Manually-assembled foundation

A prefabricated and basic technology, applied in infrastructure engineering, construction, etc., can solve the problems of inconvenient movement, inability to disassemble the base plate, waste of cost, etc., and achieve the effect of enhancing shear resistance, increasing weight, and avoiding relative torsion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

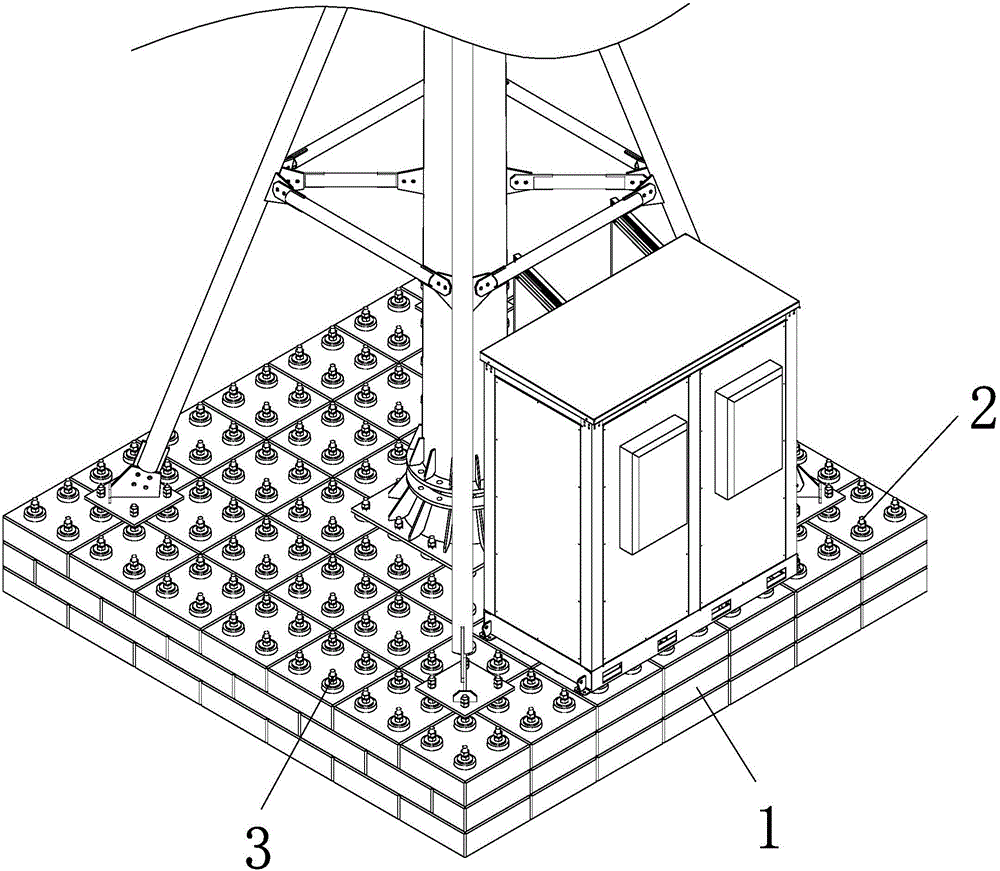

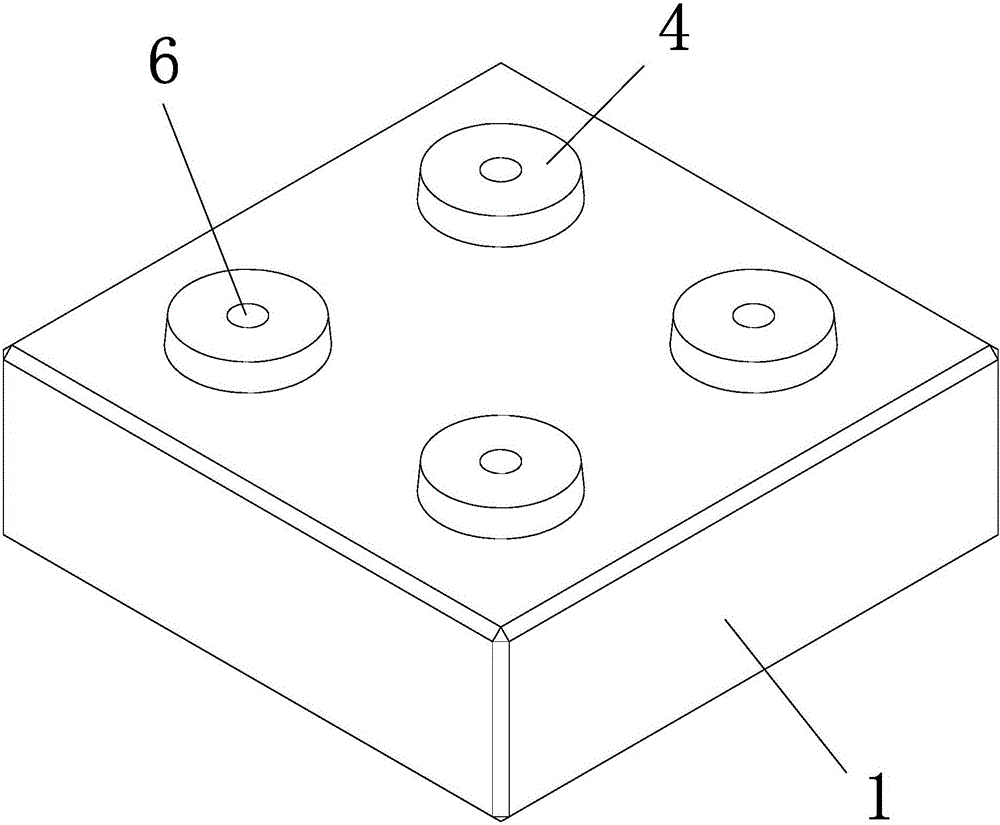

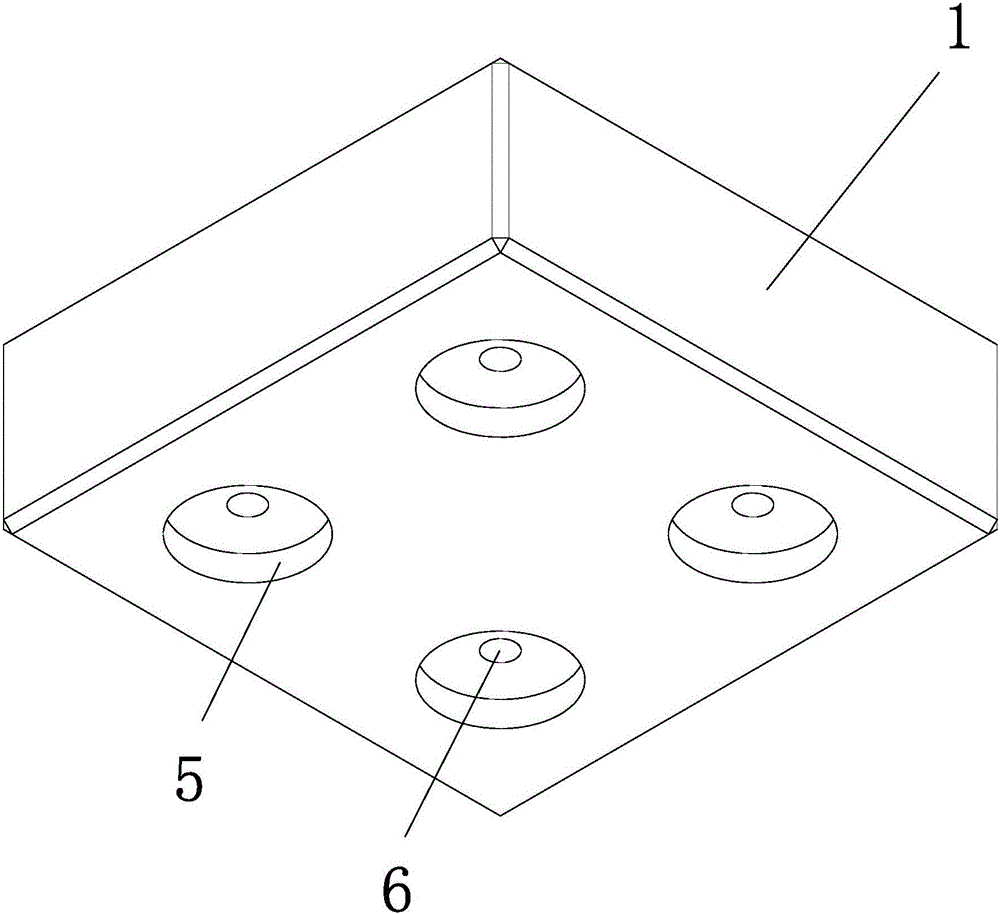

[0023] Embodiment 1: as figure 1 , 2 As shown in , 3, a kind of artificial assembly type foundation, comprises basic unit block 1, and basic unit block is square, and the upper surface corner of basic unit block is provided with positioning projection 4, and the lower surface of basic unit block is provided with another The positioning protrusion of a basic unit block matches the positioning pit 5, and the positioning protrusion runs through the basic unit block to be provided with a positioning hole 6, the positioning hole runs through a positioning rod 2, and the upper end of the positioning rod is provided with a lock nut 3. Such as Figure 4 As shown, the distance between the axes of the two positioning protrusions is twice the distance from the axis of the positioning protrusions to the two adjacent sides of the basic unit, and the positions of two adjacent basic unit blocks up and down are staggered.

[0024]The basic unit block is made of pre-cast concrete, and the ba...

Embodiment 2

[0025] Embodiment 2: The structure of this embodiment is basically the same as that of Embodiment 1, the difference is that, as Figure 5 , 6 As shown, two adjacent sides of the basic unit block are provided with limiting protrusions 7, and the other two adjacent sides are provided with limiting protrusions corresponding to the limiting protrusions of another basic unit block of the same structure. Matching limit groove 8. The basic unit block is provided with a fixing hole 9, and a wooden positioning sleeve 10 is arranged in the fixing hole. The height of the wooden positioning sleeve is the same as the thickness of the basic unit block, and the upper end of the wooden positioning sleeve protrudes from the surface of the basic unit block to form a positioning protrusion. The positioning hole is located at the axis of the wooden positioning sleeve. A pressure relief spring 11 is arranged between any adjacent two wooden positioning sleeves, such as Figure 8 As shown, the tw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com