Method for binding iron cores of transformer with wound stereoscopic triangular iron core before annealing

A transformer core, triangle technology, applied in transformer/inductor parts, inductor/transformer/magnet manufacturing, electrical components, etc., can solve the problems of core collapse, unusable iron core, scrapping, etc. The effect of improving the success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

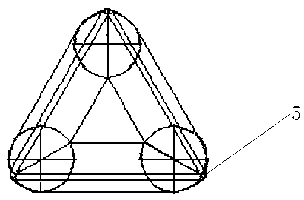

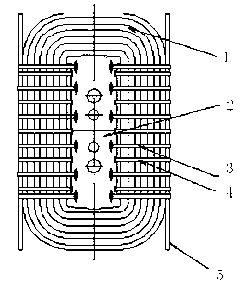

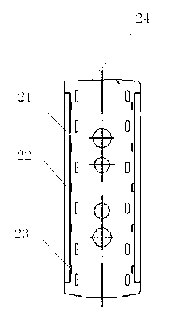

[0019] A binding method for three-dimensional triangular coiled iron core transformer cores before annealing, each three-dimensional coiled iron core is composed of three iron chips that are respectively rolled by two special combined core molds, figure 1 It is a schematic diagram of the binding method before annealing in the present invention. figure 2 It is a schematic diagram of the binding method of the inner binding steel strip and the outer binding steel strip in the present invention. The method is as follows:

[0020] 1) Place the same three-dimensional triangular coil core 1 on the platform and splice them into a three-dimensional triangular structure; see figure 1 .

[0021] 2) Auxiliary support round steel 5 is respectively set in the outer triangular zone at the joint of each piece of iron core to prevent deformation during binding;

[0022] 3) Use a special imported steel strapping machine to bind the three core columns. First, bind the inner binding steel bel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com