Stacking turnover device for cylindrical standard components

A standard and cylindrical technology, applied in the field of mold standard parts processing equipment, can solve the problems of low work efficiency, heavy workload, and high labor intensity of staff

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

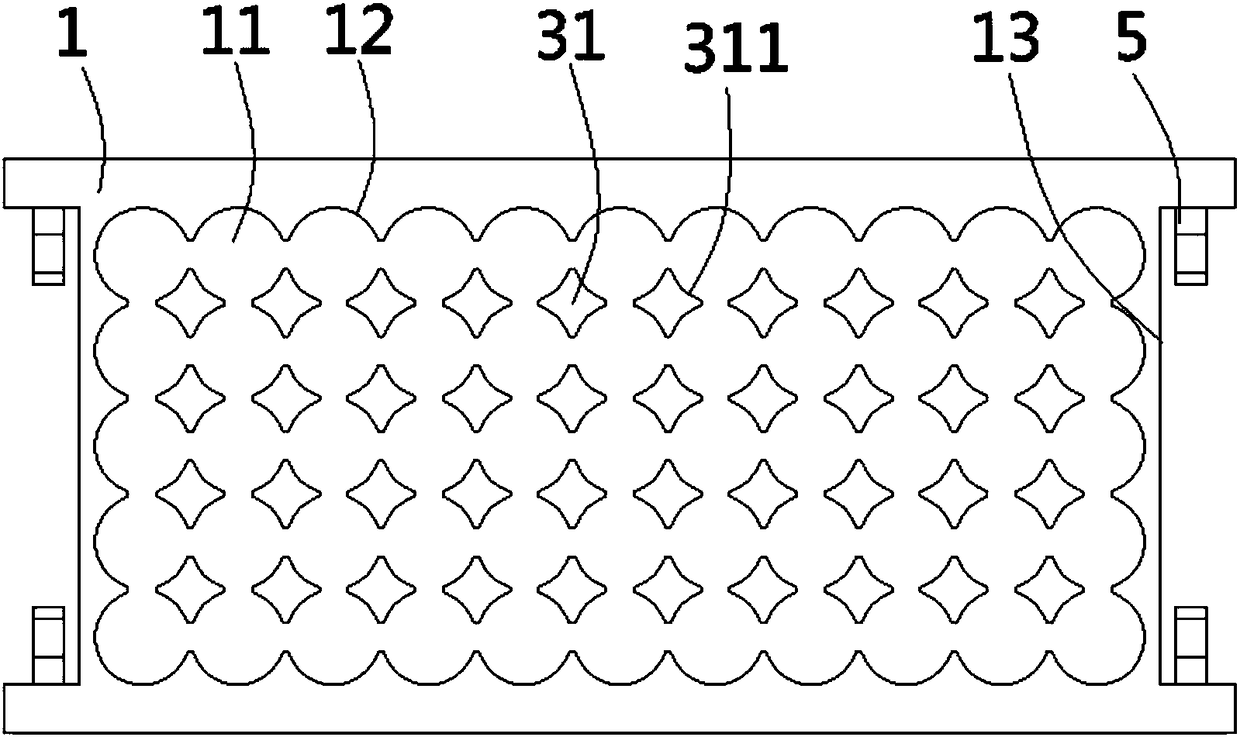

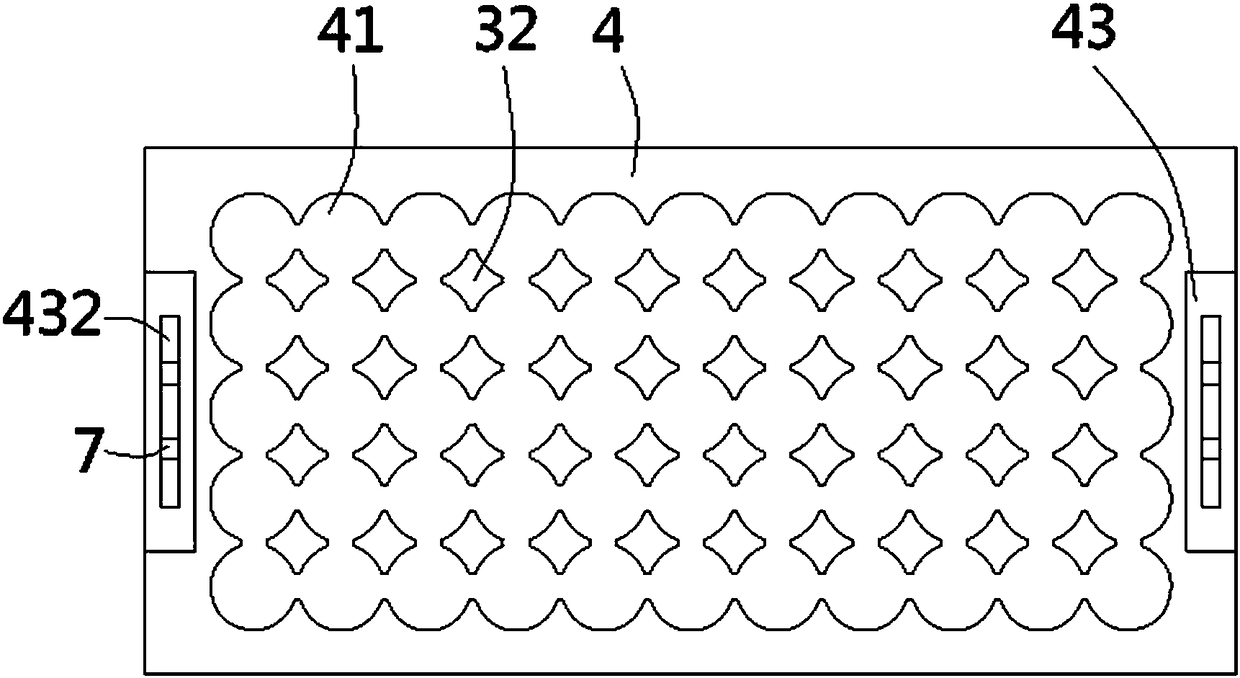

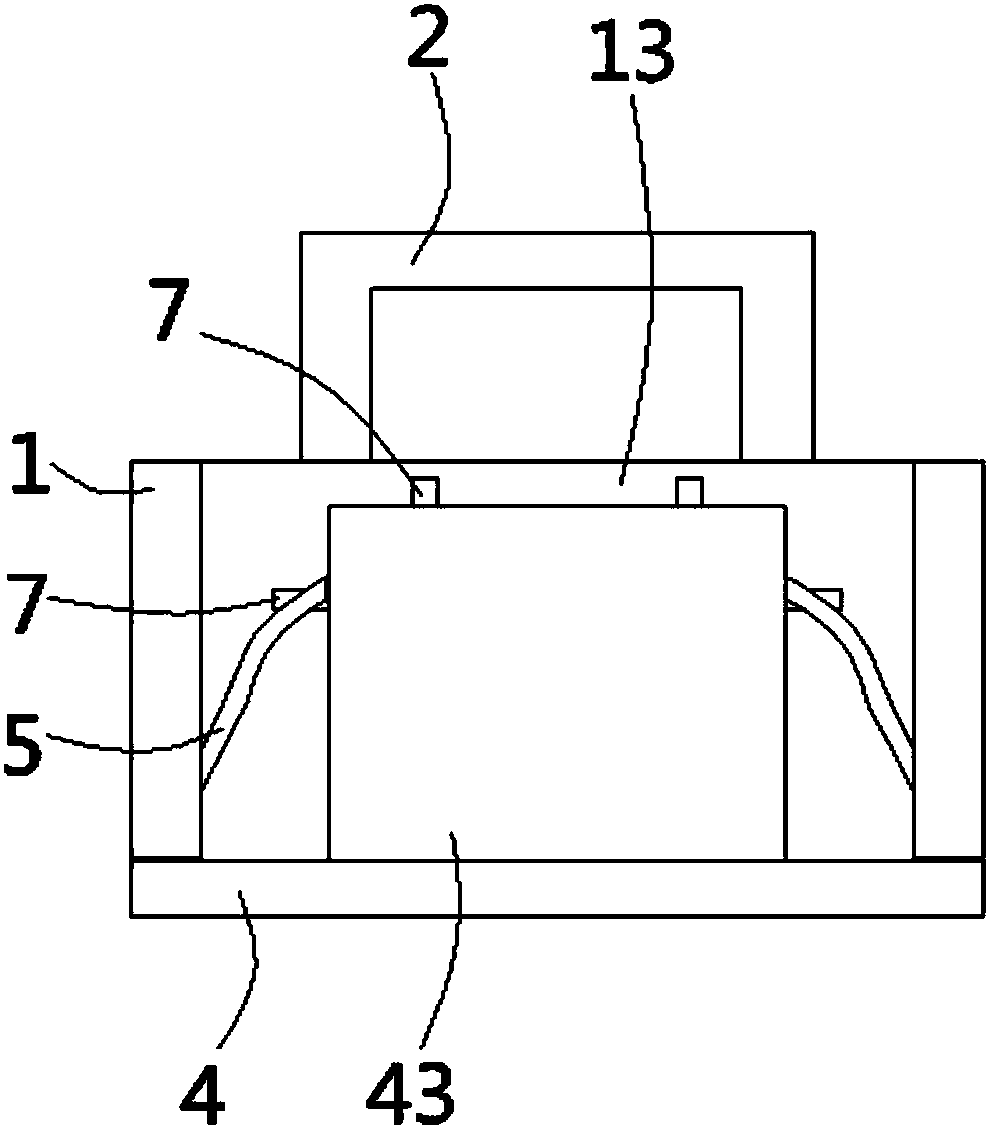

[0021] see Figure 1 to Figure 3 , a stacking turnover device for cylindrical standard parts according to the present invention, comprising a rectangular box body 1, two handles 2 are fixed on the upper end surface of the box body 1, and the lower end surface of the box body 1 is formed with A placement groove 11, the inner wall of the placement groove 11 is formed with a plurality of arc grooves 12 matching with the mold standard parts, the arc grooves 12 are connected end to end, and the placement groove 11 is provided with a plurality of ribs distributed in an array shaped partition column 31, the lower end surface of the box body 1 leans against a partition plate 4, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com