Finished steel strand bundle

A technology for steel strands and finished steels, applied in the field of finished steel strands, can solve the problems of deviation of prestressed data, affecting the use effect, difficult one-to-one correspondence of steel strands, etc., to avoid winding and deformation, improve production efficiency, The effect of high construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

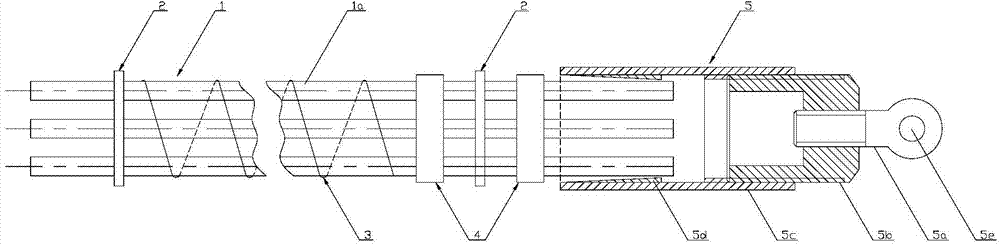

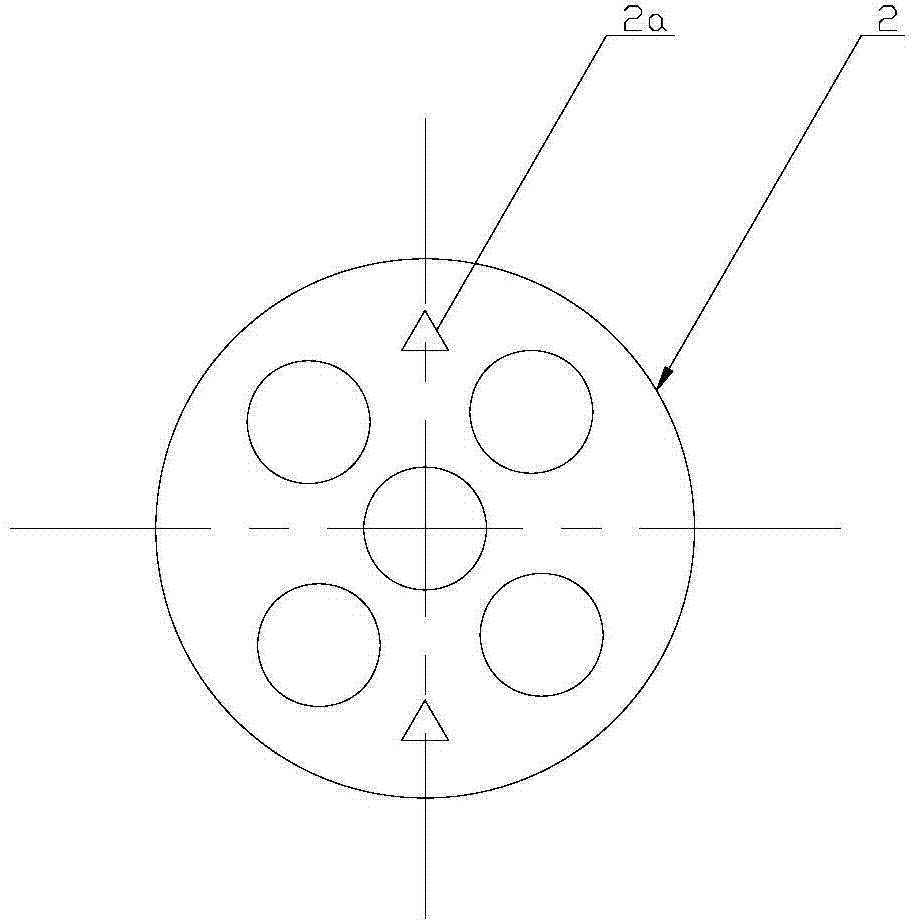

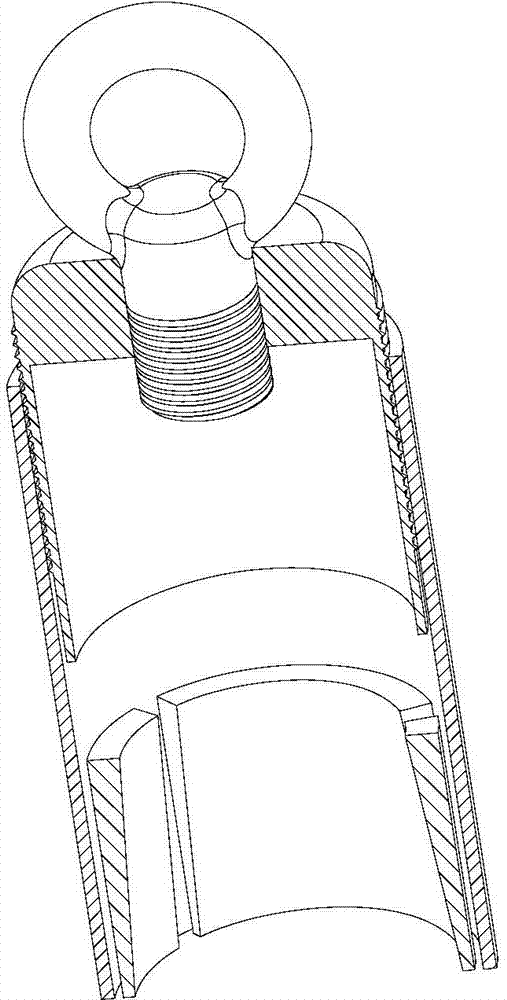

[0019] figure 1 It is a structural schematic diagram of the finished steel strand harness of the present invention; figure 2 yes figure 1 The front view of the middle marking board; image 3 yes figure 1 Cutaway perspective view of the middle retractor.

[0020] As shown in the figure, the present invention provides a finished steel strand bundle, and the finished steel strand bundle includes: a steel strand bundle 1 formed by combing a plurality of single steel strands 1a; There is a marking plate 2 with the same structure at the ends respectively; binding iron wires 3 are spirally wound on the outer contour of the steel strand bundle 1;

[0021] The present invention also includes a cylindrical puller 5 arranged at the pulling end of the steel strand bundle 1. The cylindrical puller 5 includes a cylindrical sleeve 5c, and one end of the sleeve 5c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com