Electric reactor with integrally-bound iron core and binding method of iron core of electric reactor

A reactor and iron core technology, applied in transformer/inductor magnetic cores, circuits, electrical components, etc., can solve the problems of long production cycle, high labor intensity of workers, long binding time, etc., to reduce the temperature rise of the iron core, improve Labor conditions, the effect of shortening the manufacturing cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

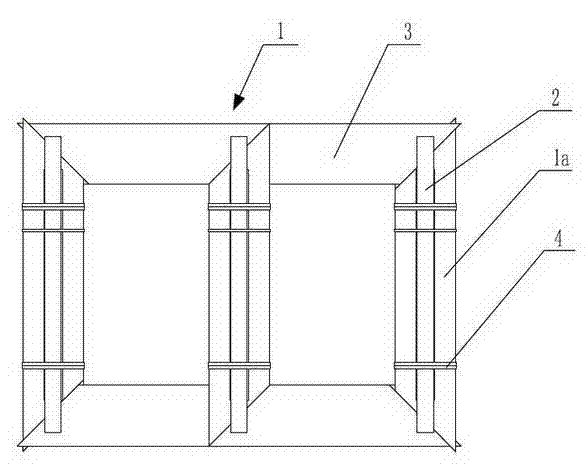

[0030] Such as figure 1 As shown, in the reactor of the present invention whose iron core is bound as a whole, the three-column iron core 1 is formed by stacking silicon steel sheets 3, and adjustment pads 2 are arranged along the outer surfaces of both sides of the iron core post 1a, outside the adjustment pads 2 There is a binding strap 4 that binds the iron core column 1a and the adjustment pad 2 together. The binding strap 4 is made of Tenax polyester tape, and the binding strap 4 is tied to both ends of the adjustment pad 2. Turn binding strap 4, the other end is bound two turns of binding strap 4, and the spacing of binding strap is 120-150mm.

[0031] The binding method of the reactor iron core comprises the following steps: forming a three-column iron core 1 by stacking silicon steel sheets, and setting adjustment pads 2 along the outer surfaces of both sides of the iron core post 1a; The column 1a and the adjustment pad 2 are bound together with Tenax polyester bindi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com