Three-purlin beam center node steel bottom plate prefabricating method

A technology of central node and steel bottom plate, applied in lighting and heating equipment, furnaces, buildings, etc., can solve the problems of difficult to guarantee the compactness of concrete, inability to discharge air, low work efficiency, etc. The effect of eliminating deformation modulus and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0041] A method for prefabricating a central node steel floor of a three-pronged beam of the present invention comprises the following steps:

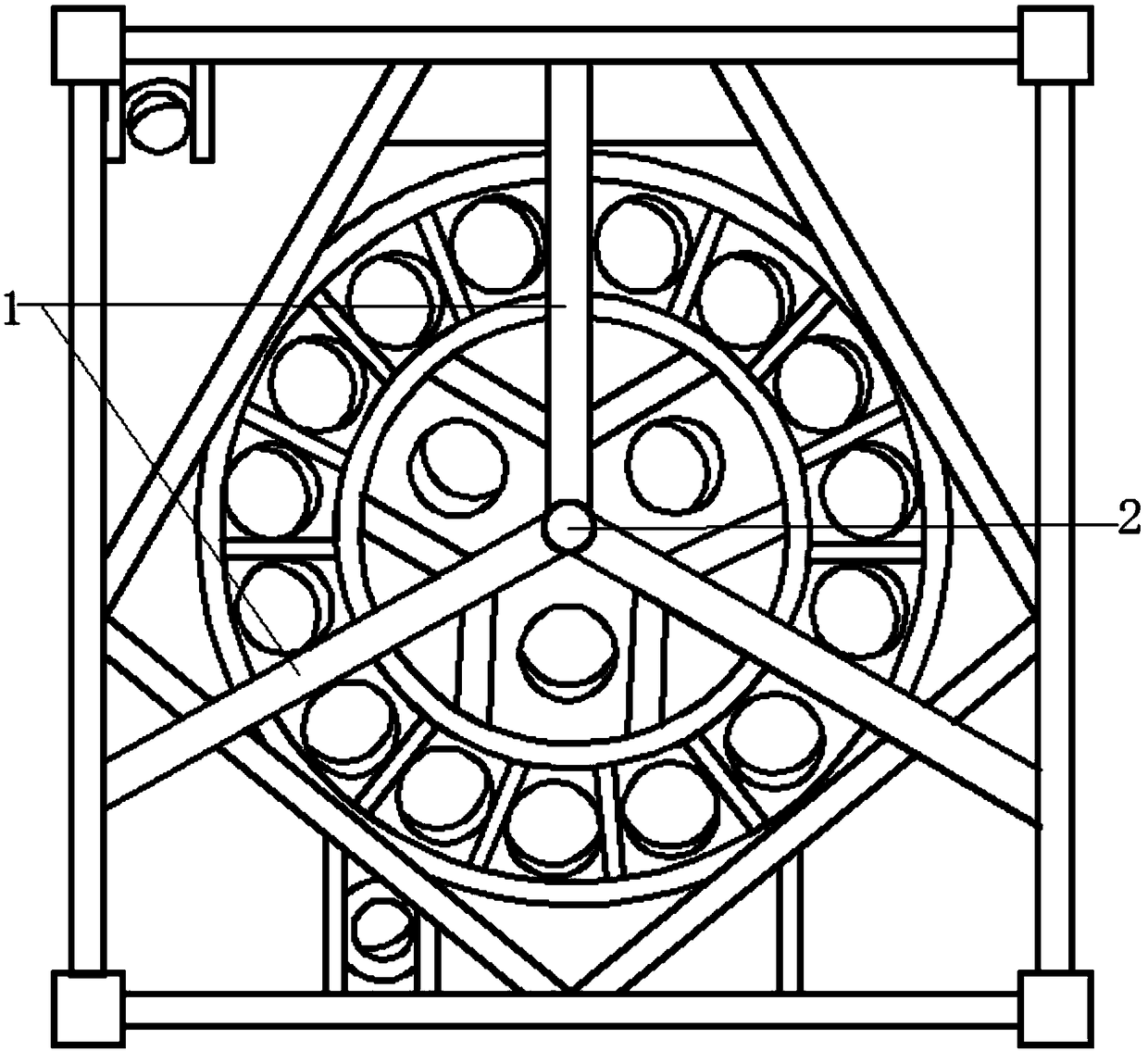

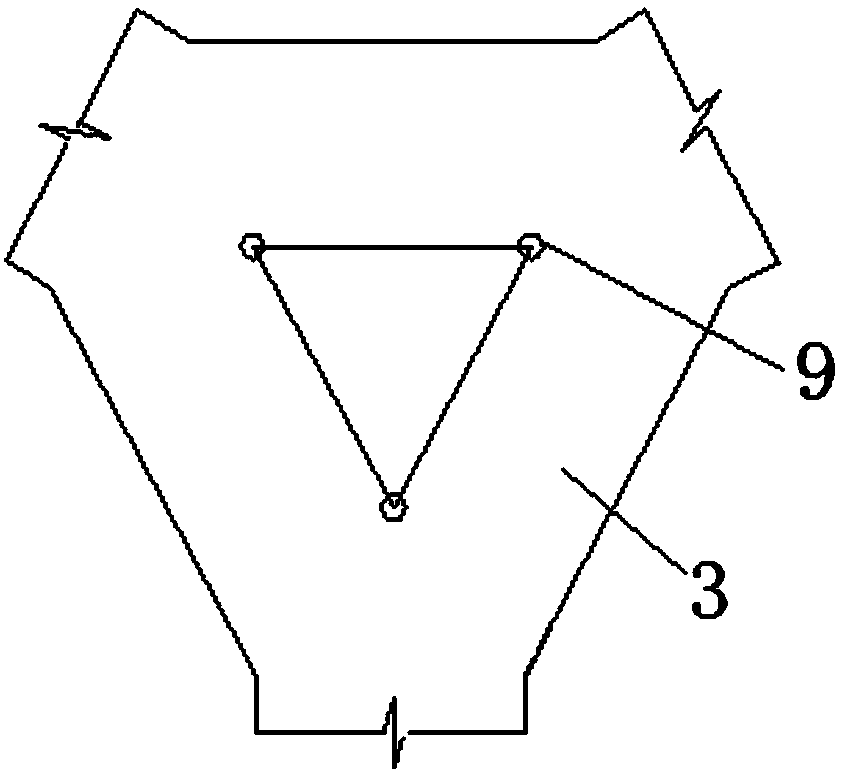

[0042] Step 1, take two special-shaped steel plates, fix the gusset plates 2 of the two special-shaped steel plates on the operating table, and cut each special-shaped steel plate with a cutting machine according to the design drawings, and each special-shaped steel plate is cut into, as figure 1 As shown: It includes three support beams 1 connected to the gusset plate 2, and the angle between any two support beams 1 is 120°, and then the special-shaped steel plate is removed from the operation table;

[0043] The steel plate adopts a special-shaped steel plate, which does not allow welding and splicing on the whole steel plate; the joint plate 2 is fixed with the operating table by a screw, and is te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com