Hoisting ring manufactured by using prestressed concrete steel strand tailings

A technology of concrete and stranded wire, which is applied in the processing of building materials, construction, building structure, etc., to achieve the effect of high strength, good flexibility, and saving useful steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be described in detail below with reference to the accompanying drawings.

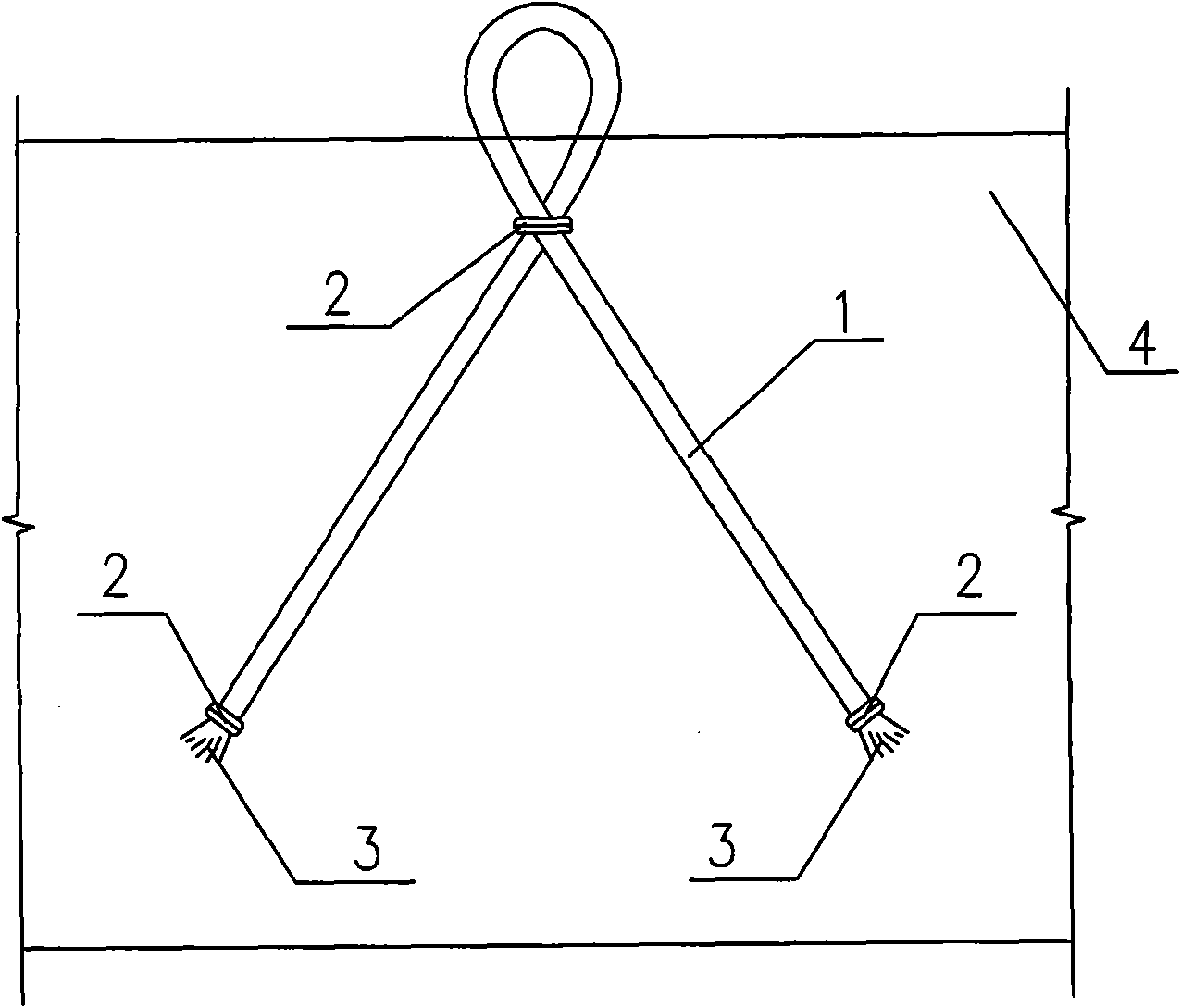

[0011] The present invention utilizes the good mechanical properties of the prestressed steel strand tail material, such as high strength, good flexibility, and no brittle fracture, to make various concrete prefabricated components 4 for lifting, installing rings, turning waste into treasure, and saving a lot of energy. Useful steel. The suspension ring is composed of a steel strand tail material 1, an anchoring end 2 with a thick hydraulic pier and an iron wire ring 3 binding the end of the tail material. The present invention utilizes the tail material of the prestressed steel strand as the prefabricated concrete member suspension ring, and the suspension ring includes the steel strand tail material 1, the thick anchoring end 2 of the application hydraulic pier and the iron wire ring 3 binding the end of the tail material, and is placed on the steel wire Twisted wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com