Novel reinforcing steel bar binding device

A new type of technology for steel bar binding, applied in construction, building structure, construction material processing, etc., can solve the problems of high construction cost, high labor intensity, long construction period, etc., and achieve the effect of shortening construction period, low investment and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

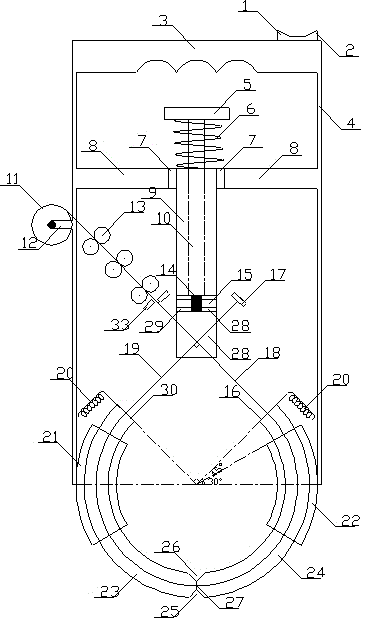

[0021] With reference to accompanying drawing, the implementation of the present invention is described in detail:

[0022] First, hold the handle (3) with your hand, align the outer openings (25) of the wire chute at the lower sections (27) of the left and right wire chutes to the binding points of the steel bars, and press the handle (3) downwards because the wire chute The left wire chute (23) and the right wire chute (24) at the outer opening (25) are squeezed by the bound steel bars, and move along the left wire chute sleeve (21) and the right wire chute sleeve (22) respectively. ) moves upward, and the bound steel bar enters the arc-shaped space at the lower part of the steel bar binding device. The upper section (30) of the left wire chute and the upper section (16) of the right wire chute are equipped with tension springs (20) respectively, so that the left wire chute (23) and the right wire chute (24) slide along the left wire respectively. The groove sleeve (21) and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com