Method and system for preparing winding-free high-efficiency amorphous ribbon

A high-efficiency, non-twisting technology, applied in the field of non-twisting high-efficiency amorphous thin ribbon preparation method and preparation system, can solve the problems of mutual winding, low production efficiency and high production cost, and achieve reduced energy consumption and production efficiency. Low, high cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

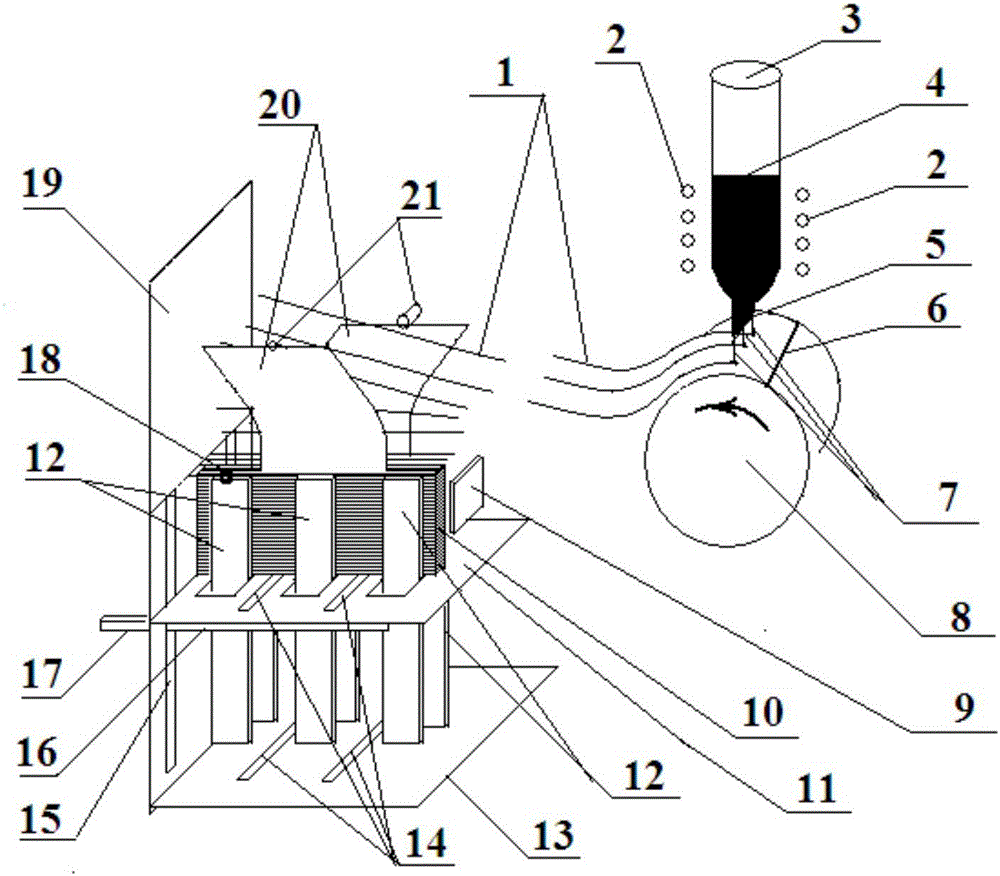

[0089] Further, the non-tangle high-efficiency preparation method of thin amorphous ribbons specifically includes:

[0090] The masterbatch is configured according to the target requirements, and the master alloy is configured by AC arc melting method or high frequency induction heating method;

[0091] Set grooves on the surface of the quenching cooling roll according to the target requirements;

[0092] According to the requirements of the target, configure the collection device of the thin amorphous strip;

[0093] Configure the melt nozzle and melt the master alloy according to the target requirements;

[0094] According to the target requirements, a single-roll quick quenching method is used to prepare neat stacks of amorphous thin strips.

[0095] Further, the width of the thin amorphous strip is 0.01 mm to 5 mm, which is controlled according to the rotation speed of the cooling roll or according to the size and pitch of the melt nozzle;

[0096] The composition of th...

Embodiment 1

[0099] Complete embodiment 1 of the present invention according to the following steps:

[0100] 1. Master alloy preparation: mix and prepare the alloy masterbatch by mixing Fe with 78% atomic ratio, Si with 9% atomic ratio and B with 13% atomic ratio. Under the protection of argon, use high-frequency induction heating method or AC arc melting method After melting the alloy masterbatch, it is cooled to obtain the master alloy.

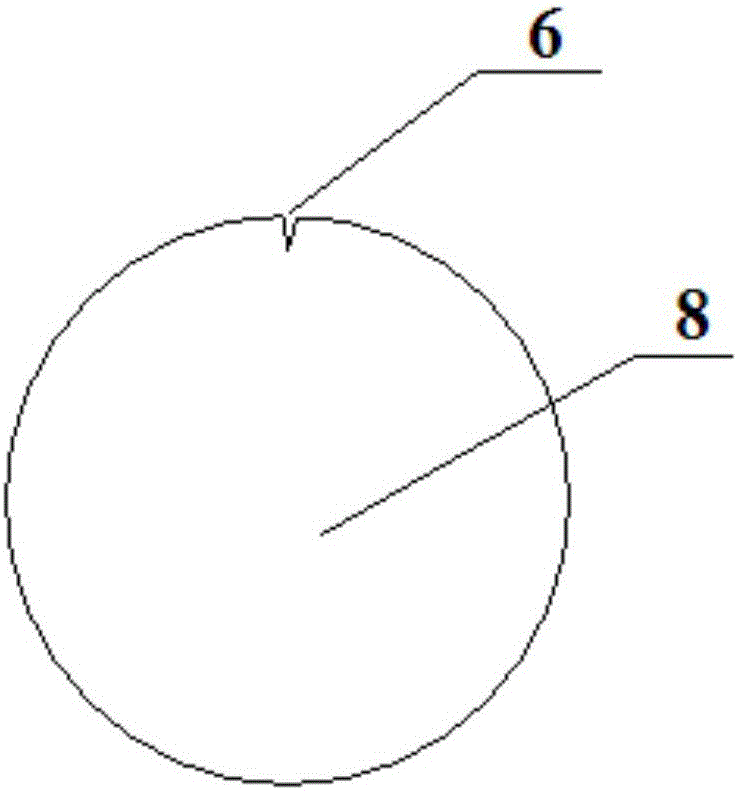

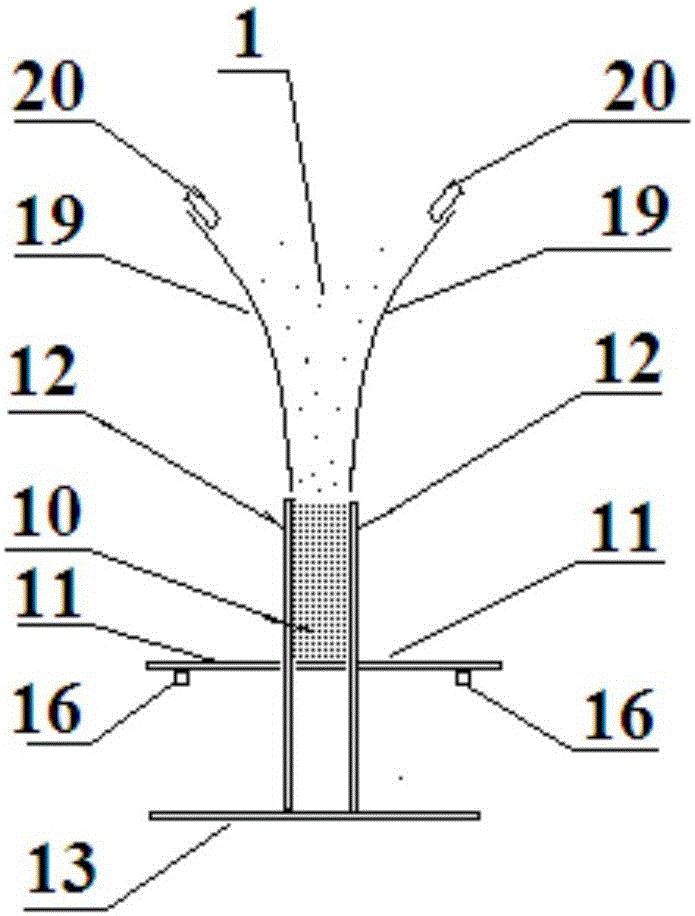

[0101] 2. On the roll surface of the cooling roll 8 with a diameter of 45cm, 10 equally spaced 0.1mm wide and 0.1mm deep grooves 6 are set perpendicular to the direction of rotation, and then the cooling roll surface is polished.

[0102] 3. Set 7 melt injection holes with a diameter of 0.08 mm at intervals of 2 mm in the middle of the central axis of the nozzle 5 .

[0103] 4. Install the nozzle 5 on the bottom of the crucible 3 .

[0104] 5. Utilize the single-roll rapid quenching technique comprising the following sub-steps to prepare the thin amo...

Embodiment 2

[0114] Complete embodiment 2 of the present invention according to the following steps:

[0115] 1. Master alloy preparation: mix and prepare alloy masterbatch by 74.5% atomic ratio of Fe, 8.8% atomic ratio of Si, 9.8% atomic ratio of B, 4.9% atomic ratio of P and 2.0% atomic ratio of C, in argon Under protection, the alloy masterbatch is melted by high-frequency induction heating method or AC arc melting method, and cooled to obtain the master alloy.

[0116] 2. Master alloy preparation: the alloy masterbatch is prepared by mixing 74.5% atomic ratio of Fe, 8.8% atomic ratio of Si, 9.8% atomic ratio of B, 4.9% atomic ratio of P and 2.0% atomic ratio of C. Under the protection of argon, the alloy masterbatch is heated and melted by high-frequency induction method or AC arc melting, and the master alloy is obtained after cooling.

[0117] 3. Five grooves 6 with a width of 0.1 mm and a depth of 0.15 mm are arranged at equal intervals perpendicular to the direction of rotation on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com