Patents

Literature

43results about How to "Easy stacking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

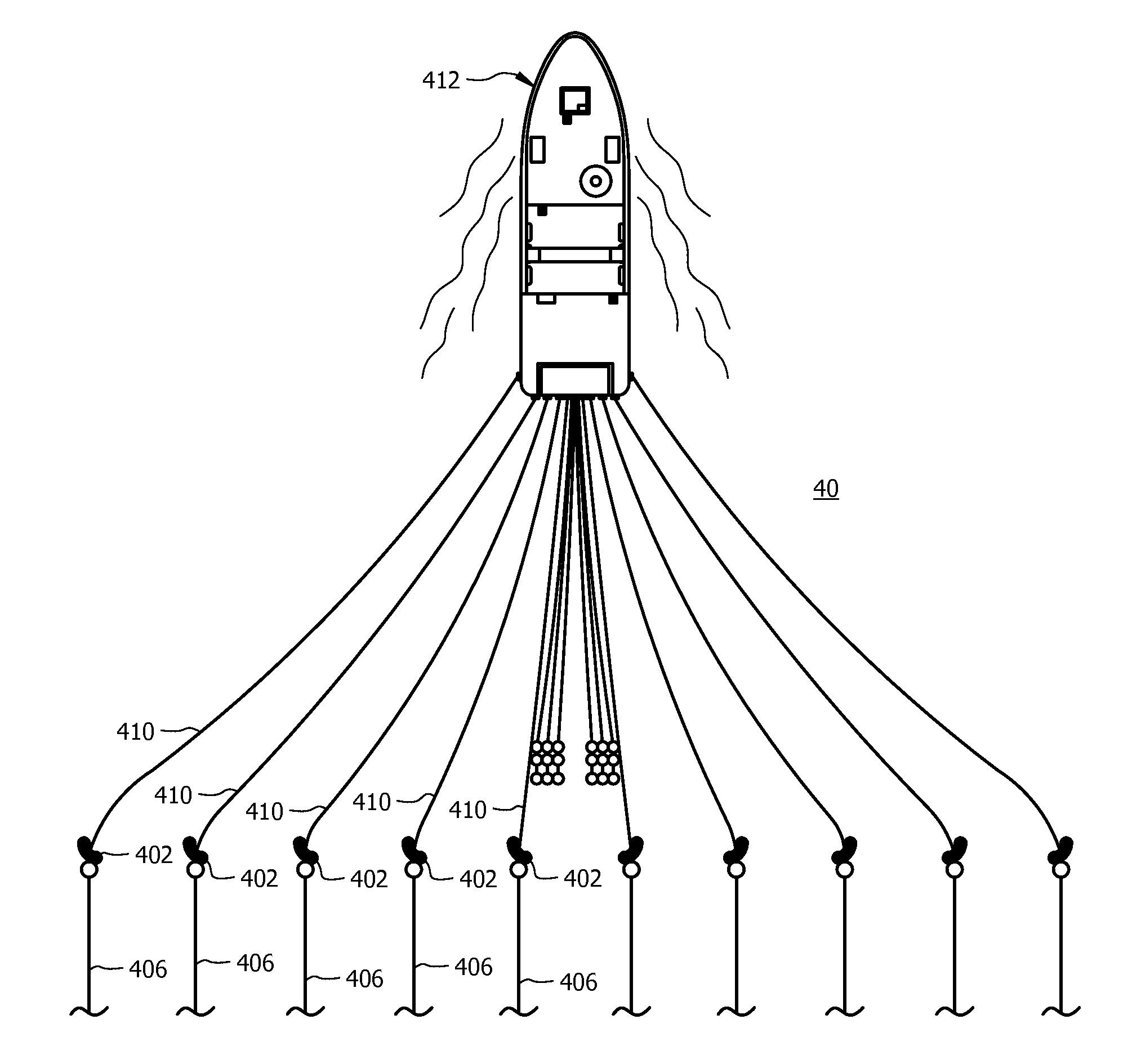

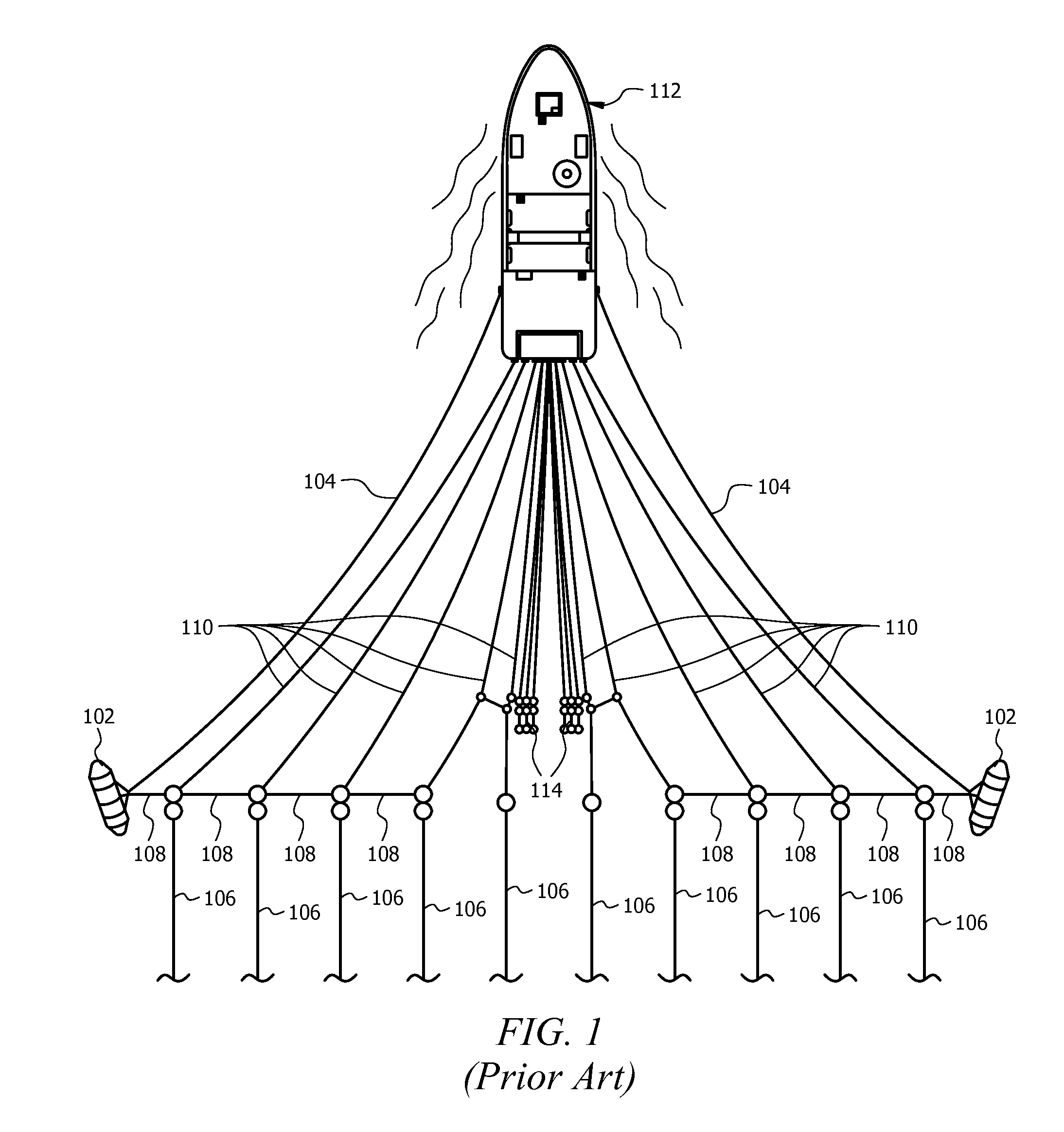

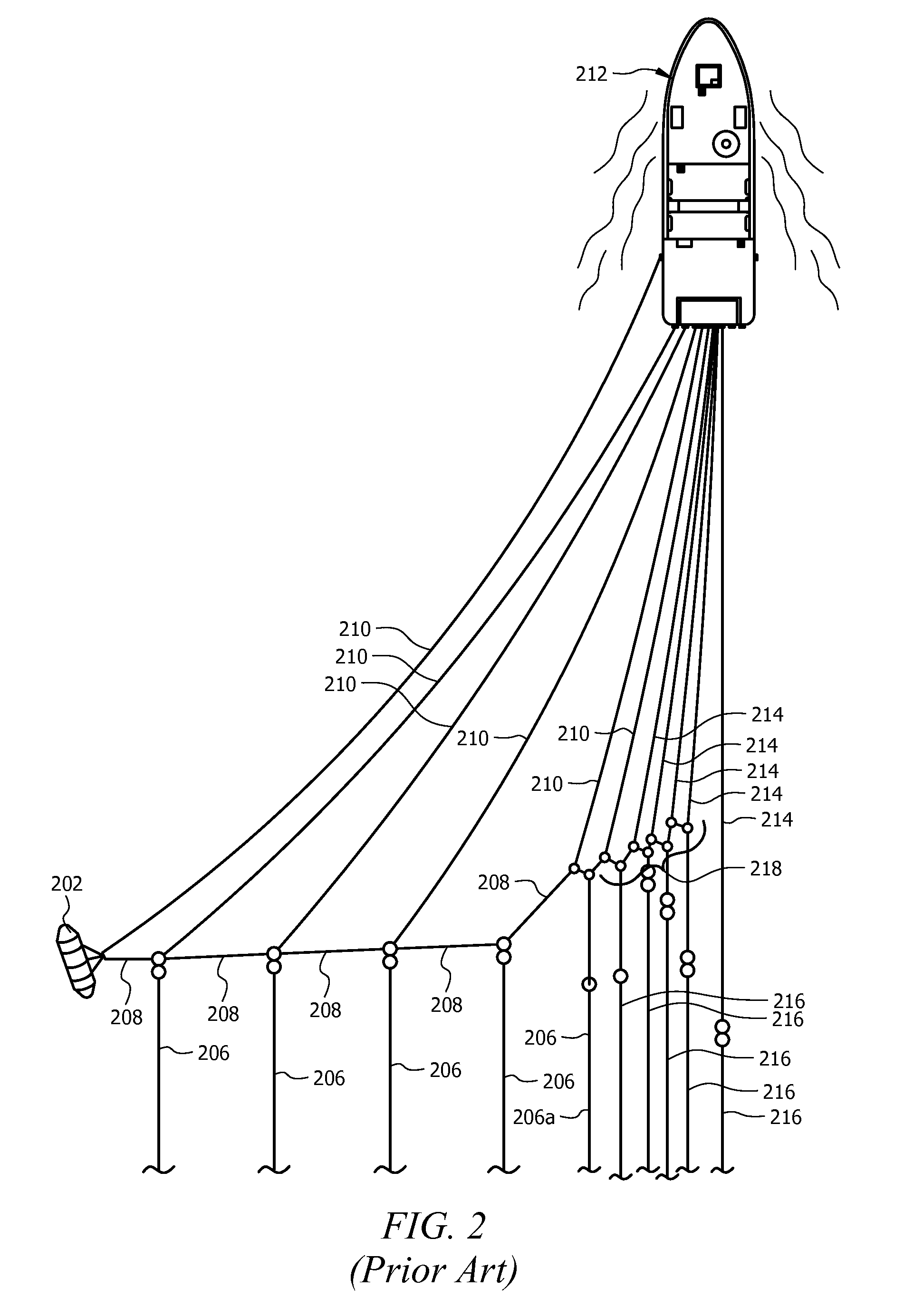

Seismic array towing system

ActiveUS20100149910A1Towed efficientlyReduce resistanceSeismology for water-covered areasEngineeringFlow diverter

A system for a more efficient towing of a marine seismic array comprising one or more diverters attached to each lead-in cable. Because each lead-in cable has its own diverter, the need for dedicated towing ropes and taglines between lead-in cables is eliminated, thereby reducing the overall drag and fuel consumption. The diverters of the present invention are directly attached to the respective lead-in cables and are submerged, eliminating the need for taglines and additional flotation. The diverter of the present invention comprises of either a single span-wise hydro foil or two foil sections and is steerable. Similarly, the diverters of the present invention can be installed on the umbilical cables of seismic source subarrays to obtain the same benefits. As such, at least one diverter of the present invention can be attached directly to at least one umbilical cable of the seismic source subarray.

Owner:SERCEL INC

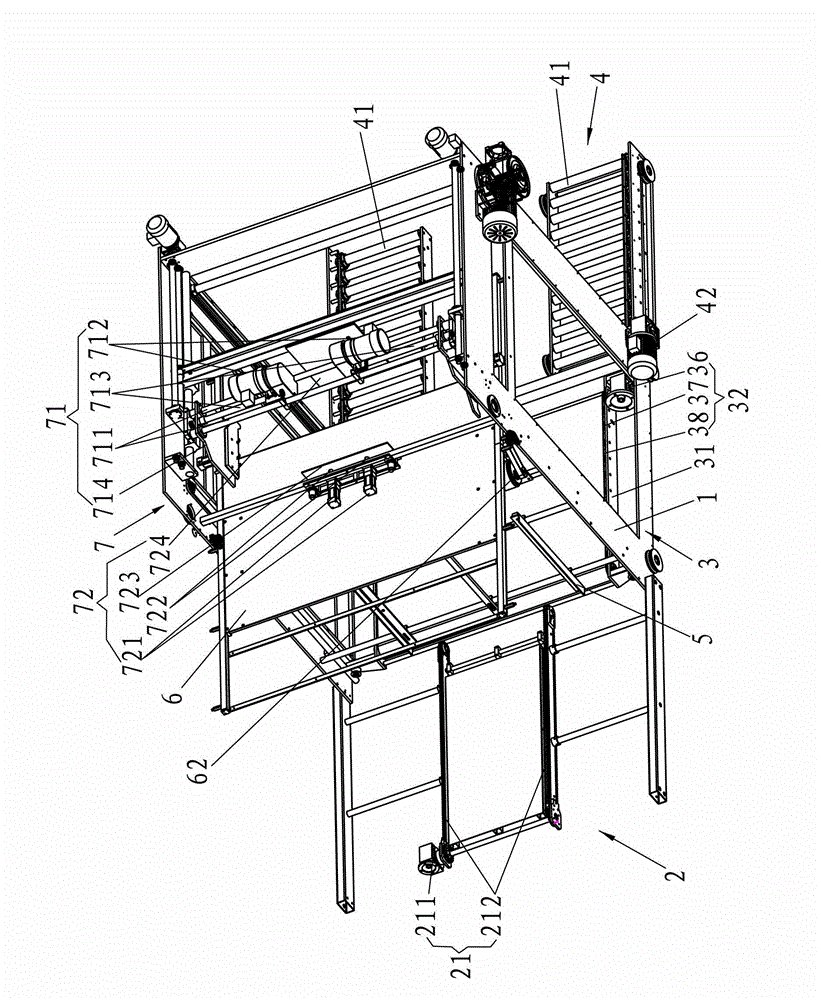

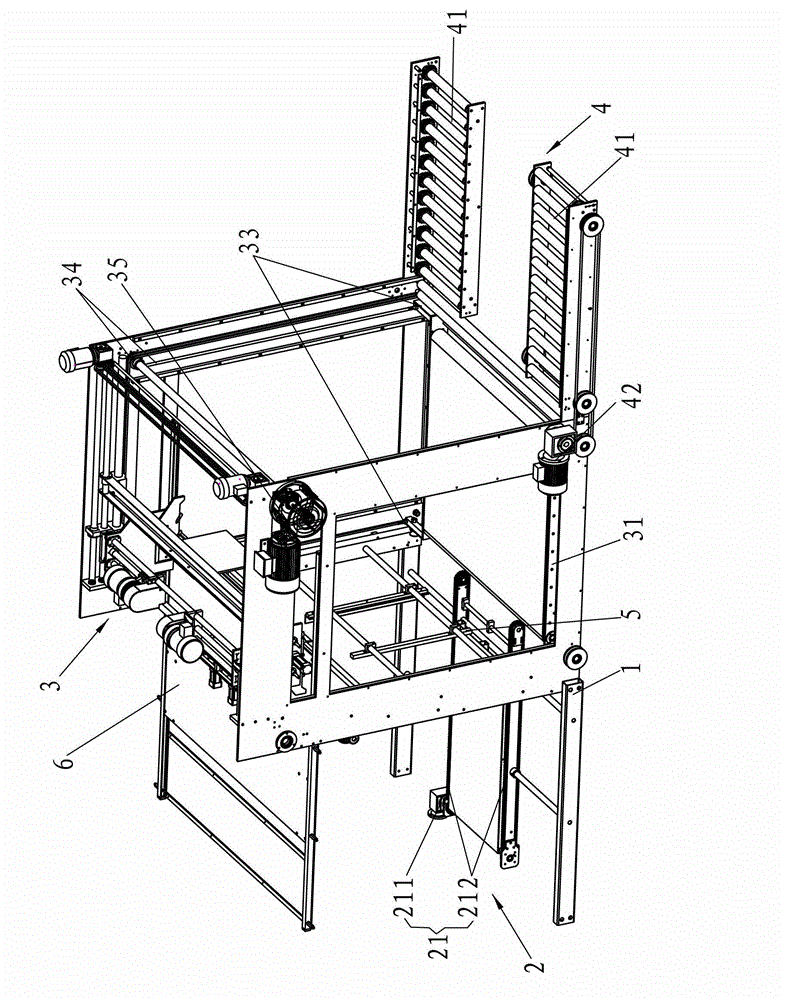

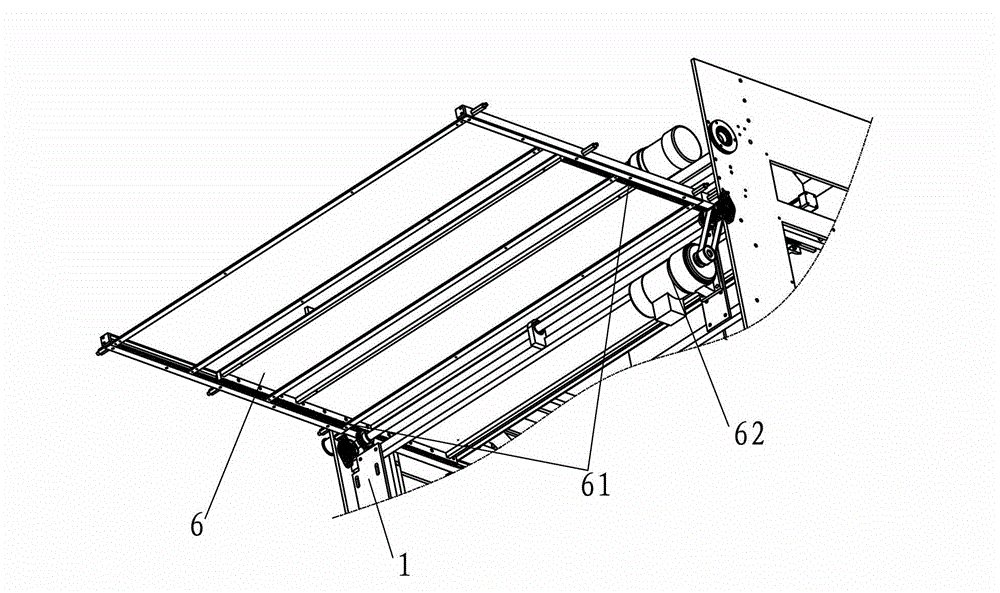

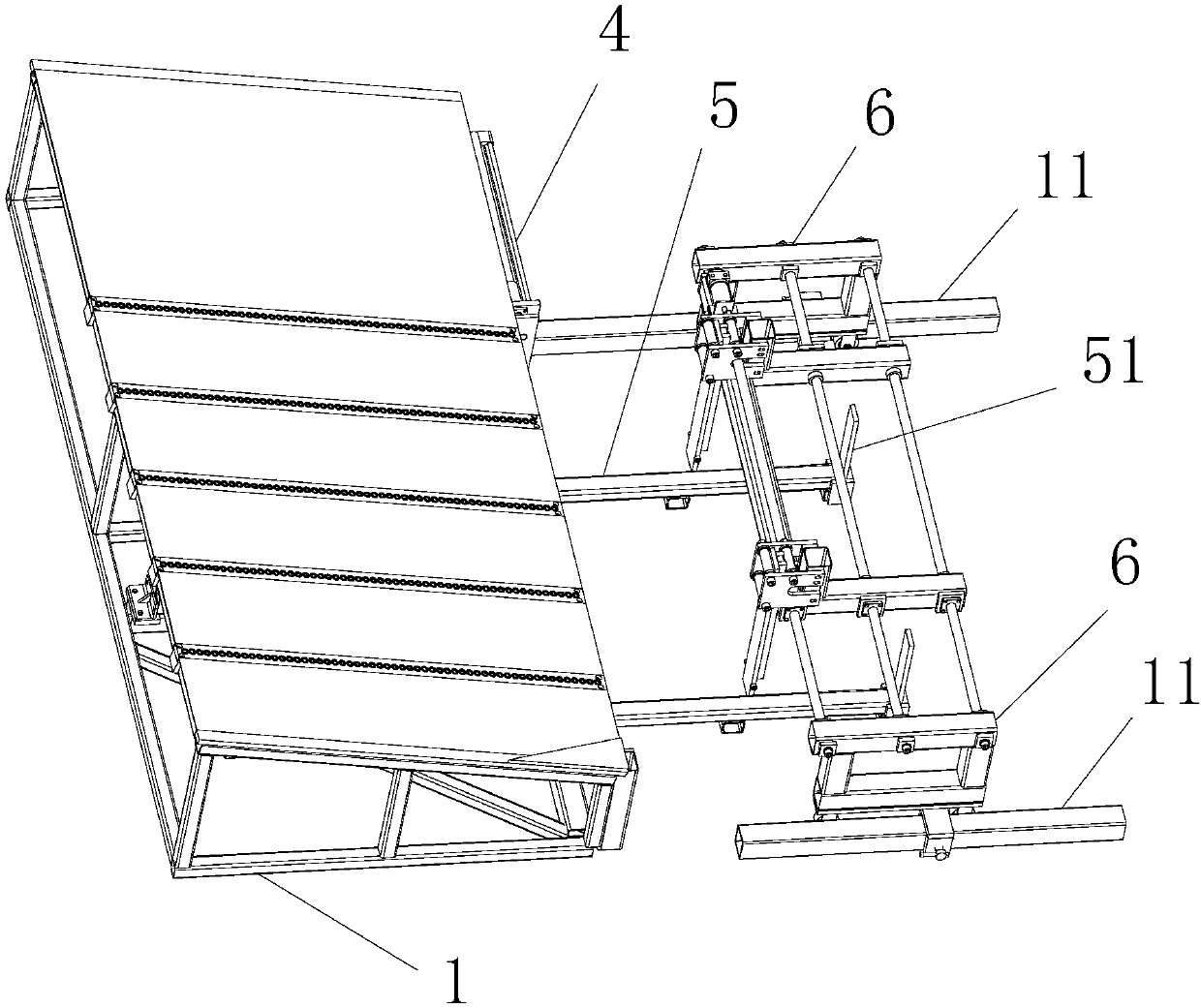

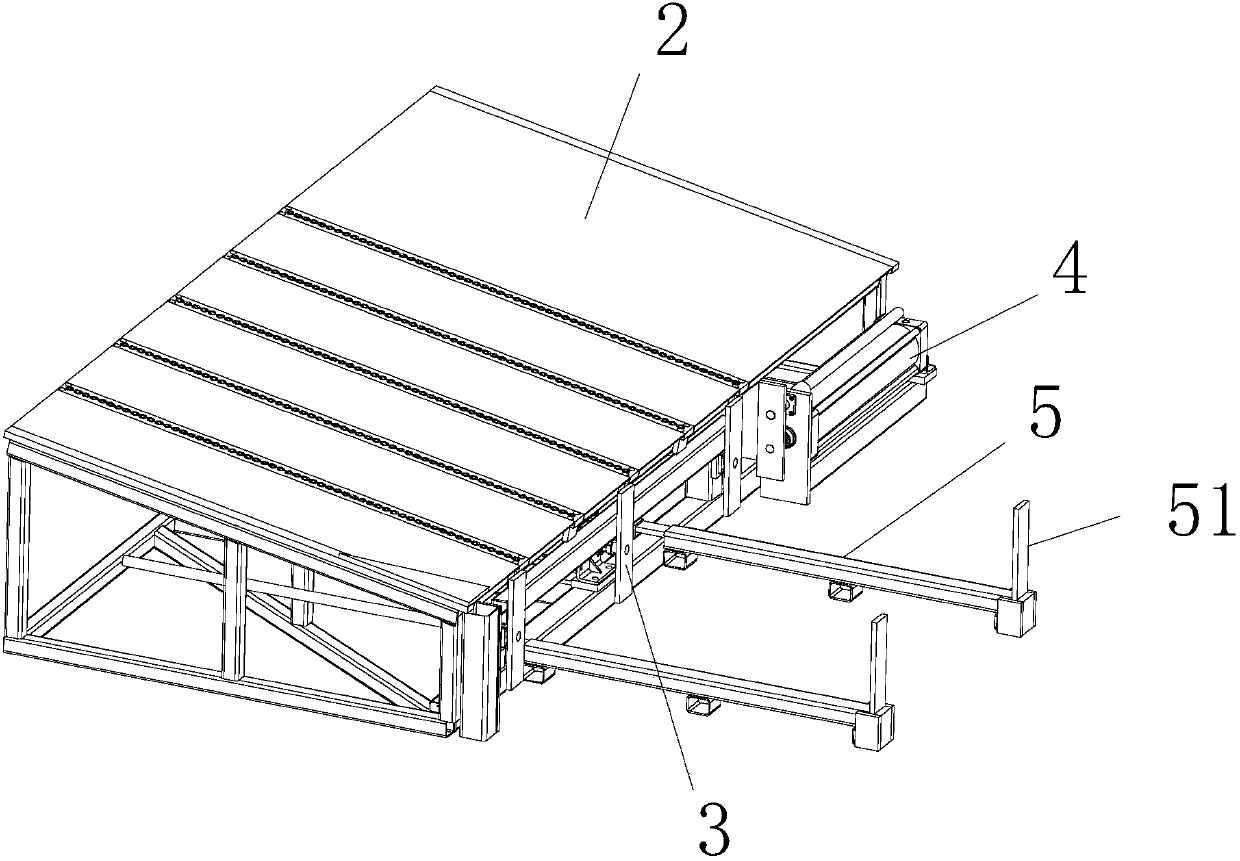

Automatic paper collecting stacker

The invention relates to the technical field of paper treatment machinery, in particular to an automatic paper collecting stacker which comprises a pallet conveying platform, a paper collecting and stacking lifting platform and a discharge platform which are arranged on a frame in sequence; when in production, the pallet conveying platform feeds a pallet into the paper collecting and stacking lifting platform through a pallet conveying device; the stacking bottom plate of the paper collecting and stacking lifting platform ascends on the frame and reaches the position of a paper inlet for the convenience of paper collection and stacking; every time after a pile of paper is sent, the stacking bottom plate descends for a certain height under the action of a control system, so that the stacked paper is always at a certain height, for the convenience of paper collection and stacking; when the paper collecting and stacking lifting platform descends to a bottom end and paper on the pallet reaches a delivery height, a stacking conveying device conveys the pallet on which a stacking material is arranged to the discharge platform; and the discharge platform conveys the stacking material to a piling area through a forklift and other devices. According to the automatic paper collecting stacker, the automation degree is high, the working efficiency is improved, and manpower resources are reduced.

Owner:广东锋驰印刷机械有限公司 +1

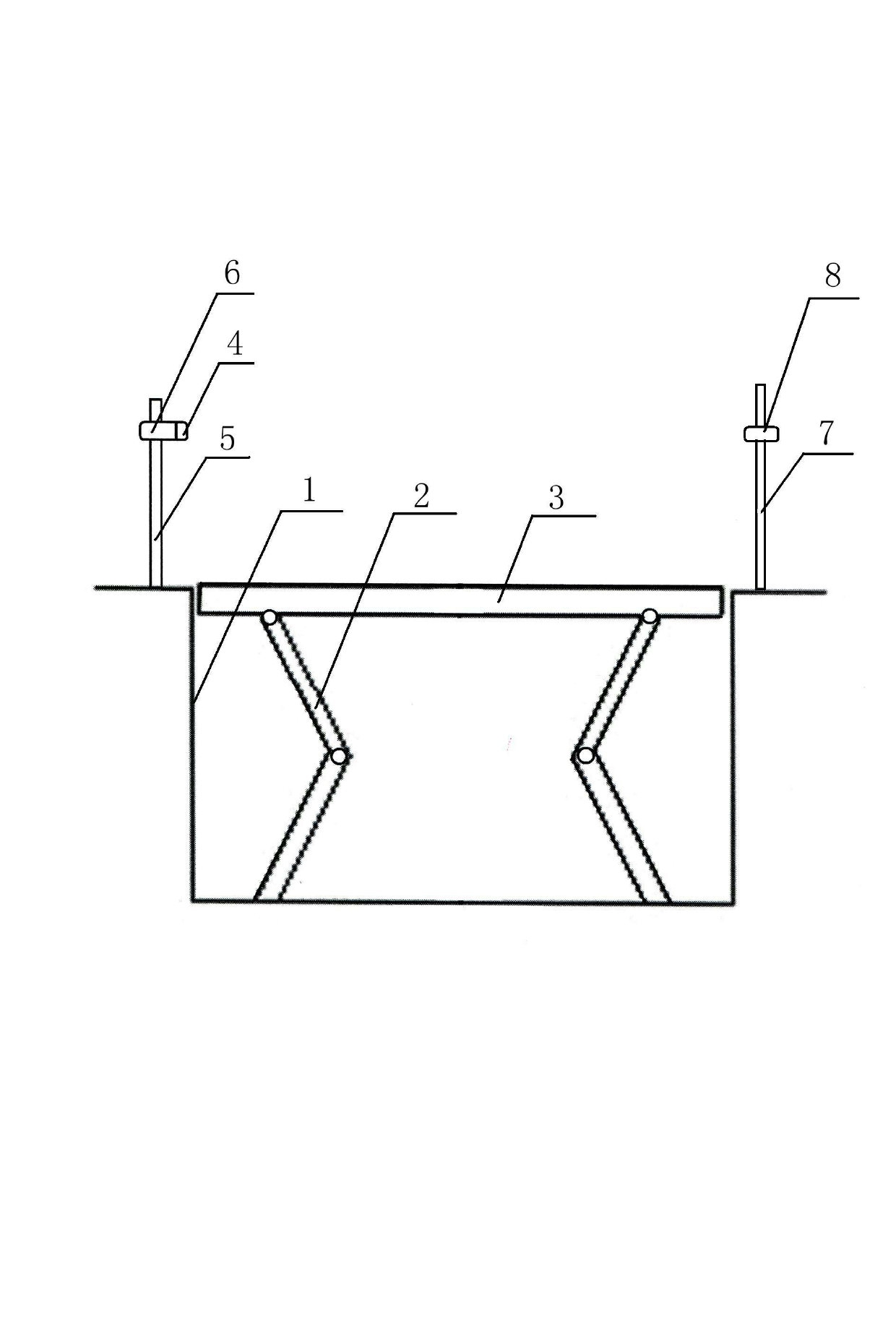

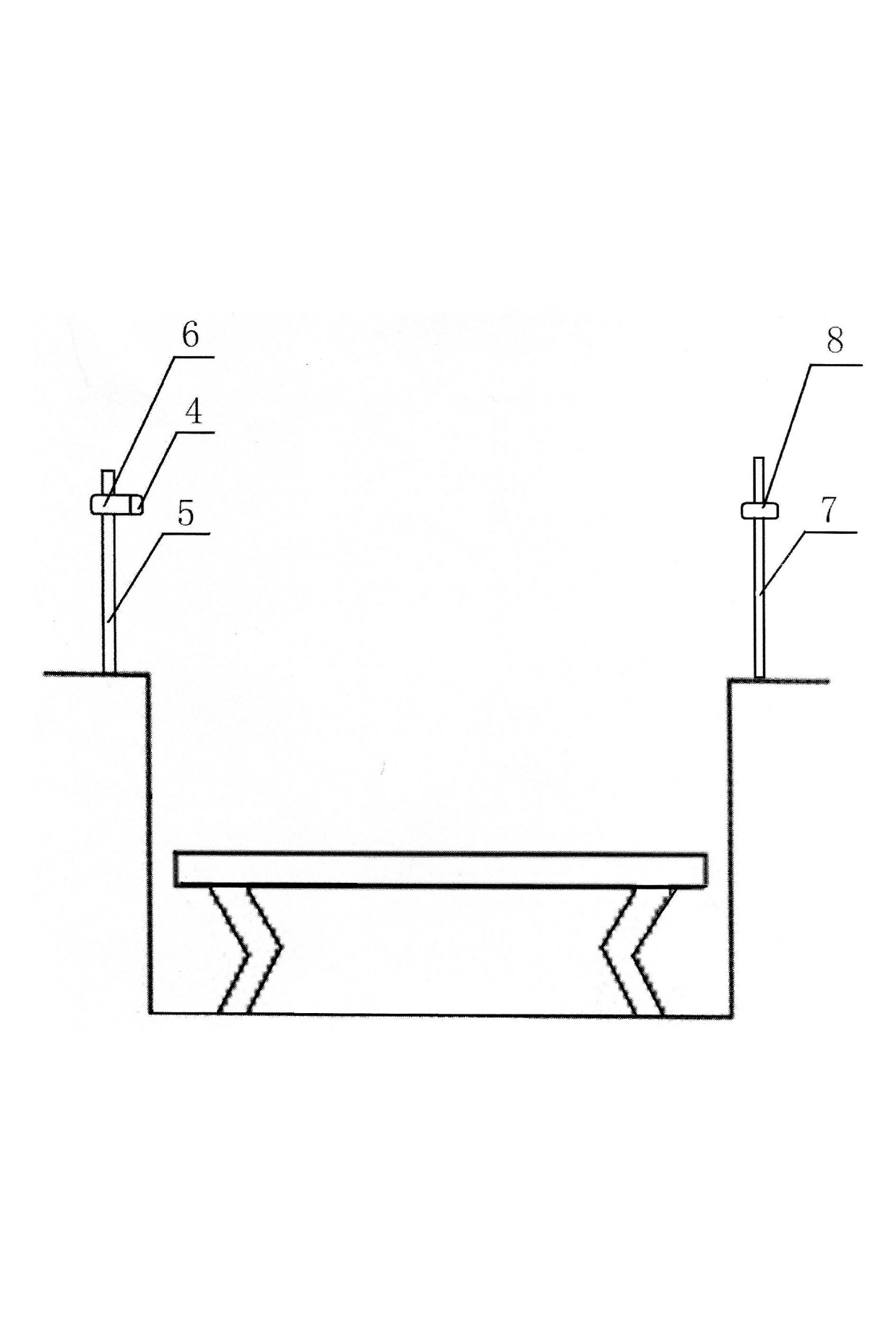

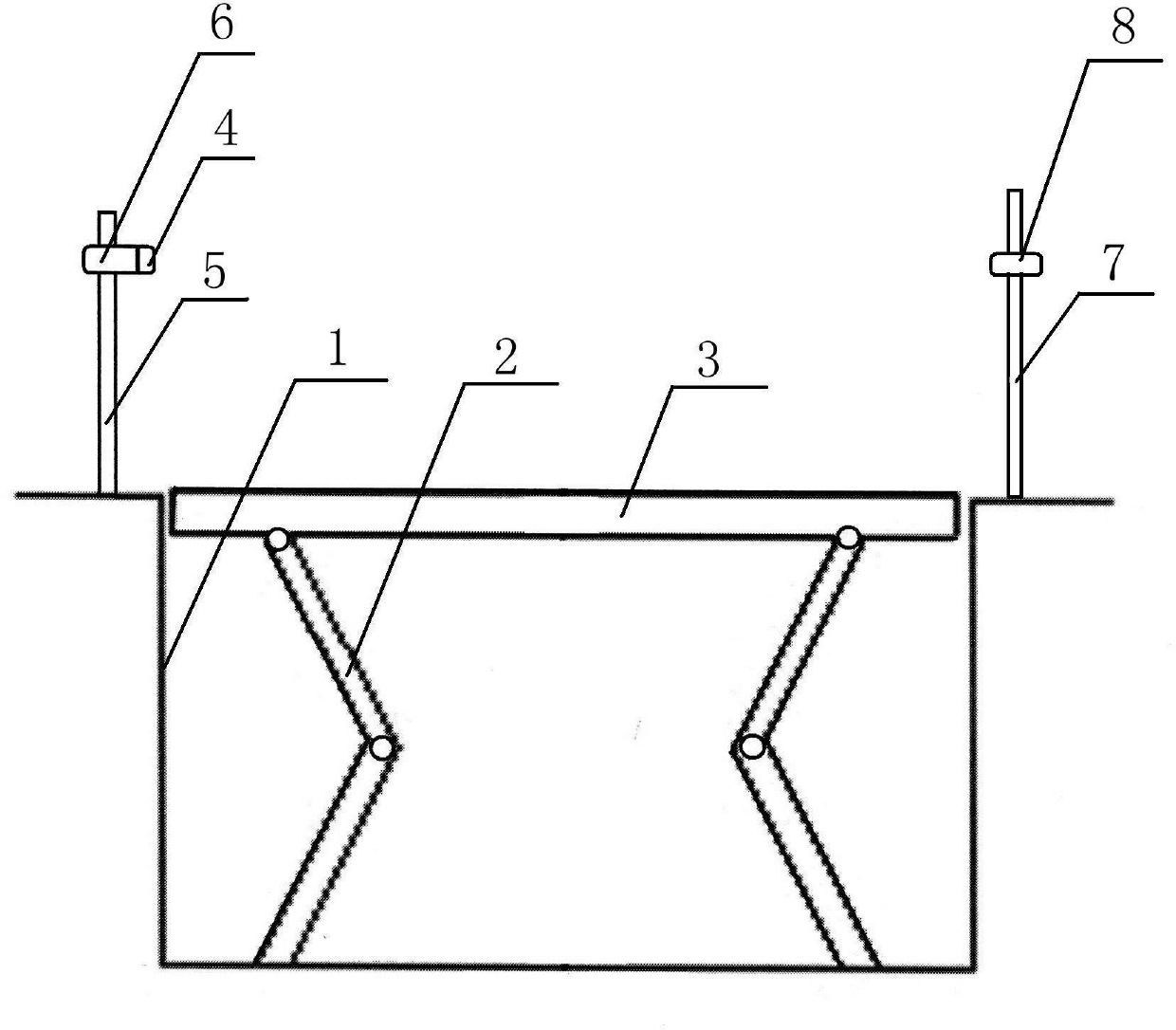

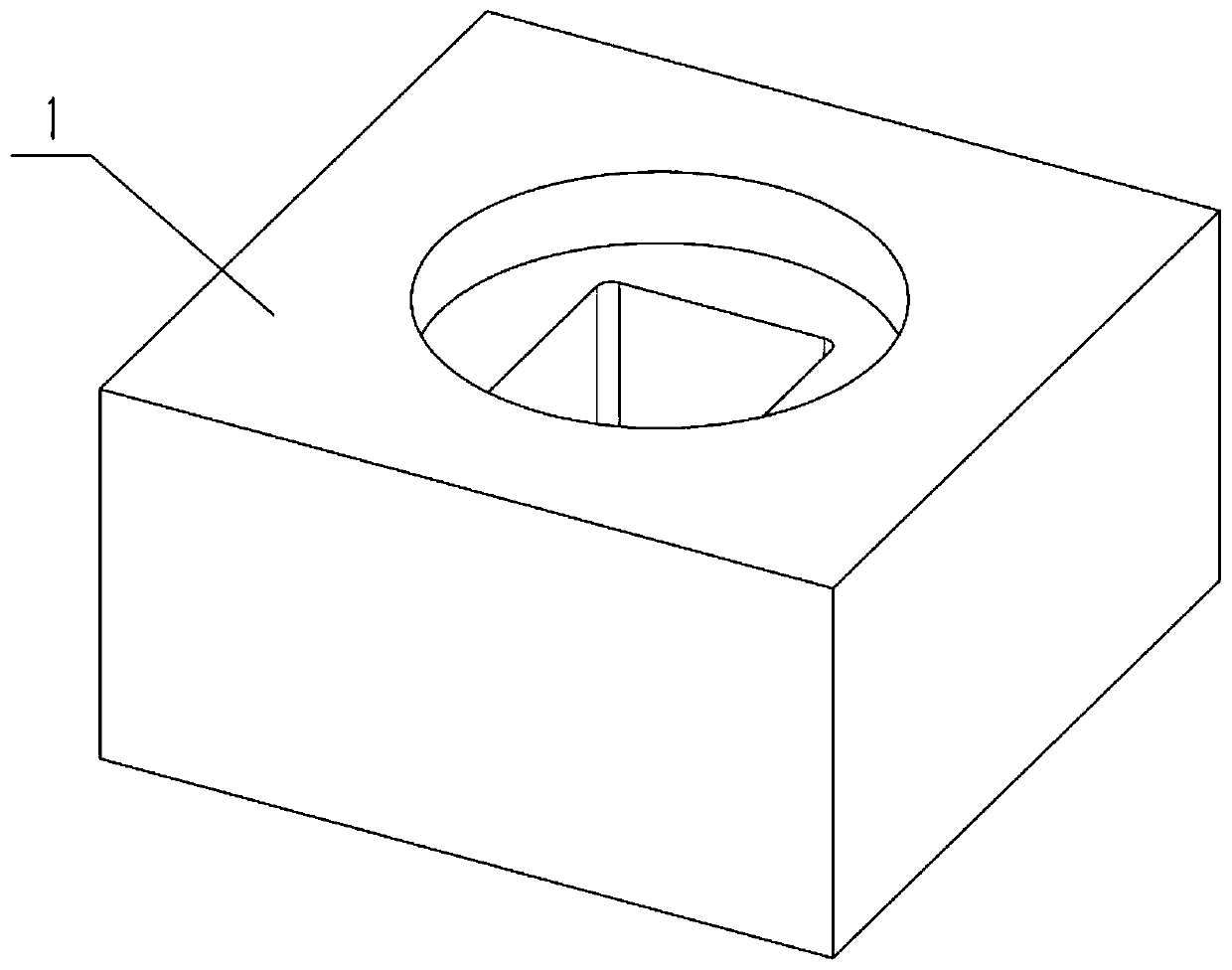

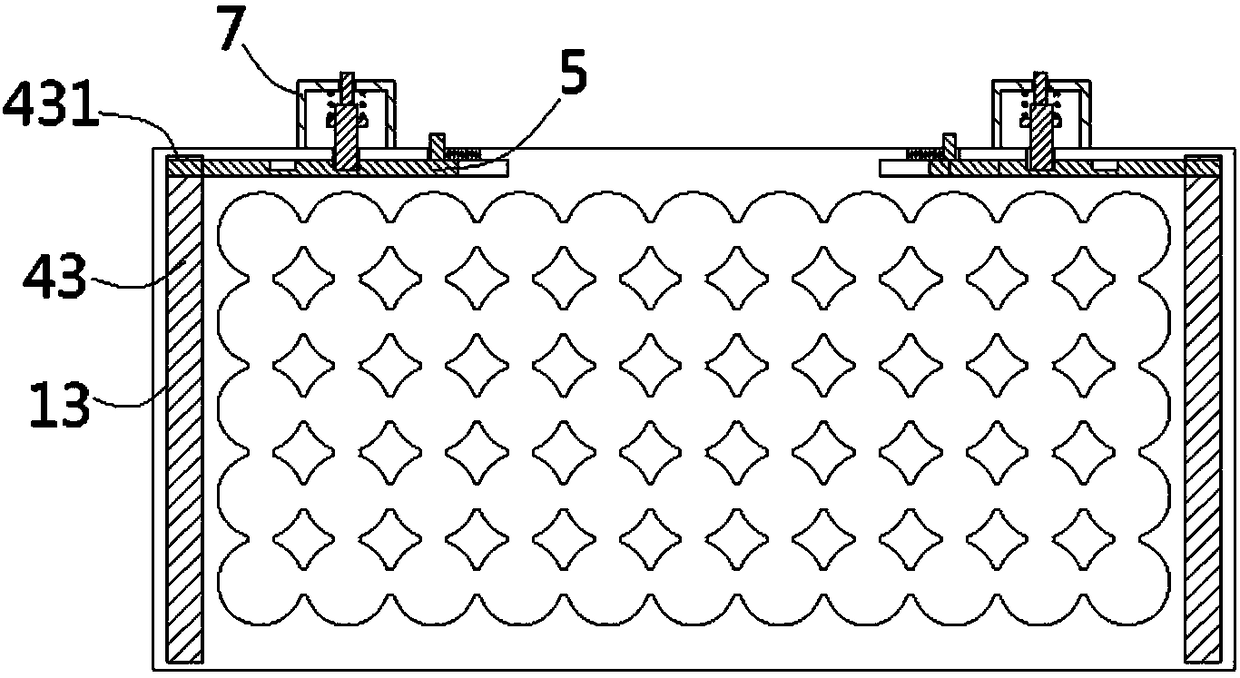

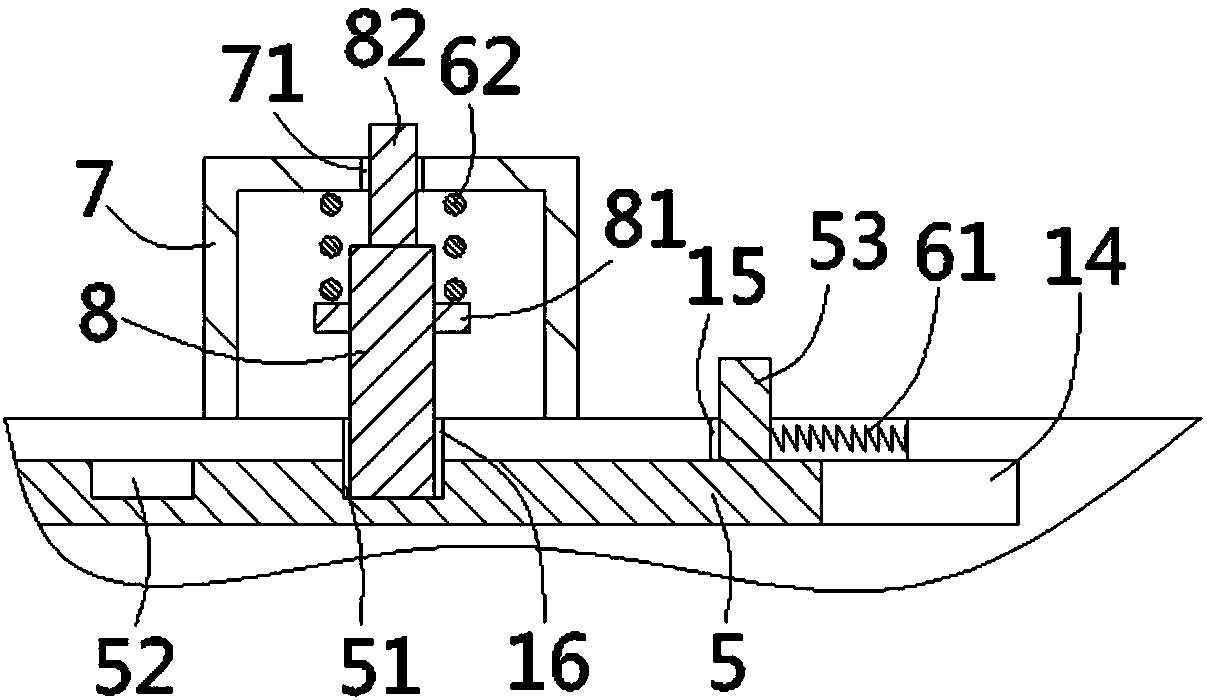

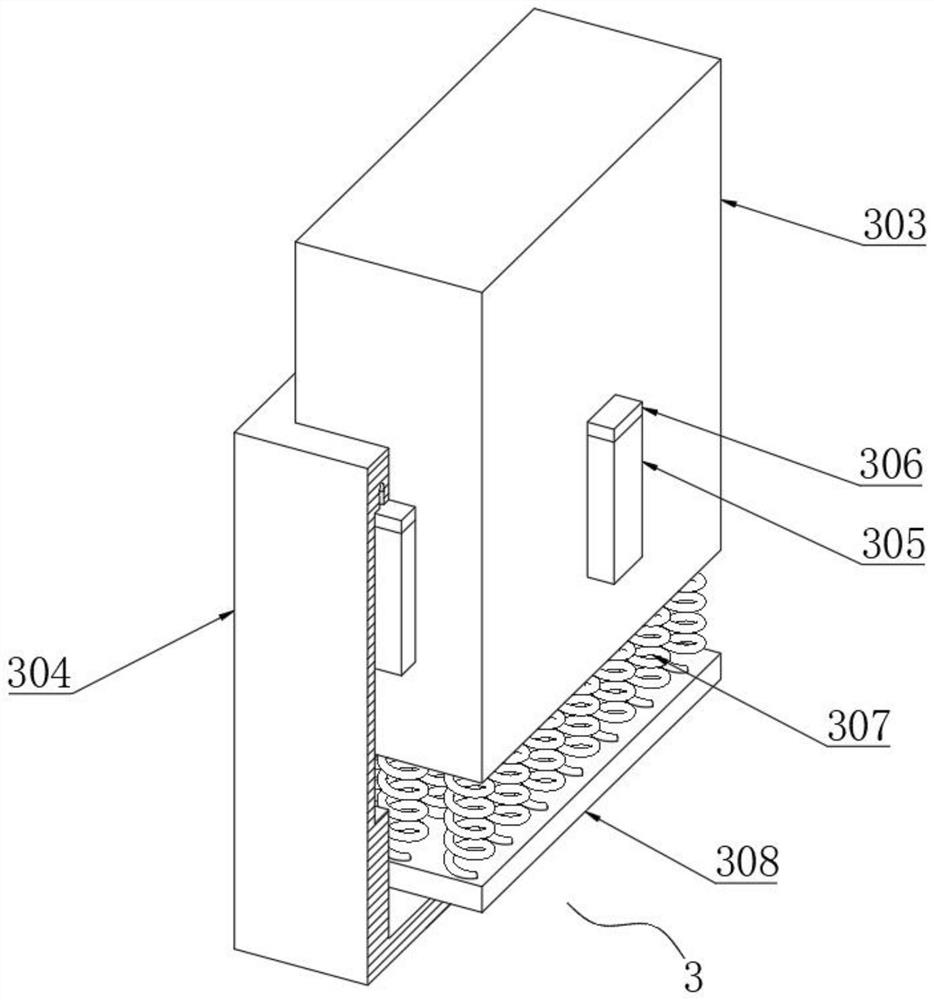

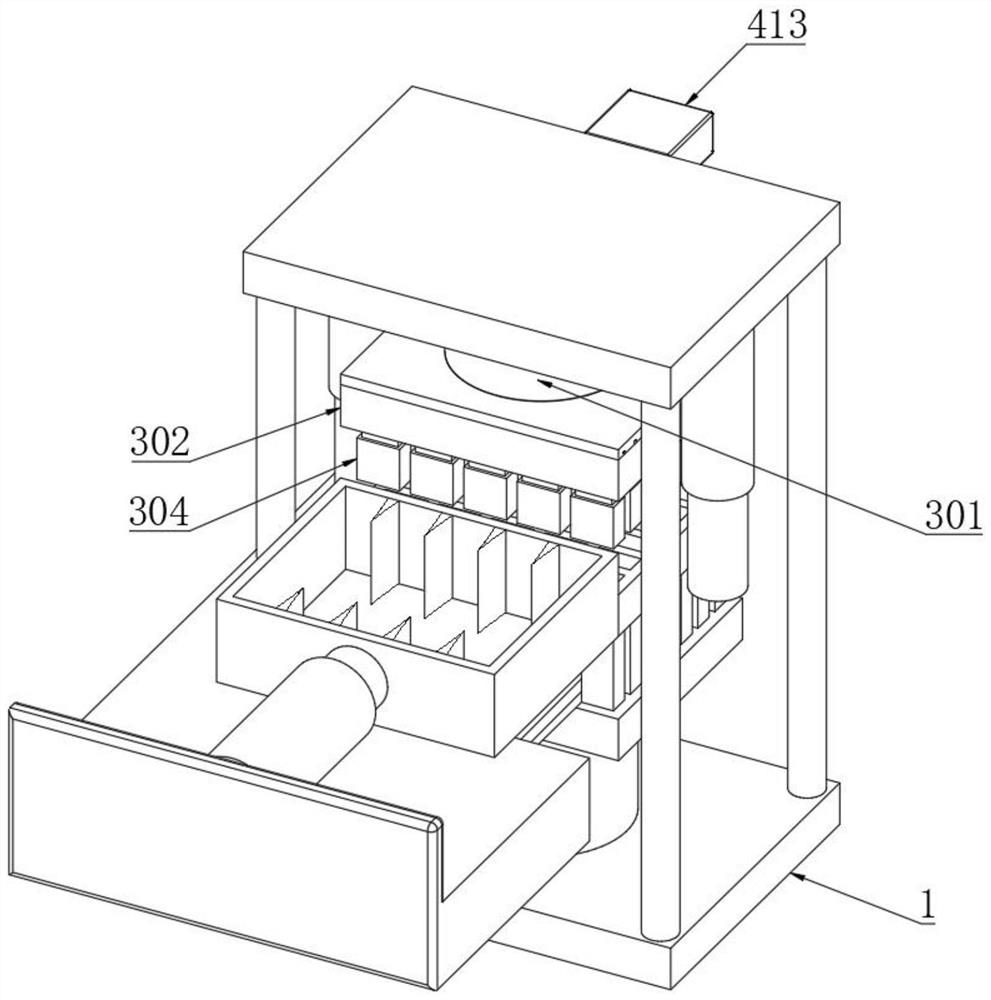

Stacking structure with automatic sensing lifting device

The invention discloses a stacking structure with an automatic sensing lifting device, which is characterized in that automatic lifting stands are arranged in a stacking groove, the lower ends of the automatic lifting stands are fixed at the bottom of the stacking groove, a stacking platform is arranged at the upper ends of the automatic lifting stands, an adjusting rod is arranged on one side of the upper edge of the stacking groove, a slidable support is arranged at the adjusting rod, an infrared sensing emitter is arranged at one end of the slidable support, and a receiver corresponding to the infrared sensing emitter is arranged on the other side of the upper edge of the stacking groove and mounted on an adjusting threaded rod. An infrared device is capable of positioning height accurately, so that the automatic lifting stands can adjust stacking height automatically, stacking operation can be performed on the optimum operation plane conveniently, labor intensity of the operators is effectively reduced, stacking efficiency is improved, and equipment with the stacking structure is convenient in mounting and maintaining, fine in service effect, stable in working state. In addition, the stacking structure with the automatic sensing lifting device has higher practicality and has outstanding substantial advantages and evident improvement as compared with the prior art.

Owner:SHANGHAI JIUMU BIOLOGICAL TECH

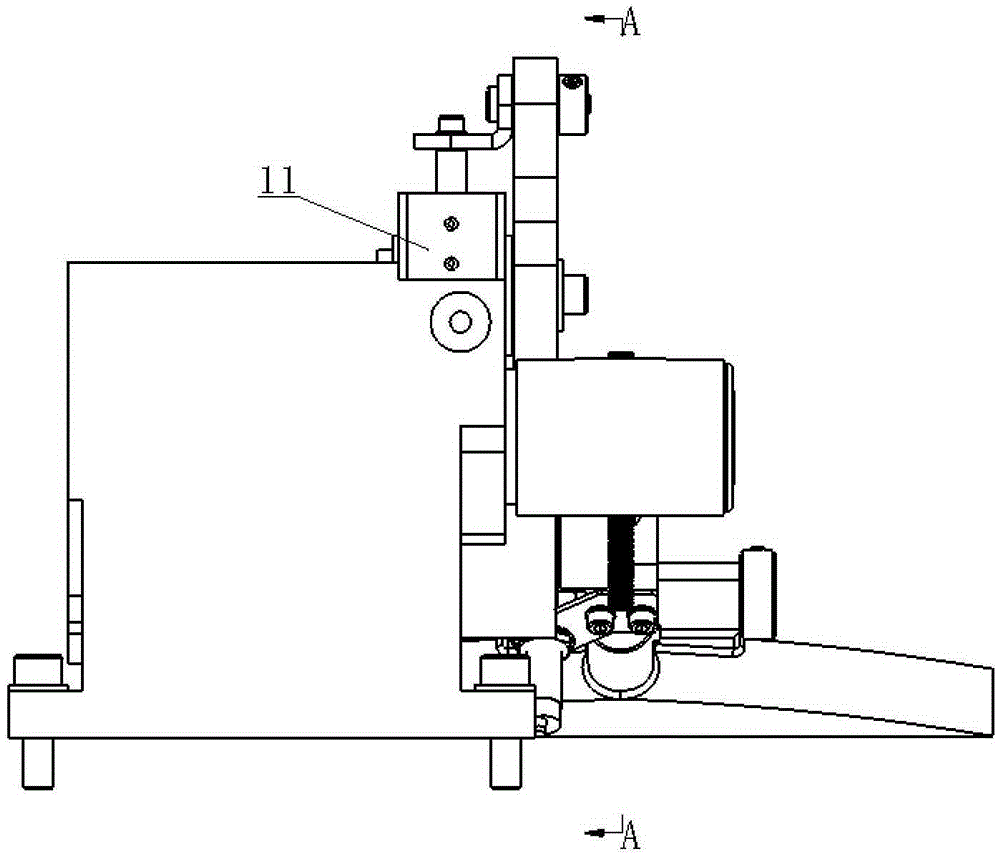

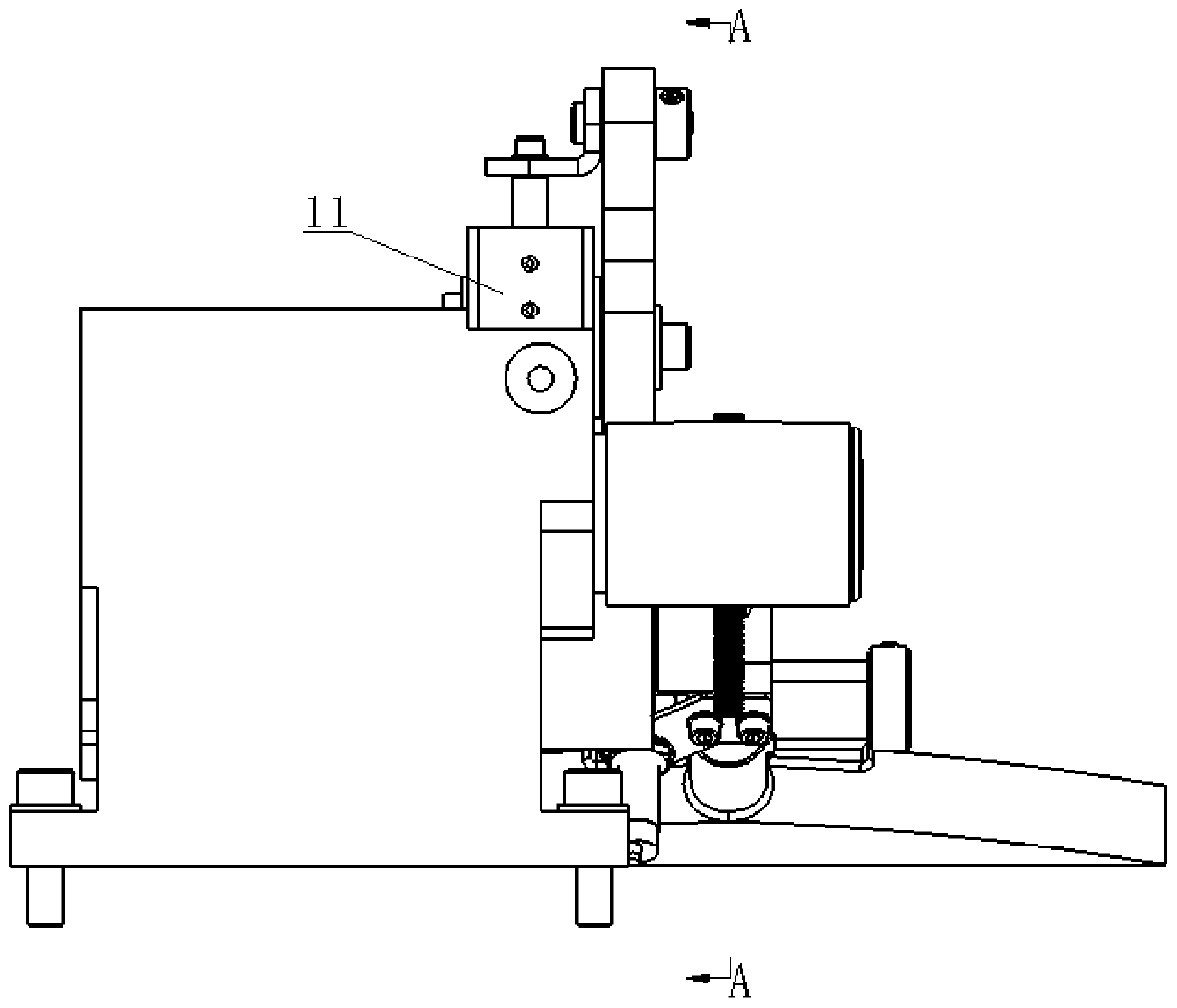

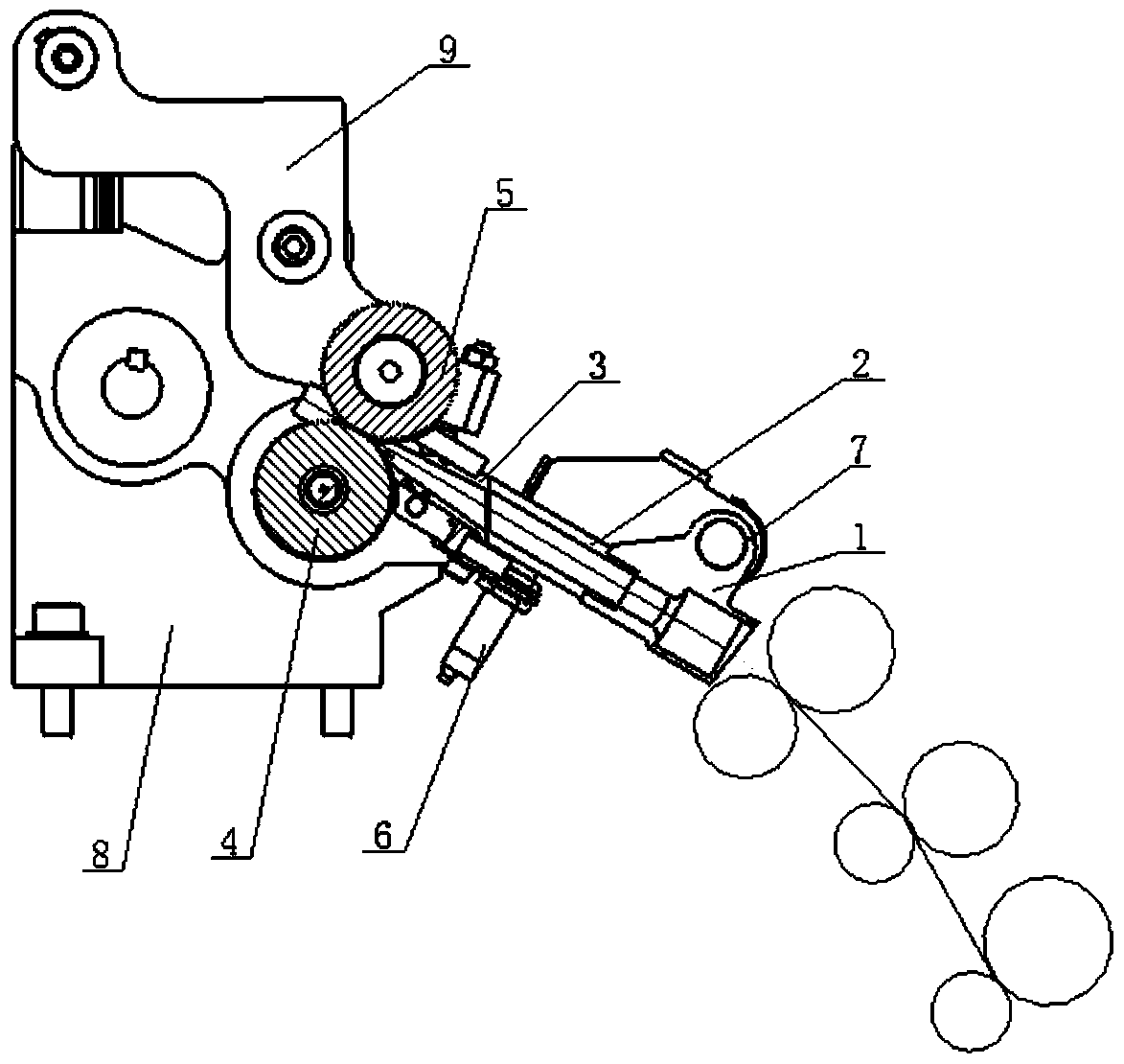

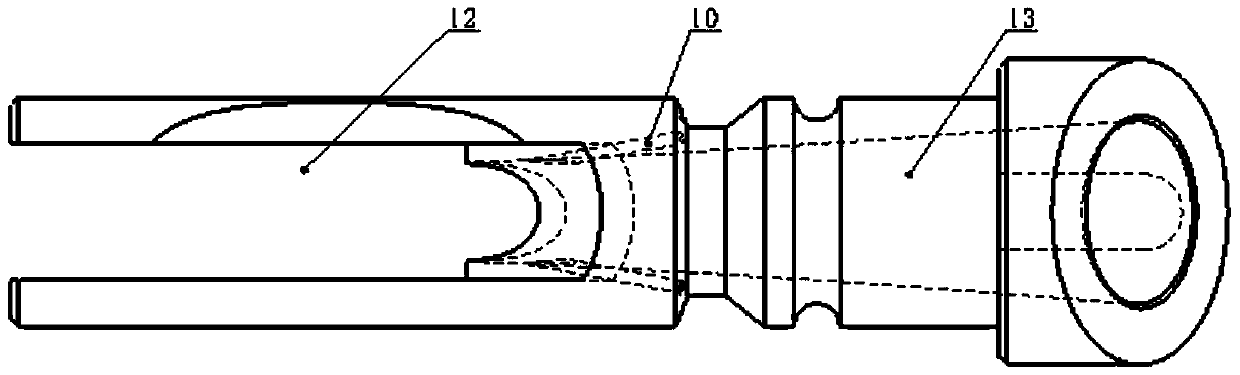

Cotton web bundling mechanism of intelligent comber

The invention discloses a cotton web bundling mechanism of an intelligent comber. The cotton web bundling mechanism adopts the structure that a first press roller and a second press roller on a supporting seat of the intelligent comber are mutually meshed for transmission; a driving device drives the first pressure roller to rotate; the inlet of a gathering pipe is just positioned behind a drafting output roller; the inlet of a conveying pipe is fixedly communicated with the outlet of the gathering pipe; a bundling horn mouth is fixedly mounted on the supporting seat of the intelligent comber; the inlet of the bundling horn mouth can be communicated with the outlet of the conveying pipe; a horn hole of which the outlet diameter is smaller than the inlet diameter is formed in the inner side of the bundling horn mouth; the meshing point between the first and second press roller just faces the outlet of the bundling horn mouth; a flat groove is formed in the side wall positioned at the outlet end of the bundling horn mouth; the mutually meshed ends of the first and second press rollers are just inserted into the flat groove; the meshing point between the first and second press roller is just positioned in the flat groove. Through adoption of the cotton web bundling mechanism, the cohesive force of gathered cotton slivers is remarkably improved, so that the cotton slivers are not easy to loosen when being conveyed on a conveying belt and not easy to break at a turning point, and then high-speed conveying and convenient maintenance of the cotton silvers are facilitated.

Owner:JIANGSU KAIGONG MACHINERY

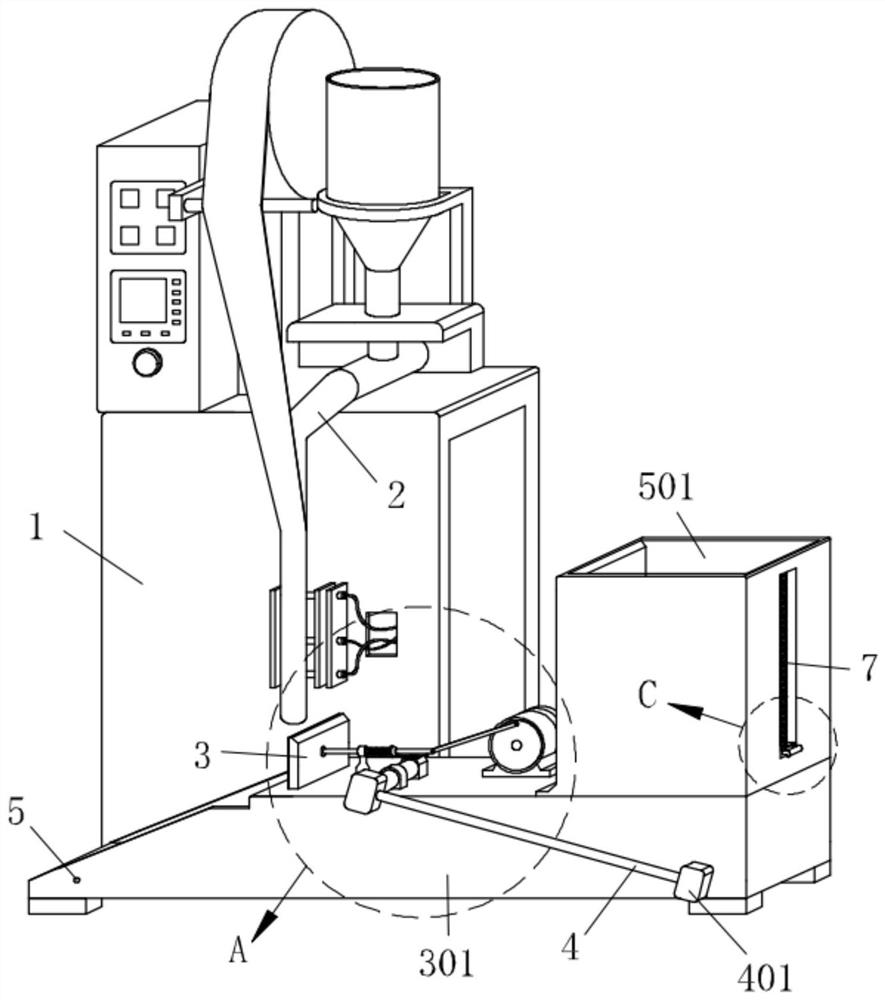

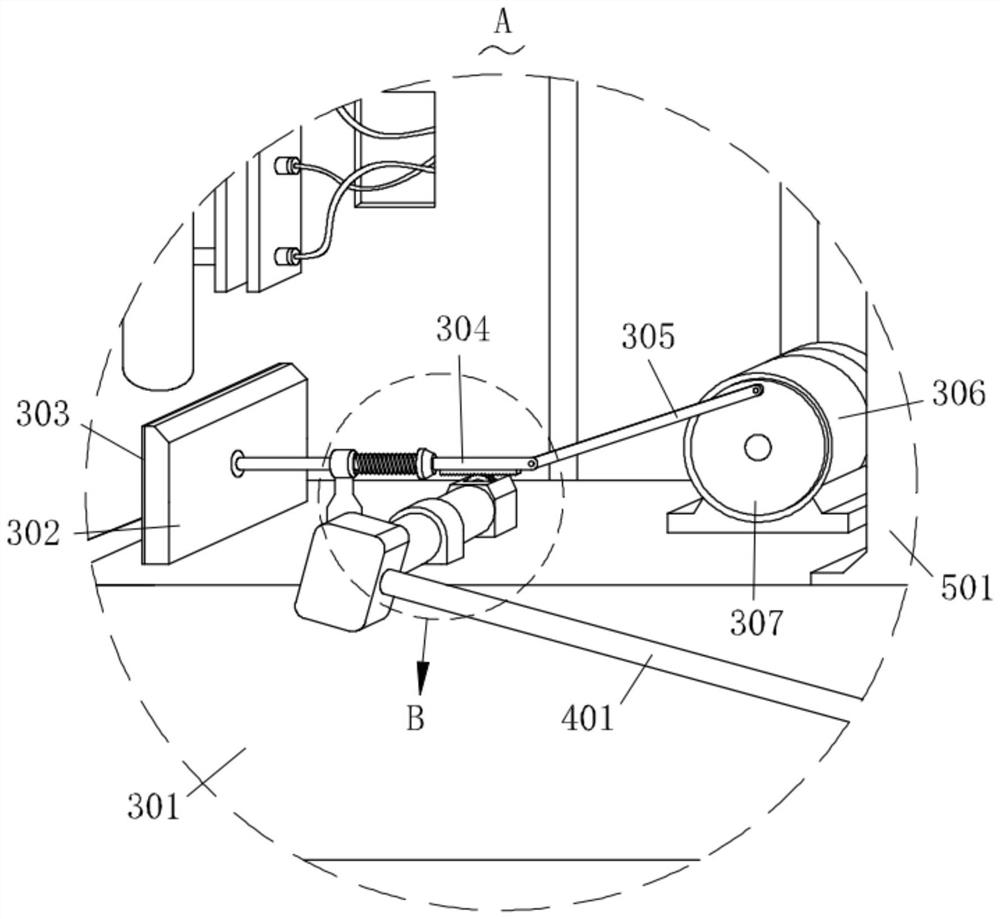

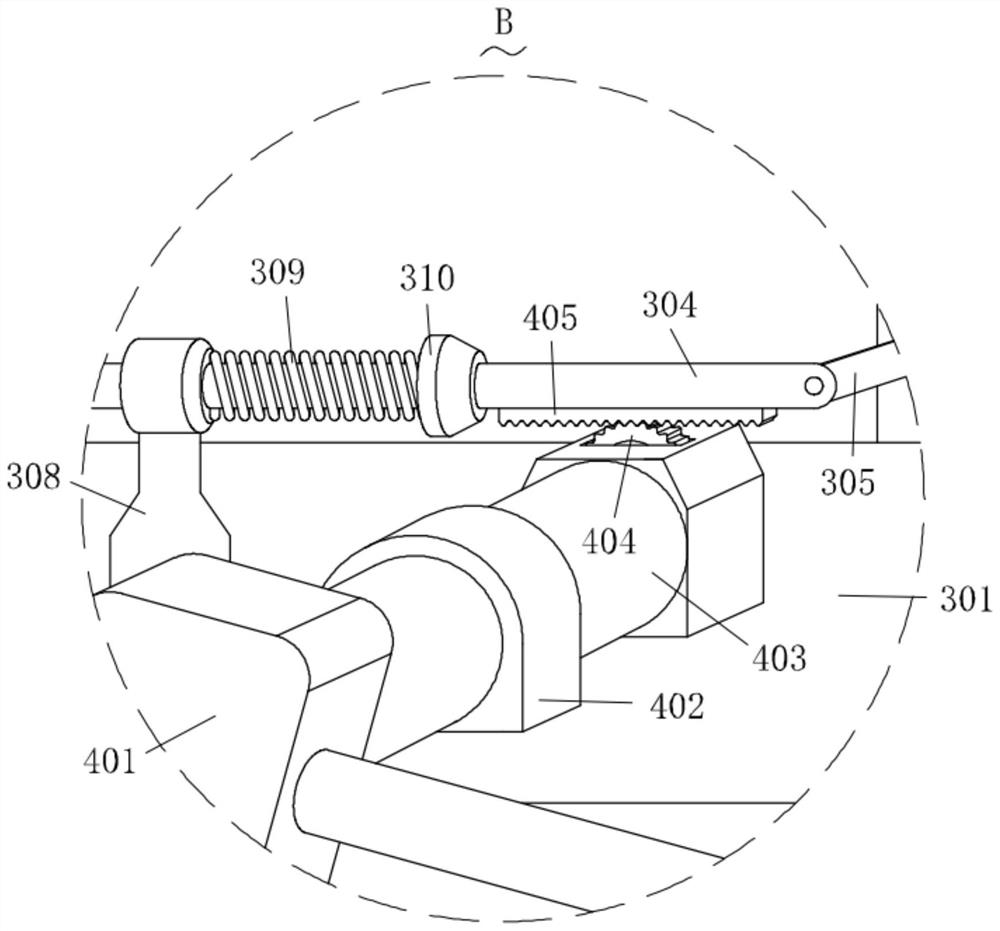

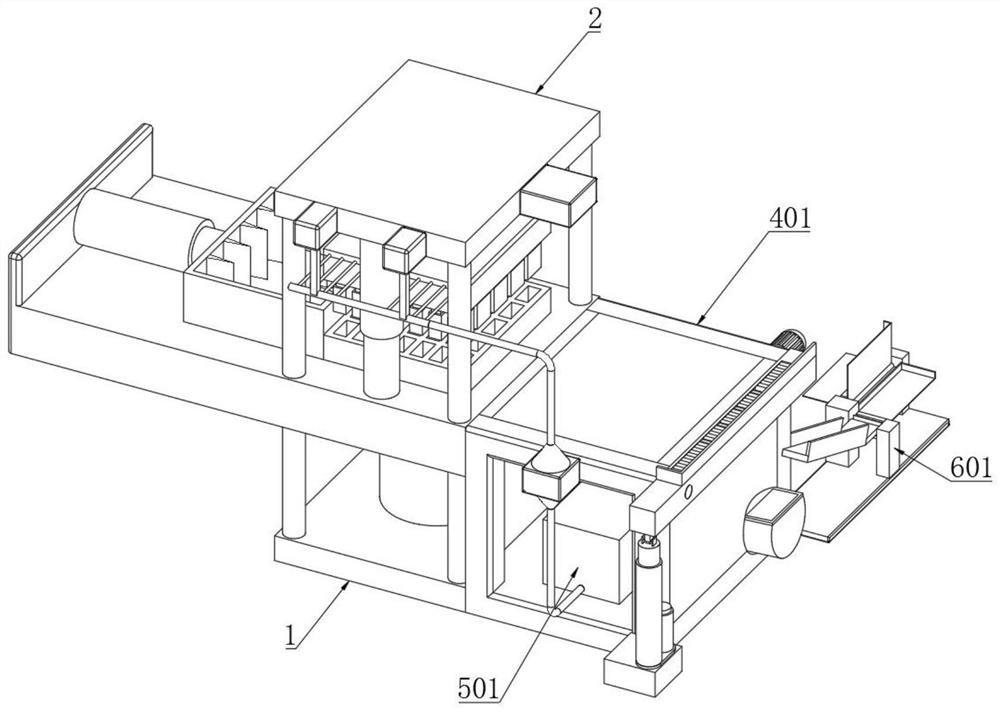

Filling and sealing machine in rice wine manufacturing

PendingCN114751018AEasy to transportPrevent obscenitySuccessive articlesProcess engineeringMechanical engineering

The invention provides a filling and sealing machine in rice wine manufacturing, which comprises a sealing machine, a material conveying pipe is mounted on the sealing machine, a protection mechanism is mounted in the material conveying pipe, a material pushing mechanism is mounted on one side of the sealing machine, a conveying mechanism is connected to the material pushing mechanism, a transmission mechanism is connected between the material pushing mechanism and the conveying mechanism, and the transmission mechanism is connected to the sealing machine. The conveying mechanism is connected with a pressing mechanism, and the pushing mechanism is connected with a driving mechanism. According to the device, the conveying pipe is conveniently protected through the protection mechanism, residual rice wine can be prevented from flowing downwards when conveying is not conducted, sealed packaging bags are conveniently pushed into a packaging box to be stored under the action of the pushing mechanism, and the conveying mechanism works to convey the packaging box through cooperation of the transmission mechanism; and through work of the pressing mechanism and the driving mechanism, the packaging box can be better conveyed conveniently, and the jamming phenomenon cannot be caused.

Owner:HUBEI SHUANGLUSHUANG FOOD CO LTD

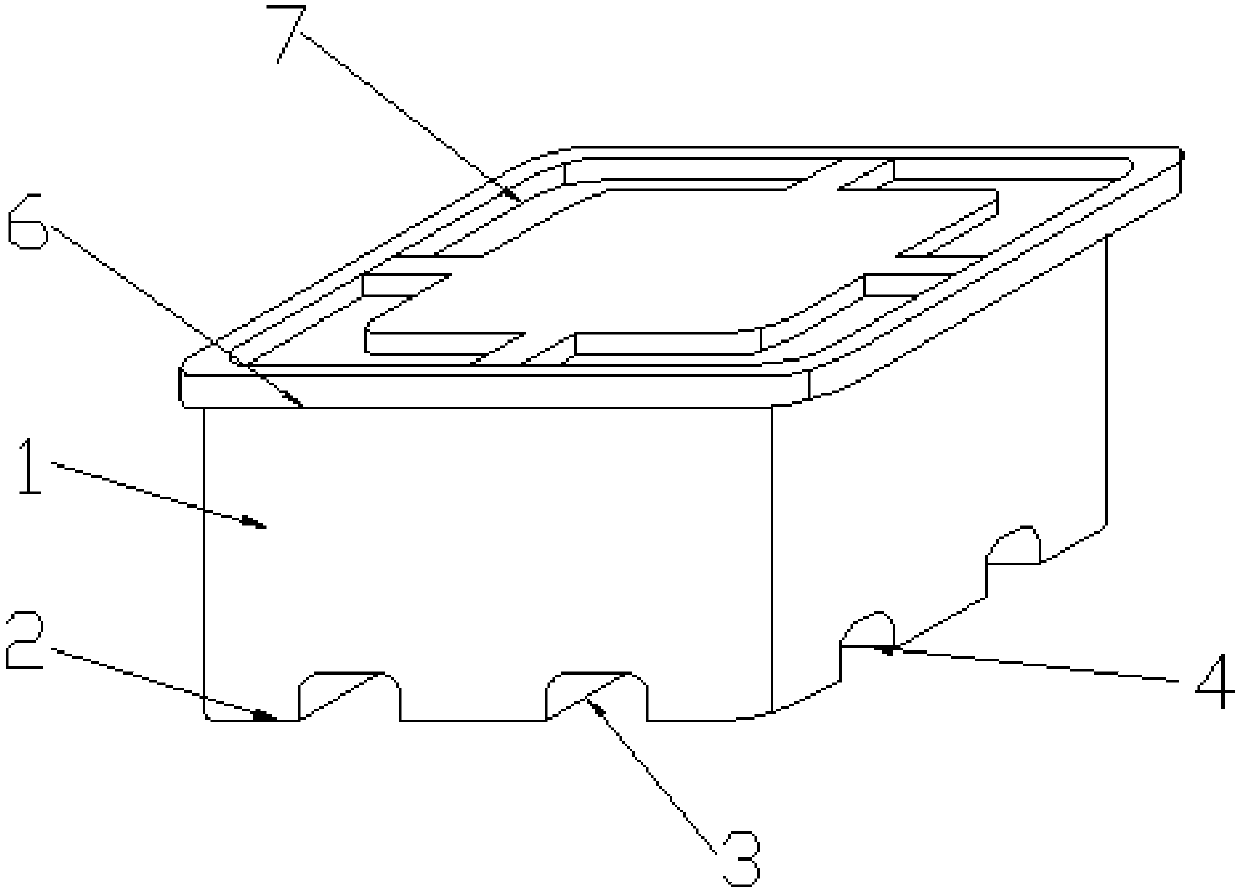

Multifunctional plastic packaging box

The invention discloses a multifunctional plastic packing box, which comprises a plastic packing box body, a base is arranged at the bottom of the plastic packing box body, a first slot is arranged on the front of the plastic packing box body, and the first slot runs through the plastic packing box body The bottom of the plastic packing box body is provided with a second slot, the second slot runs through the bottom of the plastic packing box body and is vertically connected with the first slot, the top of the plastic packing box body is provided with a flange, the plastic The packaging box body is fixedly connected with the plastic sealing cover through the flange, the top of the plastic sealing cover is provided with a base groove, the two sides inside the plastic packaging box body are symmetrically fixed with the first slideway, and the two ends inside the plastic packaging box body are symmetrical Equipped with the second slideway, the present invention can be used for packaging various articles, has abundant functions, is easy to be reused, is relatively economical and environmentally friendly, has a simple overall structure, low cost, strong practicability, and is easy to popularize.

Owner:湖州风生科技有限公司

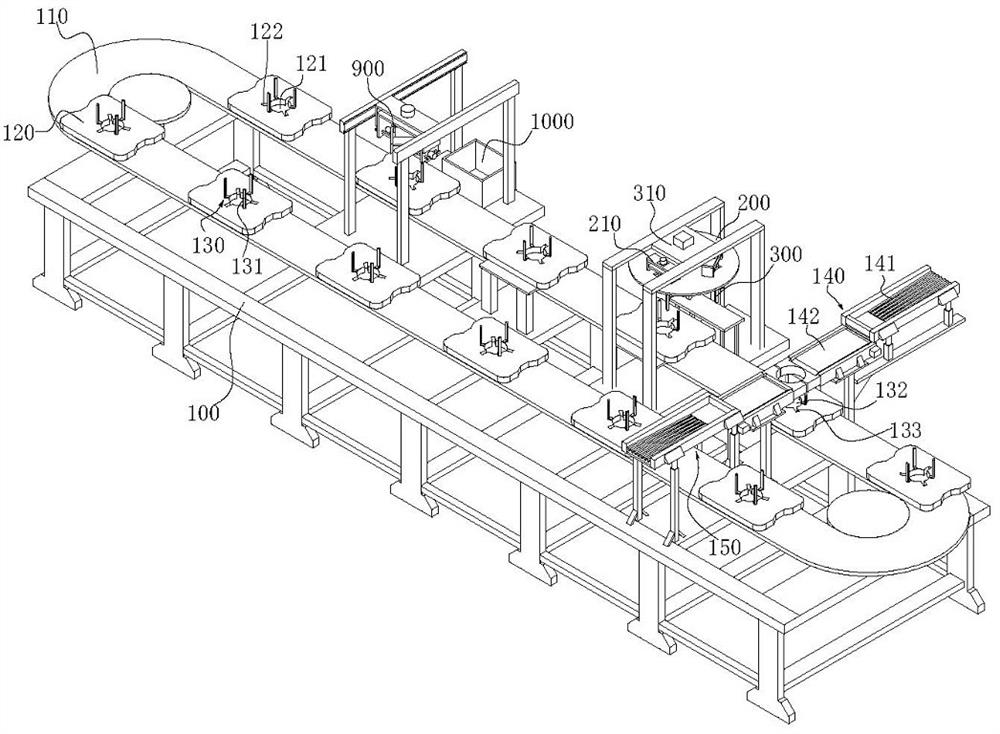

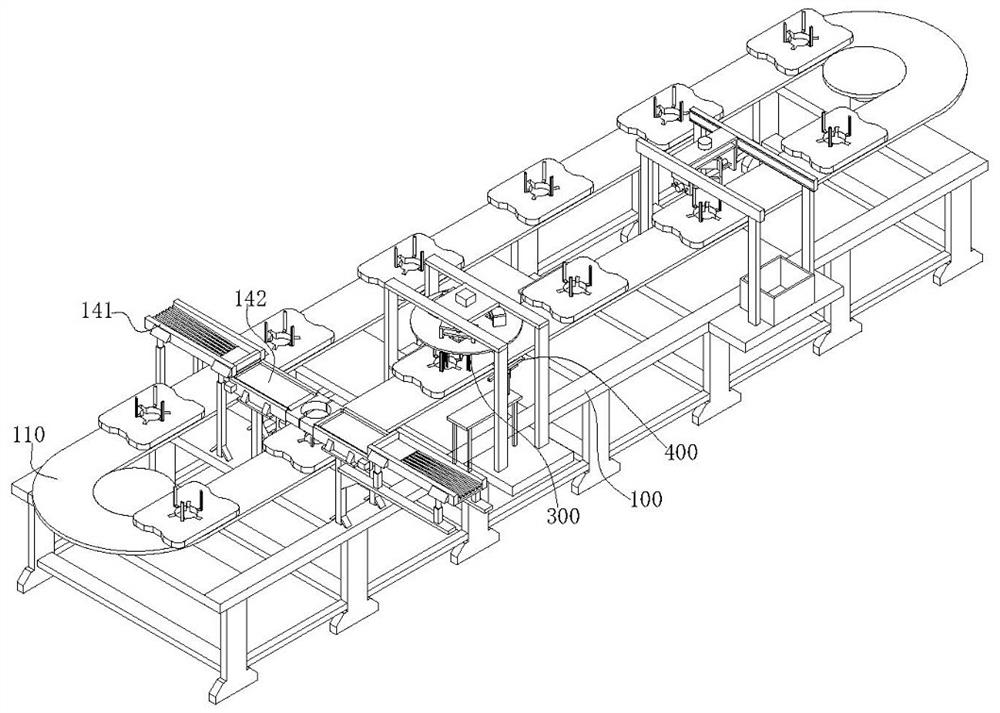

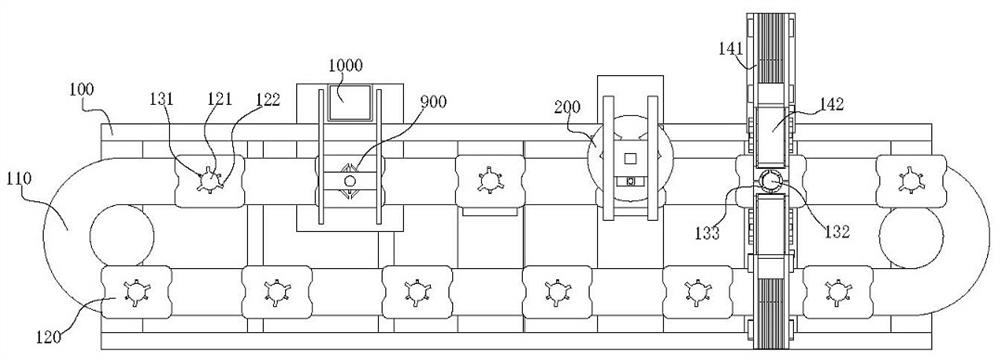

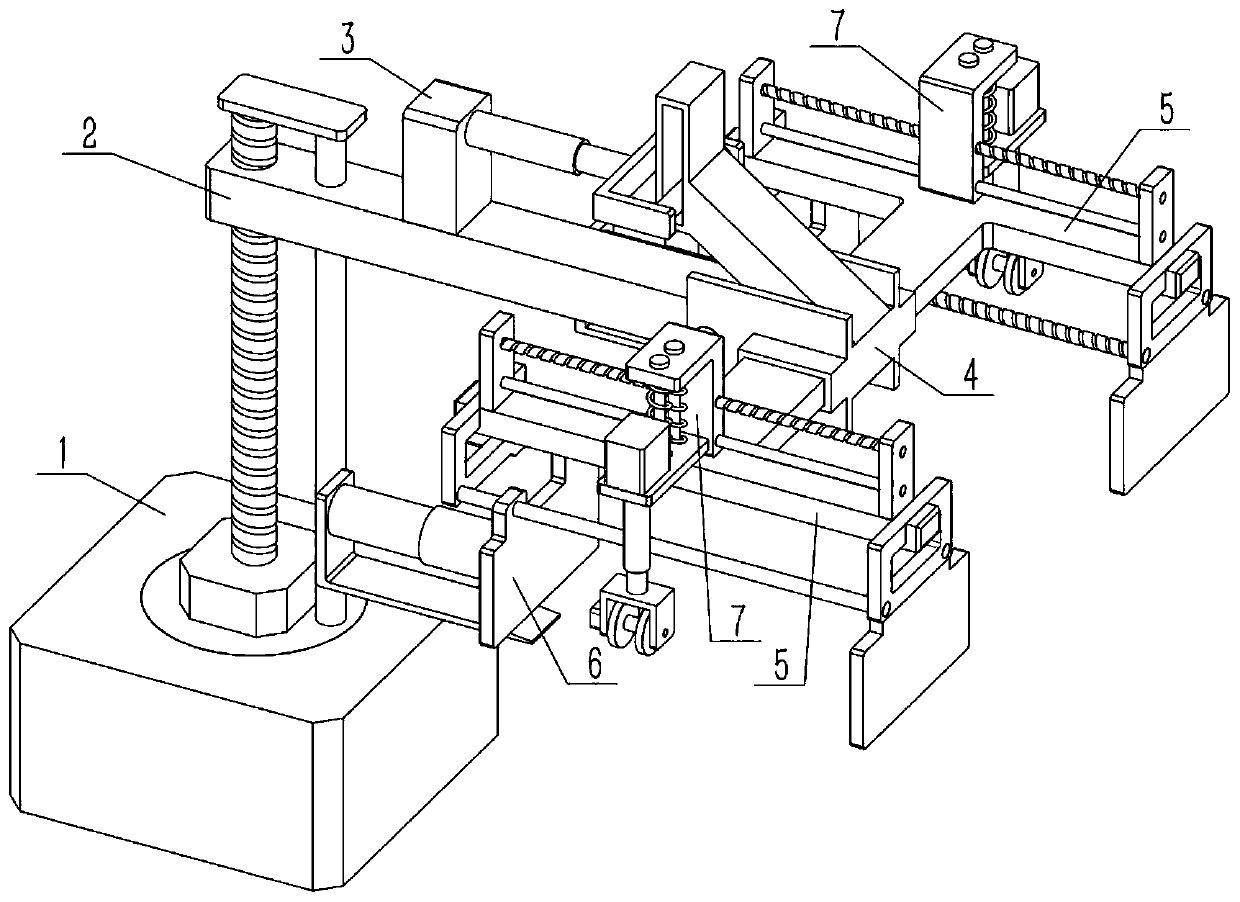

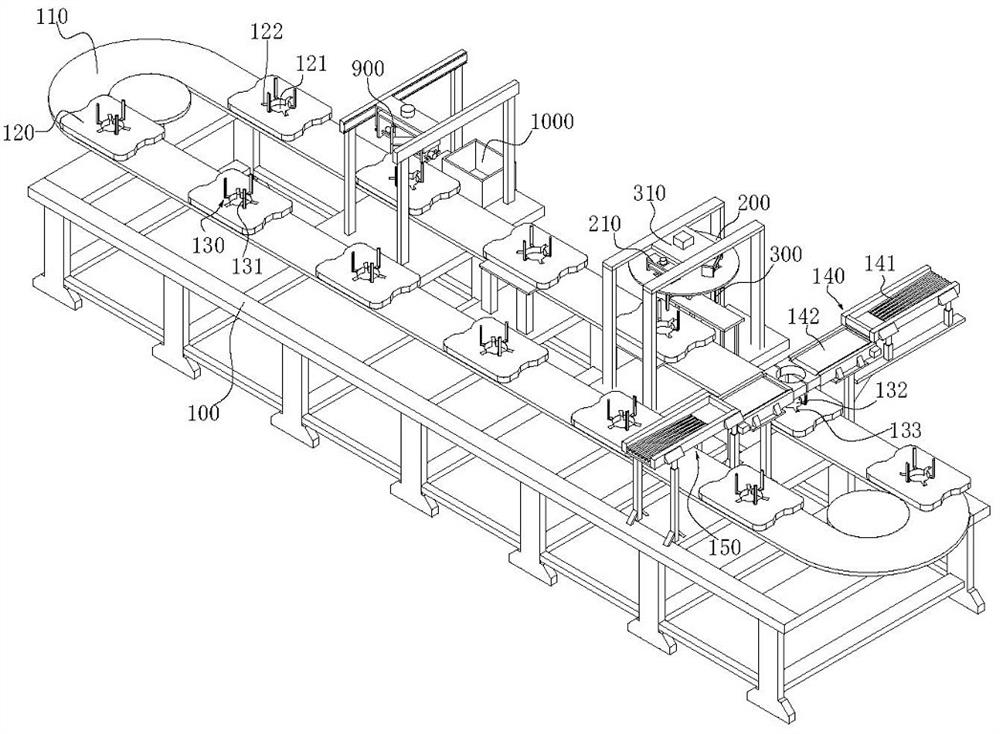

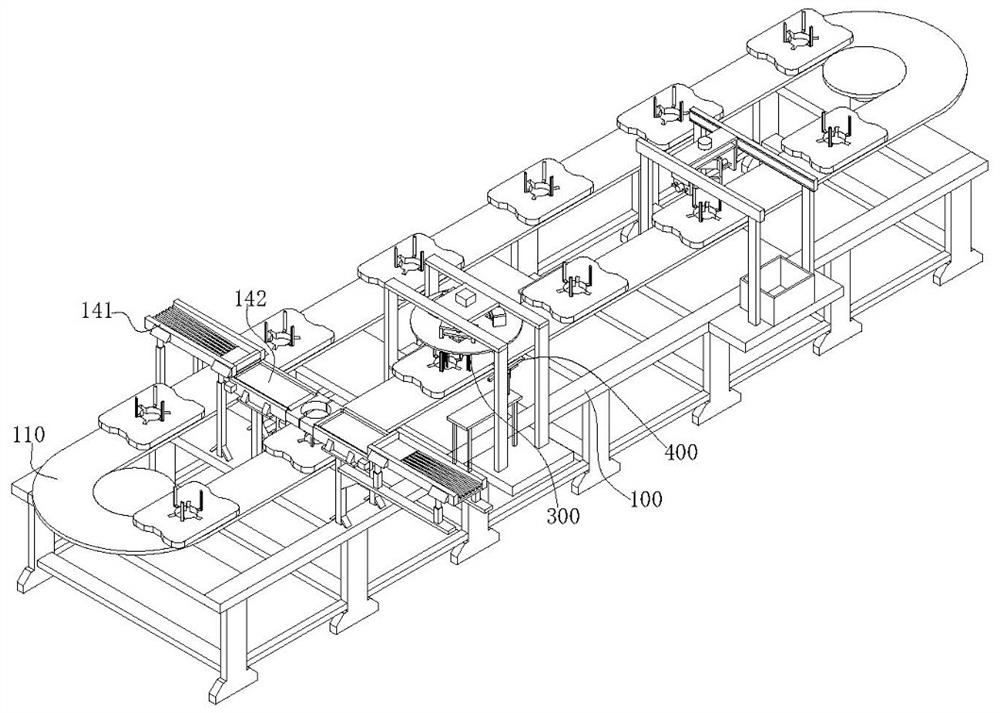

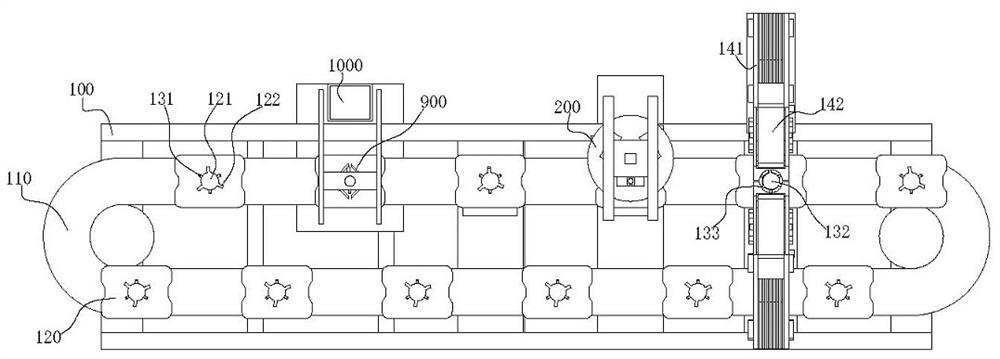

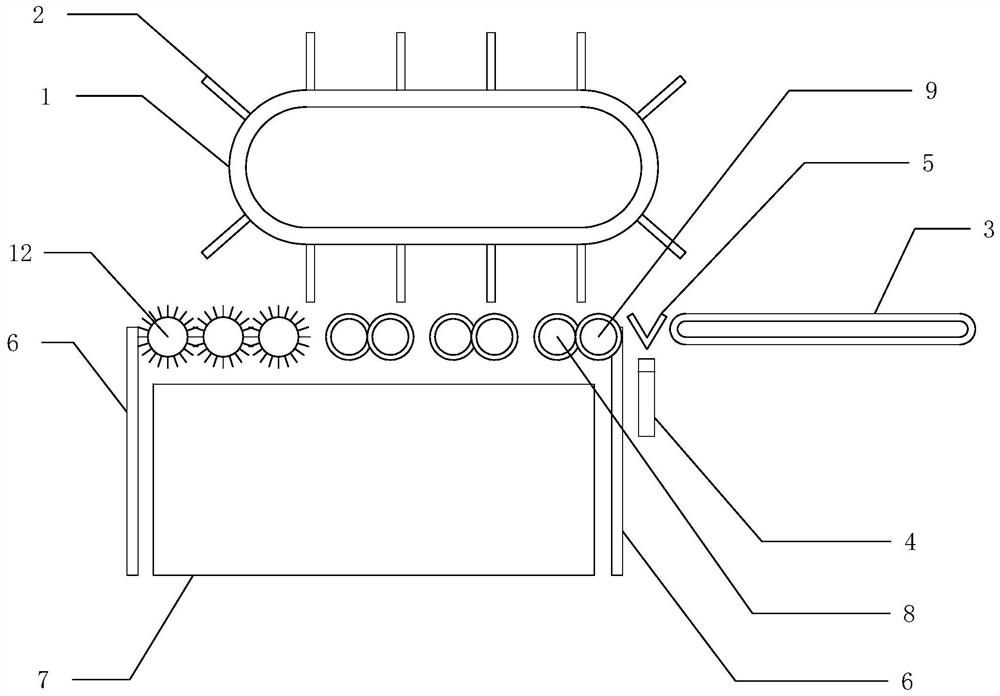

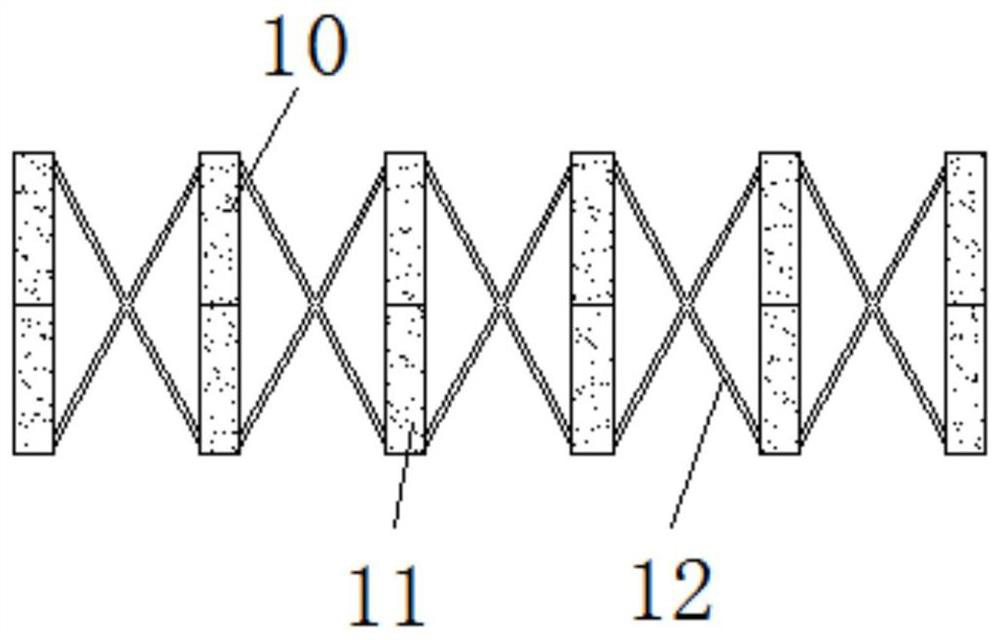

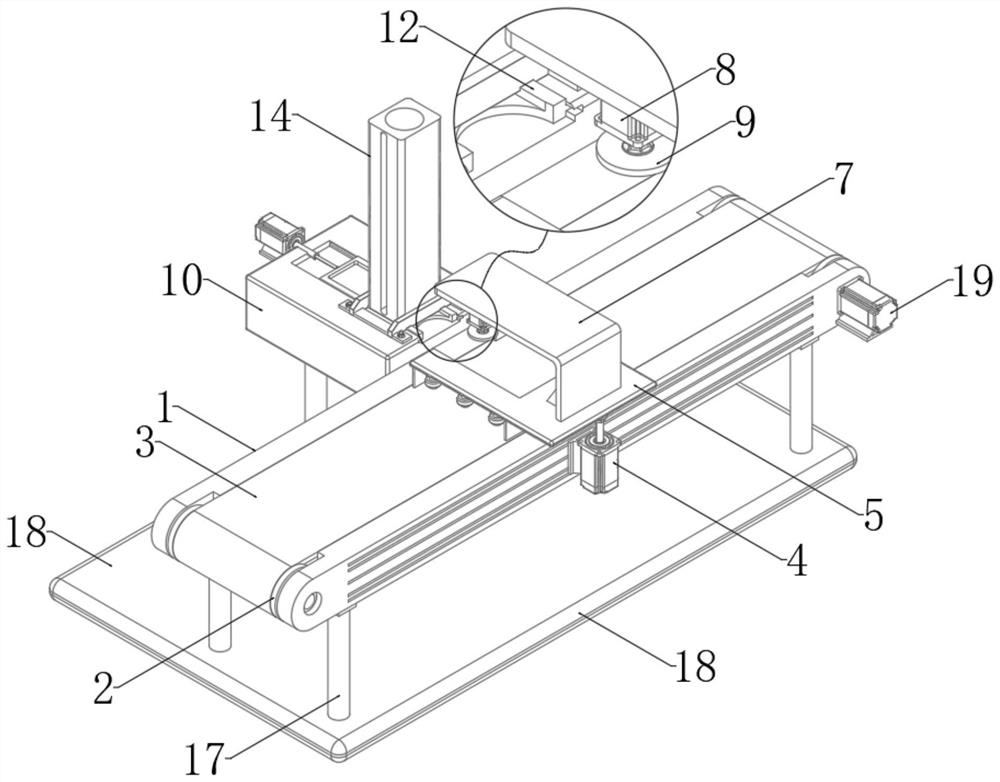

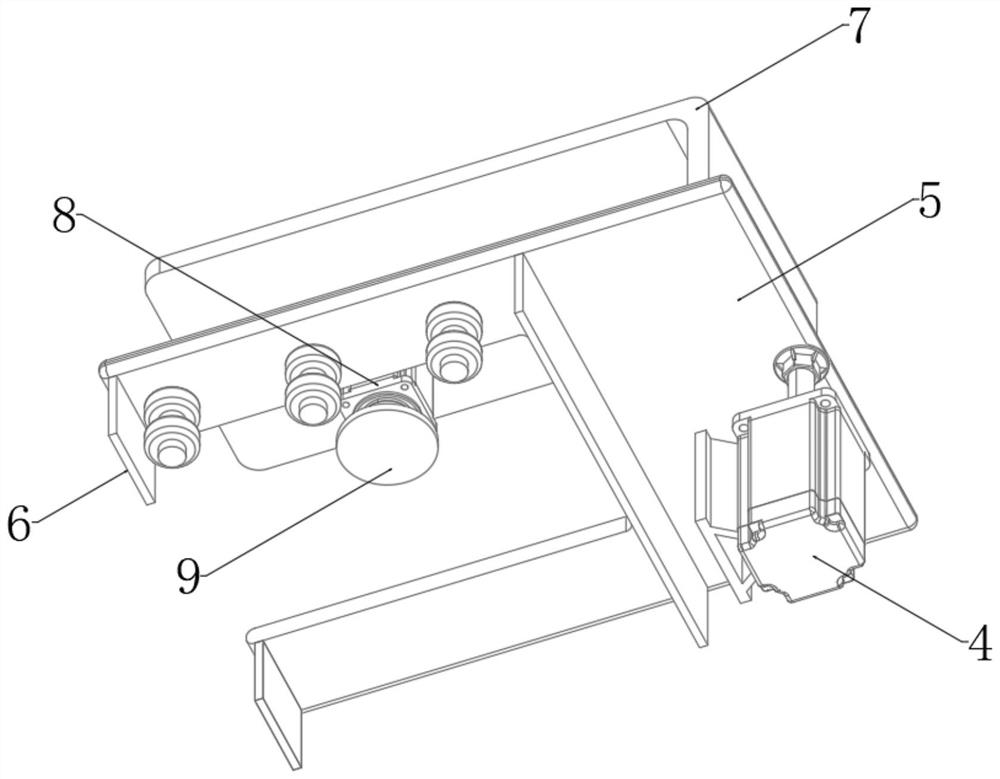

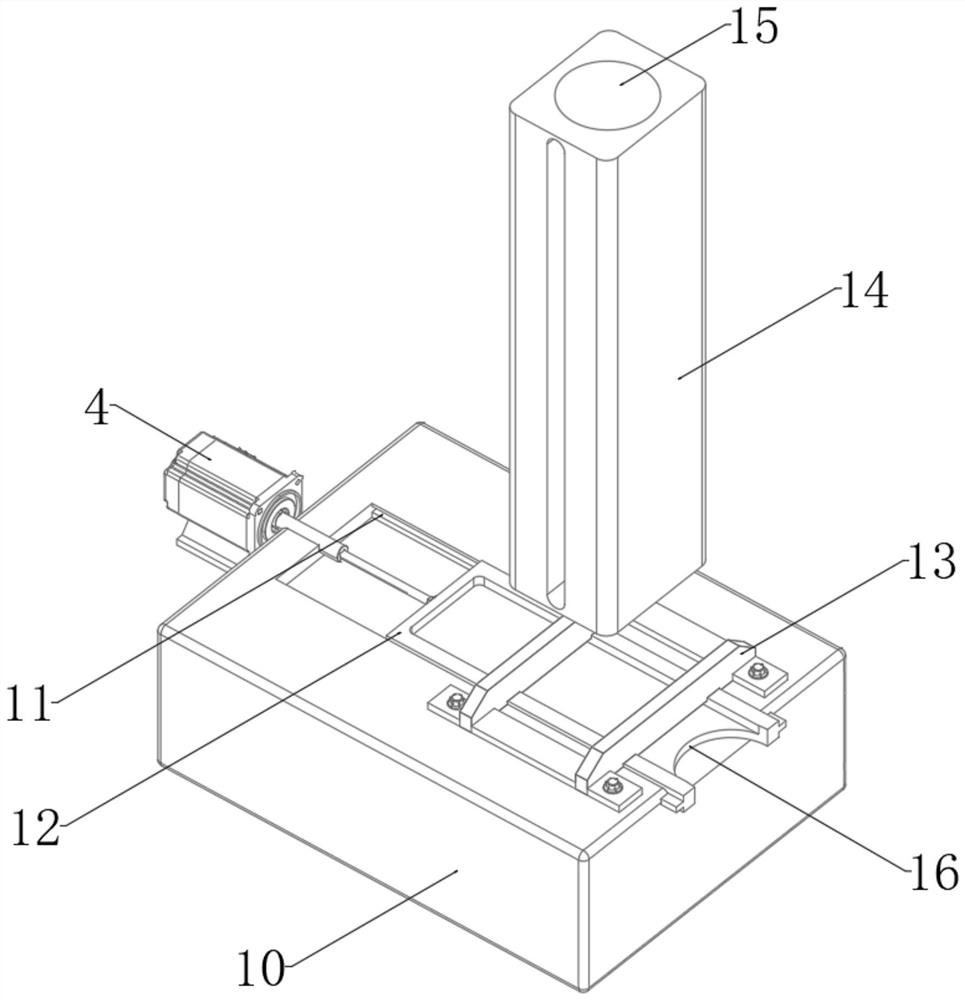

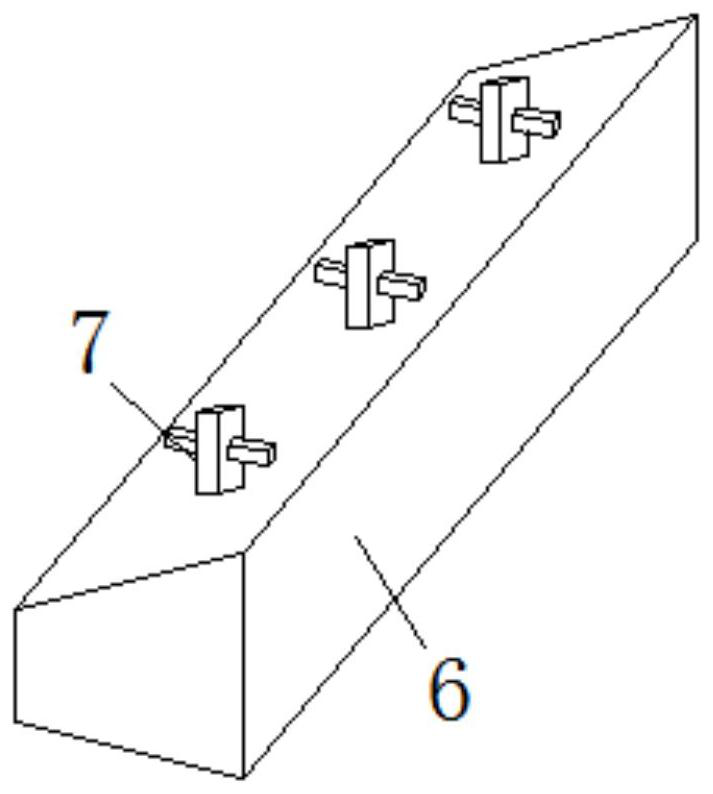

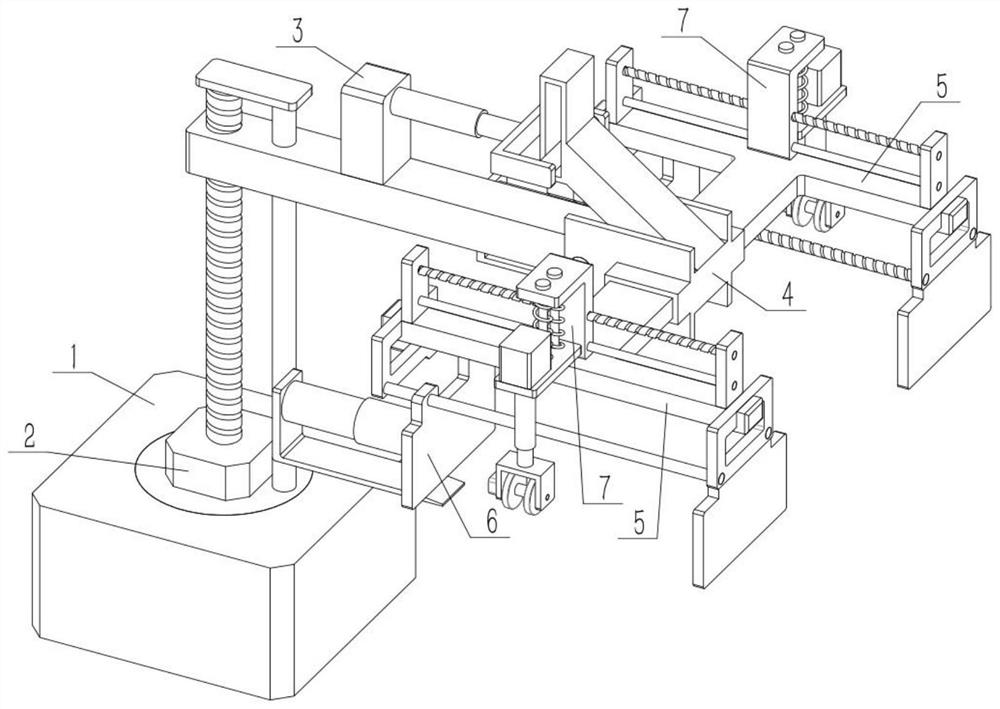

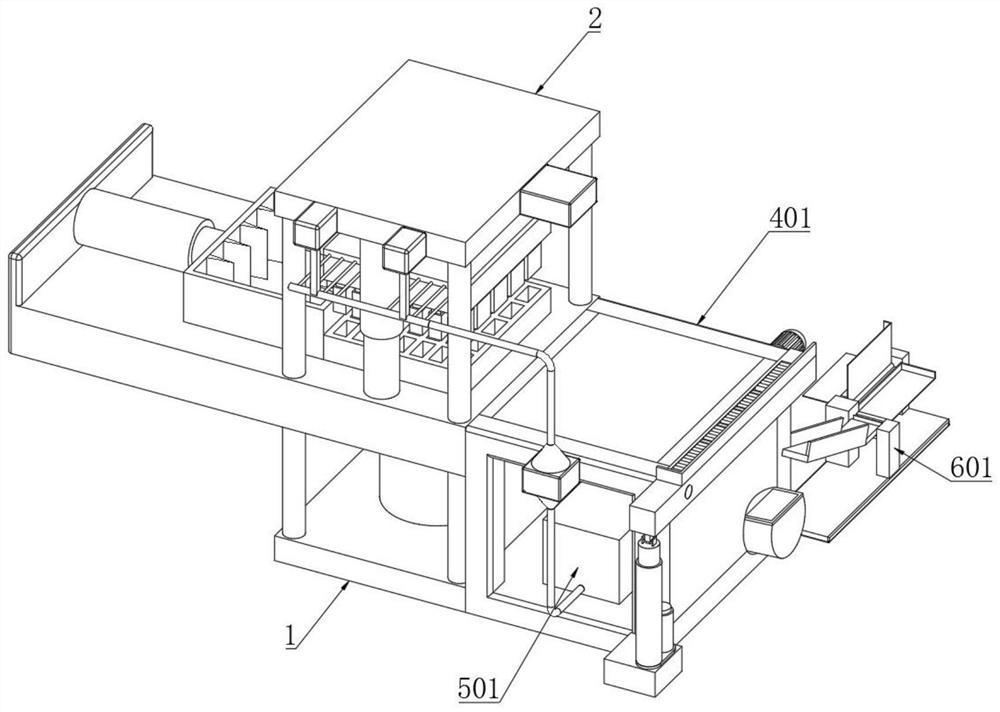

Automatic production binding equipment

InactiveCN112357184AEasy stackingEasy to useBinding material applicationPiston ringStructural engineering

The invention relates to automatic production binding equipment which comprises a conveying line and material carrying devices which are sequentially arranged on the conveying line at intervals and used for carrying piston rings. A feeding station, a first binding station, a second binding station and a discharging station are sequentially arranged on the conveying line. A feeding device used forarranging the piston rings on a material carrying unit to enable the piston rings to be arranged in a stacked manner is arranged at the feeding station in the axial direction, and a wire arranging device and a first binding device used for arranging and binding iron wires on the piston rings on the material carrying unit are arranged at the first binding station. A second binding device for secondarily binding iron wire heads bound by the first binding device is arranged at the second binding station. The equipment is good in production effect, high in piston ring stacking and binding machining efficiency, high in automation level and convenient to use.

Owner:安庆柯麦机电科技有限公司

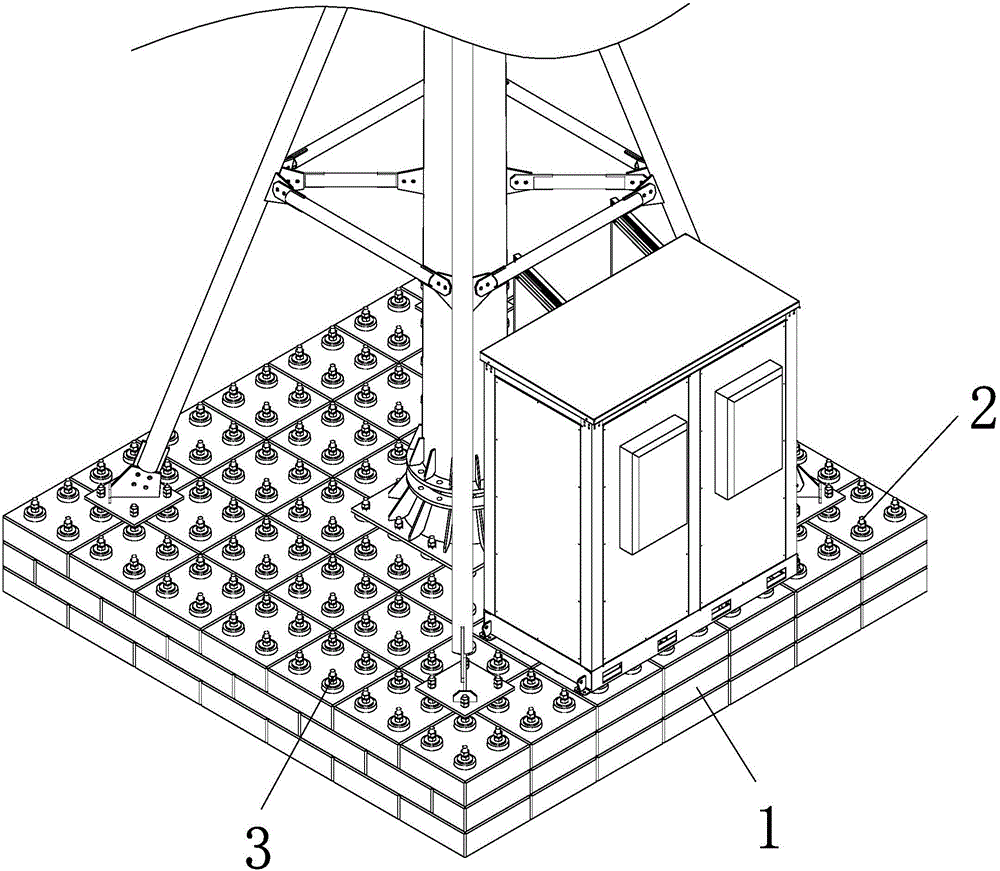

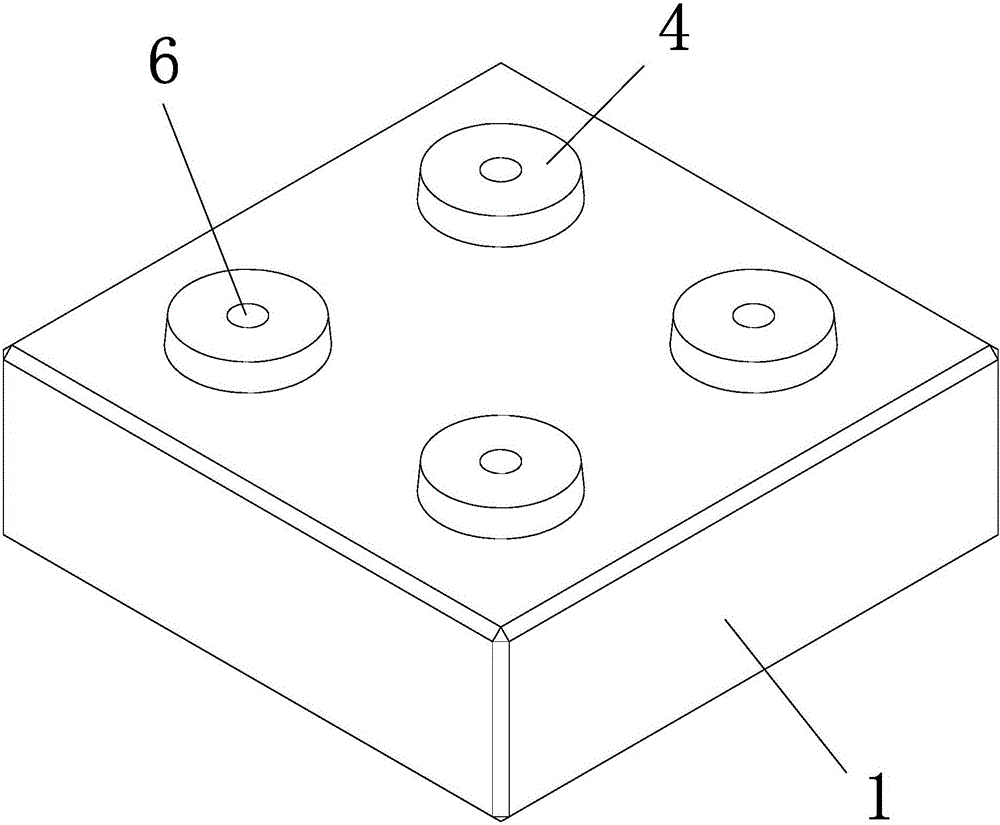

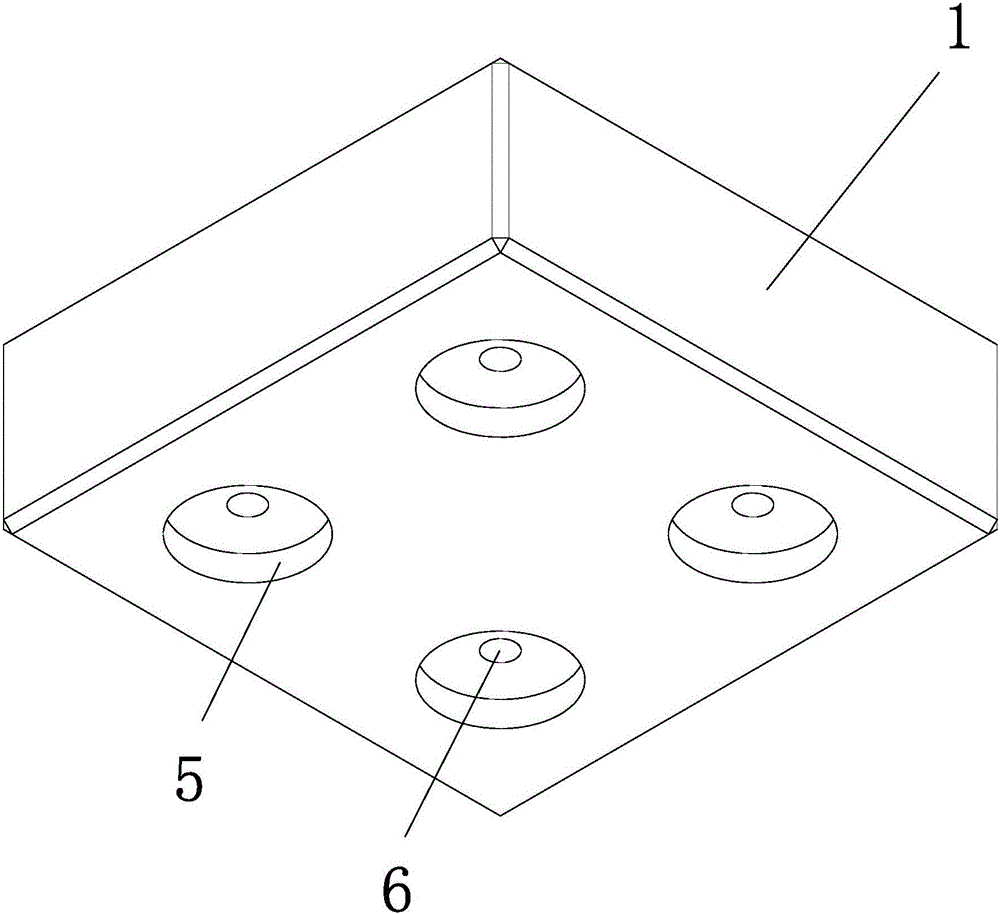

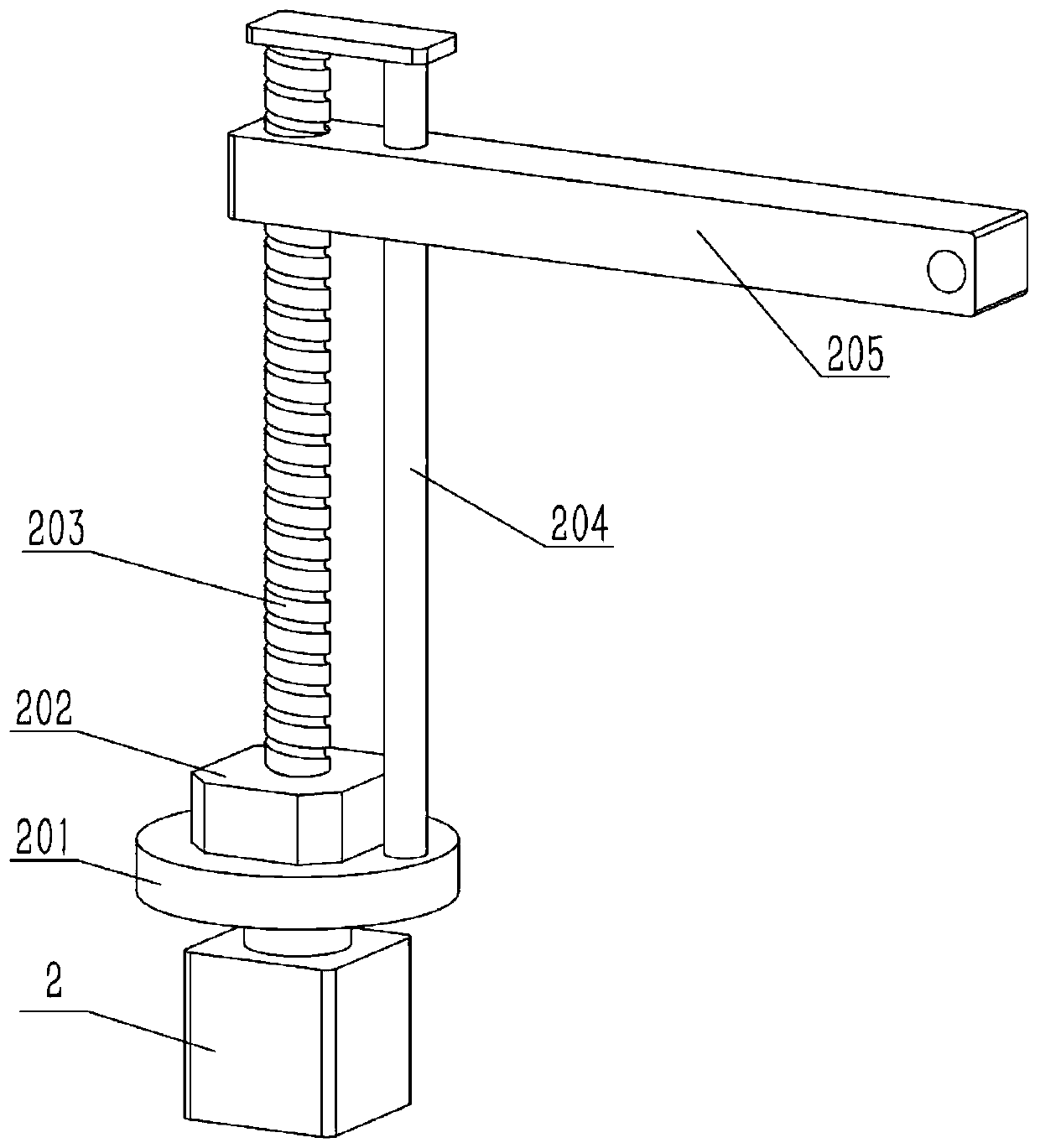

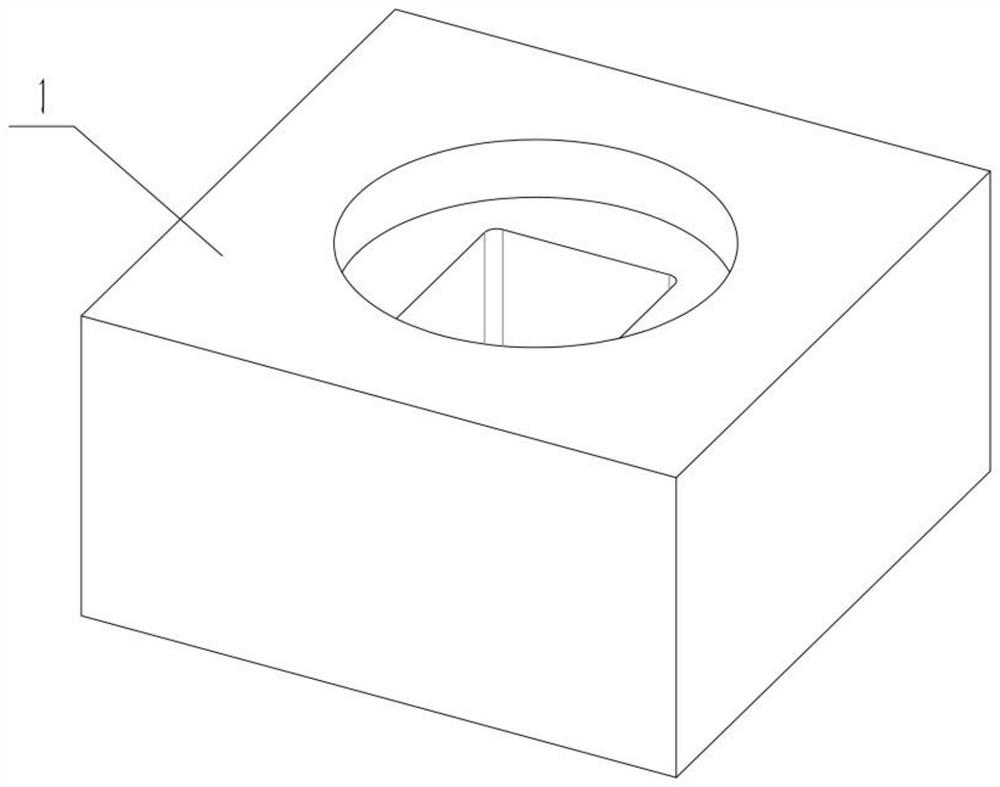

Manually-assembled foundation

The invention relates to a communication base station, in particular to a manually-assembled foundation. The manually-assembled foundation comprises foundation unit blocks, the foundation unit blocks are square, locating protrusions are arranged at the corners of the upper surface of each foundation unit block, locating pits matched with the locating protrusions of another foundation unit block are arranged on the lower surface of each foundation unit block, locating holes penetrating through the foundation unit blocks are formed in the locating protrusions, locating rods penetrate through the locating holes, and locking nuts are arranged at the upper ends of the locating rods. The manually-assembled foundation has the beneficial effects that disassembly can be realized, the position of a tower foundation is convenient to change, and the utilization rate of the tower foundation can be effectively increased.

Owner:ZHEJIANG HEQIN COMM ENG

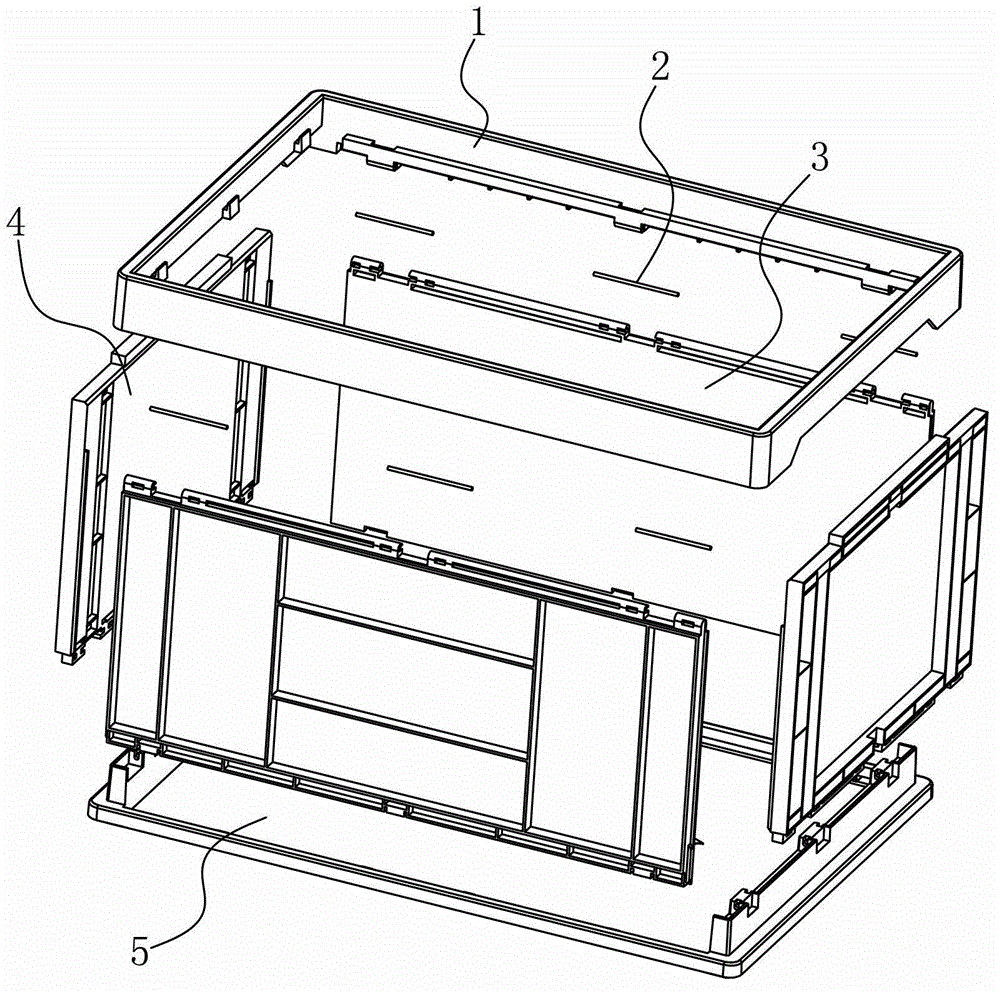

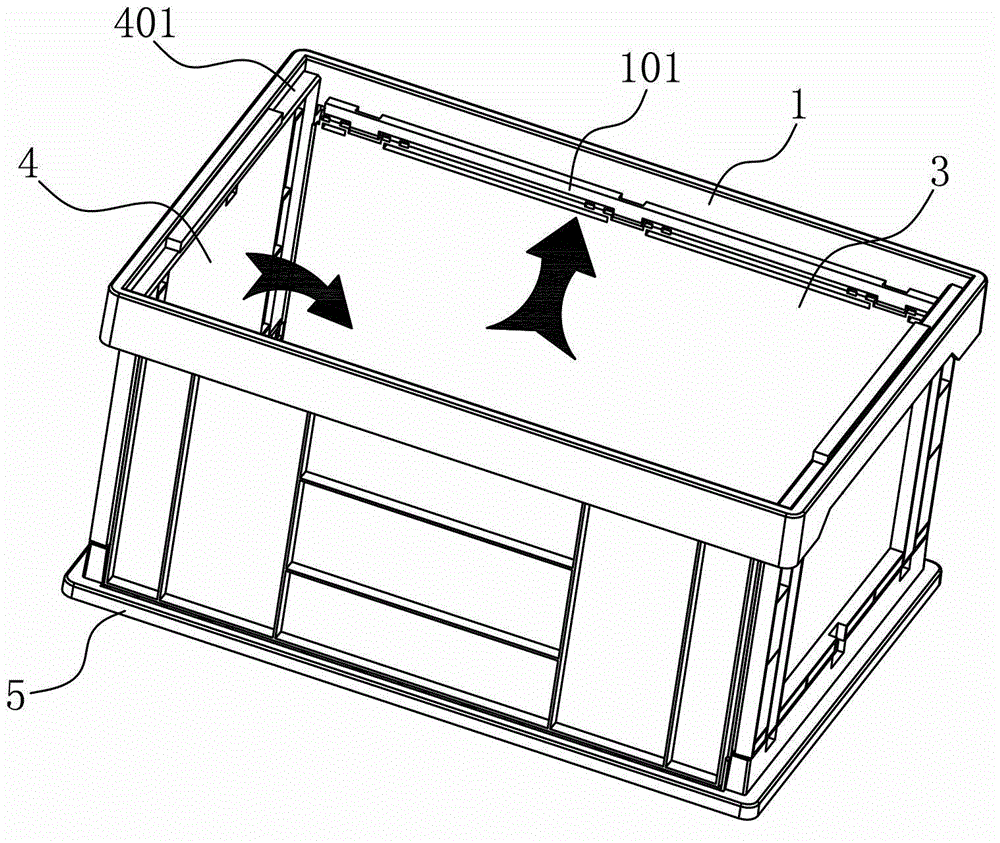

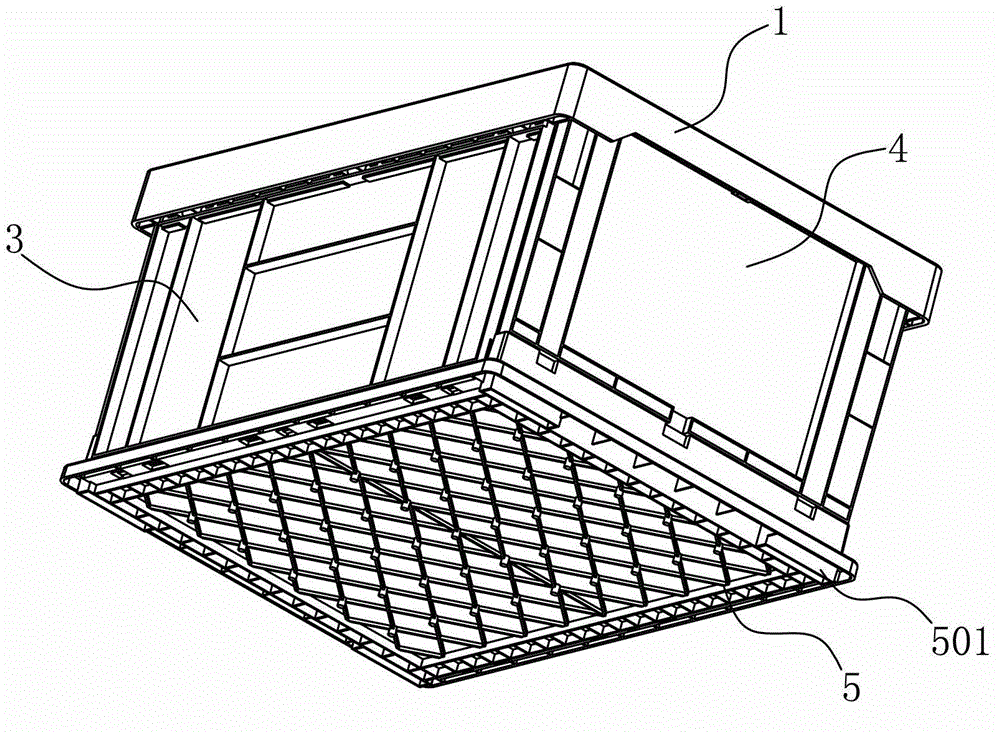

Container and folding using method thereof

Owner:FENGHUA DONGXIN INSTR

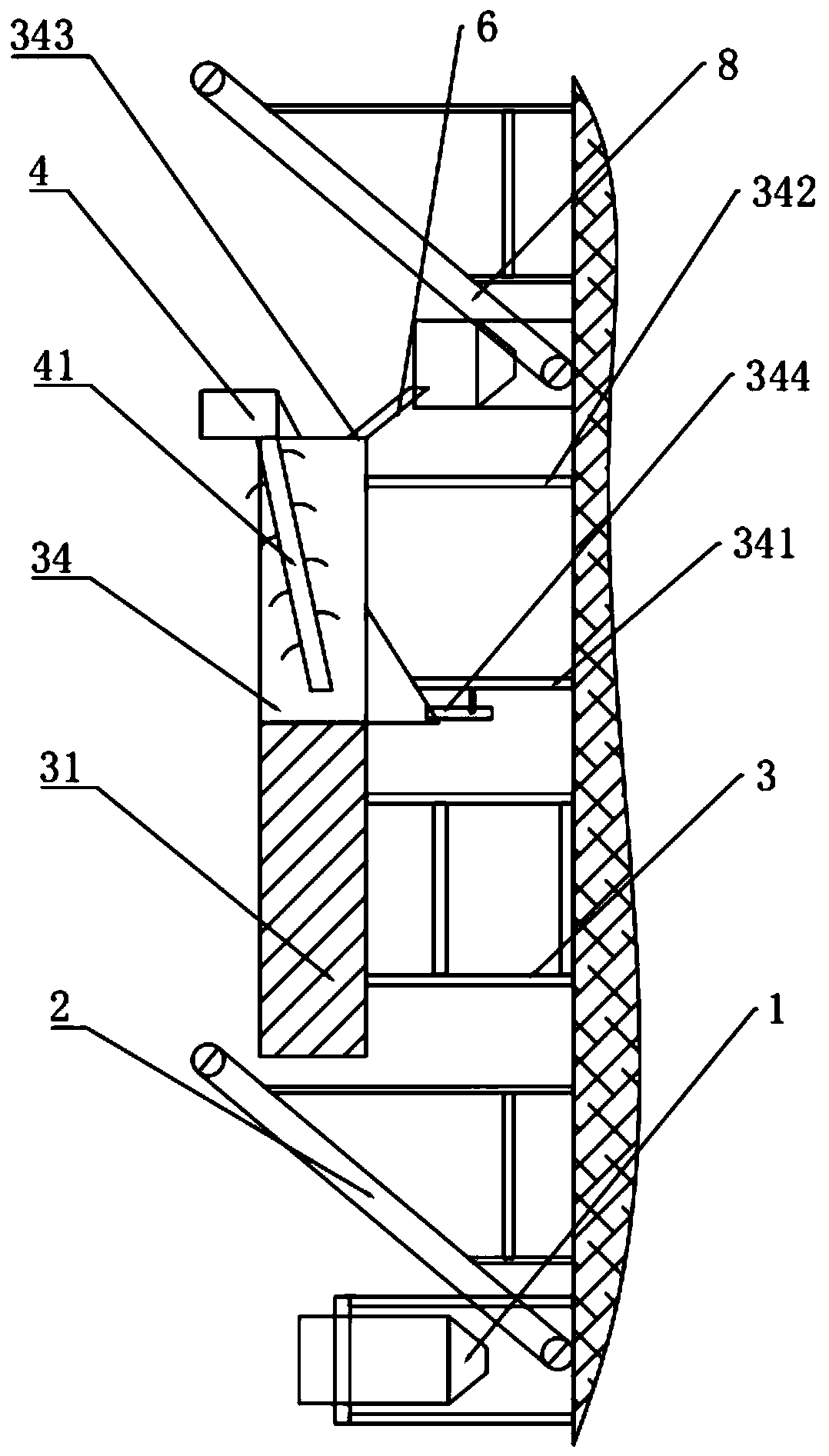

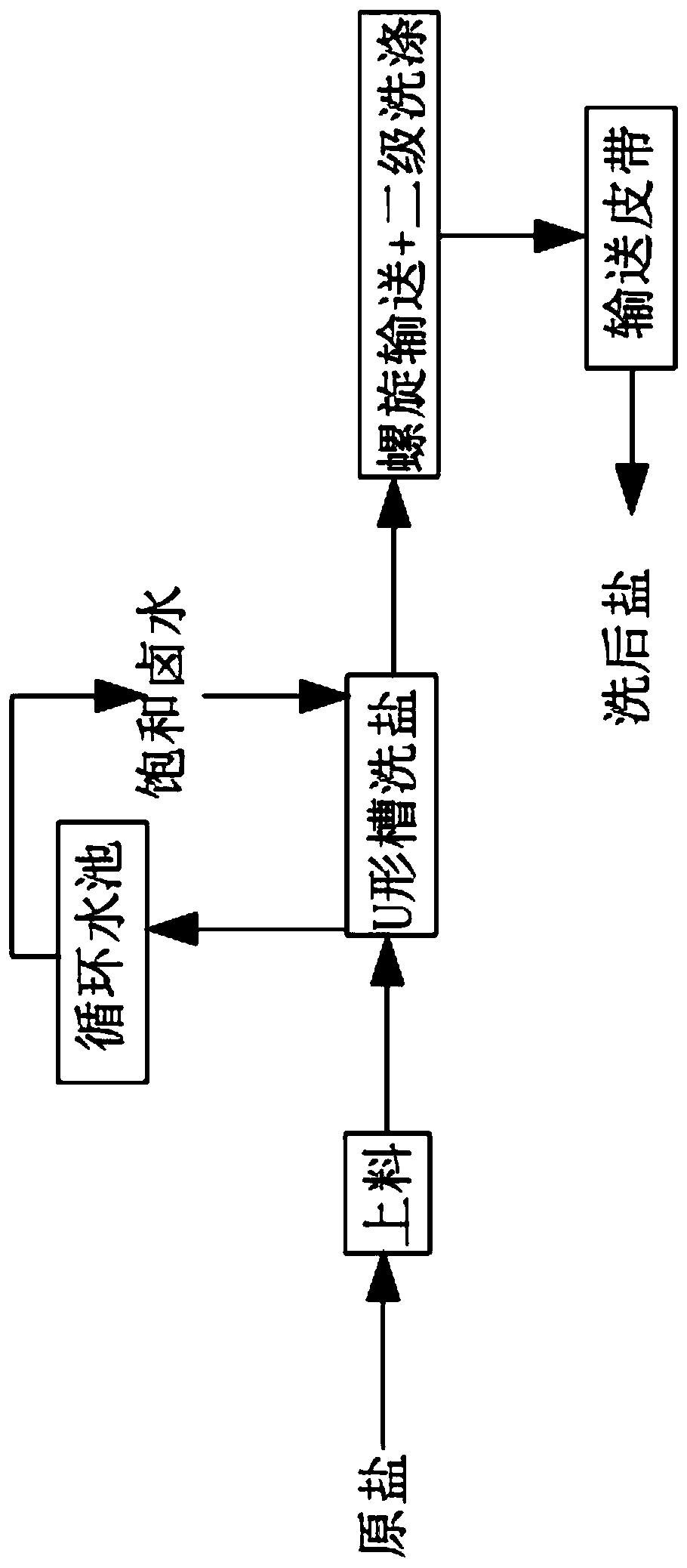

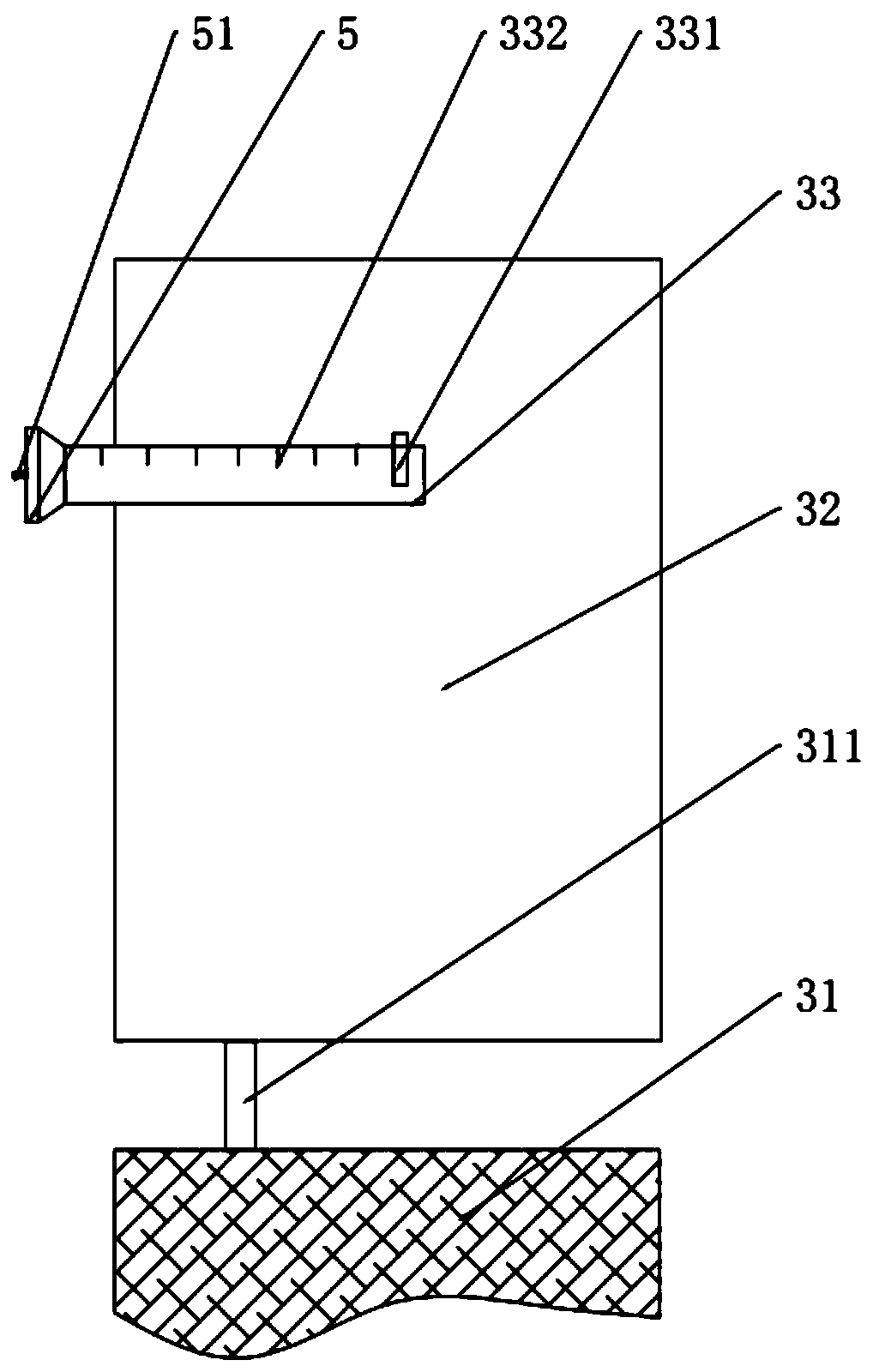

Salt leaching device and salt leaching method for removing impurities in crude salt

InactiveCN111170337AEasy to cleanQuality improvementAlkali metal halide purificationWastewaterElectric machinery

The invention belongs to the technical field of salt production equipment, and provides a salt leaching device and a salt leaching method for removing crude salt impurities. The salt leaching device comprises a feeding machine, a first inclined belt conveyor and a salt leaching mechanism, wherein the salt leaching mechanism comprises a salt leaching tank, a clear water tank, a brine injection cylinder and a separation tank; the first inclined belt conveyor is correspondingly arranged at the upper part of one end of the salt leaching tank, and the other end of the salt leaching tank communicates with the separation tank; a clear water inlet pipe is arranged on the outer wall of the salt leaching tank, and one end of the clear water inlet pipe is connected with the clear water tank; a motoris arranged on the outer wall of the separation tank; a spiral separation shaft is arranged in the separation tank, and the motor is connected with the spiral separation shaft; a crude salt outlet isformed in the end of the separation tank; a wastewater outlet pipe is arranged at the tail end of the separation tank. According to the salt leaching device and the salt leaching method for removing the impurities in the crude salt, the crude salt can be cleaned, the impurities in the crude salt are removed, and the quality of the crude salt is greatly improved.

Owner:SHANDONG CAIYANGZI SALTWORKS

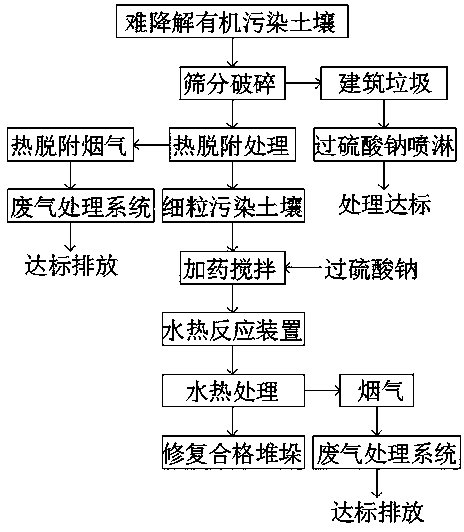

Restoration method suitable for soil polluted by polycyclic aromatic hydrocarbon, dioxin and pesticide

InactiveCN111299314AImprove repair rateShort processContaminated soil reclamationPolycyclic aromatic hydrocarbonPesticide pollution

The invention belongs to the technical field of soil remediation, discloses a restoration method suitable for soil polluted by polycyclic aromatic hydrocarbon, dioxin and pesticide, and aims to solvethe problem of high residual quantity of chemicals due to insufficient reaction of chemicals in the remediation process of refractory organic matters such as polycyclic aromatic hydrocarbon, dioxin and pesticides. Compared with the prior art, sodium persulfate can fully react with polycyclic aromatic hydrocarbon, dioxin, pesticides and other organic matters, thereby lowering the consumption of sodium persulfate and lowering the secondary pollution of the medicament (sodium persulfate). Meanwhile, in the process of reacting the sodium persulfate with refractory organic matters such as polycyclic aromatic hydrocarbon, dioxin and pesticides, any auxiliary raw material or catalyst does not need to be added.

Owner:中冶成都勘察研究总院有限公司

Robot grabbing mechanism

InactiveCN111185932AIncreased access to the interior of the cargo compartmentAuxiliary loading and unloading operationsGripping headsHand partsShaped beam

The invention relates to the field of robots, in particular to a robot grabbing mechanism. The robot grabbing mechanism comprises a main arm, a multi-joint frame, a shaft II, a groove-containing inclined frame, a through opening, a T-shaped beam, side mounting frames, a fixing and clamping portion and a hand mechanism, wherein parts above the fixing and clamping portion and on the left side of thefixing and clamping portion can be integrally lowered by anticlockwise inclining the fixing and clamping portion and a driving portion, the distance for an object to enter a cargo compartment can beincreased, the view field in the compartment is increased, and the clamped object can be conveniently stacked in the cargo compartment; by means of the identification and object abutting of the fixingand clamping portion, the object cannot move in the object clamping process in combination with the independently-moving driving portion, the clamping process is stabler, and the object can be placedand aligned by means of the independently-moving driving portion; and guide wheels are used for being in contact with a circular-tube-shaped object and rotates to drive the circular-tube-shaped object to move front and back, and loading and unloading operation of the circular-tube-shaped object is assisted.

Owner:HARBIN UNIV OF COMMERCE

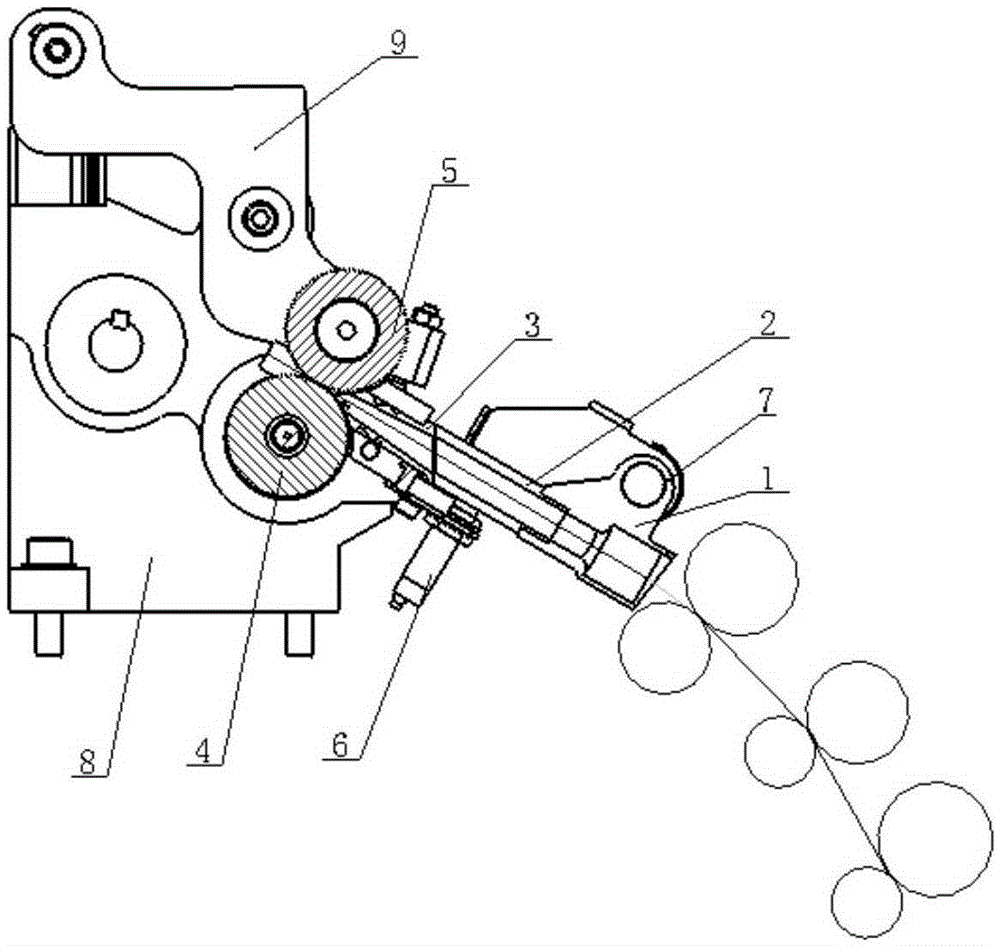

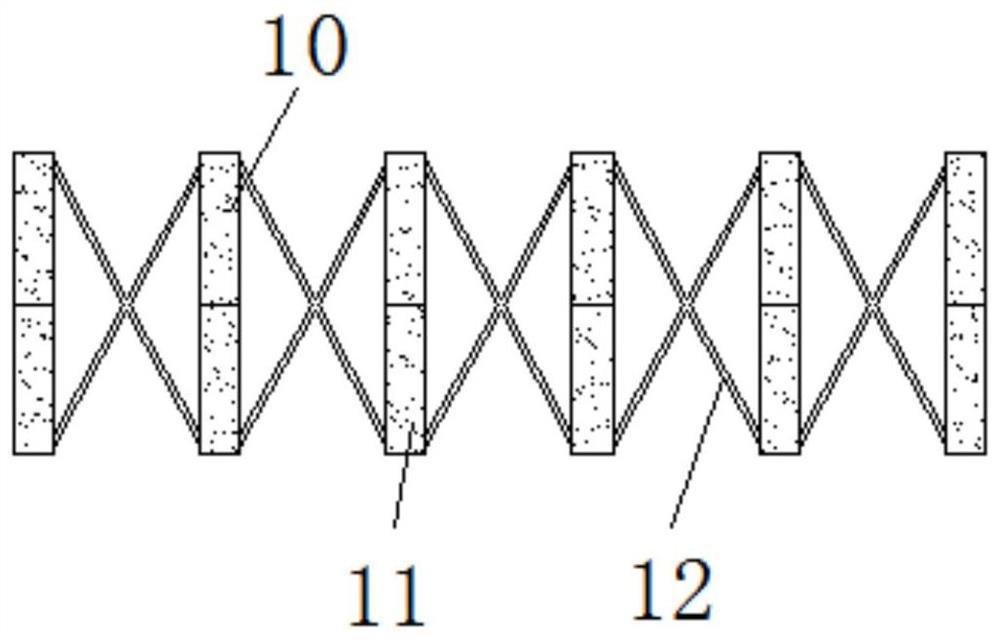

A bundling method for automatic production of piston rings

ActiveCN112407965BEasy stackingEasy to useBinding material applicationStacking articlesPiston ringEngineering

The invention relates to a bundling method for automated production, comprising the following steps: Step S1: firstly laying end material rings, then stacking piston rings on the end material rings to form a piston ring column, and placing the piston ring at the end of the piston ring column Step S2: insert the formed U-shaped iron wire on the ring body of the piston ring column; Step S3: then carry out the operation on the end of the U-shaped iron wire inserted into the piston ring column Binding; Step S4: Gather the bundled iron wires, and then continue to bind the gathered iron wires; Step S5: Collect the piston ring cylinders that have been bundled twice. The equipment has good production effect, high processing efficiency for stacking and bundling piston rings, high automation level and convenient use.

Owner:安庆柯麦机电科技有限公司

Placing and stacking device for storing cylindrical mold standard parts

Owner:嘉兴市康立德构件股份有限公司

A kind of tableware deslagging machine

ActiveCN110710940BSlow down the turning speedReduce impactTableware washing/rinsing machine detailsProcess engineeringConveyor belt

The invention discloses a tableware slag remover, which comprises a main conveyor belt, on which a plurality of partition plates are evenly arranged along the conveying direction of the main conveyor belt, and any two adjacent partition plates There is a gap between the plates, and a flipping auxiliary device, a sub-conveyor and a slag removal section are arranged below the main conveyor belt, the sub-conveyor is located directly below the end of the main conveyor The device is arranged between the sub-conveyor belt and the slag removal section, and the conveying direction of the sub-conveyor belt is extended along the direction from the sub-conveyor belt to the slag removal section. The first water nozzle on the side of the sub-conveyor belt, the water outlet direction of the first water nozzle is towards the end of the conveying direction of the main conveyor belt, and the present invention can automatically clean up the food residue on the dinner plate, reducing Manual operation improves the efficiency of tableware recycling.

Owner:佛山市钢联厨房设备工程有限公司

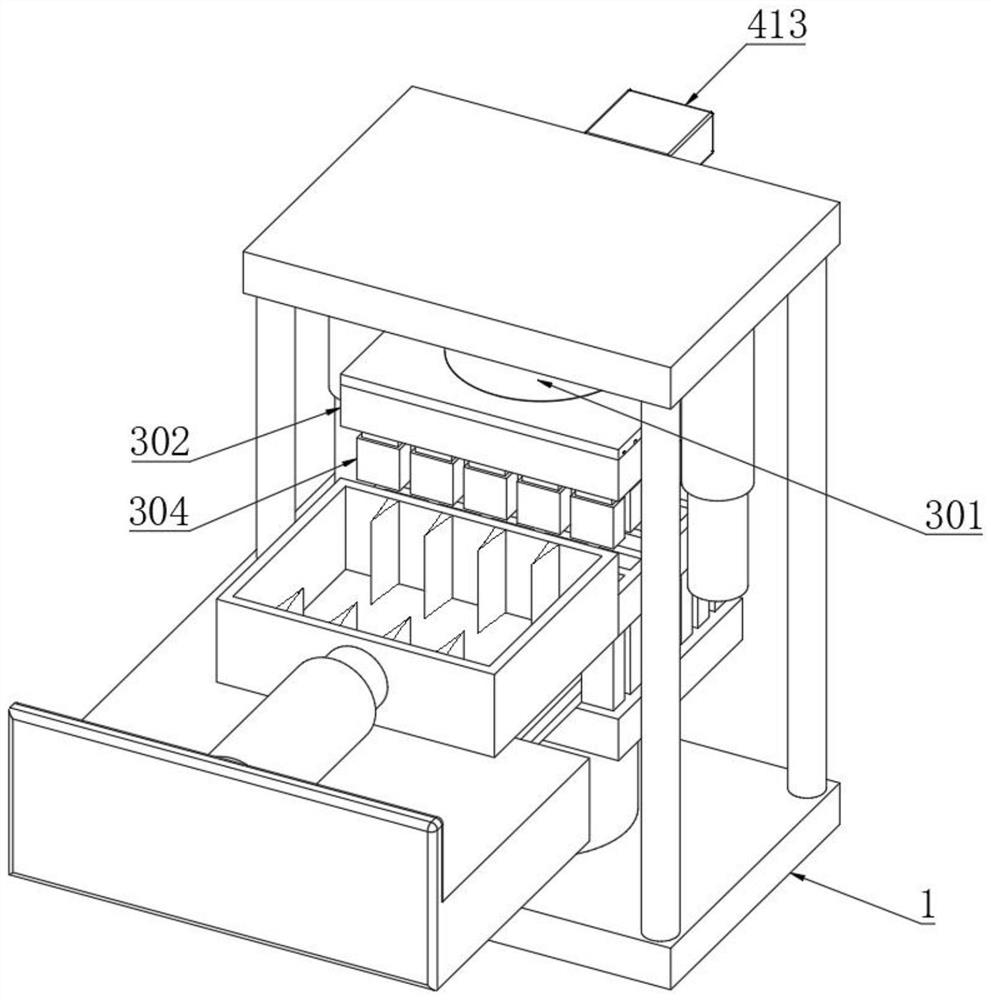

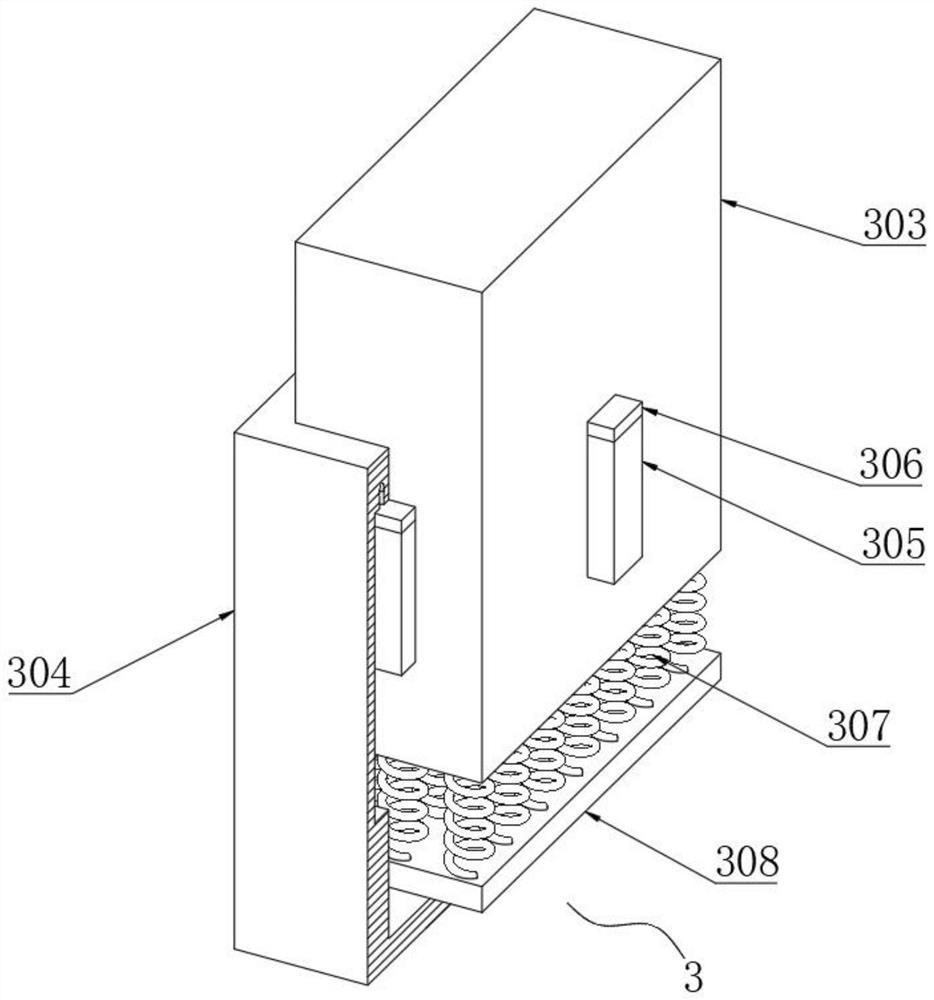

Two-way pressurization stable limiting brick making machine

ActiveCN112497431AScientific and reasonable structureEasy to useAuxillary shaping apparatusShaping press ramBrickStructural engineering

The invention discloses a two-way pressurization stable limiting brick making machine which comprises a fixing base. A fixing top plate is installed at the top end of the fixing base, a multi-pressureexhaust mechanism is installed at the bottom end of the fixing top plate, and the multi-pressure exhaust mechanism comprises a hydraulic rod, a connecting plate, pressing blocks, shells, sliding blocks, rubber plugs, multi-pressure springs, pressing plates, vent holes, exhaust holes, connecting ropes and rubber columns. According to the two-way pressurization stable limiting brick making machine,multi-stage pressure application can be conducted in the material pressing process through the multi-pressure exhaust mechanism, so that the material pressing process can be gradually increased stageby stage, pressure borne by materials in the material and shell separation process can also be gradually decreased stage by stage, and then the phenomenon that formed bricks break as the materials are suddenly subjected to huge pressure or separation in the material pressing process is avoided; and besides, air can be rapidly discharged in the material pressing process, meanwhile, the inner sidesof the vent holes can be cleaned when the shells are separated from the bricks, and the bricks can also be conveniently separated from the surfaces of the shells.

Owner:TANGSHAN COLLEGE

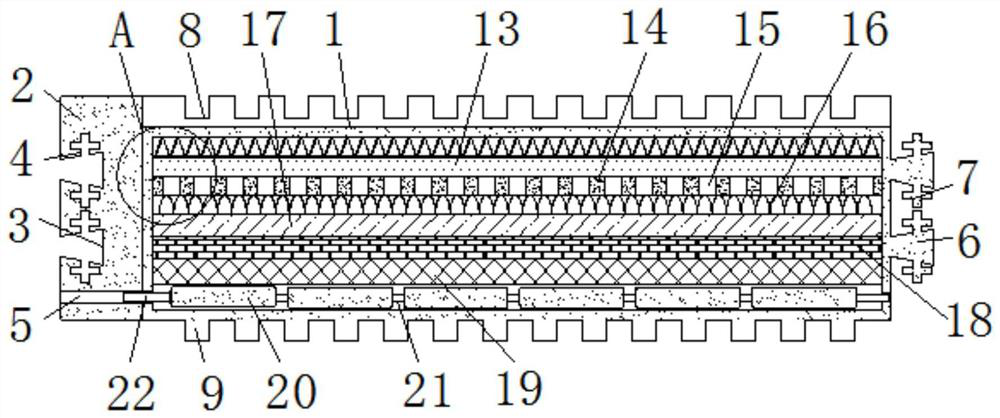

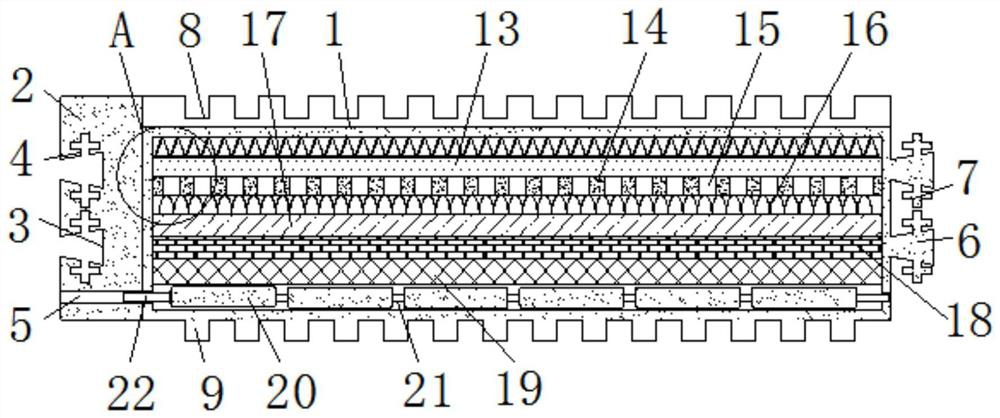

High-strength easy-to-overlap building brick

ActiveCN112095906AGood stitchingIncrease usage intensityHeat proofingSound proofingVapor barrierBrick

The invention discloses a high-strength easy-to-overlap building brick which comprises a building brick body, a concrete layer and a hard material layer. A lateral fixing block is fixedly mounted at the left side of the building brick body, a clamping block is fixedly mounted at the right side of the building brick body, and side guide blocks are fixedly connected to the upper side and the lower side of the clamping block; connecting steel bars are fixedly connected to the side edges of second reinforcing ribs, the concrete layer is installed at the lower ends of the second reinforcing ribs, built-in vertical blocks are fixedly installed at the lower end of a sound absorption plate and fixedly installed above a heat preservation layer, and a damp-proof layer is installed between the heat preservation layer and the hard material layer; and the outer end of an exhaust pipe is mounted in a circulating hole. According to the high-strength easy-to-overlap building brick, the use strength ofthe building brick can be improved, meanwhile, splicing between adjacent building bricks is facilitated, meanwhile, a certain sound insulation and noise reduction effect can be achieved when the building brick is used in a building, and a certain flame-retardant and fireproof effect can be achieved when a fire occurs.

Owner:浙江金州科技有限公司

Full-automatic packaging machine for data line production and processing

InactiveCN114834718AEasy Paste HandlingAvoidance of manual labeling operationsLabelling short rigid containersLabelling machinesConveyor beltIndustrial engineering

The invention discloses a full-automatic packaging machine for data line production and processing, and relates to the technical field of data line production, the full-automatic packaging machine specifically comprises two bearing parts, rotating shafts are fixedly installed at the two ends of the surfaces of the opposite sides of the two bearing parts, and transmission rollers are fixedly installed through rotating rods in the rotating shafts; and a support is fixedly mounted in the middle of the surface of one side of one bearing part, the bearing part is fixedly connected with an electric push rod through the support, and the output end of the electric push rod is fixedly connected with a mounting part. Through the arrangement of an electric push rod, a mounting part, a blocking part, a pneumatic push rod and a hot welding head on the bearing part, when a label moves to a data line packaging box, the label can be more conveniently pasted, and then the situation that a traditional device needs a worker to conduct manual labeling operation is greatly avoided; therefore, the labeling efficiency is greatly ensured, and meanwhile, the workload of workers is greatly reduced.

Owner:徐州纬皓电子有限公司

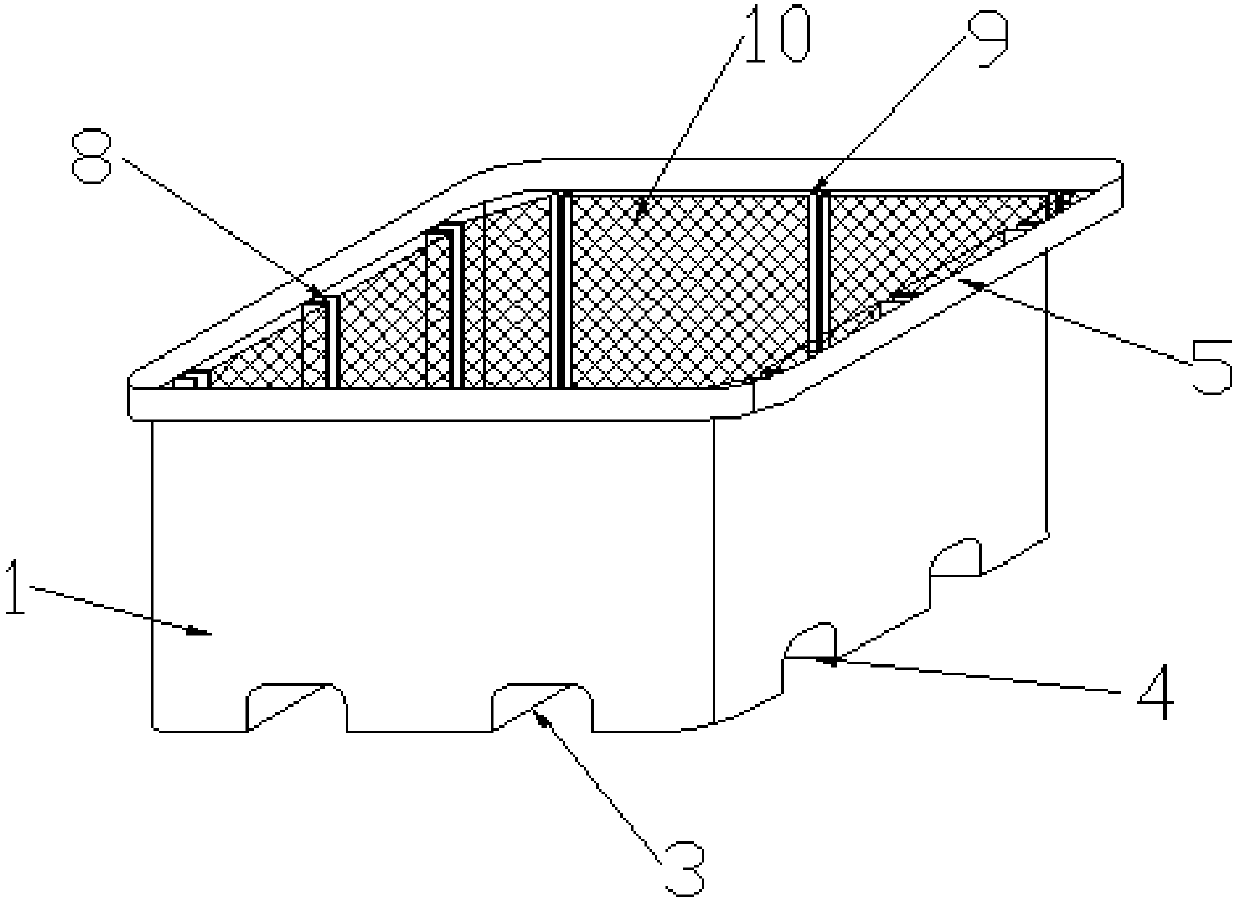

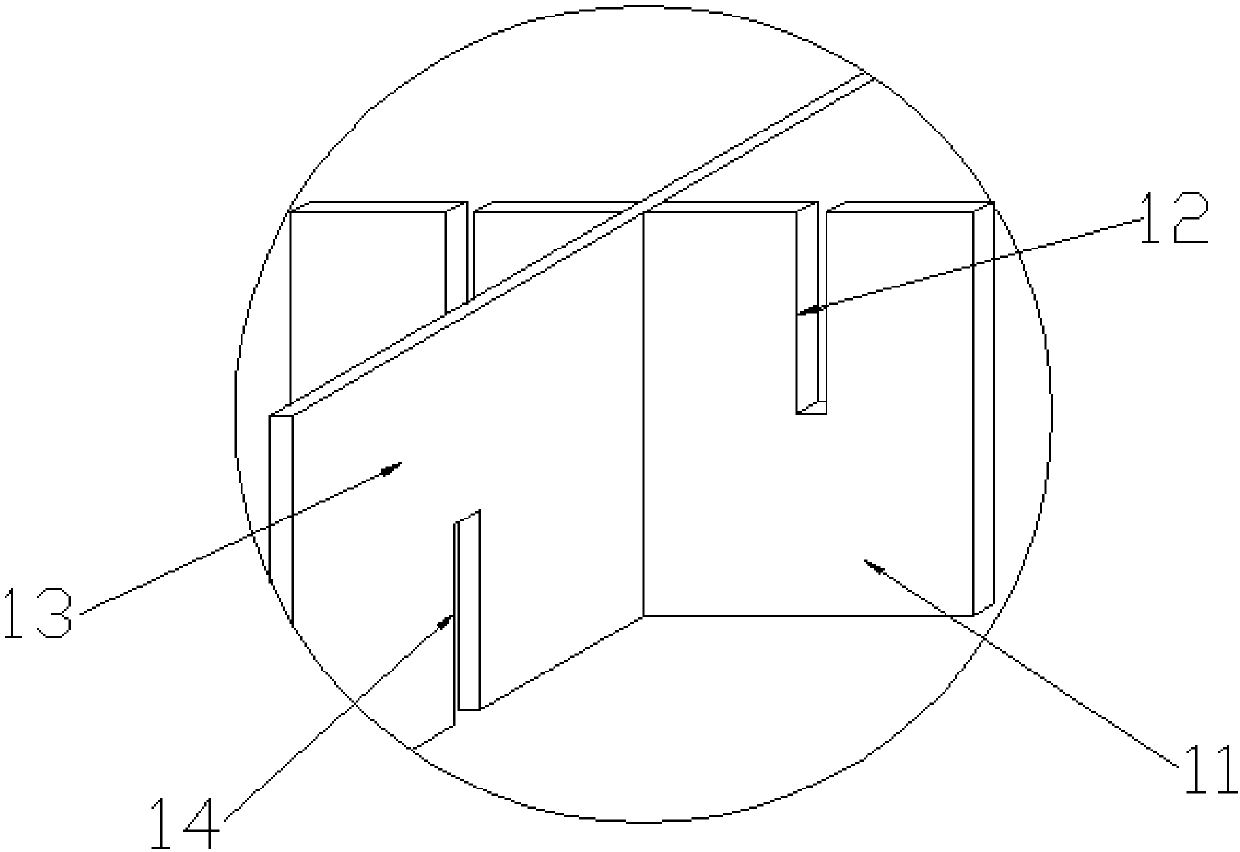

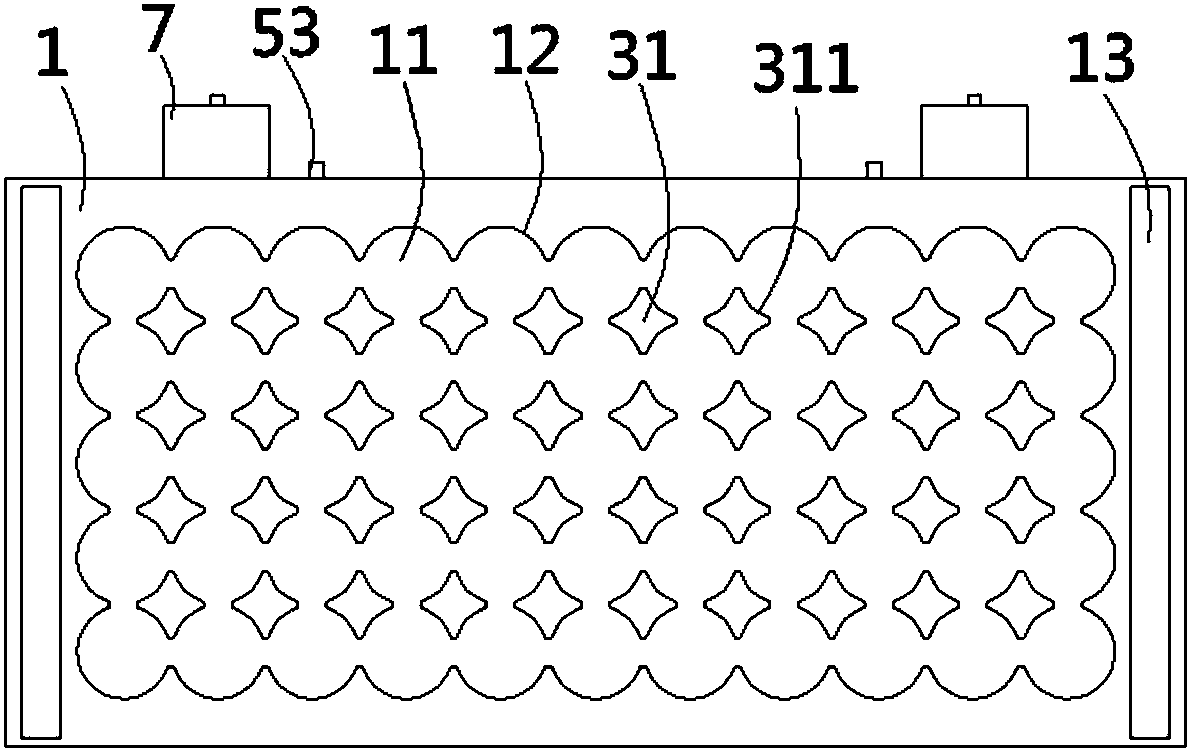

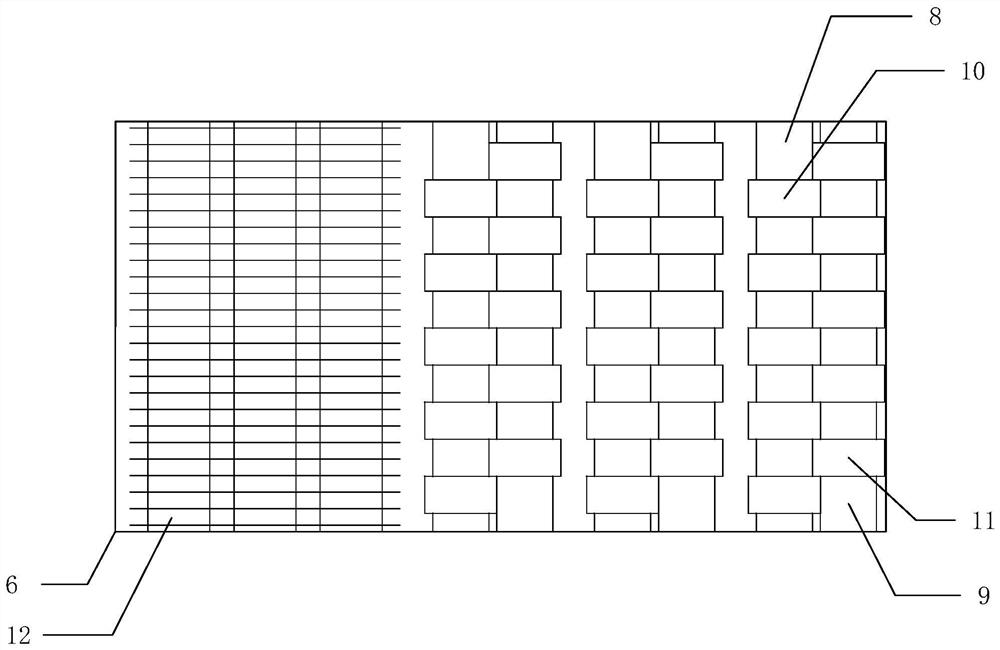

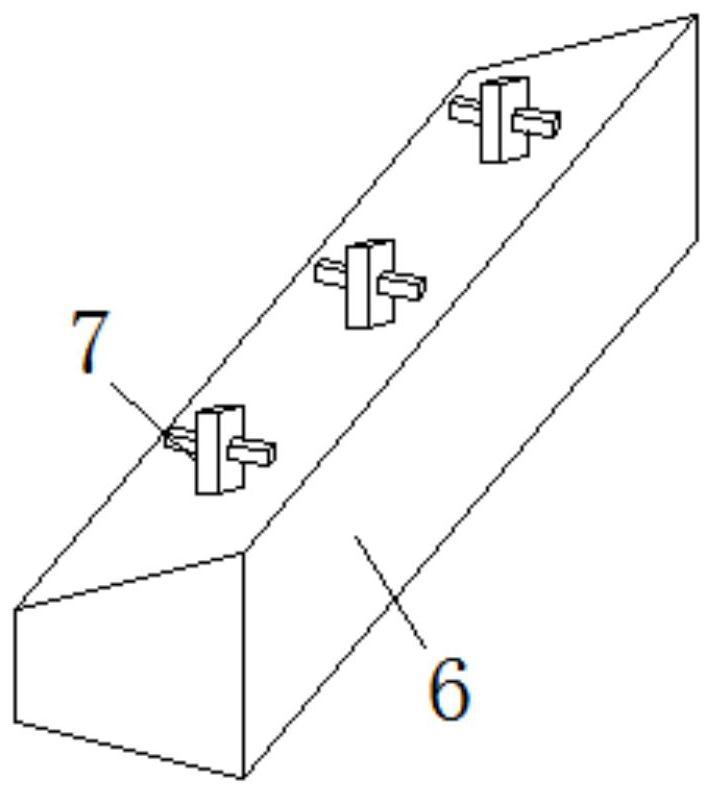

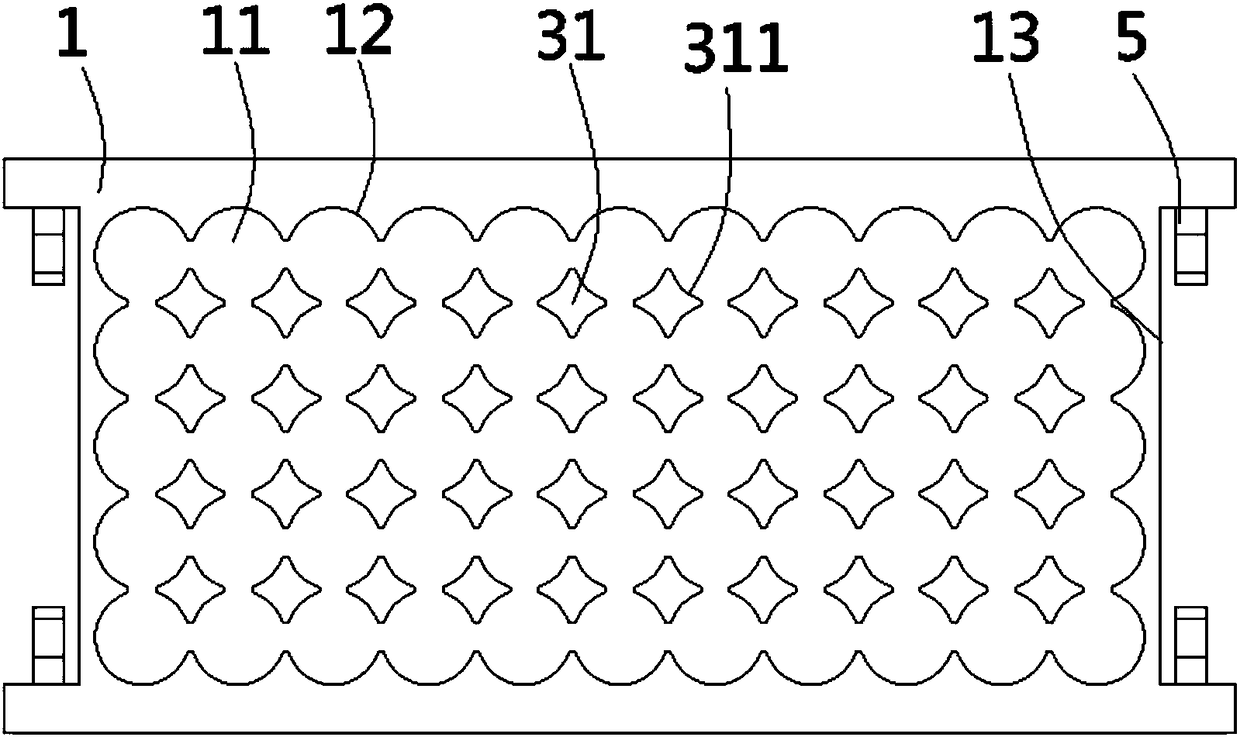

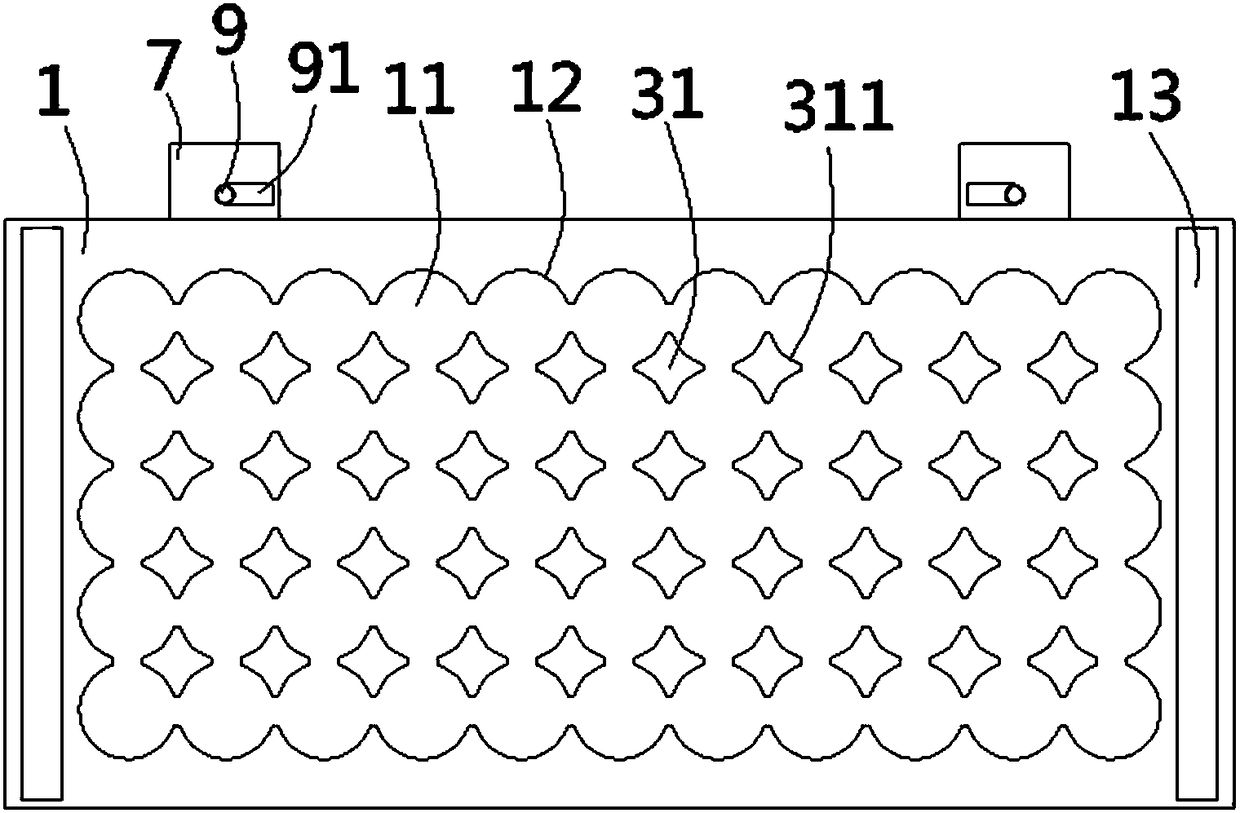

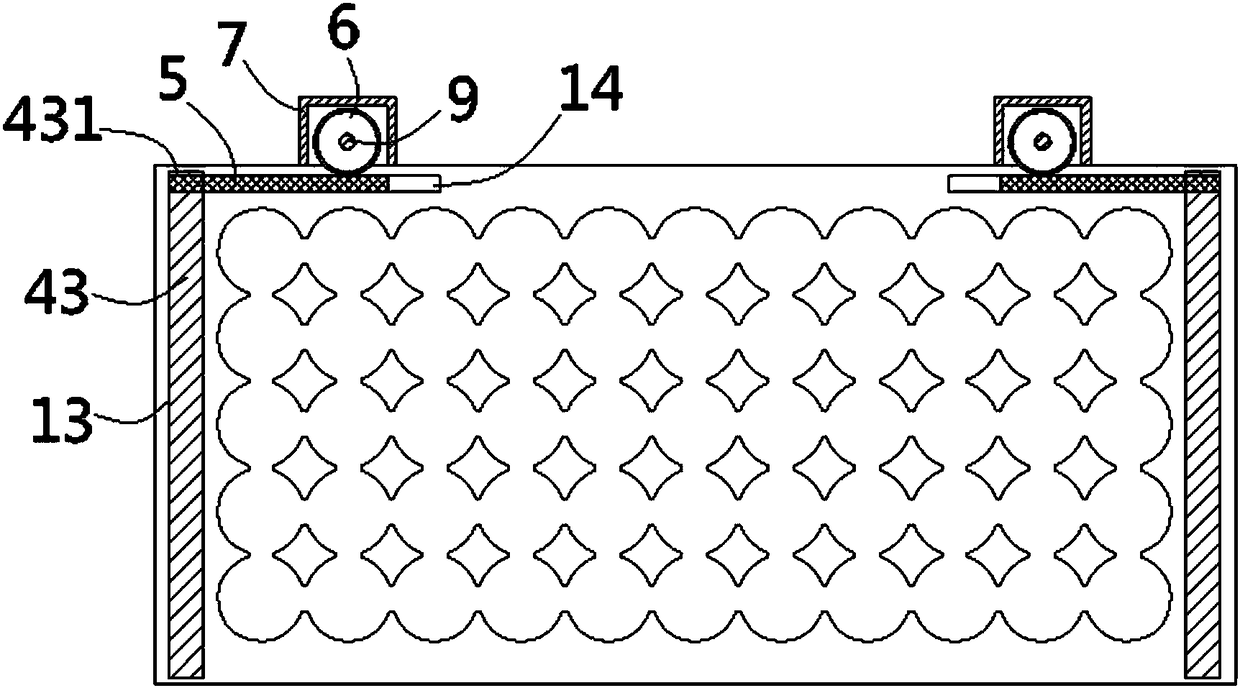

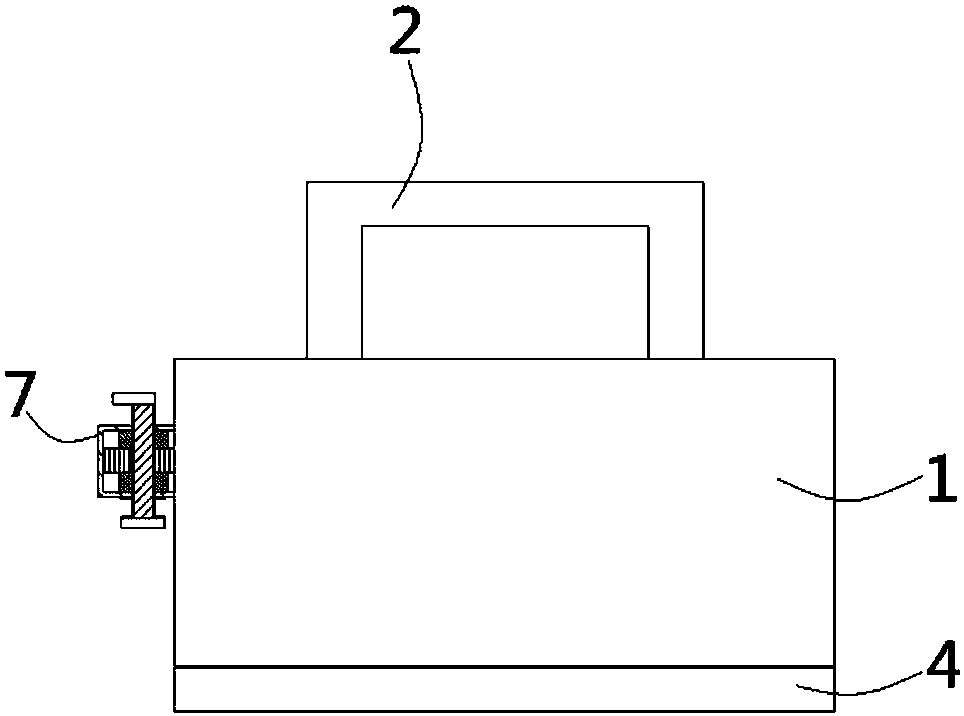

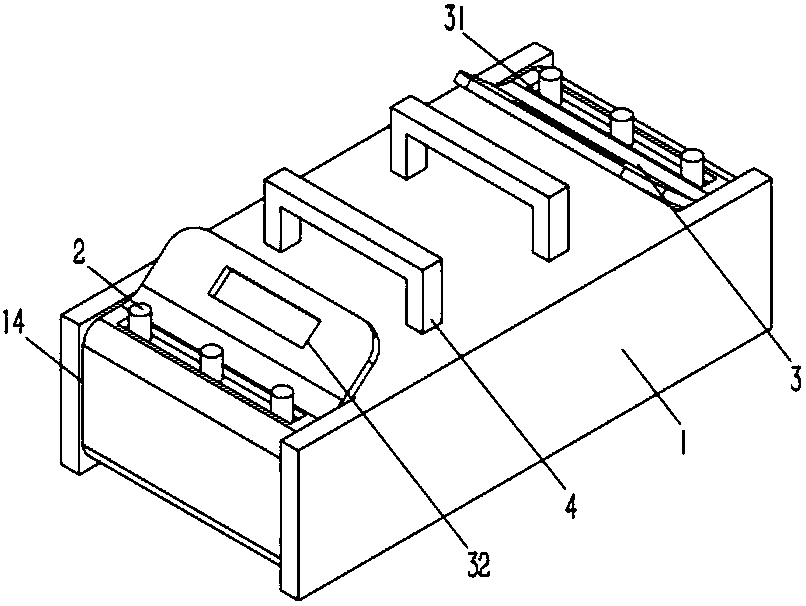

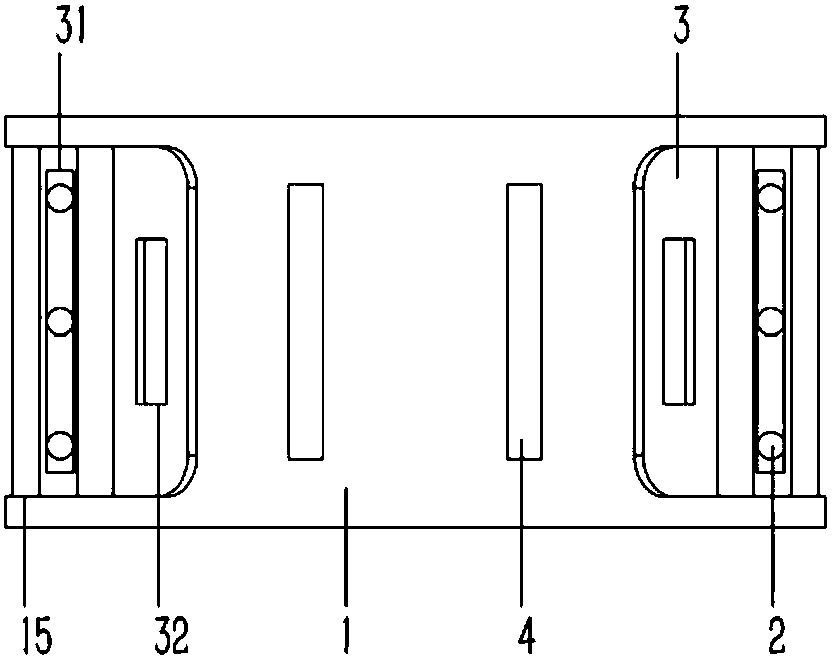

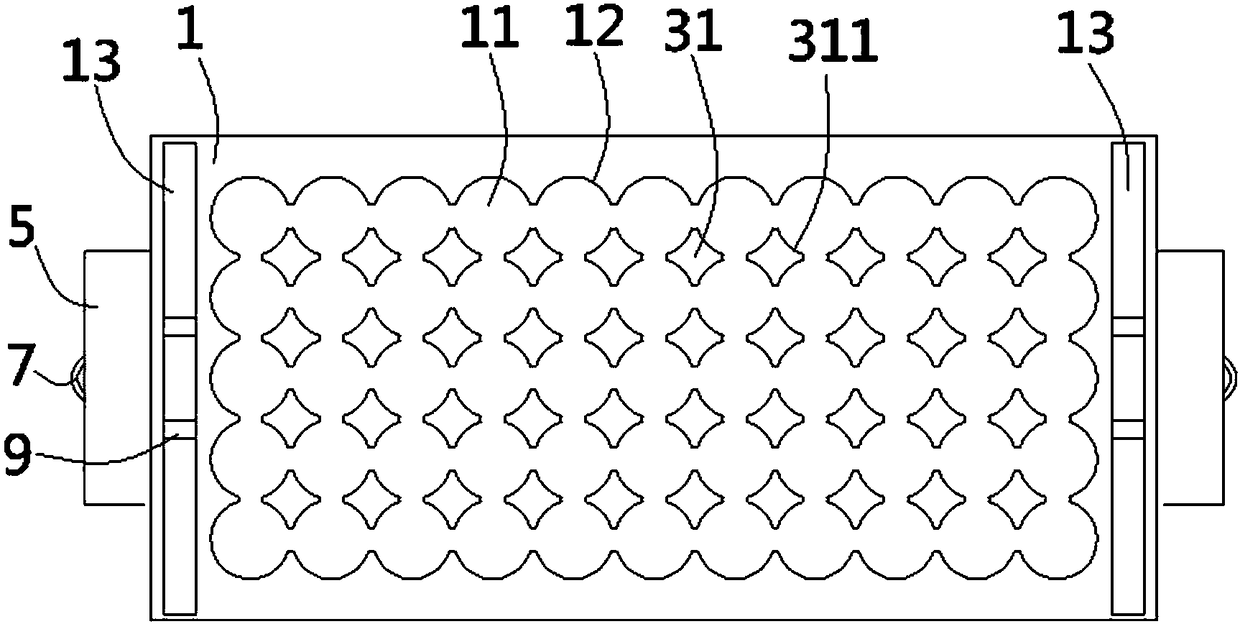

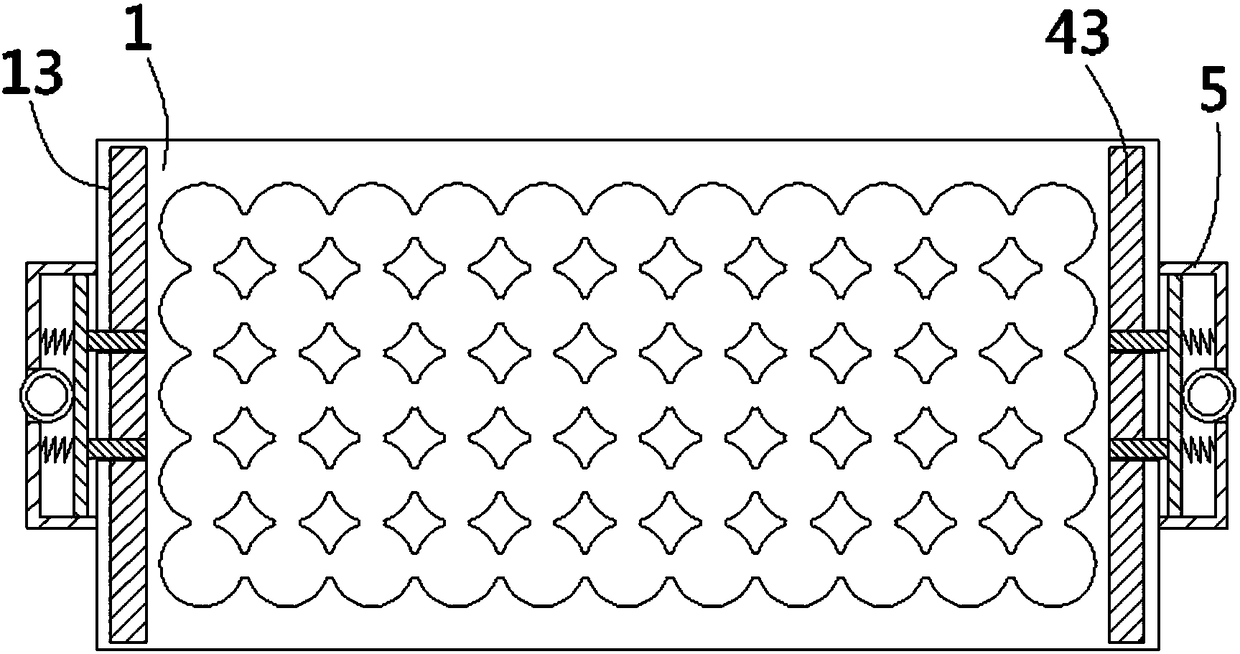

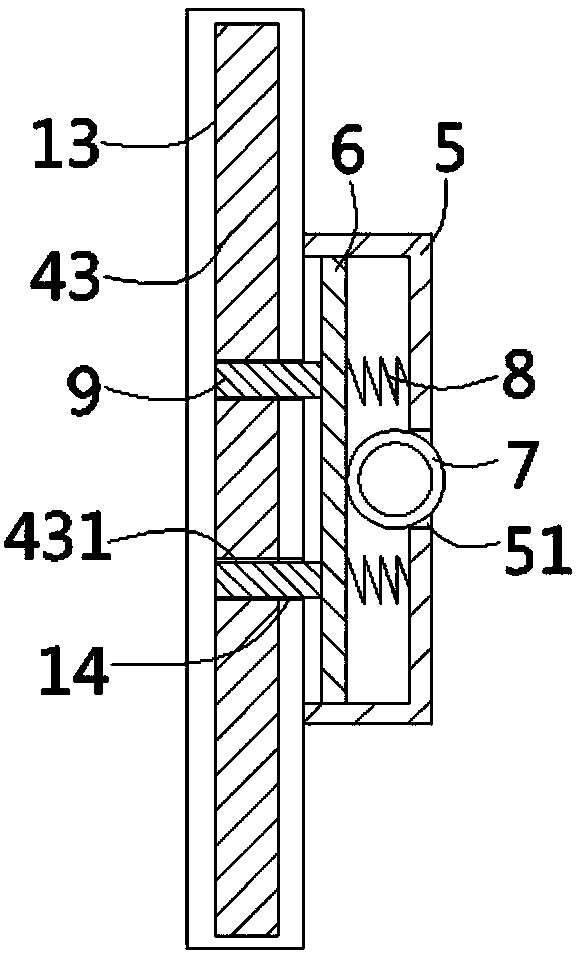

Stacking turnover device for cylindrical standard components

ActiveCN108284974AAchieve connectionEasy to put inIndividual articlesEngineeringMechanical engineering

The invention discloses a stacking turnover device for cylindrical standard components. The device comprises a rectangular box, wherein a placement groove is formed in the lower end surface of the box, multiple prismatic partition columns in array distribution are arranged in the placement groove, partition boards are propped against the lower end surface of the box, a countersunk table corresponding to the placement groove is formed on the upper end surfaces of the partition boards, and prismatic partition blocks corresponding to the partition columns are formed on the bottom surface of the countersunk table; limiting plates are formed on the upper end surfaces of the partition boards on two sides of the countersunk table, rectangular cutting grooves are formed in two side walls of the box, the limiting plates are inserted into the cutting grooves, insert slots are formed in the limiting plates, guiding grooves are formed in the upper end surfaces of the limiting plates, L-shaped locking pieces are inserted into the guiding grooves and the insert slots, locking rods are hinged to two side walls of the cutting grooves, an insert hole is formed in one end of each locking rod, the upper ends of the locking pieces penetrate out of the guiding grooves, and the lower ends of the locking pieces penetrate out of the insert slots and are inserted into the insert holes. According to thestacking turnover device for the cylindrical standard components, stacking operation of mold standard components is realized conveniently, and the mold standard components are conveniently stored inthe box.

Owner:YANGZHOU BENSE LIGHTING TECH CO LTD

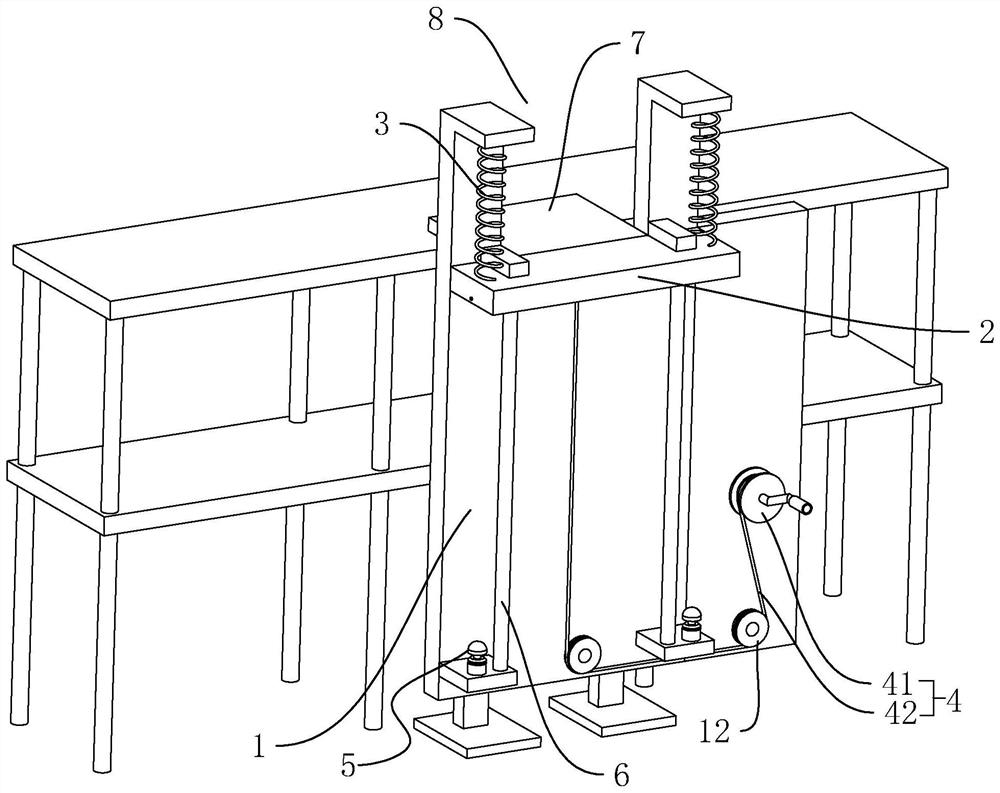

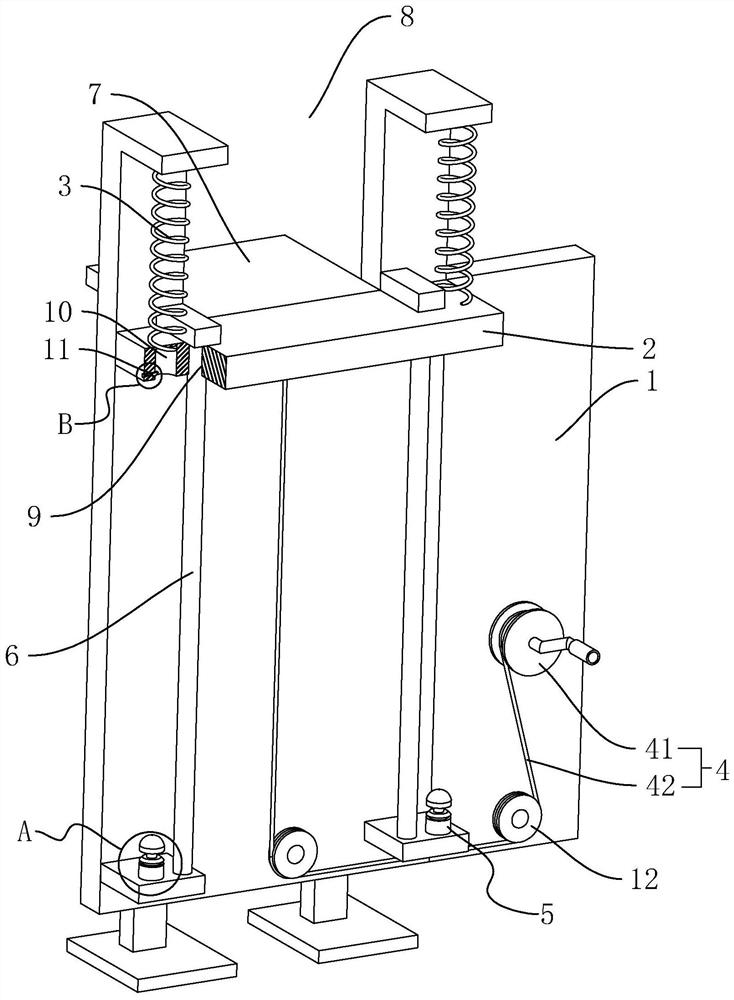

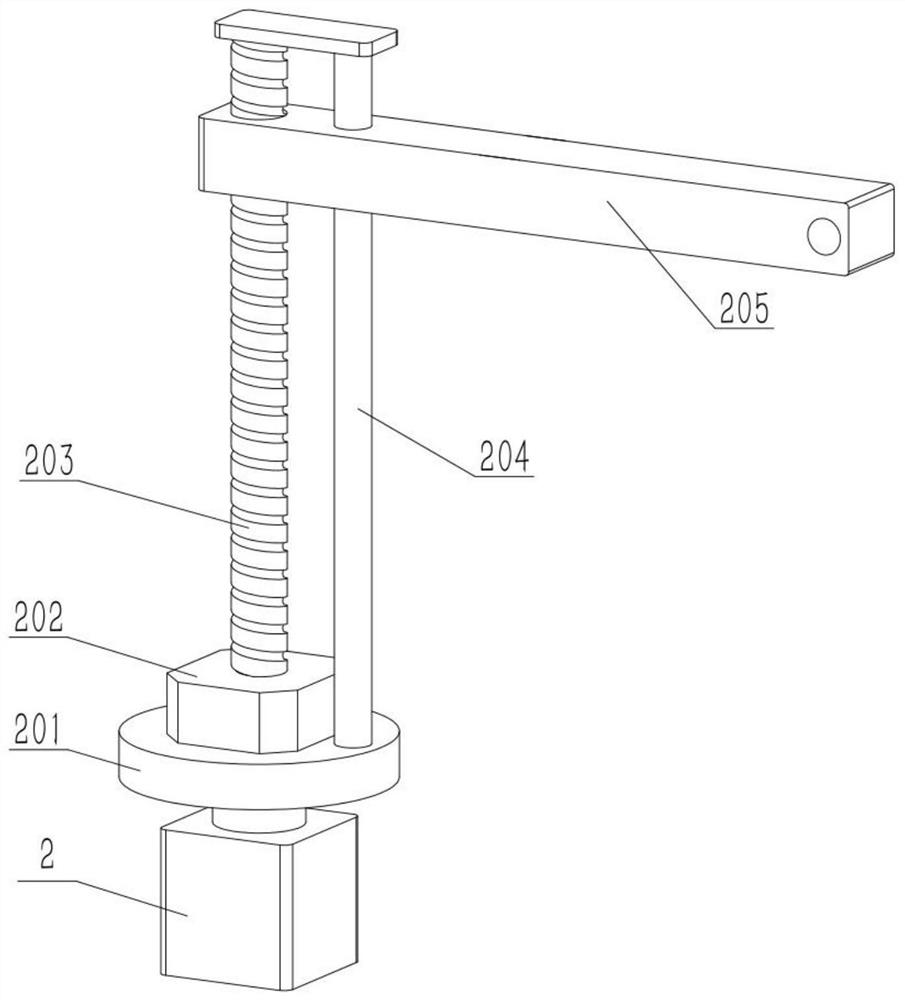

A block lifting structure

ActiveCN111535594BEasy to transportEasy to operateBuilding material handlingElectric machineryStructural engineering

The invention discloses a block lifting structure, which relates to the technical field of construction engineering, and is used for connecting to a heightening device, comprising: a mounting frame, which is arranged vertically; a lifting seat, which slides along the vertical direction Connected to the mounting frame; return spring, the two ends of the return spring are fixedly connected to the mounting frame and the lifting seat respectively, and the lifting seat is set close to the upper end of the mounting frame; the driving assembly is used to move the lifting seat against the elastic force of the returning spring Near the lower end of the mounting frame, the driving assembly includes a winding wheel rotatably connected to the mounting frame, a winding rope fixedly connected to the lower end surface of the lifting seat and connected to the winding wheel. The return spring and the drive assembly are provided, so that the transportation of the blocks is more convenient, and the operation of building the wall is also more convenient. In addition, the intervention of motors or other driving equipment is avoided, so that the operation of building walls is more environmentally friendly.

Owner:中力建设集团有限公司

Auxiliary jig for transferring cylindrical mold standard parts

InactiveCN108408129AAchieve positioningTo achieve a fixed connectionIndividual articlesEngineeringMechanical engineering

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

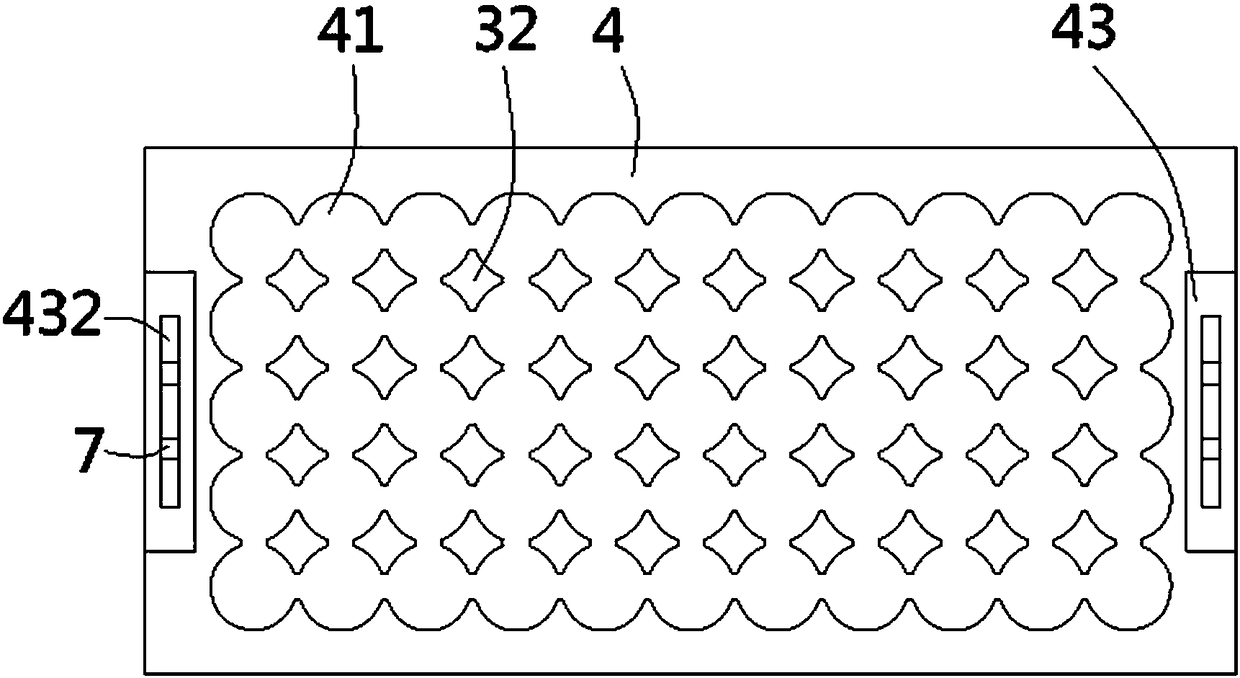

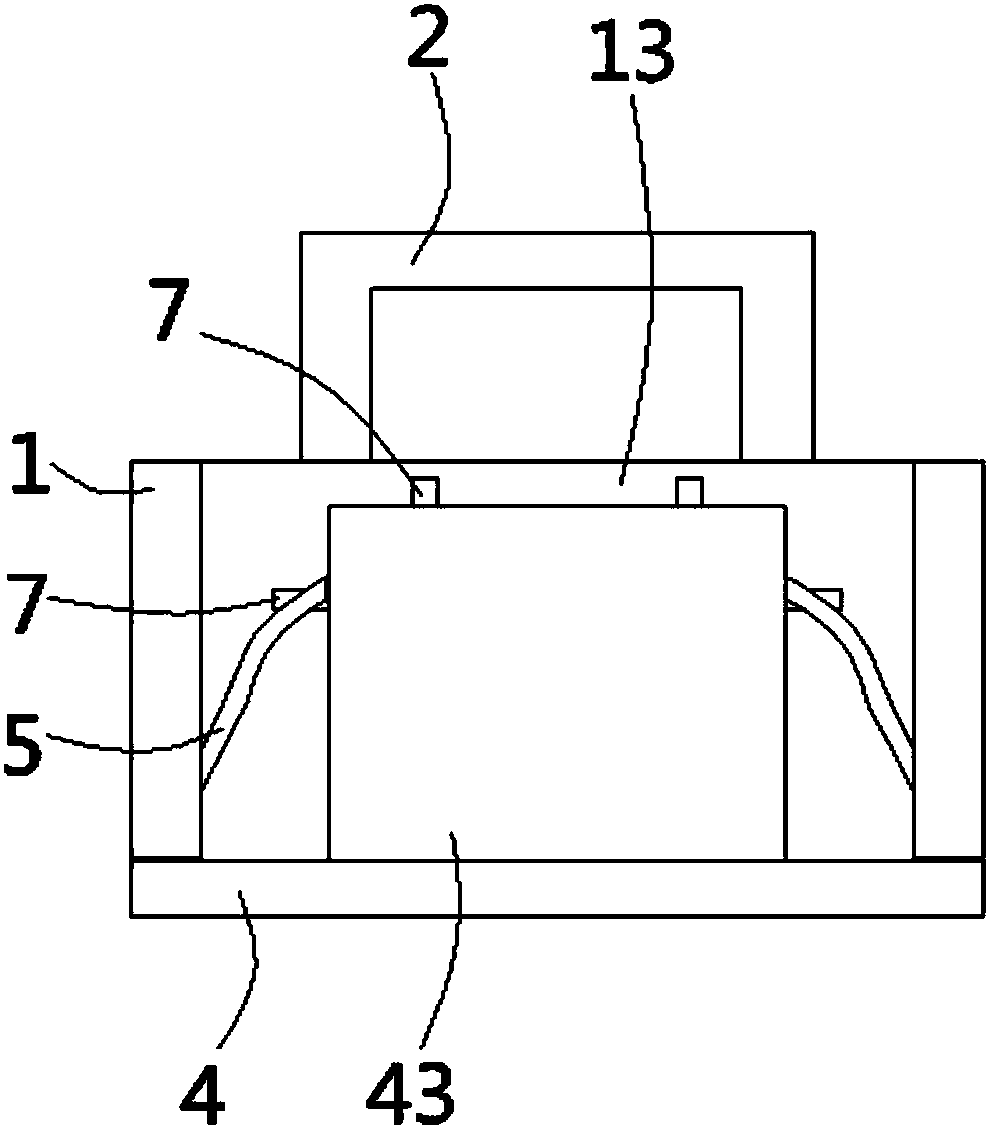

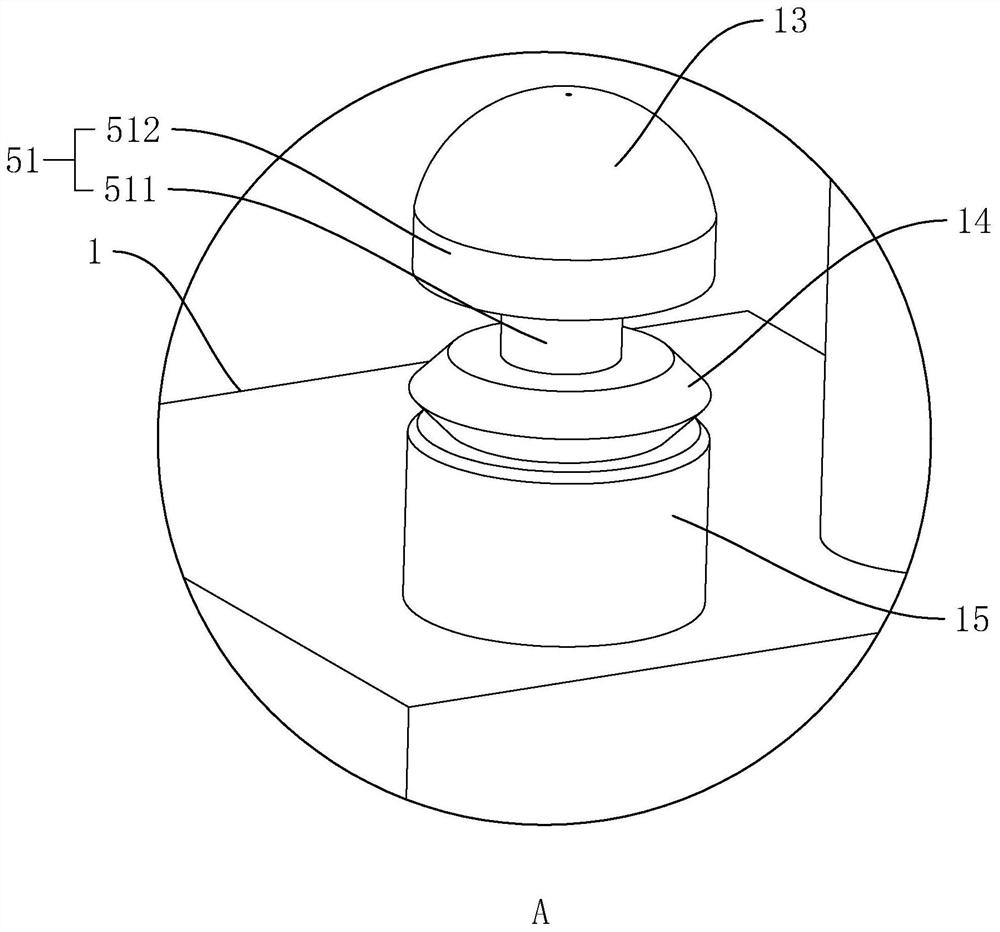

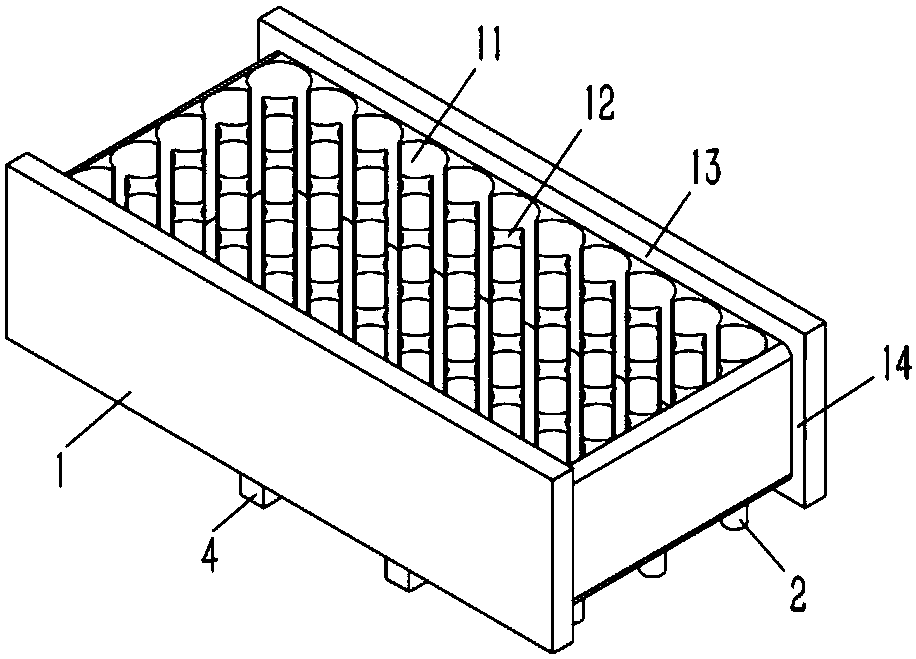

Jig for storing cylindrical mold standard parts

The invention discloses a jig for storing cylindrical mold standard parts. The jig comprises a pass box. A box groove is formed in the lower end surface of the pass box. A plurality of rhombic separating pillars are formed in the box groove. A sinking table is formed on the lower end surface of the pass box. Grooves connected with the sinking table are formed in two sides of the pass box. Slots communicating with the grooves are formed in two sides of the upper end surface of the pass box. A plurality of positioning pillars are fixed to the bottom surfaces of the slots. An elastic flexible board is inserted in the sinking table of the pass box. The two sides of the elastic flexible board are installed in the grooves of the pass box. Handle grooves are formed in the two ends of the elasticflexible board. Positioning groves are formed in the parts, near the handle grooves, of the elastic flexible board. The positioning pillars are inserted in the positioning grooves of the elastic flexible board. A plurality of handles are fixed to the upper end surface of the pass box. The jig is used for arranging the mold standard parts firstly, the mold standard parts are conveniently put into the box and conveniently stacked, the workloads and labor intensity of workers are effectively relieved, and the stacking efficiency of the mold standard parts can be improved.

Owner:DONGGUAN TIANHE ELECTROMECHANICAL DEV CO LTD

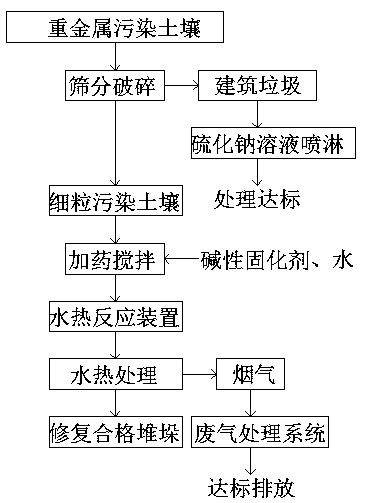

Hydrothermal alkali solidification treatment method for heavy metal contaminated soil

PendingCN111250533AImprove solubilityReduced ability to migrateContaminated soil reclamationSoil scienceSoil remediation

The invention belongs to the technical field of soil remediation, discloses a hydrothermal alkali solidification treatment method for heavy metal contaminated soil, and aims to solve the problems of complex process and poor soil remediation capacity in heavy metal contaminated soil remediation. According to the method, physical remediation and chemical remediation in the prior art are organicallycombined together, the technological process can be shortened, and meanwhile the soil remediation efficiency can be improved; and an alkaline curing agent is easy to obtain and has the characteristicof low cost.

Owner:中冶成都勘察研究总院有限公司

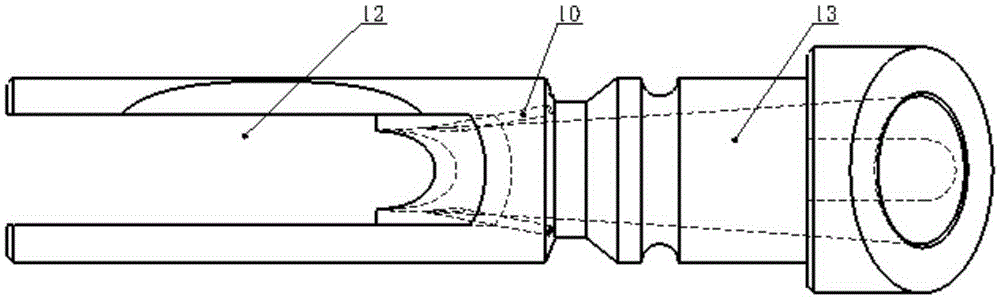

Cotton web bundling mechanism of intelligent combing machine

ActiveCN105369401BRealize secondary cohesionConvey compactCombing machinesEngineeringMechanical engineering

The invention discloses a cotton web bundling mechanism of an intelligent comber. The cotton web bundling mechanism adopts the structure that a first press roller and a second press roller on a supporting seat of the intelligent comber are mutually meshed for transmission; a driving device drives the first pressure roller to rotate; the inlet of a gathering pipe is just positioned behind a drafting output roller; the inlet of a conveying pipe is fixedly communicated with the outlet of the gathering pipe; a bundling horn mouth is fixedly mounted on the supporting seat of the intelligent comber; the inlet of the bundling horn mouth can be communicated with the outlet of the conveying pipe; a horn hole of which the outlet diameter is smaller than the inlet diameter is formed in the inner side of the bundling horn mouth; the meshing point between the first and second press roller just faces the outlet of the bundling horn mouth; a flat groove is formed in the side wall positioned at the outlet end of the bundling horn mouth; the mutually meshed ends of the first and second press rollers are just inserted into the flat groove; the meshing point between the first and second press roller is just positioned in the flat groove. Through adoption of the cotton web bundling mechanism, the cohesive force of gathered cotton slivers is remarkably improved, so that the cotton slivers are not easy to loosen when being conveyed on a conveying belt and not easy to break at a turning point, and then high-speed conveying and convenient maintenance of the cotton silvers are facilitated.

Owner:JIANGSU KAIGONG MACHINERY

A high-strength and easy-to-lap building brick

ActiveCN112095906BGood stitchingIncrease usage intensityHeat proofingSound proofingBrickInsulation layer

The invention discloses a high-strength and easy-to-lap building brick, which comprises a building brick body, a concrete layer and a hard material layer, a lateral fixing block is fixedly installed on the left side of the building brick body, and the building brick body The right side is fixedly equipped with a clamping block, and the upper and lower sides of the clamping block are fixedly connected with side guide blocks, the sides of the second reinforcing rib are fixedly connected with connecting steel bars, and the lower end of the second reinforcing rib is installed with concrete layer, the lower end of the sound-absorbing board is fixedly installed with a built-in vertical block, and the built-in vertical block is fixedly installed above the insulation layer, the moisture-proof layer is installed in the middle of the insulation layer and the hard material layer, and the exhaust pipe The outer end fits inside the flow hole. The high-strength and easy-to-lap building bricks can improve their own use strength and facilitate the splicing between adjacent building bricks. At the same time, they can play a certain role in sound insulation and noise reduction when used in buildings, and can Play a certain flame retardant effect.

Owner:浙江金州科技有限公司

A robot grabbing mechanism

InactiveCN111185932BIncreased access to the interior of the cargo compartmentAuxiliary loading and unloading operationsGripping headsHand partsShaped beam

Owner:HARBIN UNIV OF COMMERCE

Circulation mechanism for storing cylindrical mold standard parts

InactiveCN108408210AAchieve connectionDisconnectContainer handlesExternal fittingsEngineeringComputer engineering

Owner:DONGGUAN LIANZHOU INTPROP OPERATION MANAGEMENT CO LTD

A two-way pressurized stable limit brick making machine

ActiveCN112497431BScientific and reasonable structureEasy to useAuxillary shaping apparatusShaping press ramBrickClassical mechanics

The invention discloses a two-way pressurized stable limit brick making machine, which comprises a fixed seat, a fixed top plate is installed on the top of the fixed seat, a multi-pressure exhaust mechanism is installed on the bottom of the fixed top plate, and the multi-pressure The exhaust mechanism includes a hydraulic rod, a connecting plate, a briquetting block, a casing, a slide block, a rubber plug, a multi-pressure spring, a pressing plate, a vent hole, an exhaust hole, a connecting rope and a rubber post. The present invention can use the multi-pressure exhaust mechanism to Multi-stage pressure is applied during the material pressing process, so that the pressure of the material can be increased step by step, and the pressure received during the separation process of the material and the shell can also be reduced step by step, and then the material is suddenly subjected to pressure during the pressing process. Huge pressure or separation causes the formed bricks to break, and also enables the material to quickly discharge gas during the pressing process. At the same time, when the shell and the brick are separated, the inside of the vent hole can be cleaned, which is also convenient for the surface of the brick and the shell. separate.

Owner:TANGSHAN COLLEGE

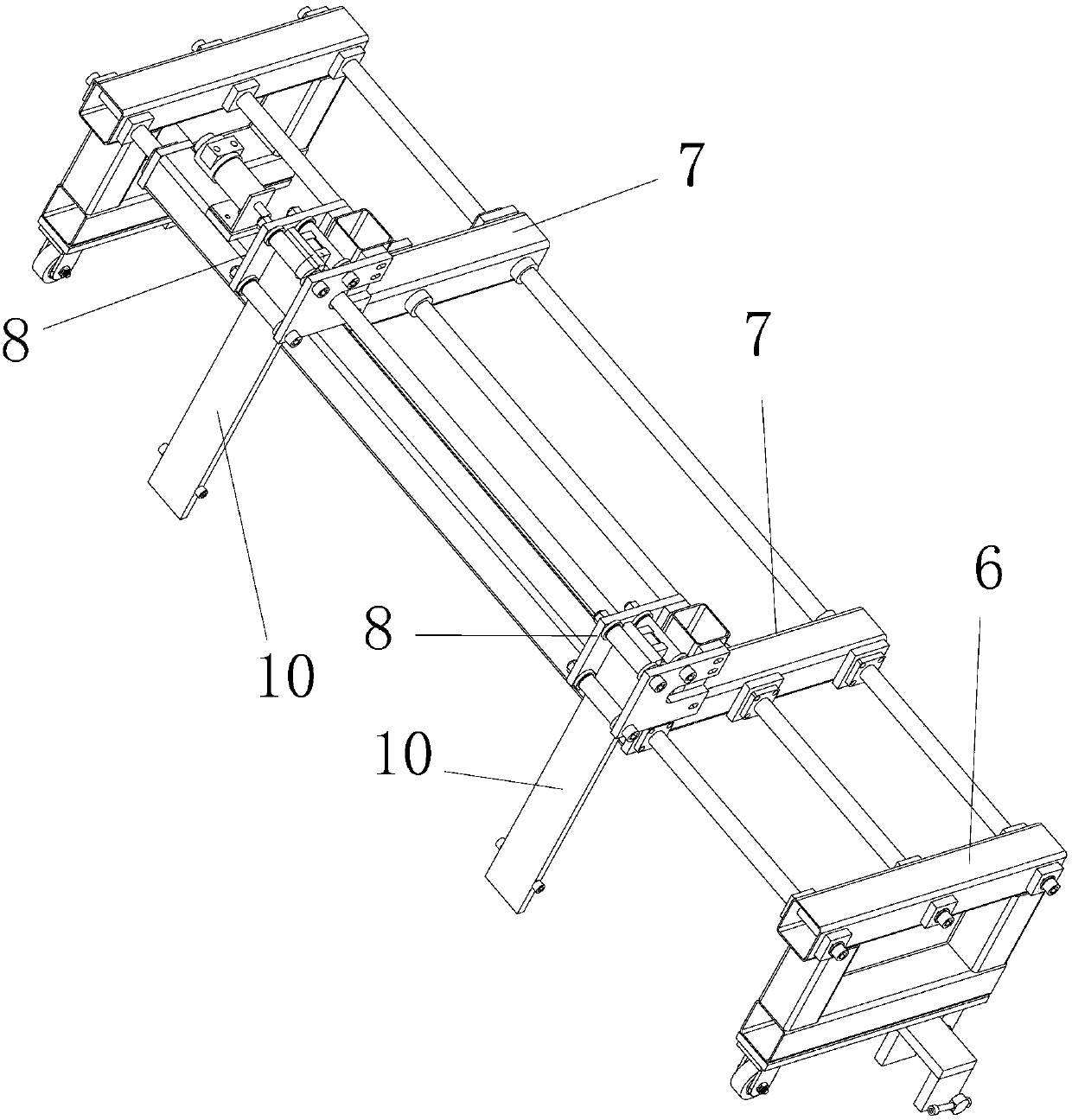

Sheet metal shearing automatic material collecting machine for power distribution cabinet

InactiveCN107804698AEasy stackingAvoid manual stackingConveyorsStacking articlesEngineeringMechanical engineering

The invention relates to a sheet metal shearing automatic receiving machine for a power distribution cabinet, which includes a blanking carriage, a slide plate is arranged on the upper end of the blanking carriage, and the blanking carriage is located in a plate blanking area; The plate blanking area is provided with two receiving slide rails; horizontal cylinders are arranged on the left and right inside the blanking carriage, and the push rods of the horizontal cylinders are connected to the push tubes, and a plurality of horizontal push plates are vertically arranged on the push tubes; The right rear end of the blanking carriage is provided with a longitudinal cylinder, the push rod of the longitudinal cylinder is connected to the longitudinal push plate, and the front end of the right side of the blanking carriage is provided with a front stopper, and the operation of the longitudinal cylinder drives the longitudinal push plate on the plate. The part blanking area moves back and forth. It is convenient to stack sheet metal, and then facilitate subsequent unified transportation, avoiding manual stacking of sheet metal.

Owner:仪征恒运电器有限公司

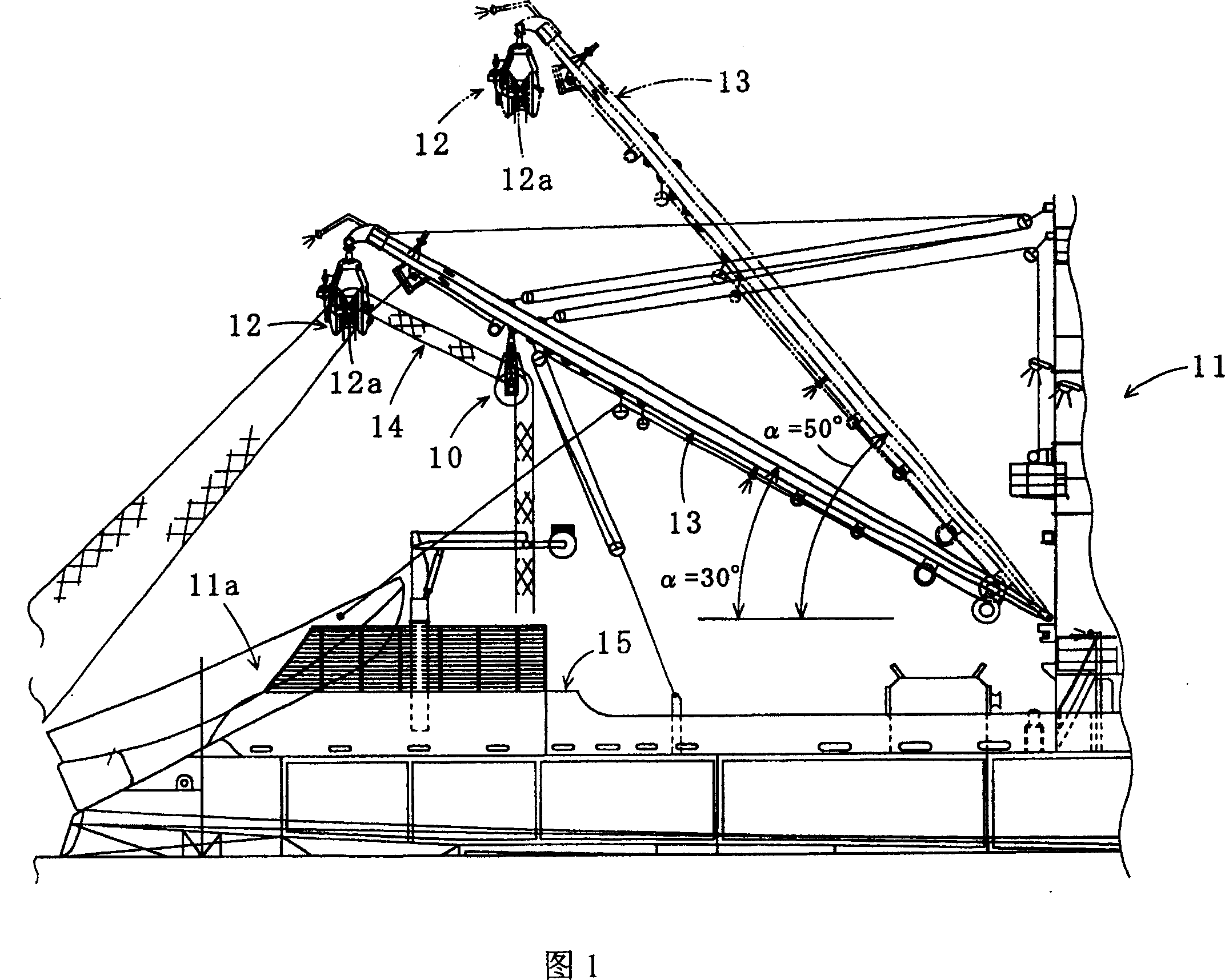

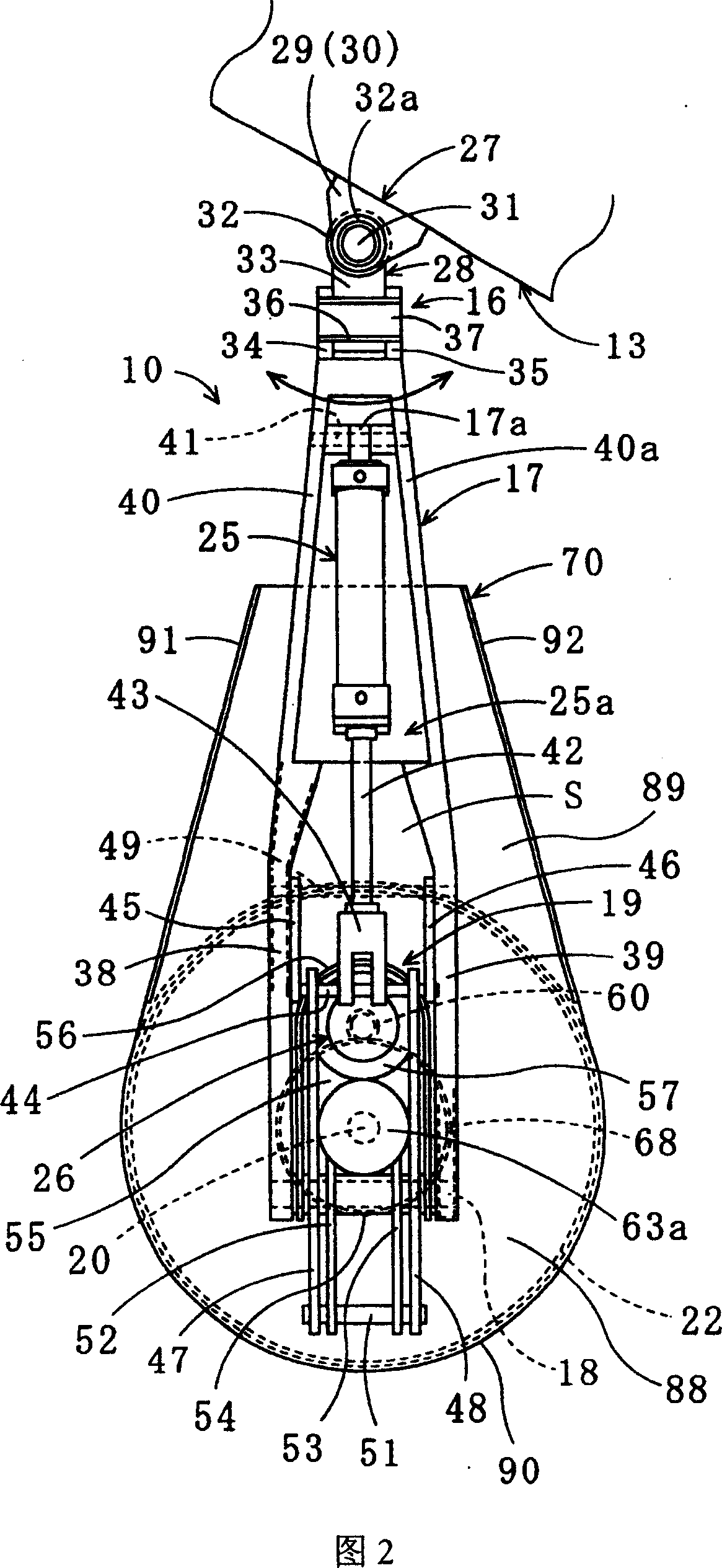

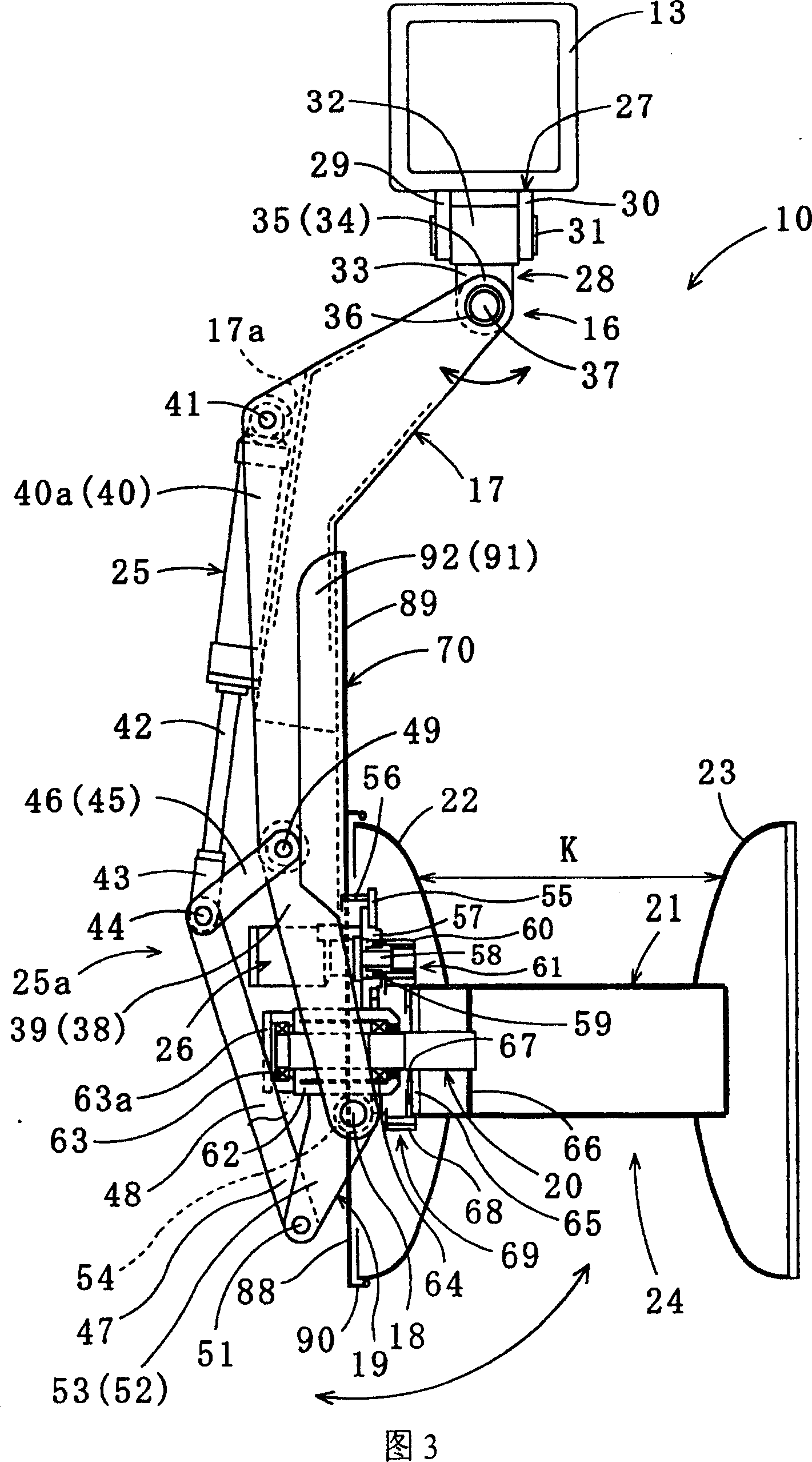

Hauling auxiliary drum device and hauling method

ActiveCN100366150CLower center of gravityImprove stabilityFishing netsAgricultural fishingHydraulic cylinderEngineering

This net-lifting auxiliary roller unit 10 is arranged in an intermediate part of a tilting mast 13 of which the top is attached with a net-lifting machine 12 and guides the fishing net 14 lifted by the net-lifting machine 12, wherein the unit is equipped with a suspension support member 17 of which the top end 16 is coupled with the intermediate part of the tilting mast 13, a base member 19 which is tiltably attached to a bottom part of the suspension support member 17 through a support pin 18, a cylindrical roller main body 21, and side plates 22, 23 which are supported on both ends of the main body 21 and form a pair, further the unit is equipped with a flanged roller 24 which is rotatably attached to the base member 19 through a shaft part 20 in a cantilevered state and a hydraulic cylinder 25 of which the one end is attached to the suspension support member 17, and furthermore the unit has a link mechanism 25a which tilts the base member 19 to the suspension support member 17. The invention provides a net-lifting auxiliary roller unit capable of safely conducting loading work of a fishing net in a short time, even in stormy weather, and capable of improving stability of a ship, and to provide a net-lifting method.

Owner:MARINE HYDROTEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com