Wire-pulling iron wire binding machine

A wire puller and binding device technology, which is applied in the field of pull wire binding devices, can solve the problems of loose wire, damage to the galvanized protective layer on the surface of the wire, convex belly or exposed seams, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The patent will be further described below in conjunction with specific embodiments.

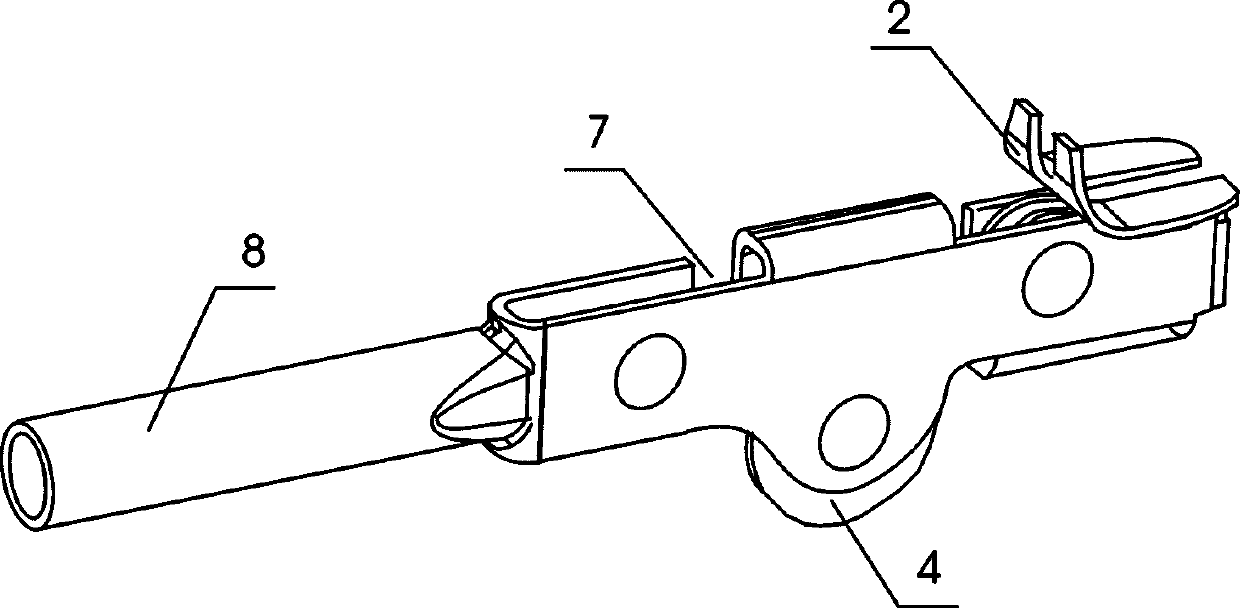

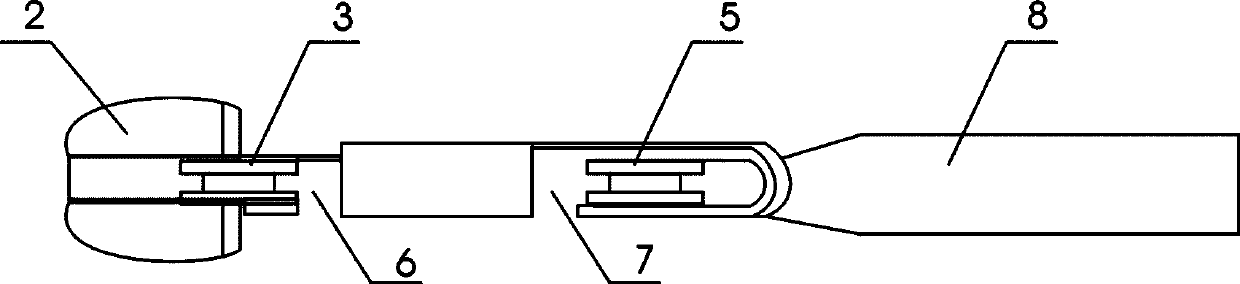

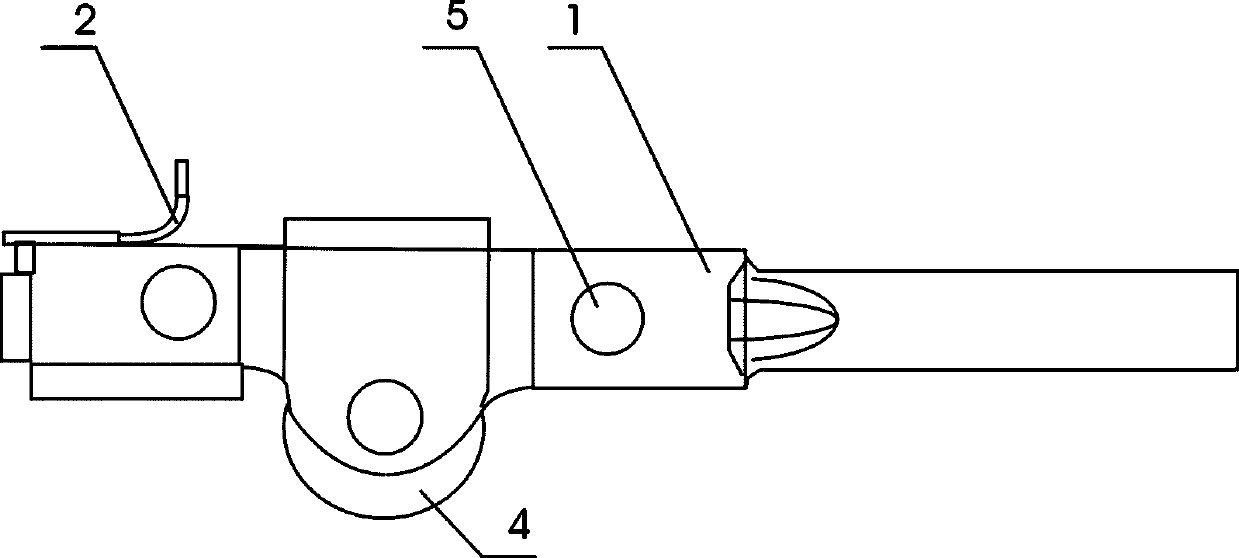

[0017] The pull wire binding device is composed of the main body of the puller, the positioning clip, the front roller, the middle roller, the rear roller, the front groove, the rear groove, and the steel pipe for the handle. The upper part of the front roller is provided with a positioning clip, and a gap is set between the positioning clips. The gap between the positioning clip and the position of the roller groove of the front roller is on the same center line, and the middle roller is set between the front roller and the rear roller. A wire passage is set on the main body of the puller, and a wire passage is set on the main body of the wire puller between the middle roller and the rear roller, and the steel pipe of the handle is welded at the end of the main body of the puller. After completion, pour the edge to 0.5 degrees to ensure that it does not scratch your hands. The diame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com