Hydrothermal alkali solidification treatment method for heavy metal contaminated soil

A technology for contaminated soil and solidification treatment, applied in the field of soil remediation, can solve problems such as poor soil remediation ability and complex process, and achieve the effects of easy acquisition, shortening the process flow, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

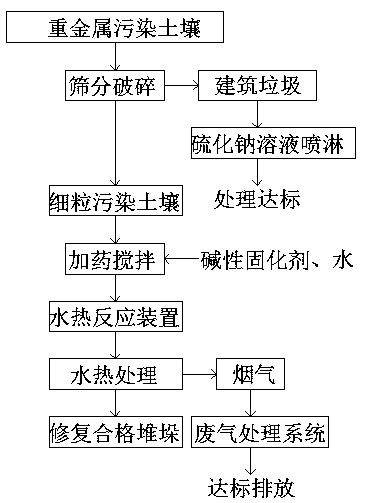

Image

Examples

Embodiment 1

[0048] The repairing method of the present embodiment comprises the steps:

[0049] (1) Send the polluted soil to the screening equipment for screening to remove the construction waste with a particle size larger than 50mm, and send the polluted soil after removing the construction waste to the crushing equipment for crushing to obtain fine-grained polluted soil with a particle size of ≤25mm;

[0050] (2) Add an alkaline curing agent to the fine-grained contaminated soil, the weight percentage of the alkaline curing agent and fine-grained soil is 10; medicinal soil;

[0051] (3) Put the dosing soil in the hydrothermal reaction device, close the hydrothermal reaction device, raise the temperature of the sealed hydrothermal reaction device to 60 ° C, seal and keep it for 1 hour, and obtain the repaired soil that meets the standard.

[0052] In this embodiment, the alkaline curing agent is lime.

Embodiment 2

[0054] The repairing method of the present embodiment comprises the steps:

[0055] (1) Send the polluted soil to the screening equipment for screening to remove the construction waste with a particle size larger than 50mm, and send the polluted soil after removing the construction waste to the crushing equipment for crushing to obtain fine-grained polluted soil with a particle size of ≤25mm;

[0056] (2) Add an alkaline solidifying agent to the fine-grained contaminated soil, the weight percentage of the alkaline solidifying agent and the fine-grained soil is 30; then add an appropriate amount of water and stir evenly to obtain a compound with a moisture content of 25%. medicinal soil;

[0057] (3) Put the dosing soil in the hydrothermal reaction device, close the hydrothermal reaction device, raise the temperature of the sealed hydrothermal reaction device to 180 ° C, seal and keep it for 15 hours, and obtain the repaired soil that meets the standard.

[0058] In this embod...

Embodiment 3

[0060] The repairing method of the present embodiment comprises the steps:

[0061] (1) Send the polluted soil to the screening equipment for screening to remove the construction waste with a particle size larger than 50mm, and send the polluted soil after removing the construction waste to the crushing equipment for crushing to obtain fine-grained polluted soil with a particle size of ≤25mm;

[0062] (2) Add an alkaline curing agent to the fine-grained polluted soil, the weight percentage of the alkaline curing agent and the fine-grained soil is 25; medicinal soil;

[0063] (3) Put the dosing soil in the hydrothermal reaction device, close the hydrothermal reaction device, raise the temperature of the sealed hydrothermal reaction device to 100°C, seal and keep it for 8 hours, and obtain the repaired and qualified soil.

[0064] In this embodiment, the alkaline curing agent is sodium bicarbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com