Two-way pressurization stable limiting brick making machine

A two-way pressurized and stable technology, applied in the direction of ceramic molding machines, manufacturing tools, forming indenters, etc., can solve the problems of difficult demoulding of bricks, easy adhesion of bricks to the surface of briquetting blocks, and fracture of bricks under pressure. It achieves the effect of facilitating diversion and utilization, improving classification work efficiency, and safe and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

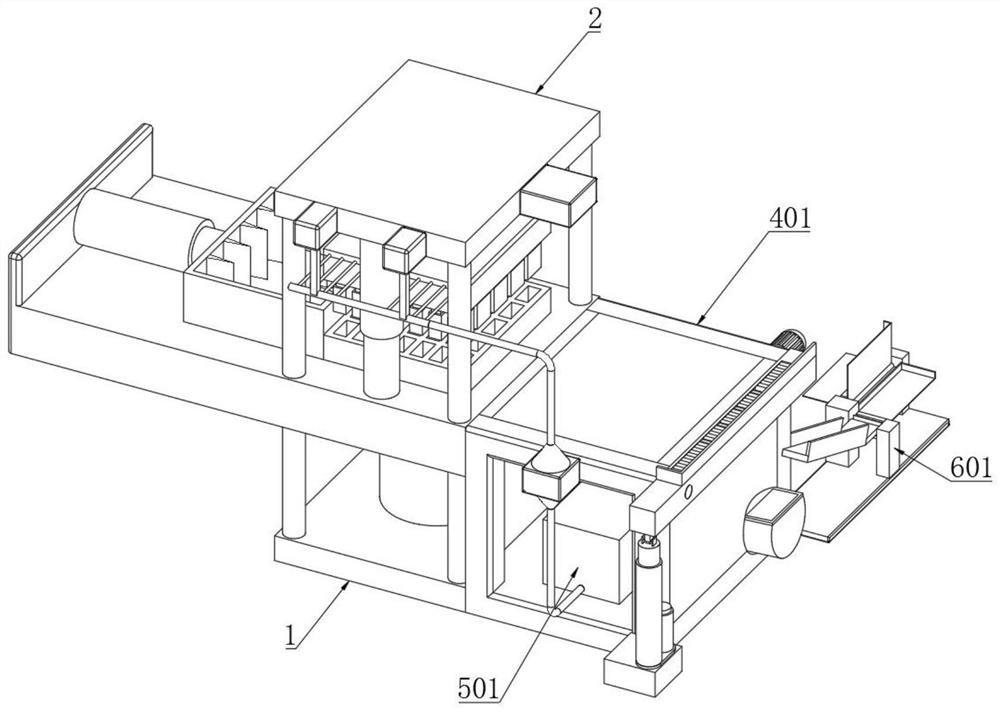

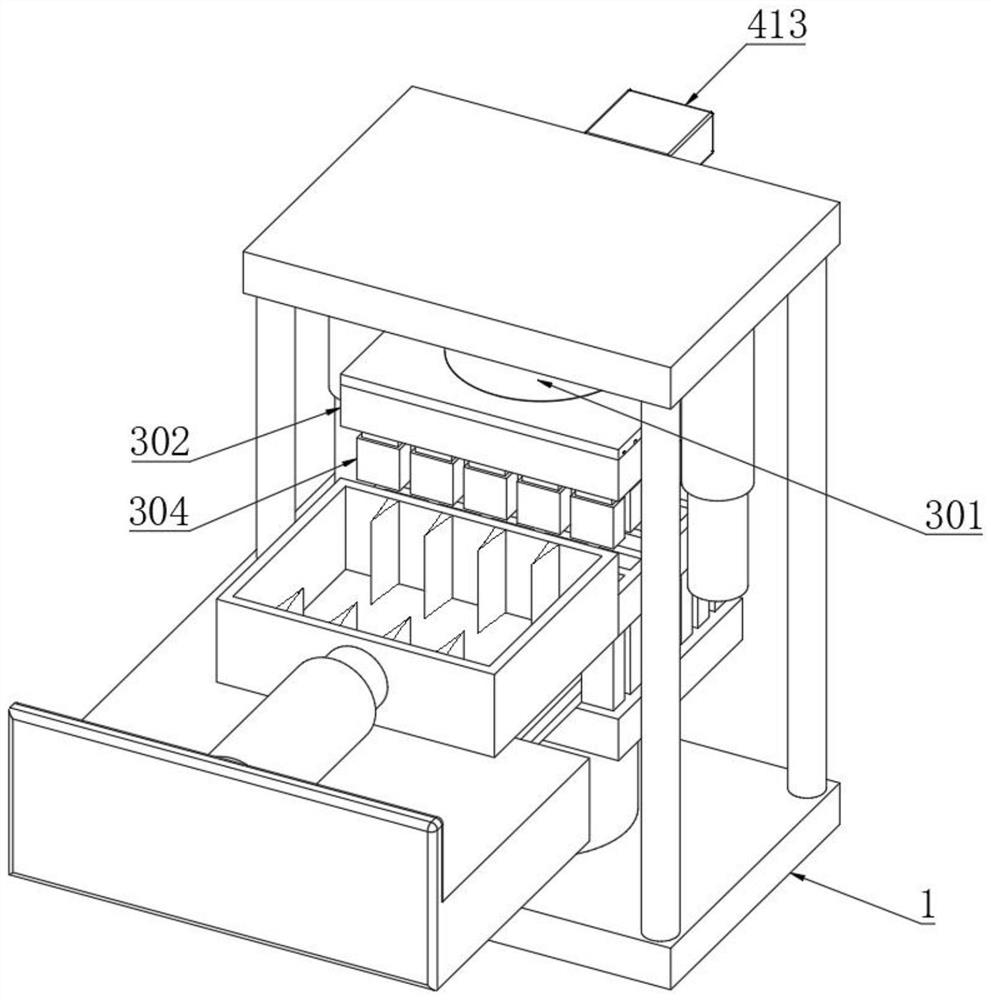

[0048] Example: such as Figure 1-10 As shown, the present invention provides a technical solution, a two-way pressurized stable limit brick making machine, including a fixed seat 1, and a fixed top plate 2 is installed on the top of the fixed seat 1, in order to facilitate the staff to carry out step-by-step construction of materials. Pressure treatment, the bottom of the fixed top plate 2 is equipped with a multi-pressure exhaust mechanism 3;

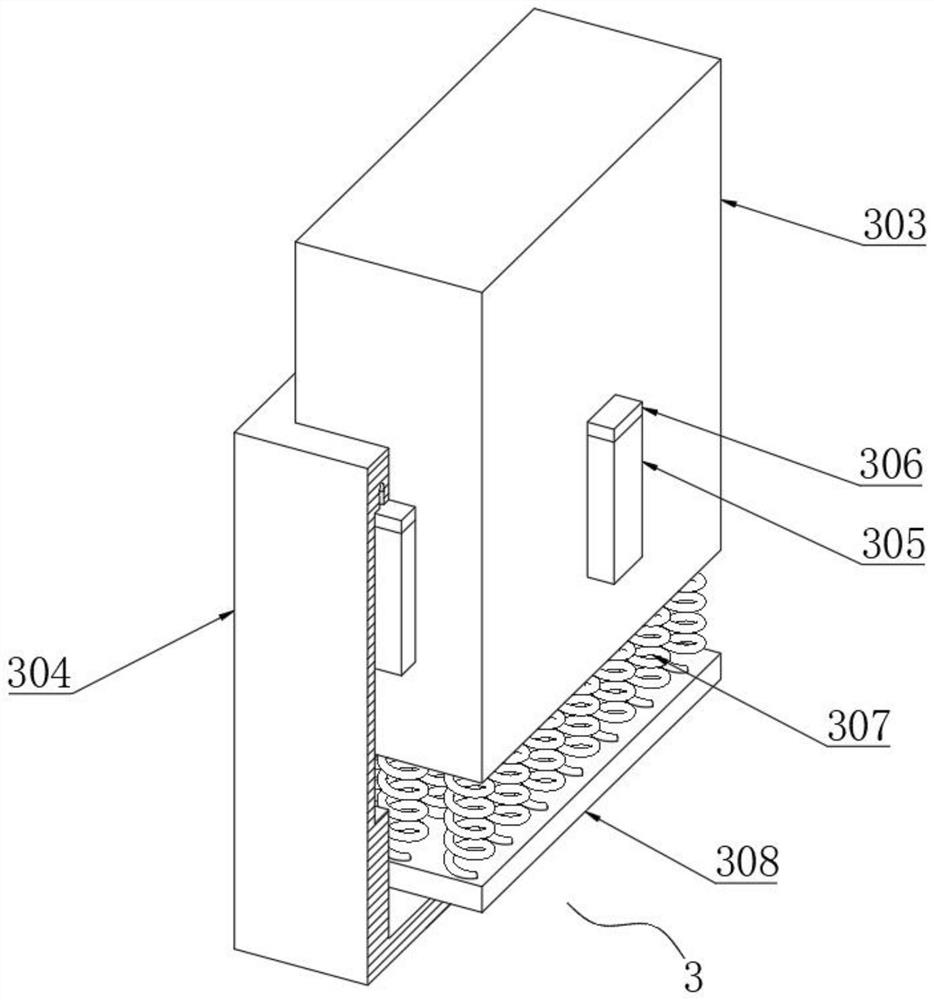

[0049] The multi-pressure exhaust mechanism 3 includes a hydraulic rod 301, a connecting plate 302, a briquetting block 303, a casing 304, a slider 305, a rubber plug 306, a multi-pressure spring 307, a pressing plate 308, an air hole 309, an air vent 310, and a connecting rope 311 and rubber column 312;

[0050] A hydraulic rod 301 is installed in the middle of the bottom of the fixed top plate 2, and a connecting plate 302 is installed at the bottom of the hydraulic rod 301. The bottom of the connecting plate 302 is in a square arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com