limiting distance adjustment holes in the inner disk are formed in the outer disk; and the inner disk and the outer disk are fixed by inserting cable limiting pins into the cable limiting distance adjustment holes.

Owner:STATE GRID CORP OF CHINA +1

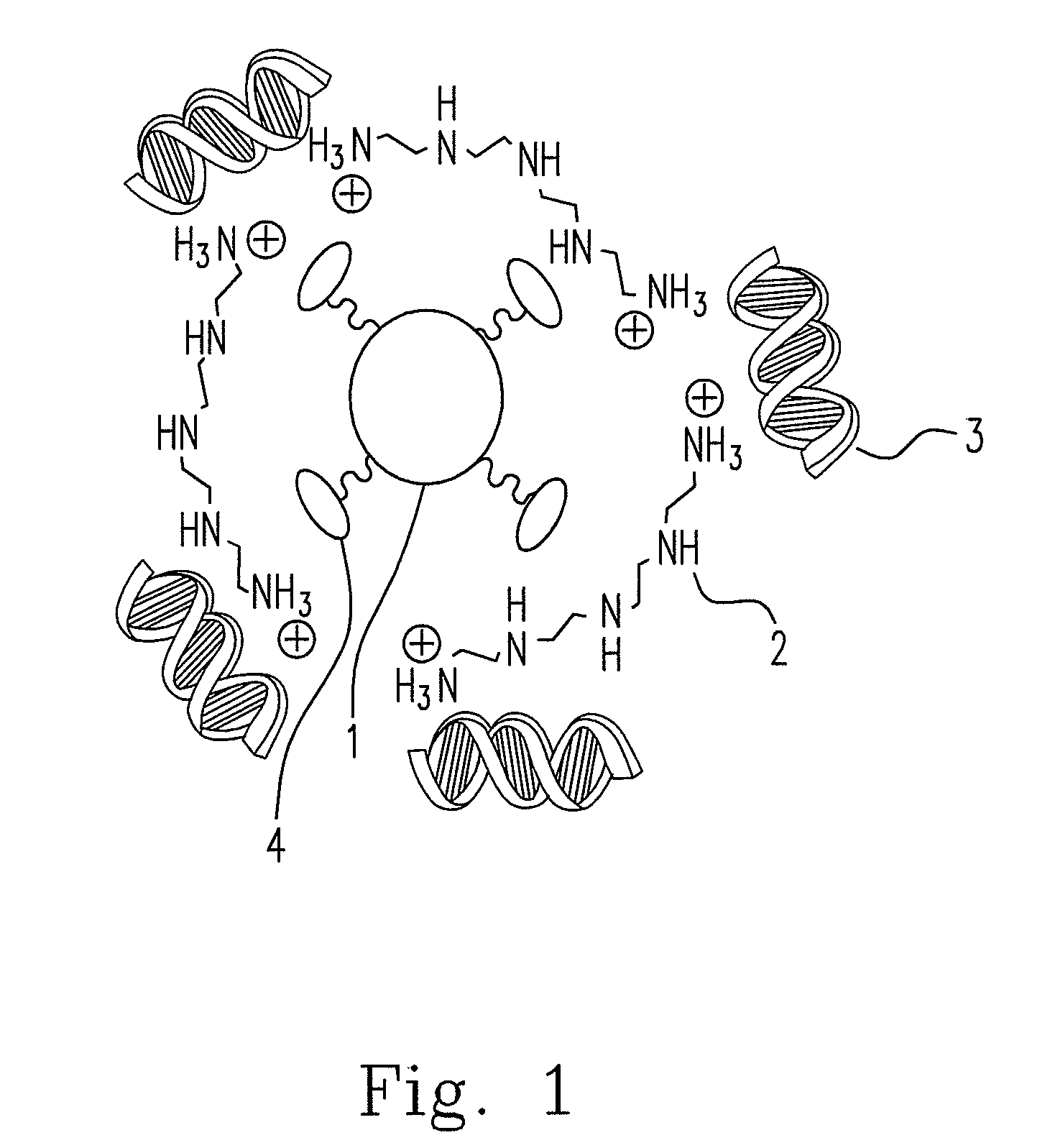

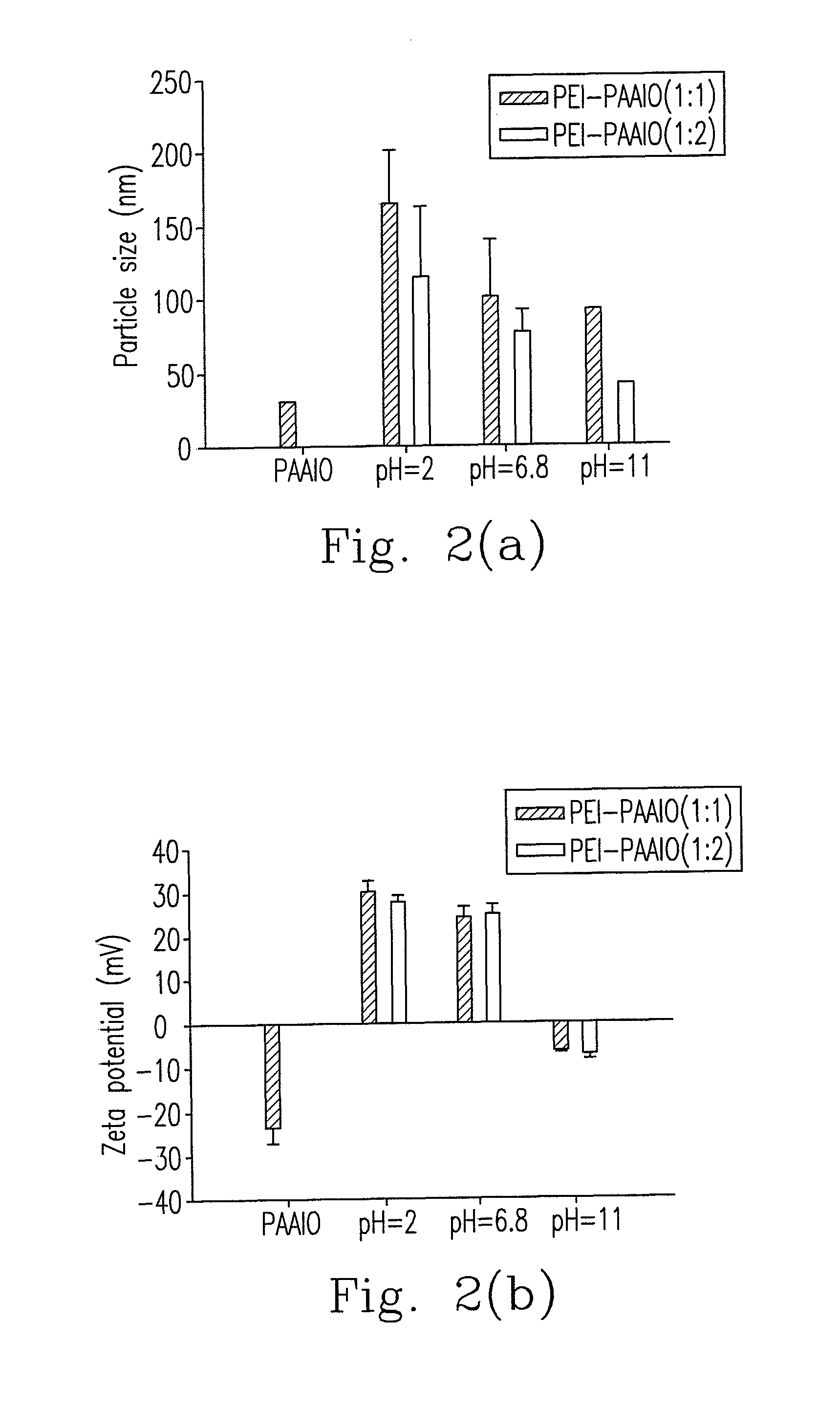

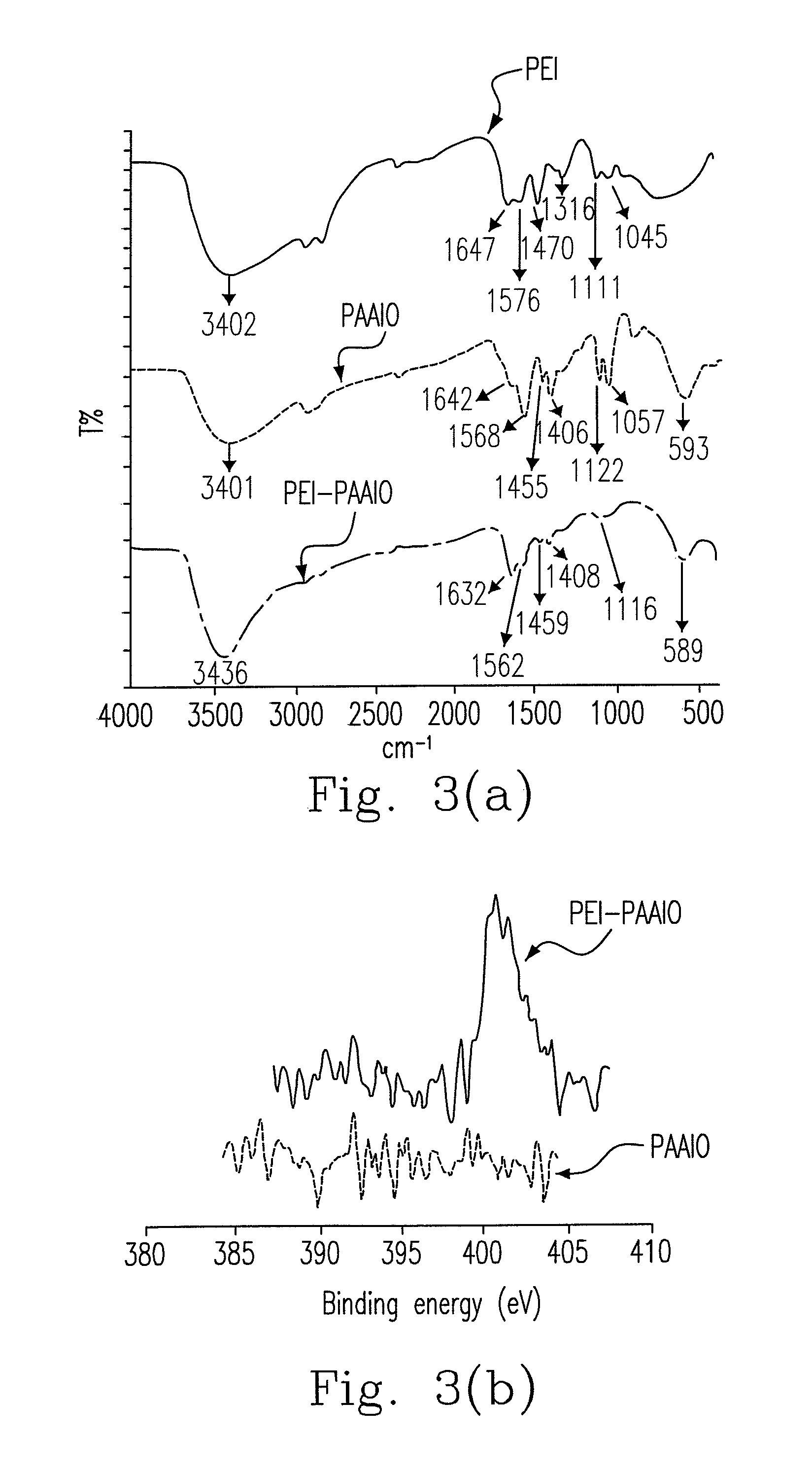

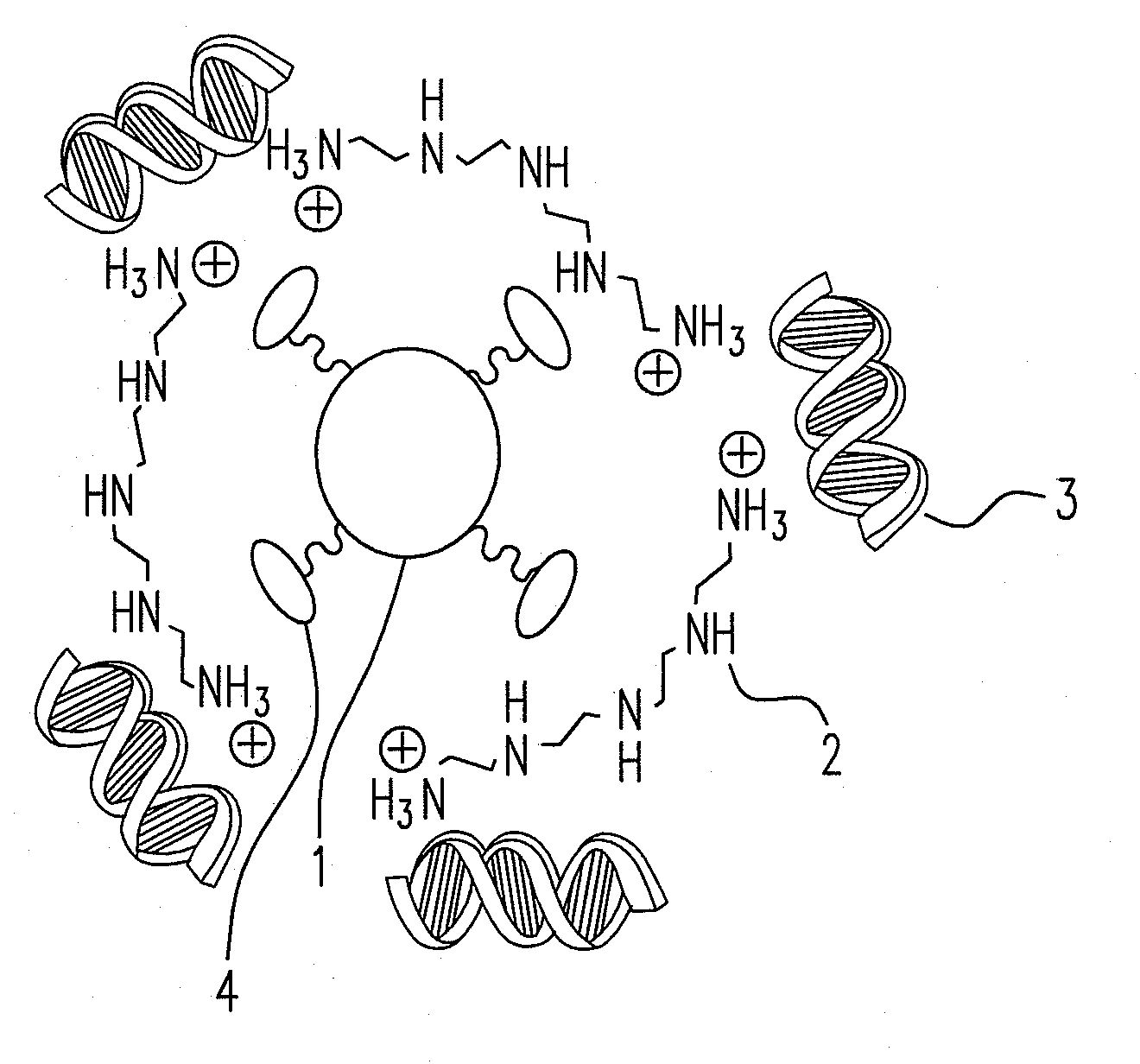

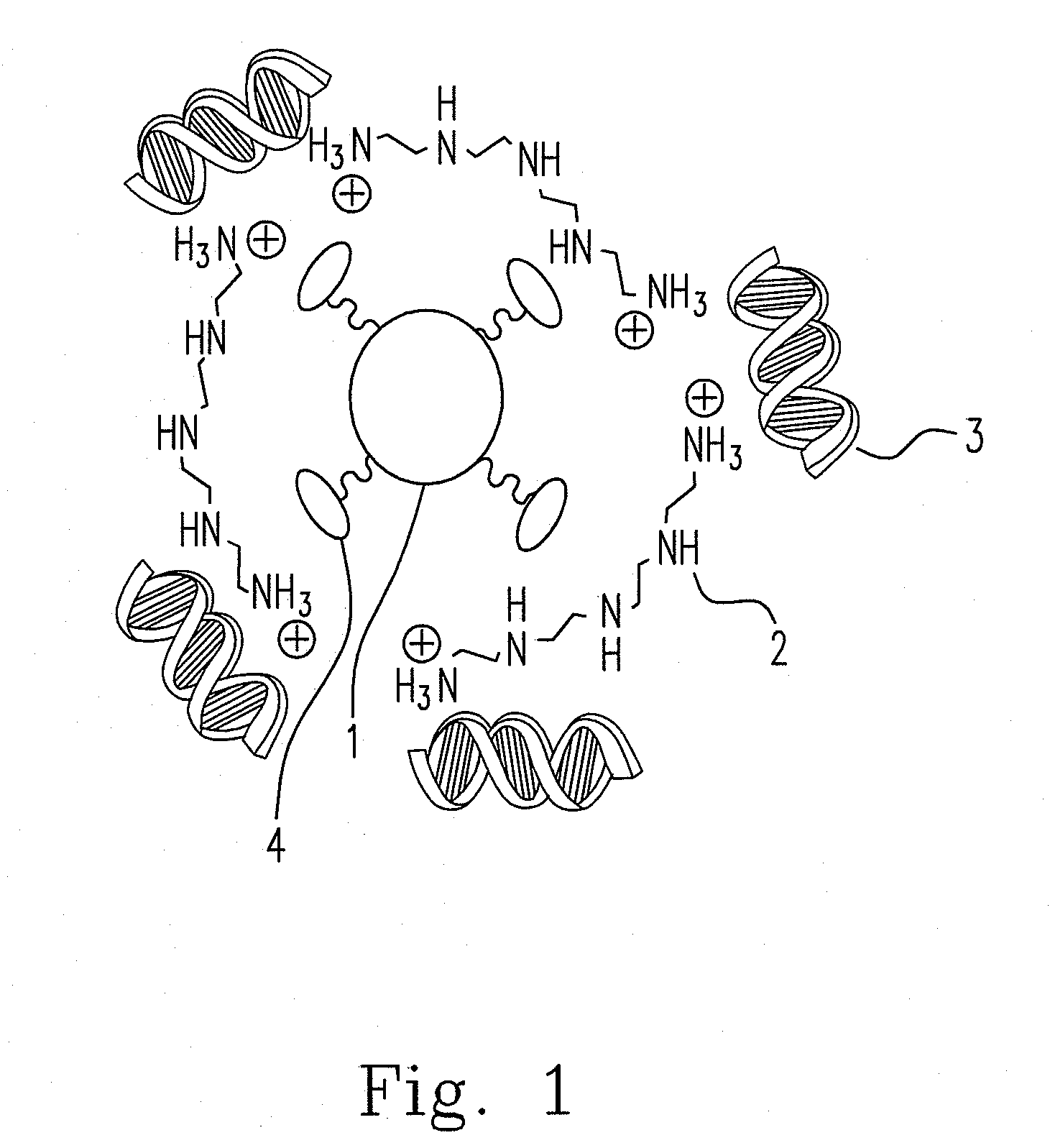

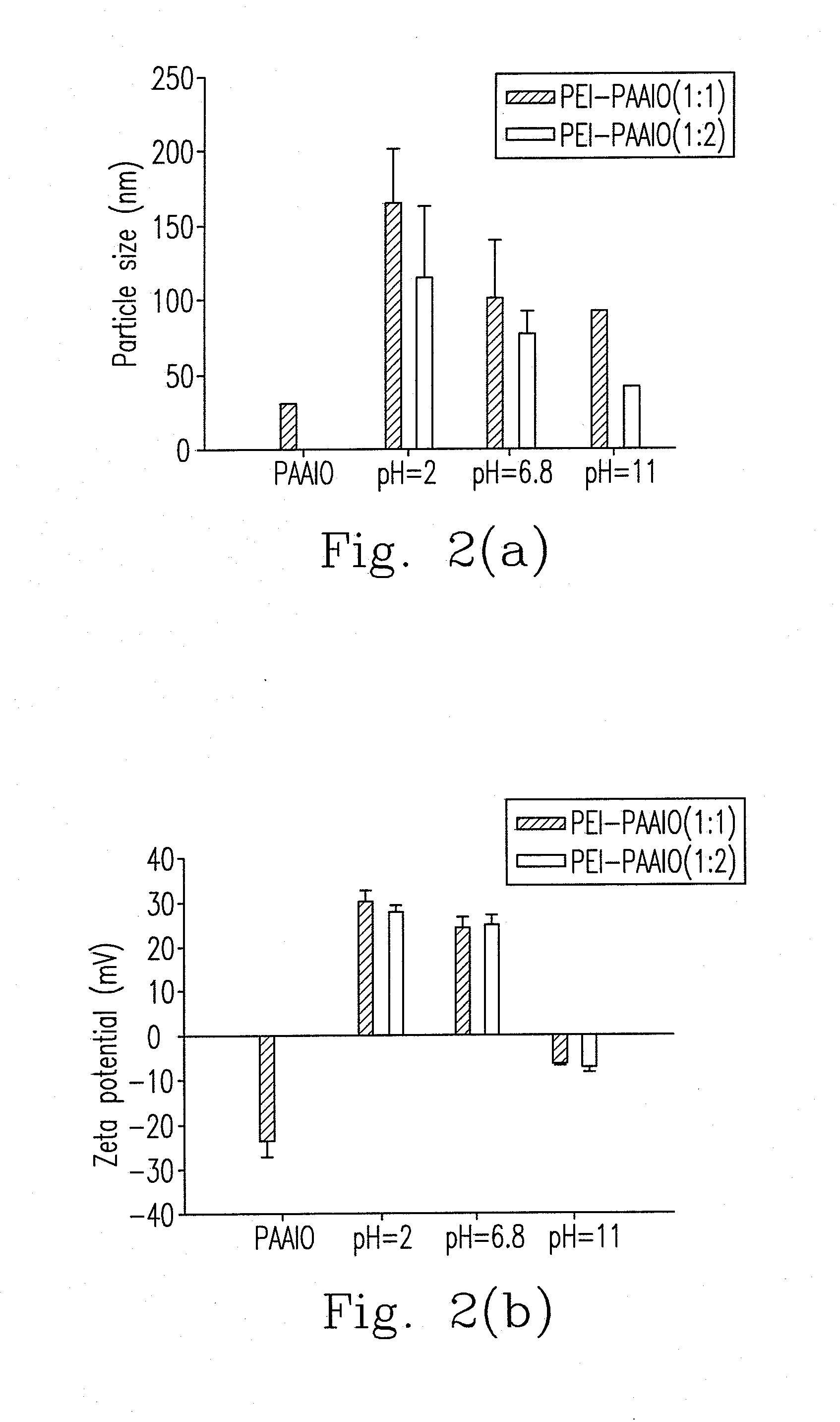

Hybrid superparamagnetic iron oxide nanoparticles and polyethylenimine as a magnetoplex for gene transfection

ActiveUS8445025B2Highly water dispensableLow cytotoxicityPowder deliveryHeavy metal active ingredientsWater dispersibleMagnetite Nanoparticles

Disclosed are the nanoparticle and the method for the same, and the preparing method includes steps of mixing polyethylenimine (PEI) with the poly(acrylic acid)-bound iron oxide (PAAIO) to form a PEI-PAAIO polyelectrolyte complex (PEC) and mixing the PEI-PAAIO PEC with genetic material such as plasmid DNA to form the PEI-PAAIO / pDNA magnetic nanoparticle. The PEI-PAAIO / pDNA magnetoplex is highly water dispersible and suitable for long term storage, shows superparamagnetism, low cytotoxicity, high stability and nice transfection efficiency, and thus the PEI-PAAIO PEC can replace PEI as a non-viral gene vector.

Owner:KAOHSIUNG MEDICAL UNIVERSITY

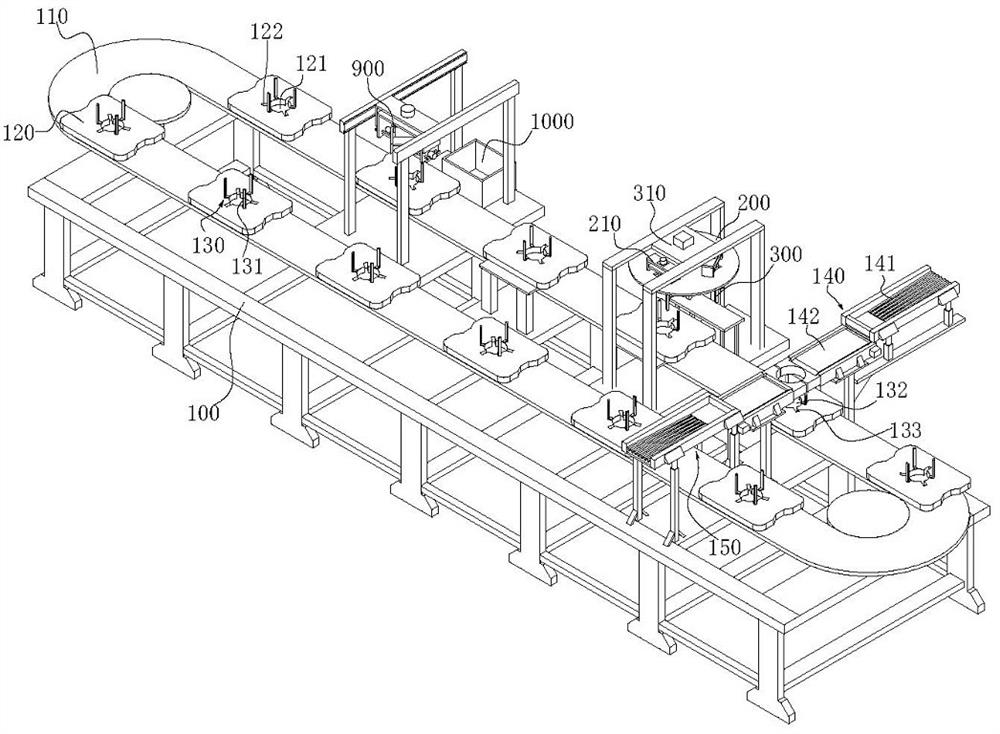

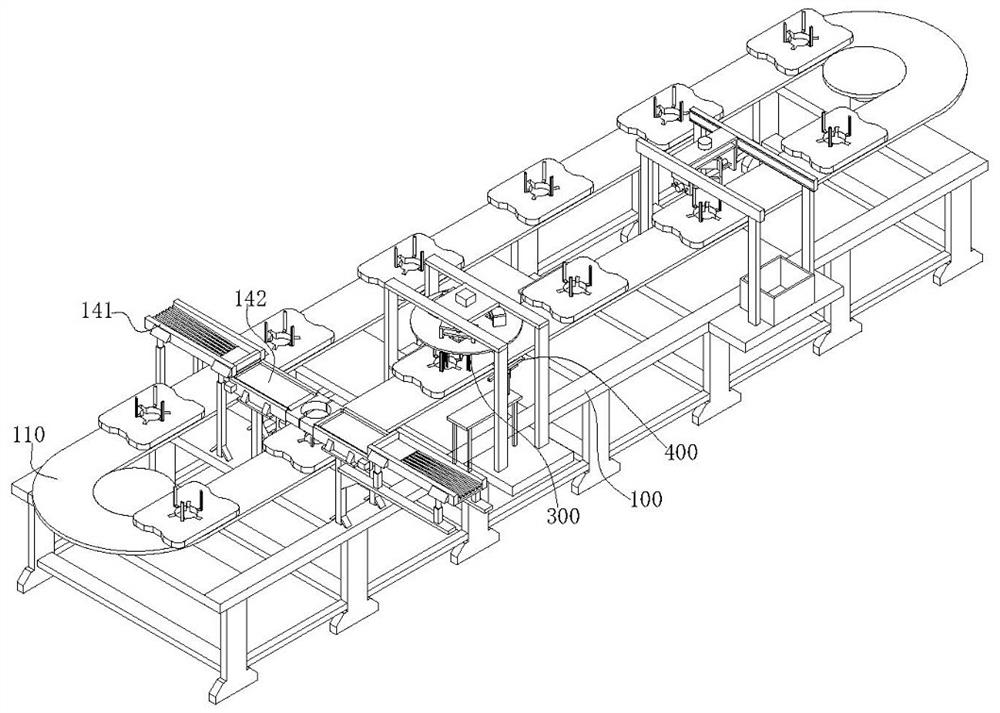

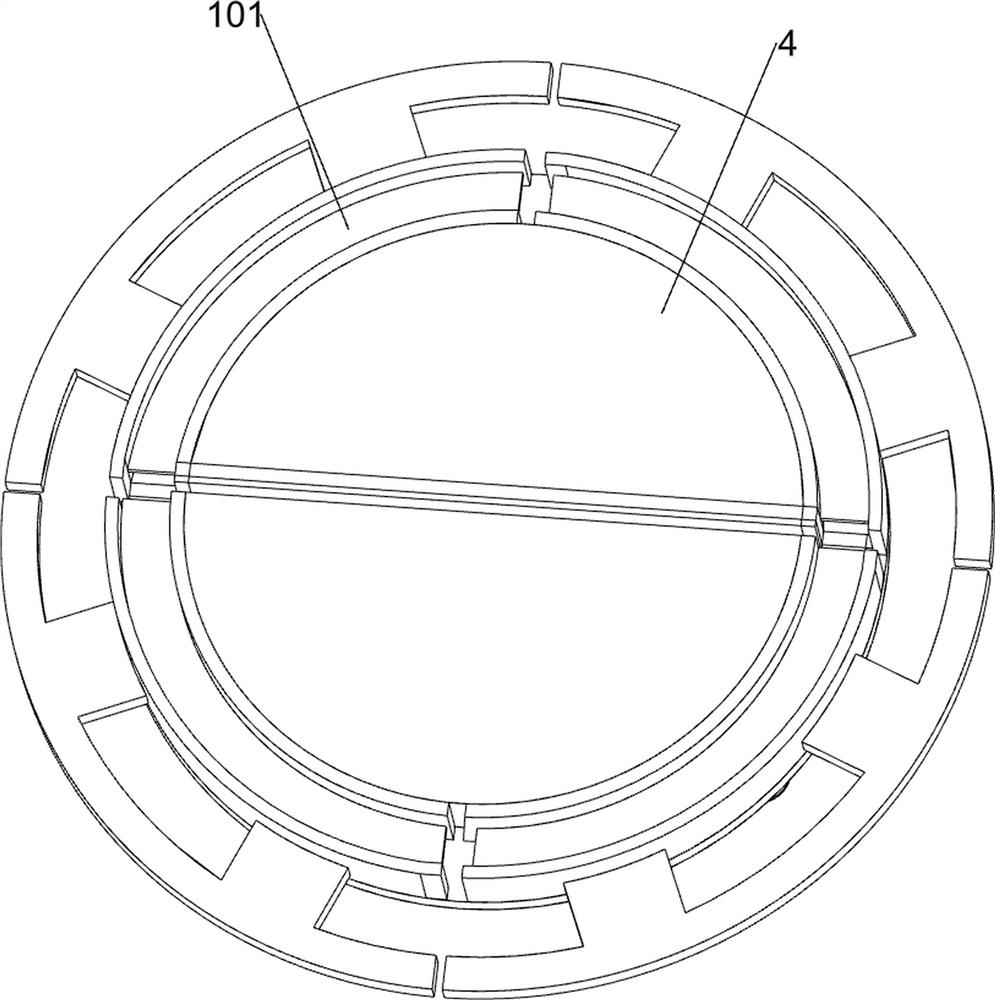

Automatic production binding equipment

InactiveCN112357184AEasy stackingEasy to useBinding material applicationPiston ringStructural engineering

The invention relates to automatic production binding equipment which comprises a conveying line and material carrying devices which are sequentially arranged on the conveying line at intervals and used for carrying piston rings. A feeding station, a first binding station, a second binding station and a discharging station are sequentially arranged on the conveying line. A feeding device used forarranging the piston rings on a material carrying unit to enable the piston rings to be arranged in a stacked manner is arranged at the feeding station in the axial direction, and a wire arranging device and a first binding device used for arranging and binding iron wires on the piston rings on the material carrying unit are arranged at the first binding station. A second binding device for secondarily binding iron wire heads bound by the first binding device is arranged at the second binding station. The equipment is good in production effect, high in piston ring stacking and binding machining efficiency, high in automation level and convenient to use.

Owner:安庆柯麦机电科技有限公司

Covalent conjugates between artemisinin-related endoperoxides and iron-carrying proteins and methods of use

In one aspect, the invention provides covalent conjugates between artemisinin-related endoperoxides and iron-carrying proteins. In some embodiments, the covalent conjugates comprise artelinate and holotransferrin. In another aspect, the invention provides methods for administering the covalent conjugates of the invention to treat cancer and infections by pathogens that bind iron-carrying proteins.

Owner:UNIV OF WASHINGTON

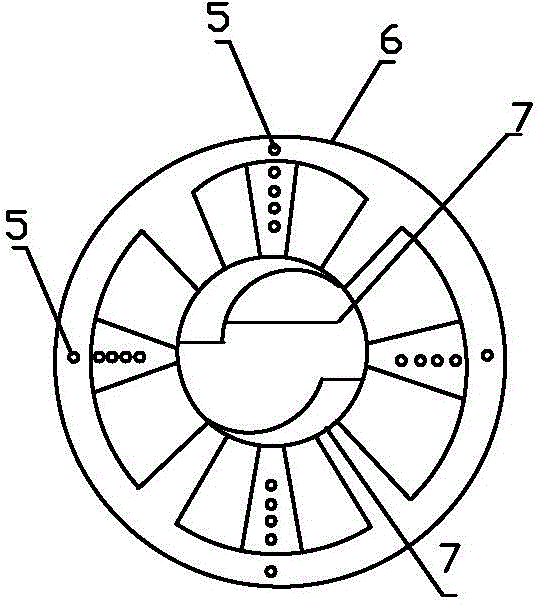

Electric reactor with integrally-bound iron core and binding method of iron core of electric reactor

InactiveCN103035375AShorten the manufacturing cycleNo curing requiredTransformers/inductances magnetic coresInductances/transformers/magnets manufactureExtensibilityPolyester

The invention relates to an electric reactor with an integrally-bound iron core and a binding method of an iron core of the electric reactor. The electric reactor comprises a three-column type iron core which is formed by stacking silicon steel sheets, adjusting pad strips are arranged along two side outer surfaces of an iron core column, and binding tapes which are used for integrally binding the iron core column and the adjusting pad strips are arranged outside the adjusting pad strips. The binding method of the iron core of the electric reactor comprises the following steps of firstly, forming the three-column type iron core by stacking the silicon steel sheets, and arranging the adjusting pad strips on the two outer side surfaces of the iron core; and then, integrally binding the iron core column and the adjusting pad strips at the outer sides of the adjusting pad strips. By adopting the structure and the binding method, disclosed by the invention, the binding tapes not only has the stretching resistance like a steel tape, but also has the shock-proof extensibility, solidification is not needed, a large amount of working hours can be saved, the manufacturing period of the iron core is shortened, the production efficiency is increased, the labor intensity of a worker is low, the running noise of a transformer is reduced, the temperature rising of the iron core is effectively reduced, and the binding arrangement of polyester tapes is regular and attractive.

Owner:QINGDAO HAIWO ELECTRICAL EQUIP

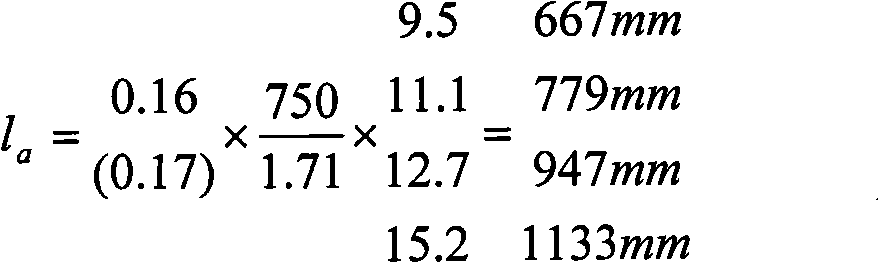

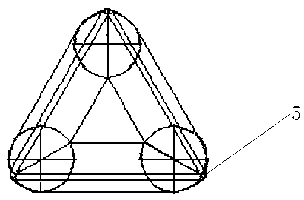

Method for binding iron cores of transformer with wound stereoscopic triangular iron core before annealing

InactiveCN103280310AAvoid deformationNo collapseTransformers/inductances detailsInductances/transformers/magnets manufactureTransformerMaterials science

The invention discloses a method for binding iron cores of a transformer with a wound stereoscopic triangular iron core before annealing. The wound stereoscopic triangular iron core is formed by combining three wound iron core sheets. The method includes: splicing the three wound iron core sheets into a stereoscopic triangular structure by arranging the same on a platform, and respectively arranging auxiliary round support steel at an outer triangular zone at the joint of the iron core sheets so as to prevent deformation during binding; binding three core limbs through a steel binding tape packing machine, and firstly binding internal steel binding tapes, aligning various contact surface edges and connecting seamlessly; then binding external steel binding tapes after the internal steel binding tapes in the three core limbs are all bound, and further firmly binding the iron core sheets into an integral stereoscopic triangular iron core. By the method, defects of collapse, deformation and waves and the like are avoided after annealing, and success rate of iron core production is greatly increased.

Owner:JIANG SU ZHONGRONG TECH

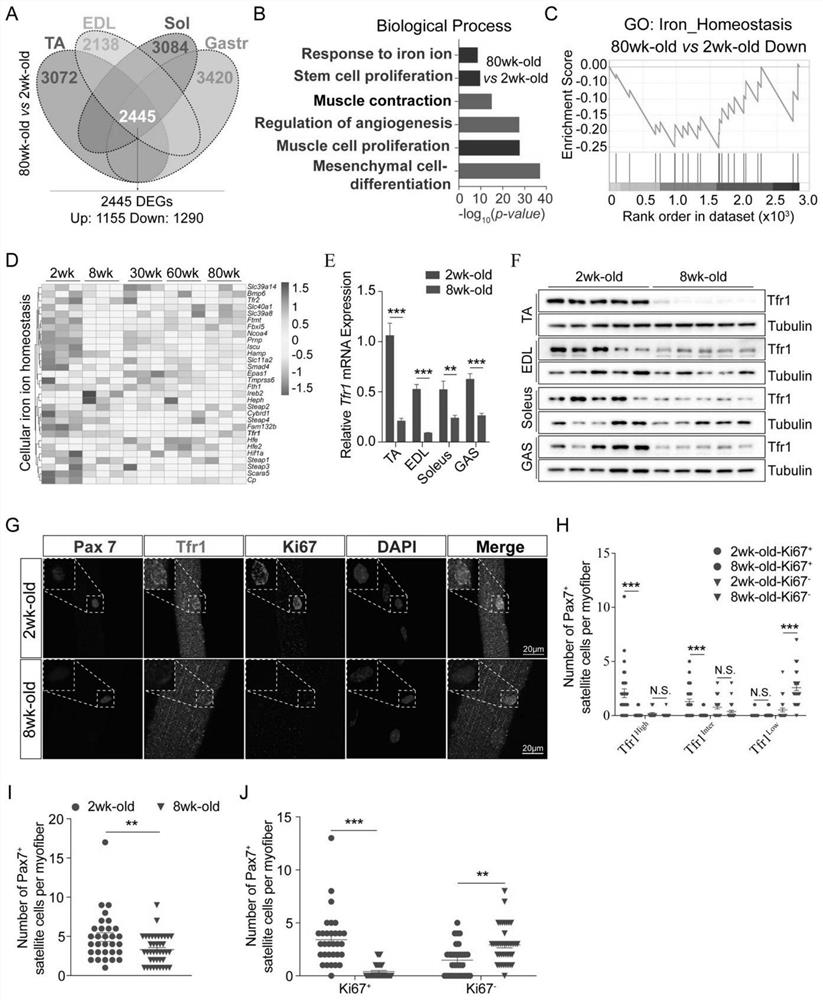

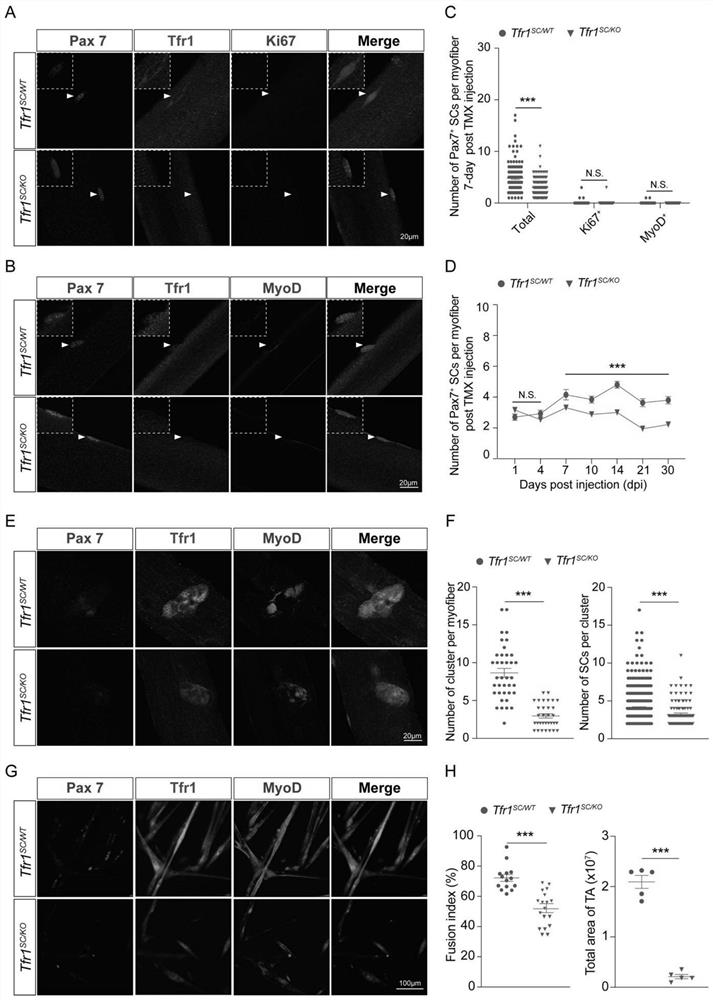

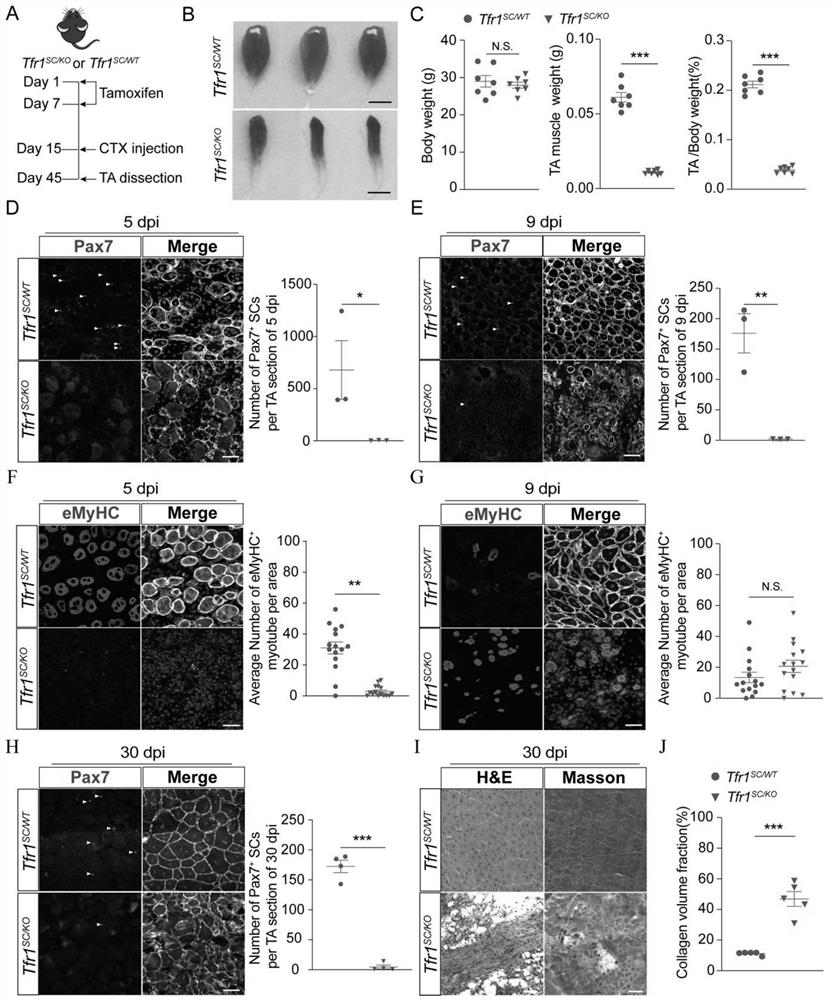

Application of ferroptosis inhibitor in preparation of preparation for improving motion function of aged individuals

PendingCN113181159AImprove movement disordersPromote absorptionOrganic active ingredientsMicrobiological testing/measurementIntraperitoneal routeFerroportin

The invention discloses an application of a ferroptosis inhibitor in preparation of a preparation for improving the motion function of aged individuals. Through transcriptome sequencing analysis, Tfr1 expression in skeletal muscle and muscle satellite cells is reduced along with age increase. The specific knockout of the Tfr1 muscle satellite cells leads to irreversible inactivation of the muscle satellite cells. The skeletal muscle regeneration process of the Tfr1 muscle satellite cell specific mouse is accompanied by amyotrophy, iron ion accumulation and increase of unsaturated fatty acid biosynthesis, and then skeletal muscle ferroptosis is induced. The senescent skeletal muscle shows that the expression of Tfr1 is reduced, and the surface of an Slc39a14 membrane is enriched, so that the absorption of non-iron transporter binding iron is promoted to be increased, and the occurrence of ferroptosis is promoted. By intraperitoneal injection of the Ferrostatin-1 into aged mice, muscle aplastic disorder and dyskinesia caused by skeletal muscle ferroptosis can be remarkably improved.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY +1

Anchor cable secondary protective device

PendingCN109339841ASolve the risk of scratchesSolve the hidden danger of wire channeling and injuryAnchoring boltsBinding ironGeotechnical engineering

The invention provides an anchor cable secondary protective device. The anchor cable secondary protective device comprises a sleeve, a cushion, connecting iron wires and binding iron wires. The anchorcable secondary protective device is fixed to the lower end of an anchor cable in a roadway, and an anchor net is fixed to the surface of the roadway; a metal pad and an anchor are installed on the anchor cable extending out of the roadway in sequence; the lower end of the anchor cable is installed in the sleeve, and the cushion is installed between the anchor cable and the sleeve; one ends of the connecting iron wires penetrate through the bottom end of the sleeve, and two ends of the connecting iron wires are fixed to the anchor net; and the binding iron wires are fixed on the two connecting iron wires above the sleeve. The anchor cable secondary protective device fundamentally solves the problem of anchor cable hurting people.

Owner:CHINA COAL XINJI ENERGY CO LTD

Combined tool for binding fire hose and application method thereof

The invention discloses a combined tool for binding a fire hose and an application method thereof. A detachable fixing table, a detachable clamp used for clamping a metal joint and a binding device used binding iron wires are designed; and the combined tool is convenient to detach, capable of being mounted in a tool box, convenient to carry and capable of achieving rapid assembling and being usedin different occasions. According to the combined tool for binding the fire hose and the application method thereof, a fire hose capable of bearing 1. 4MP water pressure can be quickly bound, time andlabor are saved, the working efficiency and the overhauling quality of the fire overhauling personnel are improved, and the combined tool can adapt to fire maintenance and use in special complex fields such as nuclear power and the like.

Owner:浙江万纳核电检修有限公司

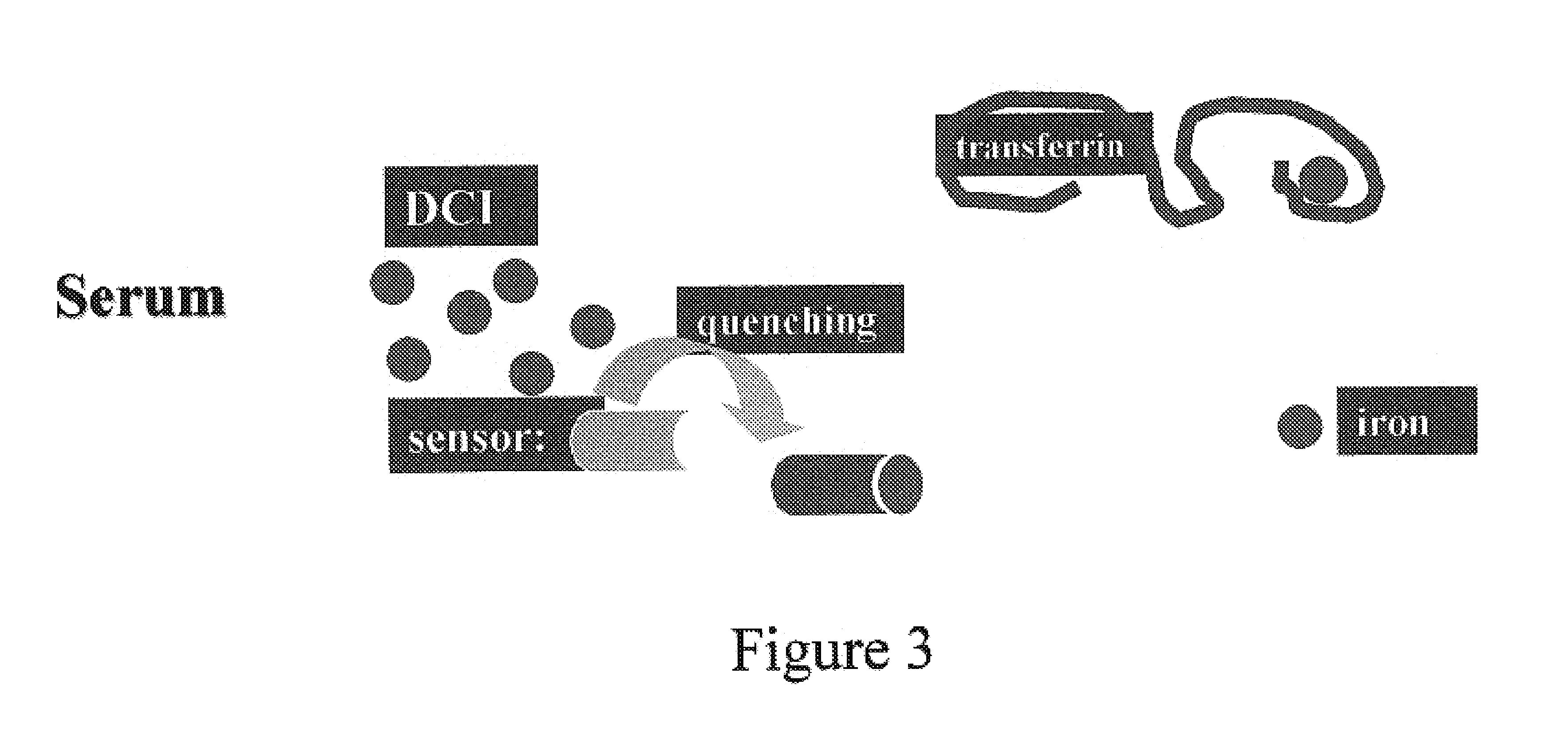

Test kit and method for measurement of metals in biological fluids

A test kit and a biomedical process is provided to estimate metals particularly non-transferrin bound iron levels (NTBI) in circulating body fluids particularly, serum. NTBI appears in serum when there is excess iron in the body. The method comprises of employing a signal generating moiety capable of complexing with iron that is a peptide like molecule having an iron binding site and also an optical signal generating functional group. The molecule is of microbial origin. The measurement is based on the alteration of optical characteristics of the probe molecule upon attachment of iron to its binding site on the molecule. Hence it generates a signal proportionate to the amount of iron available for binding and provides a direct estimate of free or unbound iron in the sample. According to this instant invention a rapid estimation method of NTBI in body fluids can be undertaken in an inexpensive way without the need of specialized expertise.

Owner:INDIAN INST OF TECH NEW DELHI

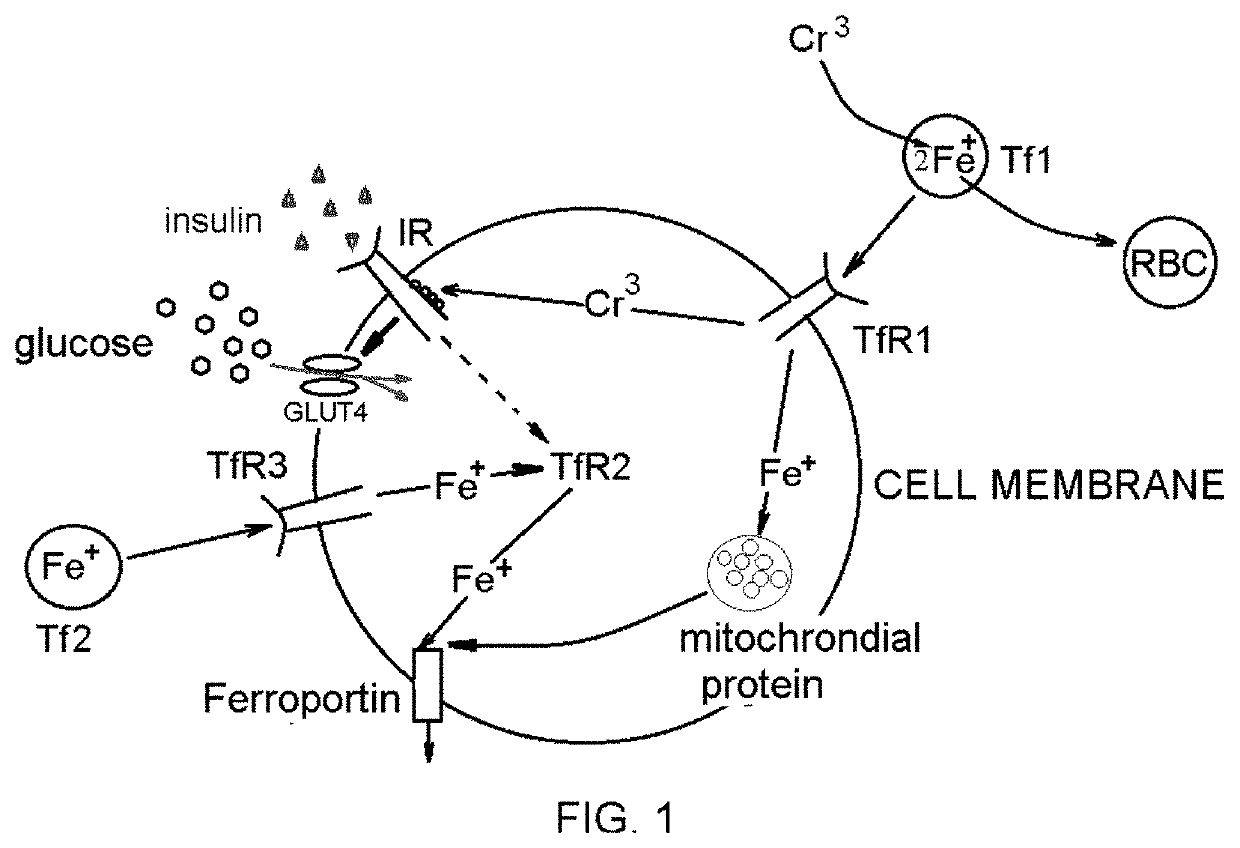

Compositions and methods for intracellular iron displacement proteins

InactiveUS20200030373A1Facilitate transferEasy transferHeavy metal active ingredientsPharmaceutical delivery mechanismBiophysicsTransferrin receptor

Methods and pharmaceutical compositions for optimizing intracellular iron by displacing iron bound transferrin (Tf) protein on a mammalian cell surface prior to its binding to a transferrin receptor (TfR), in the delivery of chromium chloride as being a Tf-binding agent to displace iron bound, and in the treatment of conditions involving disturbances in iron metabolism.

Owner:METABOLIC THERAPY INC

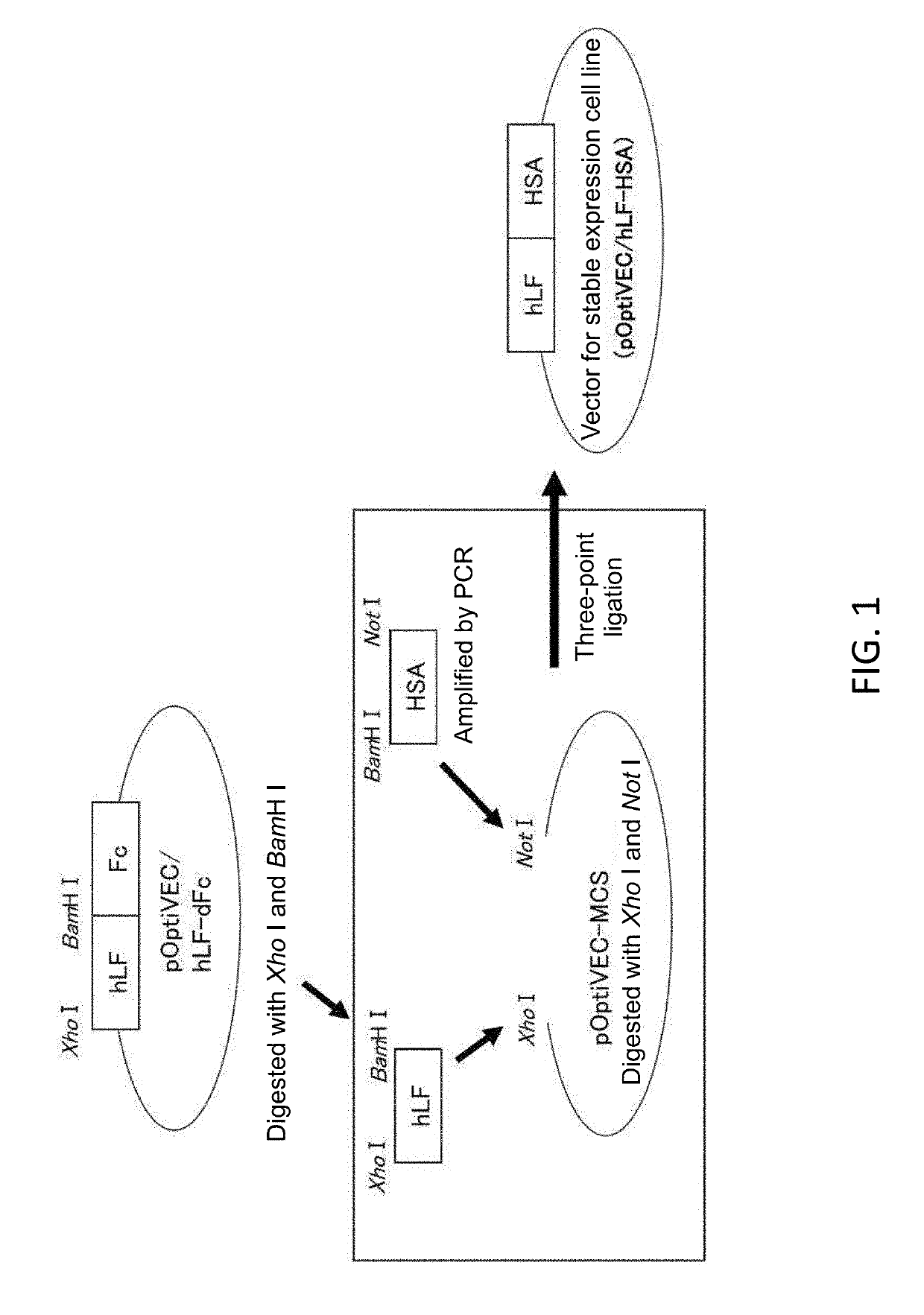

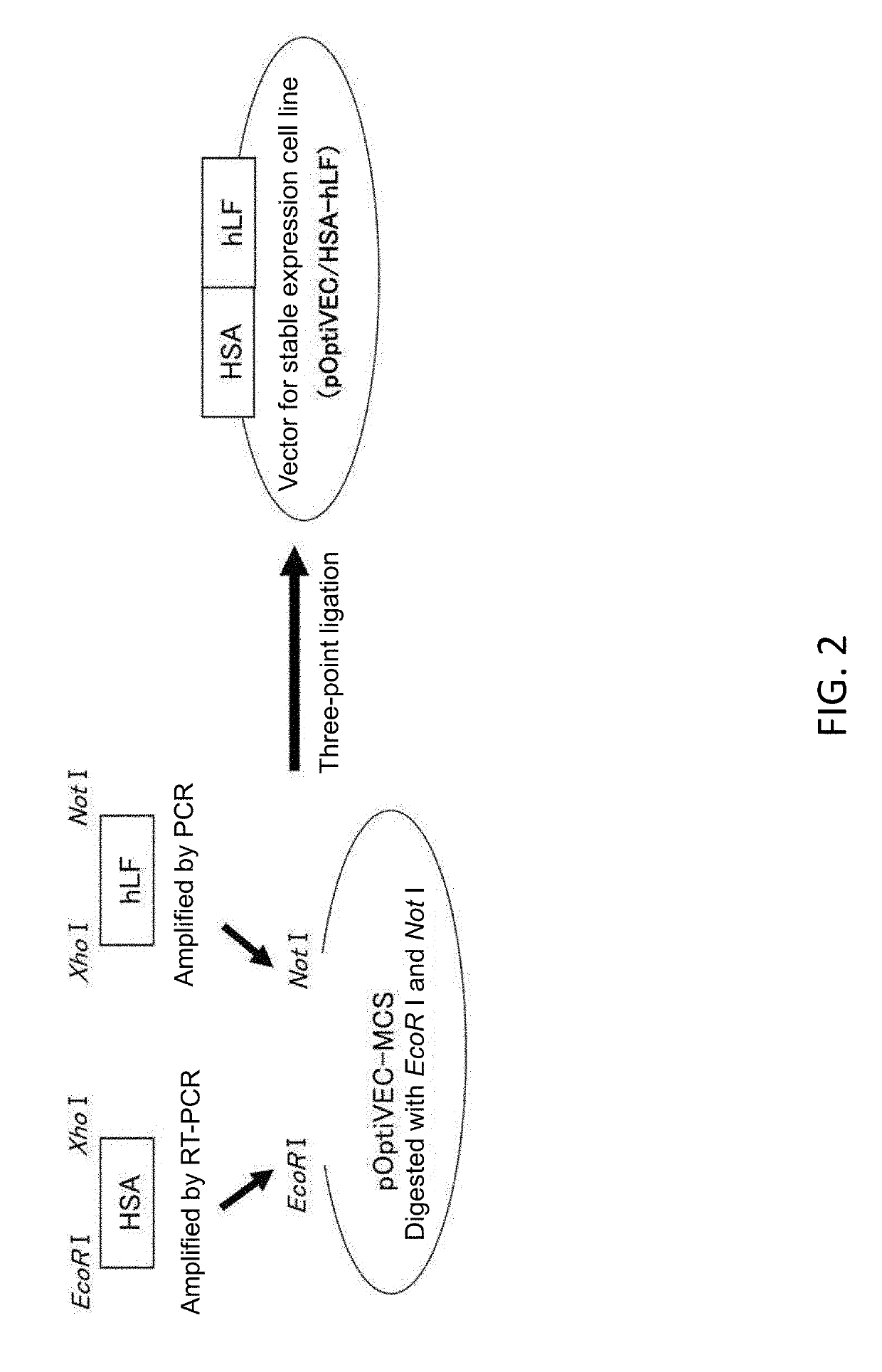

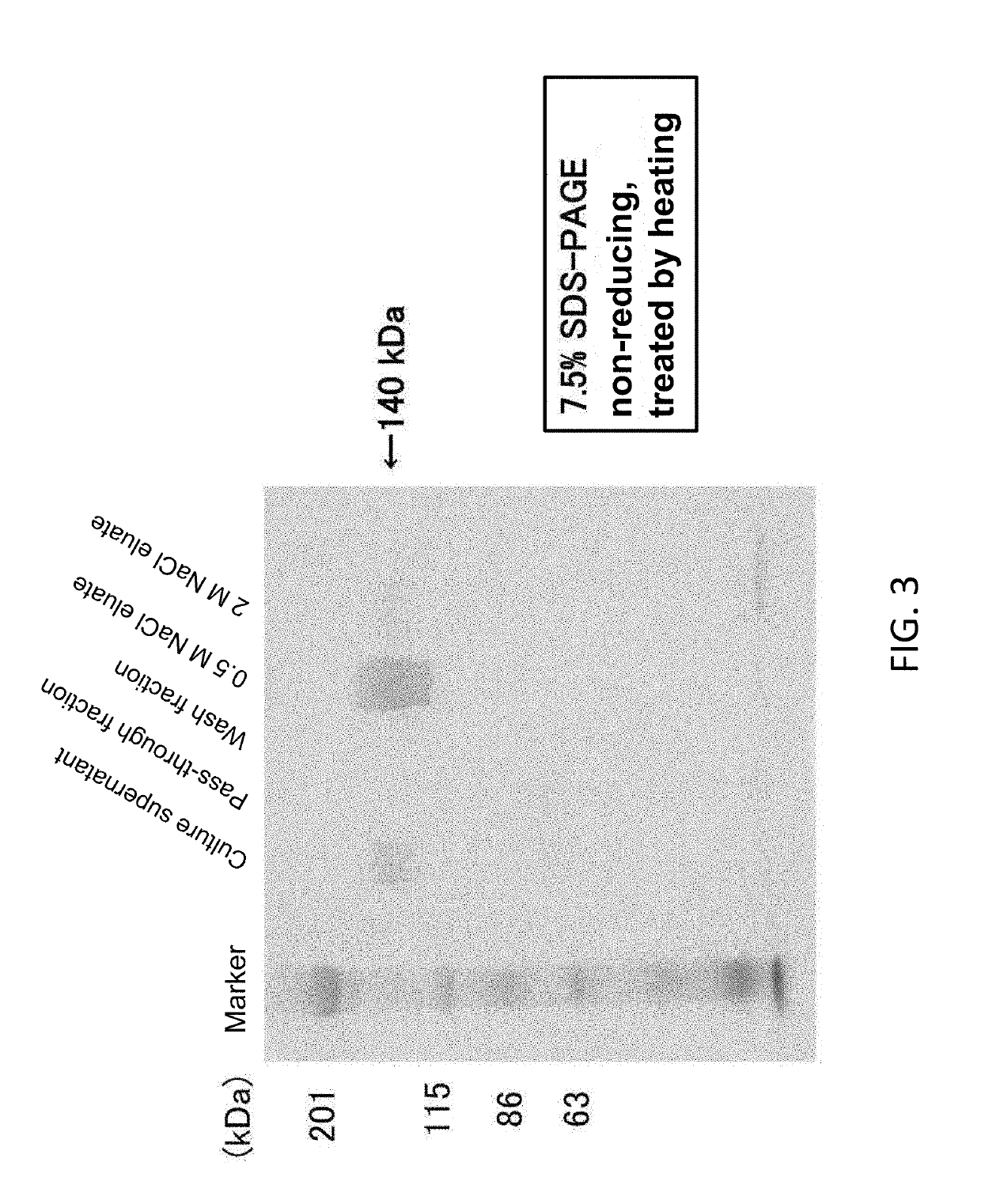

Lactoferrin/albumin fusion protein and production method therefor

ActiveUS20190309049A1Wide rangeStrong anti-oxidative stress effectPeptide/protein ingredientsTransferrinsIn vivoPepsin

The present invention provides a lactoferrin fusion protein having high clinical utility and a production method therefor. The present invention further provides: a lactoferrin fusion protein that retains the biological activity of native lactoferrin while having a significantly extended in vivo life span, and that has more clinical utility than native lactoferrin and recombinant lactoferrin; and a production method therefor. With this fusion protein or a variant thereof, the ability of lactoferrin to bind iron is retained, and therefore at least the important biological activity of lactoferrin that is based on the iron-binding ability is retained. Additionally, this fusion protein or variant thereof has bioavailability and resistance to protease, and thus can exhibit biological activity in vivo over a long period. Furthermore, this fusion protein is not easily broken down by pepsin in the stomach.

Owner:KAGAYA SHINJI +1

Method for binding iron core of transformer

ActiveCN101944423BImprove shielding effectReduce manufacturing costTransformers/inductances magnetic coresInductances/transformers/magnets manufactureTransformerInner bound

The invention relates to a method for binding an iron core of a transformer, which belongs to the technical field of transformer manufacturing processes. The method adopts a technical scheme that: the iron core is bound by a binding machine; an inner binding band of the iron core is a semiconductor electric band (6), and an outer binding band is a special weftless band (3) for iron core binding; packing wood (4) is arranged on the end part of the an exposed head of a coil, and semiconductor electric vanish (7) is coated on the packing wood for shielding the iron core; the semiconductor electric varnish is reliably connected with the semiconductor electric band; and the binding is carried out in a way of combining the iron core binding and the iron core shielding together. When the method is used, the iron core is bounded by the binding machine, the inner binding band of the iron core is the semiconductor electric band, and the outer binding band is the special weftless band for the iron core binding. In the invention, the iron core is bound by the binding machine, the inner binding band of the iron core is the semiconductor electric band, and the outer binding band the special weftless band for the iron core binding. The technology combines the regular iron core binding and an iron core shielding barrel together, and the binding bands have the double function of iron core binding and iron core shielding, so that binding time is shortened and the manufacturing cost of the transformer can be reduced; and using effects are good, binding requirements are met, the iron core is well shielded, and requirements on product quality are met.

Owner:BAODING TIANWEI BAOBIAN ELECTRICAL

Hybrid Superparamagnetic Iron Oxide Nanoparticles And Polyethylenimine As A Magnetoplex For Gene Transfection

ActiveUS20120157626A1Low cytotoxicityImprove stabilityPowder deliveryBiocideWater dispersibleCytotoxicity

Disclosed are the nanoparticle and the method for the same, and the preparing method includes steps of mixing polyethylenimine (PEI) with the poly(acrylic acid)-bound iron oxide (PAAIO) to form a PEI-PAAIO polyelectrolyte complex (PEC) and mixing the PEI-PAAIO PEC with genetic material such as plasmid DNA to form the PEI-PAAIO / pDNA magnetic nanoparticle. The PEI-PAAIO / pDNA magnetoplex is highly water dispersible and suitable for long term storage, shows superparamagnetism, low cytotoxicity, high stability and nice transfection efficiency, and thus the PEI-PAAIO PEC can replace PEI as a non-viral gene vector.

Owner:KAOHSIUNG MEDICAL UNIVERSITY

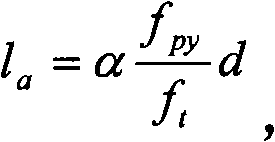

Construction method of slide type unloading filler

ActiveCN107461038BPacking efficiencyEnsure construction safetyBuilding repairsTowerUltimate tensile strength

The invention discloses a slide-way-type unloading and filling construction method which comprises the following steps that A, an unloading belt is manufactured, specifically, the unloading belt is made of a flexible and high-strength material, a hollow cavity of the unloading belt can allow fillings to freely pass through, and a steel wire wind holding rope is arranged in the unloading belt in a penetrating mode; B, an opening of the upper end of the unloading belt is fixed to a tower discharging opening, the unloading belt is freely lowered, and a first flexible device is arranged on the position, under an opening of the lower end of the unloading belt, of the ground; C, the unloading belt is opened by a circle in the circumferential direction through iron wires and is fixed to a tower in a bound mode, and the bound iron wires are evenly arranged at intervals in the length direction of the unloading belt; and D, the fillings are discharged from the tower discharging opening and then slide to the first flexible device along the hollow cavity of the unloading belt to complete unloading. According to the slide-way-type unloading and filling construction method, the higher tower fillings can be quickly and efficiently removed, it is ensured that the fillings are not damaged and construction is safe, and a more advanced construction method is provided for subsequent work such as tower body dismantling and overhauling.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Binding iron wire cutting device based on constructional engineering

The invention relates to an iron wire cutting device, in particular to a binding iron wire cutting device based on constructional engineering. The invention aims to provide the binding iron wire cutting device based on constructional engineering, which is relatively high in safety and relatively high in efficiency. According to the technical scheme, the binding iron wire cutting device based on constructional engineering comprises a bottom plate, first supporting frames, first sliding rails, a first movable plate, a first rotating shaft, a fixing block and a blade, the first supporting frames are symmetrically arranged at the top of the bottom plate, and the first sliding rails are symmetrically arranged at the tops of the first supporting frames; a first movable plate is slidably connected between the opposite sides of the first sliding rails. According to the device, the rotating mechanism is arranged, a first rack drives a first one-way gear to rotate, then a second rotating shaft, a third movable plate and a first movable plate are driven to rotate, iron wires can be evenly cut, and the first movable plate does not need to be manually controlled to rotate.

Owner:张权

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com