Method of manufacturing a face to face pile fabric on a double-plush loom

A pile fabric, double-sided technology, applied in the direction of fabrics, textiles, textiles and papermaking, can solve the problems of limiting the weft density, limiting the jacquard definition, etc., to save the weft material, improve the jacquard definition, and save the pile material. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

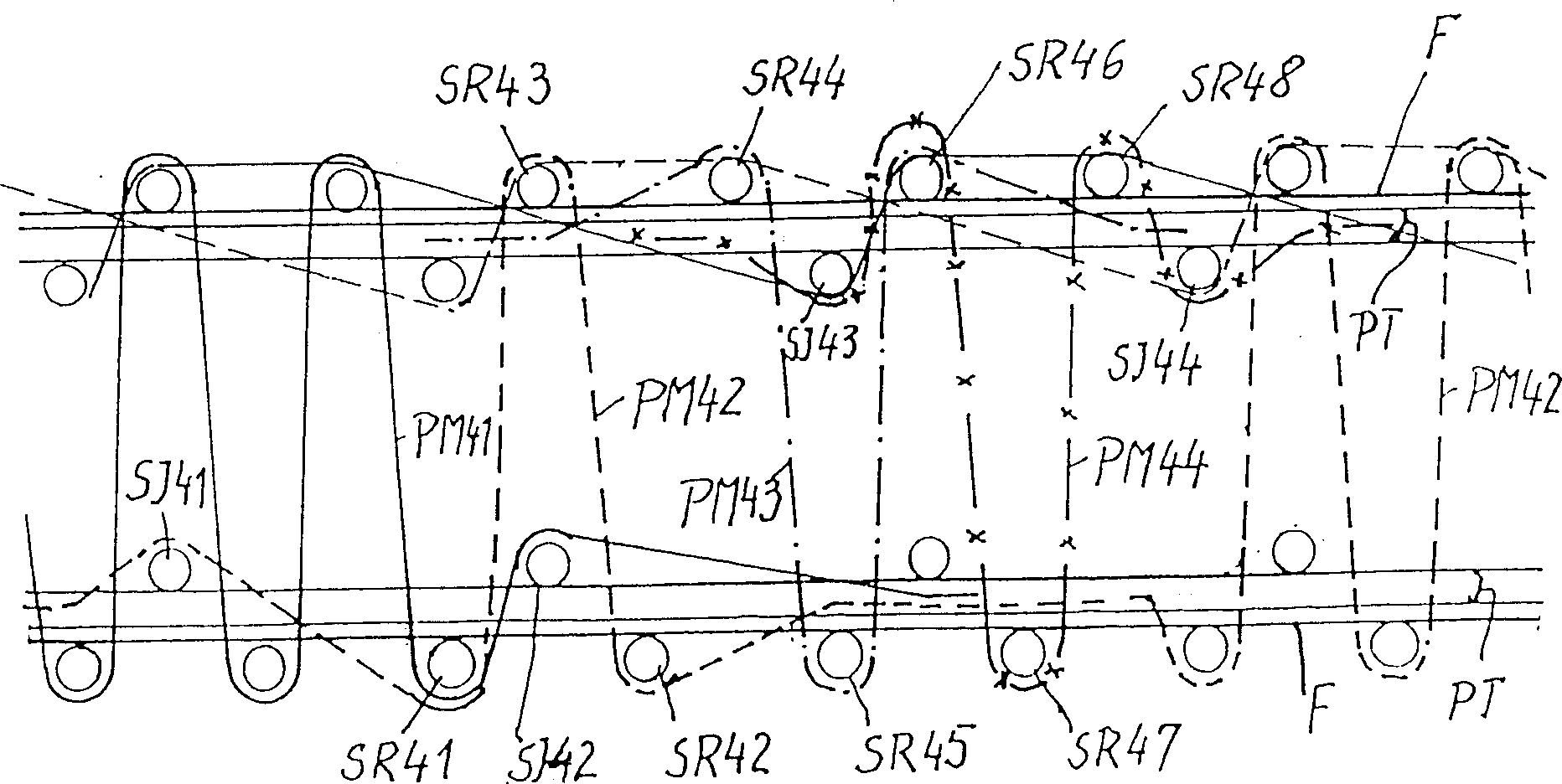

[0058] A two-ply carpet fabric loom for producing the two-ply carpet fabric described below has at least two weft insertion planes with a preferably 12-hard heddle formed by sheds for binding warp threads and inlay warp threads A Jacquard machine of at least three positions arranged and having a drive controlling the drive of the pile warp yarns for shedding.

[0059] This two-ply carpet fabric loom is equipped with a clamping and cutting device for the weft thread, which is also capable of feeding or not feeding a weft thread to the output gripper of a weft insertion system. Furthermore, said loom is equipped with a sensor which monitors whether a weft thread has been introduced according to the cycle RS.

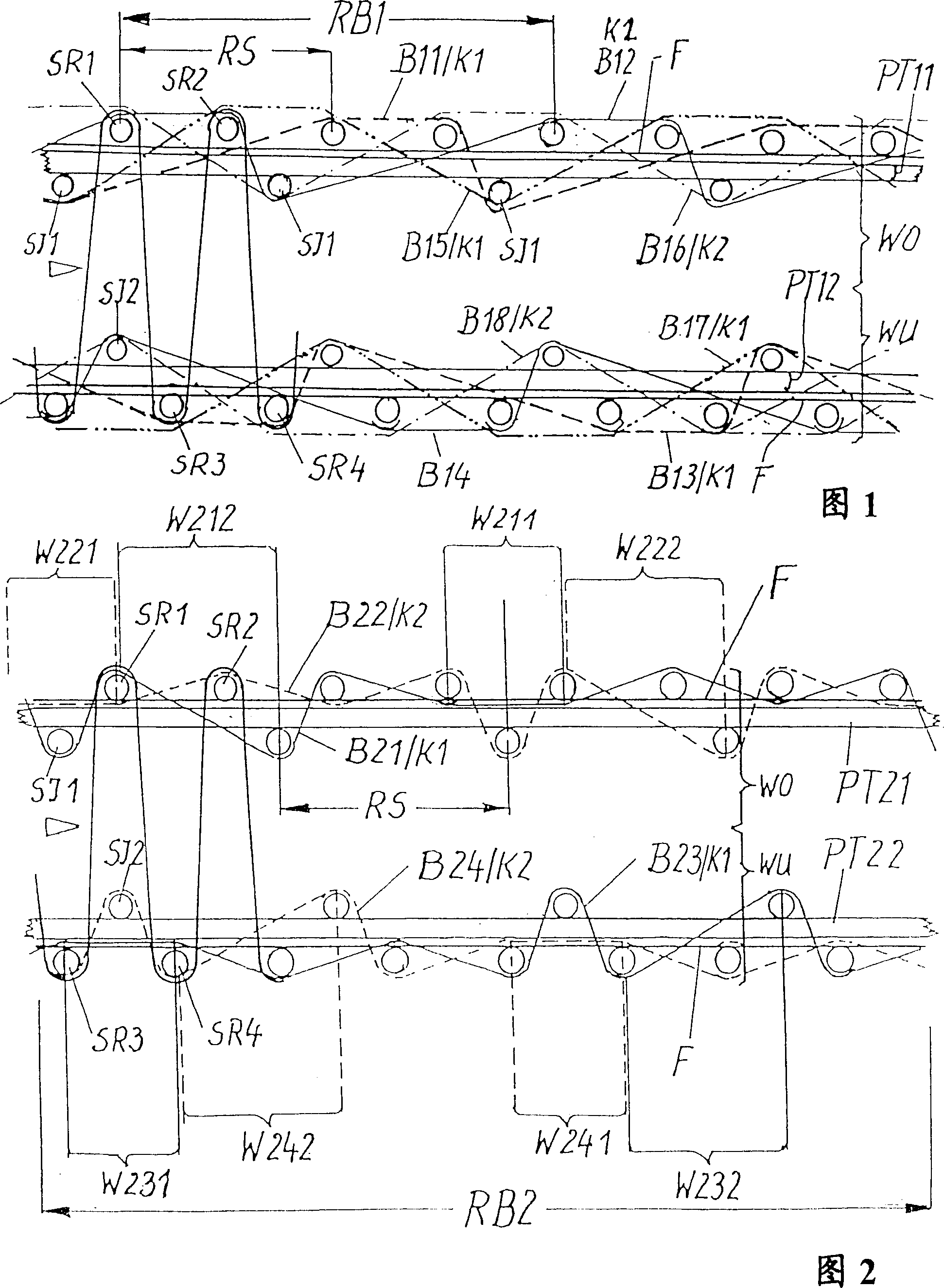

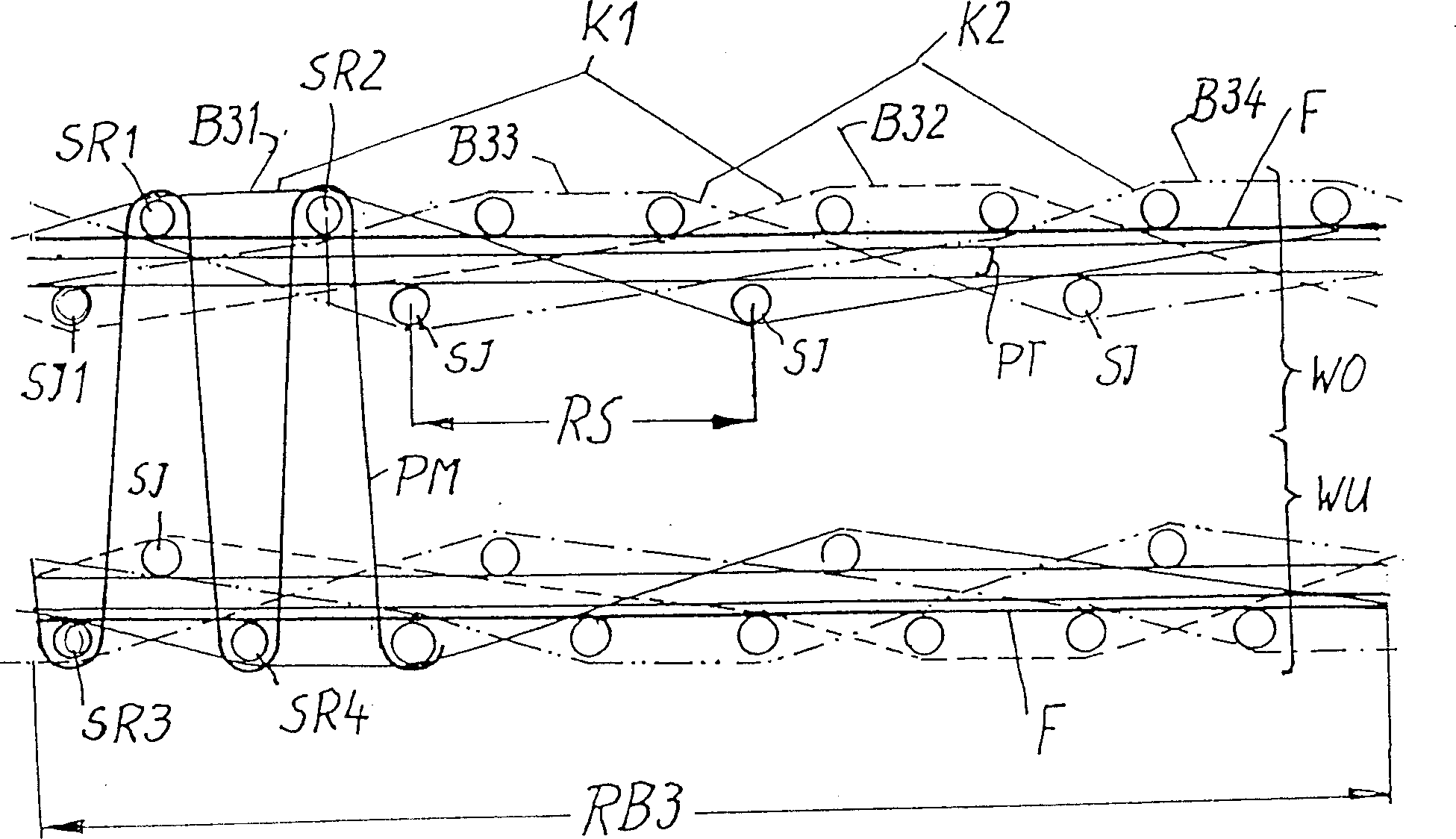

[0060] As shown in Figure 1, the weft yarns SR, SJ are introduced from the left in the order shown. The mutually overlapping weft threads are each inserted simultaneously.

[0061] In the first revolution, the under weft SR1 is introduced into the top fabric WO and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com