Automatic paper collecting stacker

A technology for paper stacking and paper stacking, which is applied in the field of automatic paper stacking machines to achieve the effects of reducing human resources, facilitating paper stacking, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

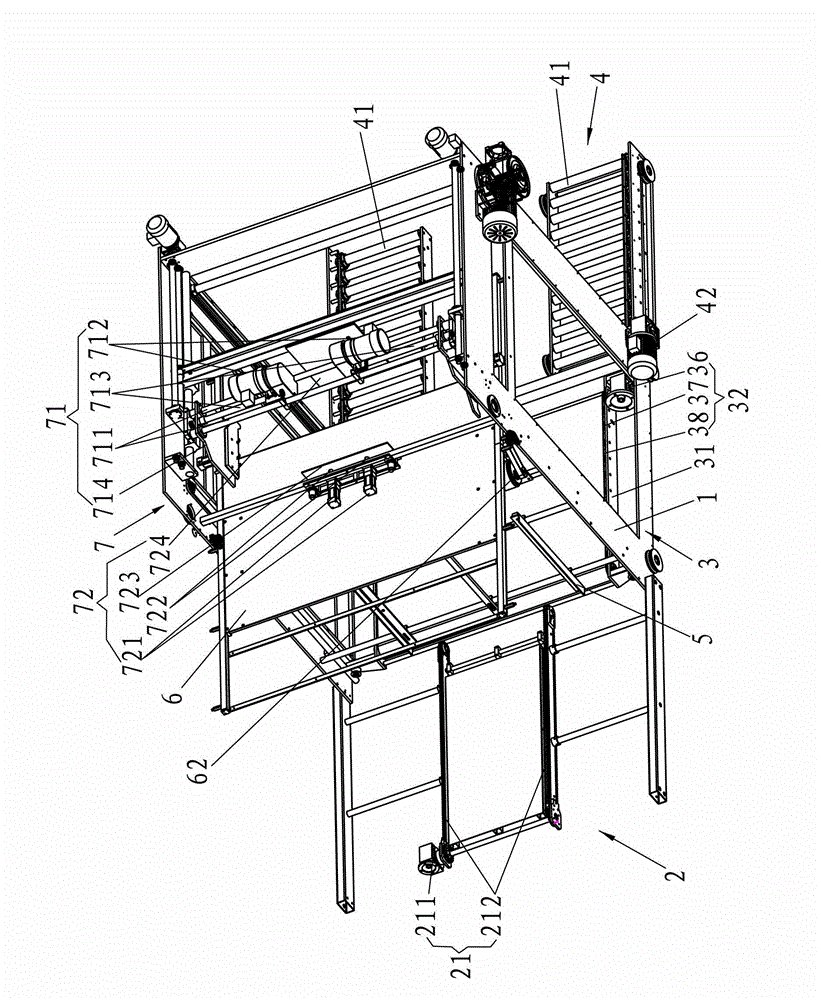

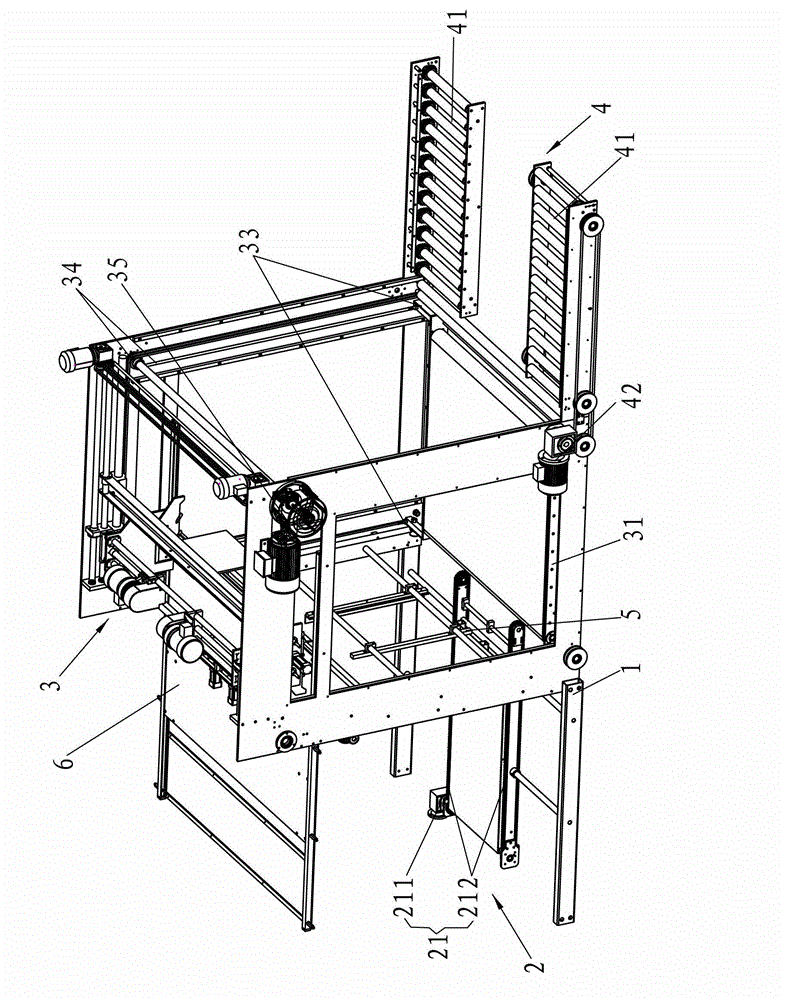

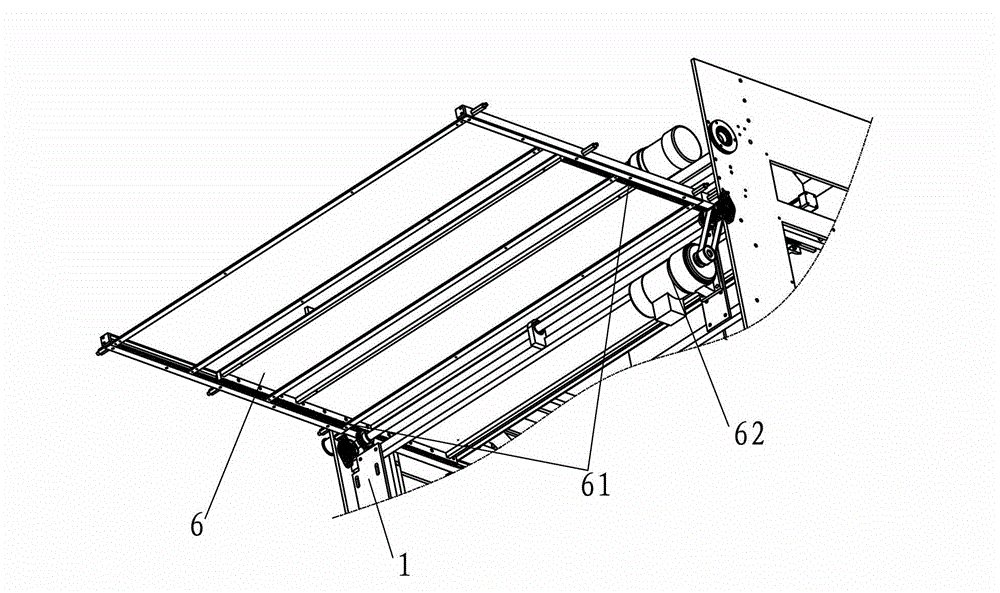

[0018] Attached below Figure 1-3 The present invention is further elaborated:

[0019] An automatic paper collection stacker, the paper collection stacker includes a frame 1, and a pallet conveying platform 2, a paper collecting stacking lifting platform 3 and a discharge platform 4 are sequentially arranged on the frame 1; the pallet conveying platform 2. Set up a pallet conveying device 21 for conveying the pallets to the paper delivery stacking lifting platform 3, the paper delivery stacking lifting platform 3 includes a stacking bottom plate 31, and the stacking bottom plate 31 is lifted and arranged on the frame 1, The upper end of the frame 1 is provided with a paper inlet 11 , and the stacking bottom plate 31 is provided with a stacking conveying device 32 for sending the stacked paper to the discharge table 4 .

[0020] As a preferred embodiment, the pallet conveying device 21 of this embodiment is a pair of conveying chains 212 driven by a pallet motor 211, which ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com