Method for binding iron core of transformer

A technology of transformers and iron cores, applied in the manufacture of inductors/transformers/magnets, transformers/inductor cores, electrical components, etc., can solve the problems of no shielding effect of the iron cores, long time, increased manufacturing costs, etc., to meet product quality requirements , good shielding effect, the effect of reducing manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

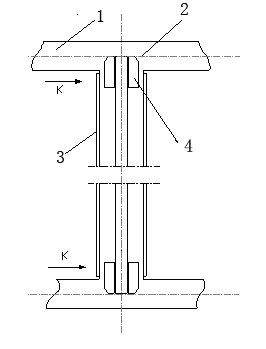

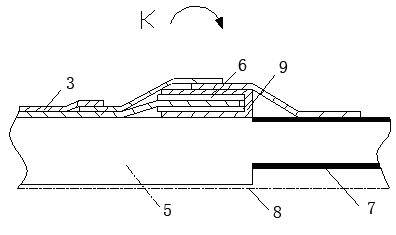

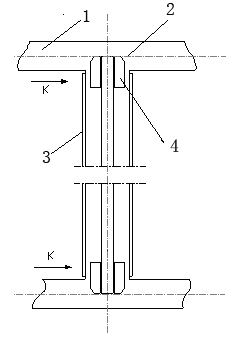

[0014] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0015] In the embodiment, the binding structure of the iron core column is as follows: the inner layer of the iron core column binding belt is a semi-conductive belt 6, the outer layer is a special non-weft belt 3 for iron core binding, and the filler wood 4 is placed at the end of the coil head, and the semi-conductive wood is brushed on the filler wood. Paint 7, shielding the iron core, and the semi-conductive paint is reliably connected with the semi-conductive strip.

[0016] Equipment and materials used.

[0017] Equipment: special binding machine for iron core;

[0018] Materials: End filler wood 4, polyimide film 8, semi-conductive paint 7, semi-conductive tape 6, carbon crepe paper 9, and grease-impregnated semi-dry netted fiberglass tape (without weft tape), etc.

[0019] Specific binding method:

[0020] ①When laying the bottom, pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com