Agricultural binding device

A binding device, agricultural technology, applied in the fields of agriculture, application, plant support, etc., to achieve the effect of preventing the end of the binding belt from splitting, quickly connecting operations, and improving operation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

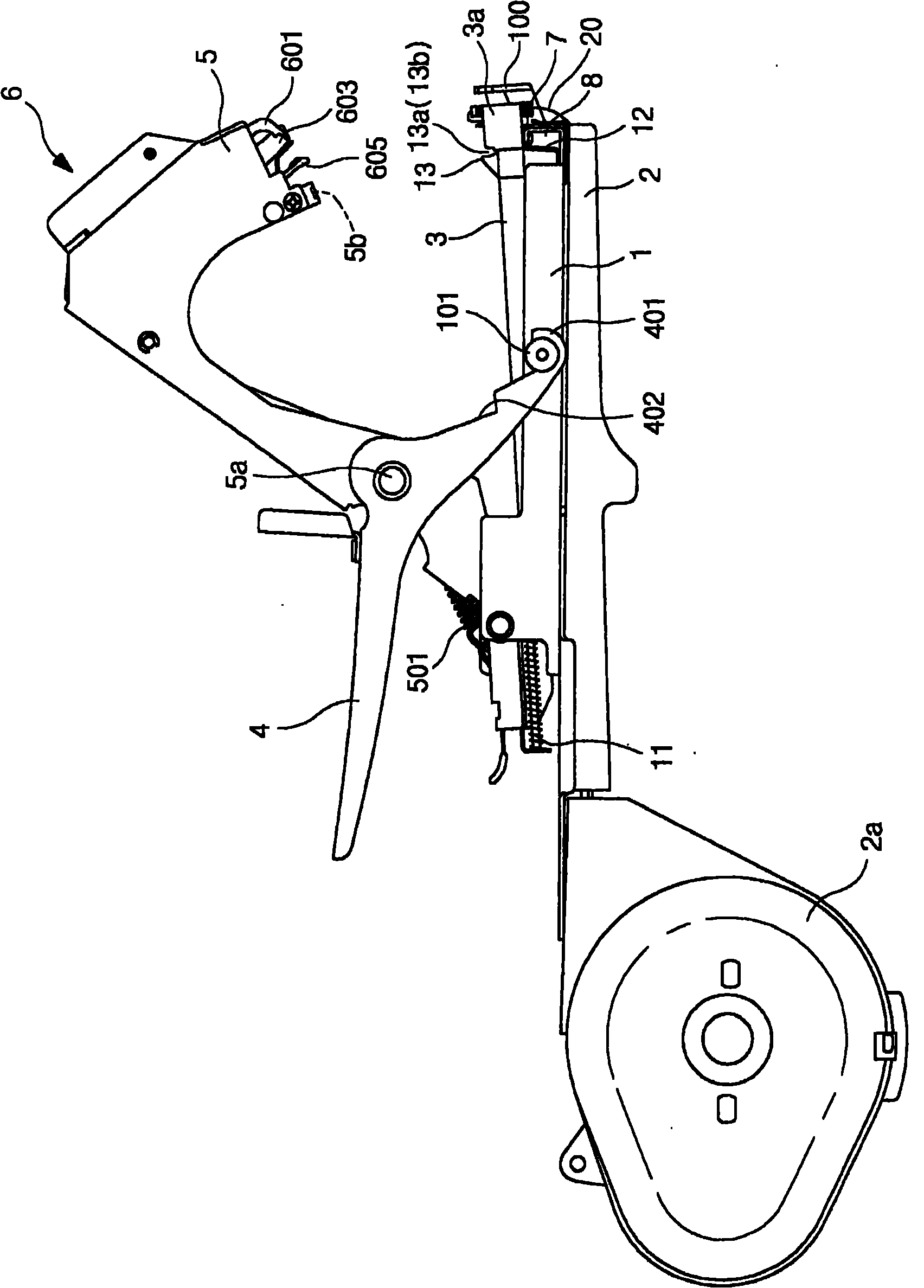

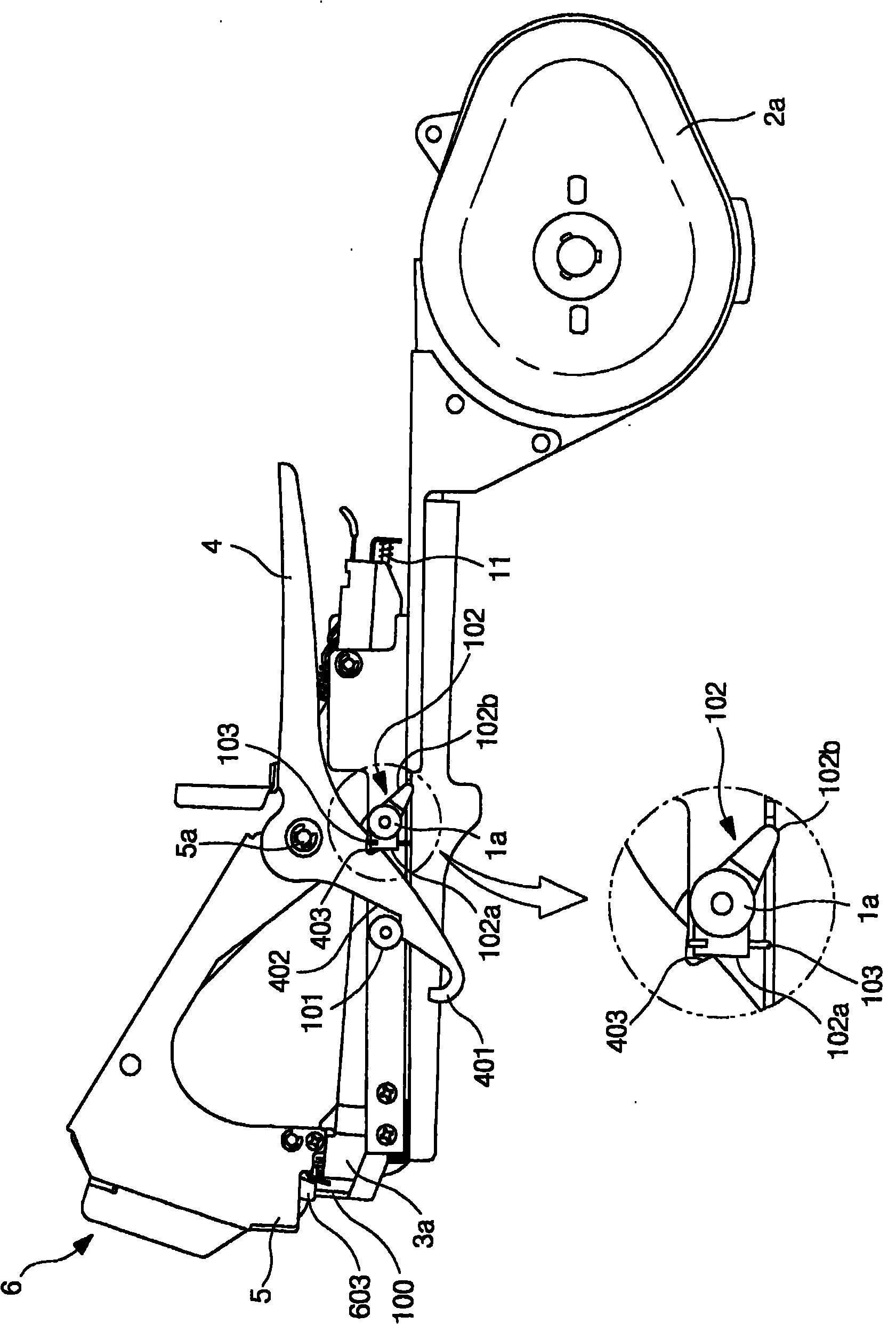

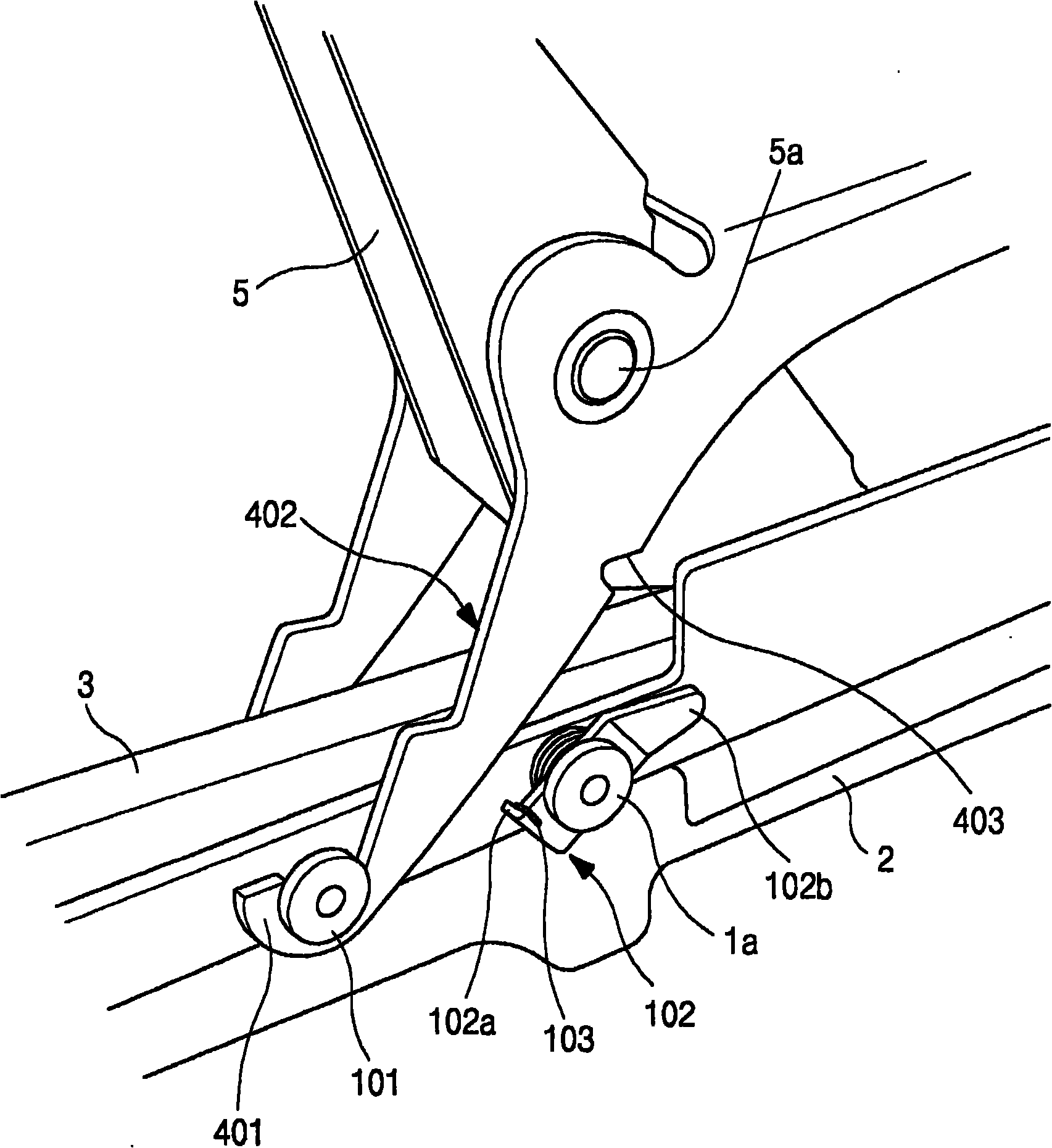

[0014] For the binding device with the following structure: a binding nail supply table 3 with binding nails 10 installed inside the binding device main body 1 is formed, and the binding nails are pushed by springs 11 to be supplied to the front-end connecting part 3a, and in the direction perpendicular to it The binding nail pressing out plate 12 is installed on the lower side, and a binding nail pressing outlet 3b is formed at the upper end opposite to it, so that a binding nail can be pushed out. There is a cut-off chamber 3c and a waiting room 8 outside the binding nail pressing outlet.

[0015] On one side of the bottom surface of the binder main body 1, there is a tape storage chamber 2a equipped with a tape reel, and on its opposite side, a tape supply portion 2 with a tape outlet 2b is formed to supply the binding tape 20 to the waiting tape chamber 8,

[0016] On the main body 1 of the binding device, the rotating shaft 5a is used to connect the lifting action body 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com