Patents

Literature

78results about How to "Not prone to misalignment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

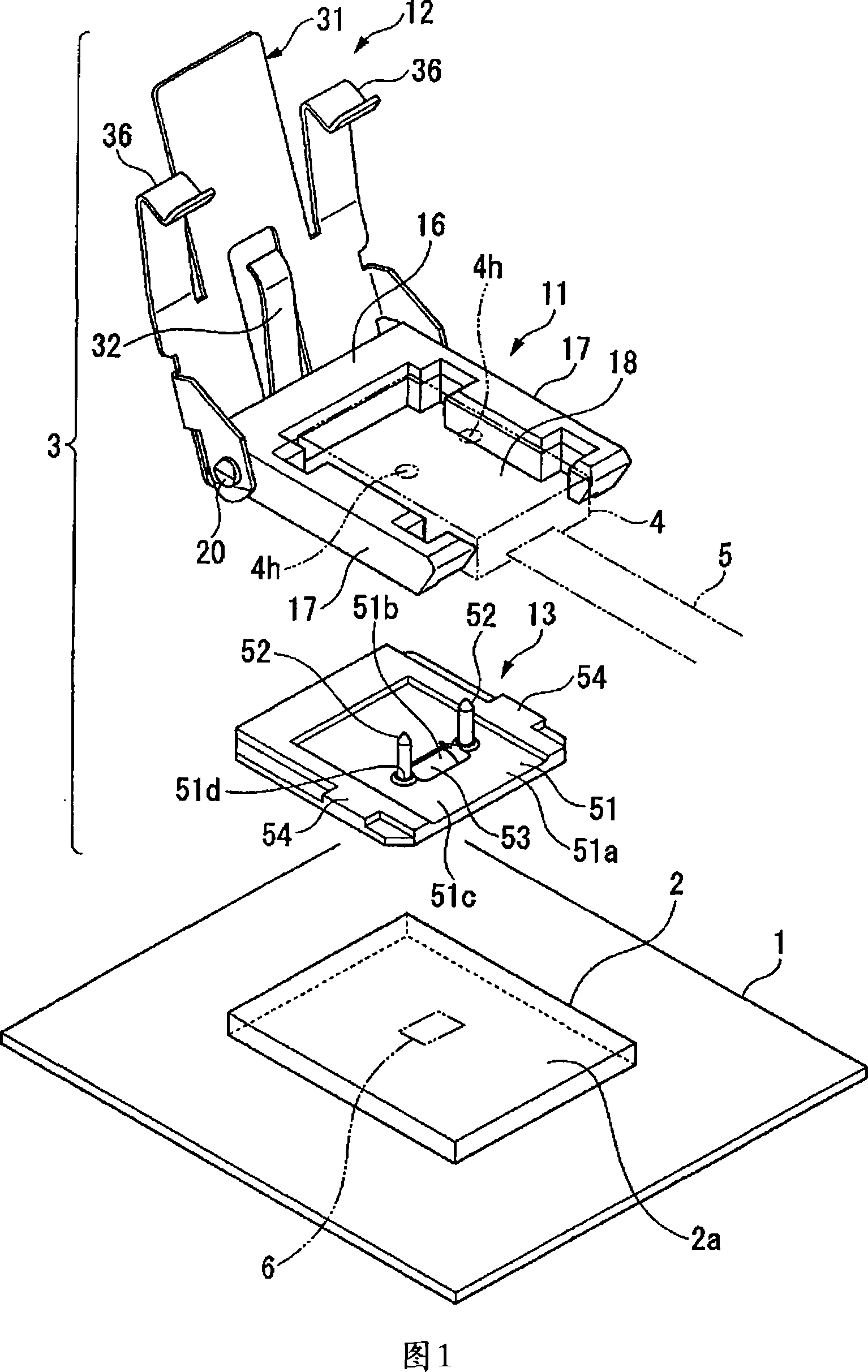

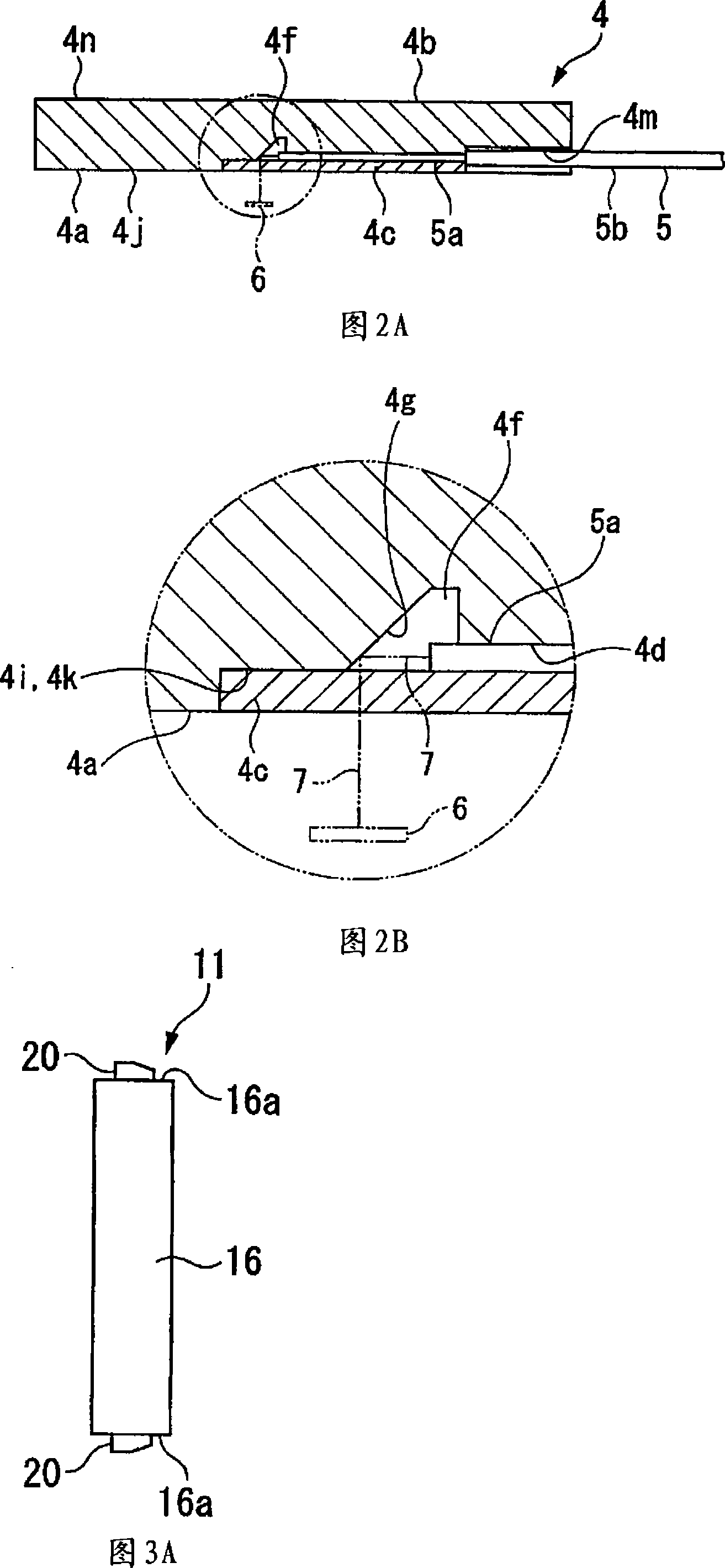

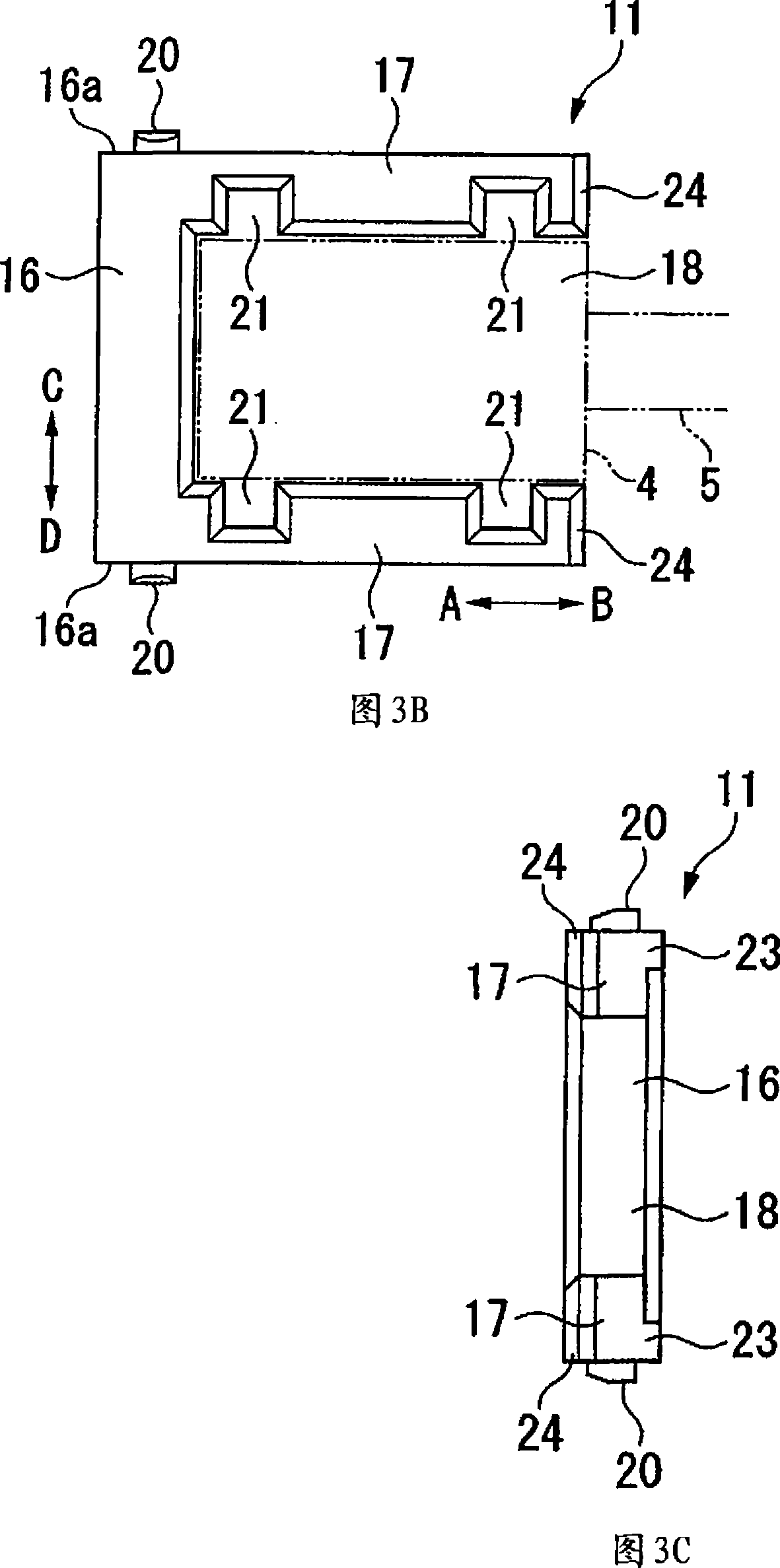

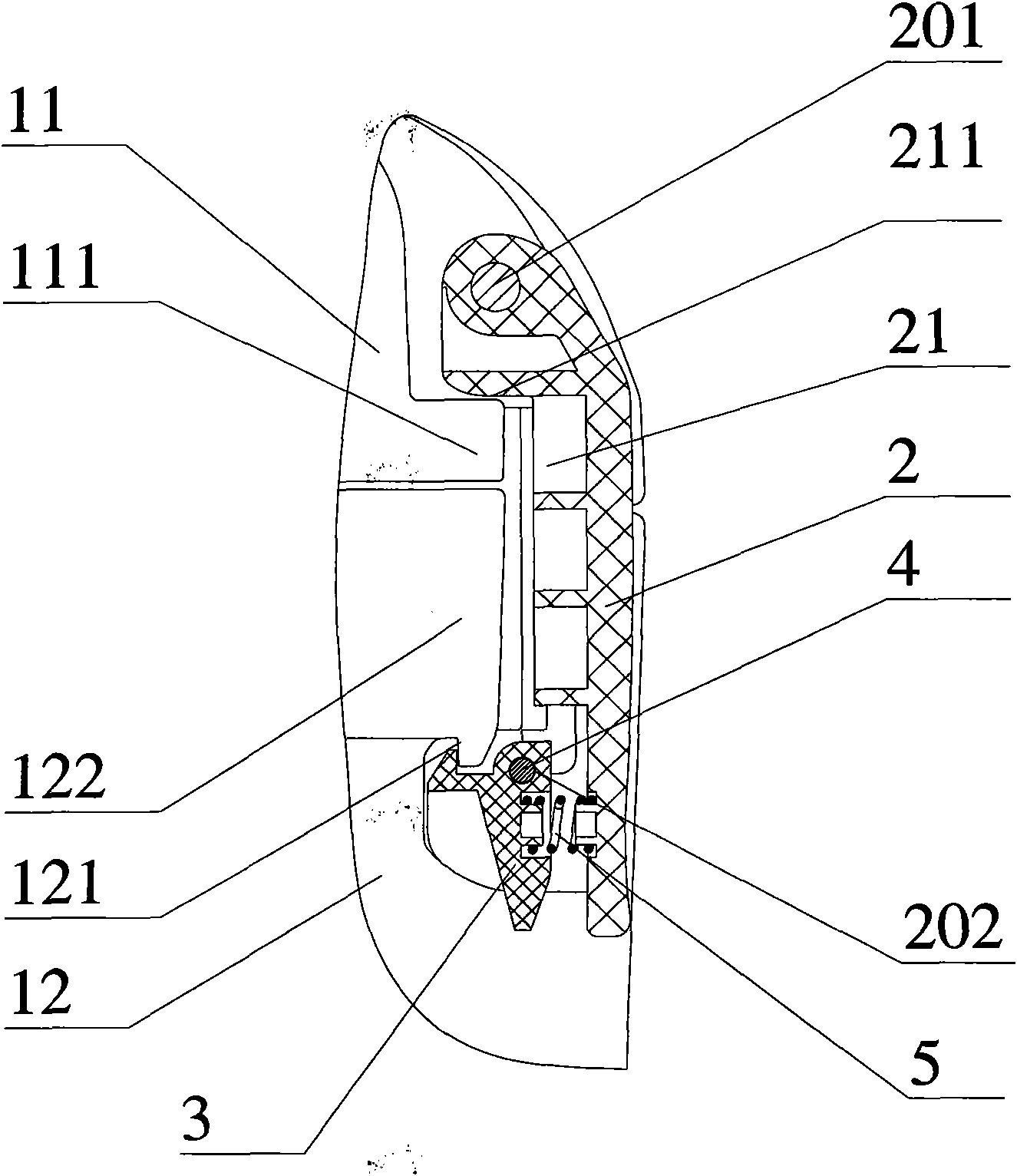

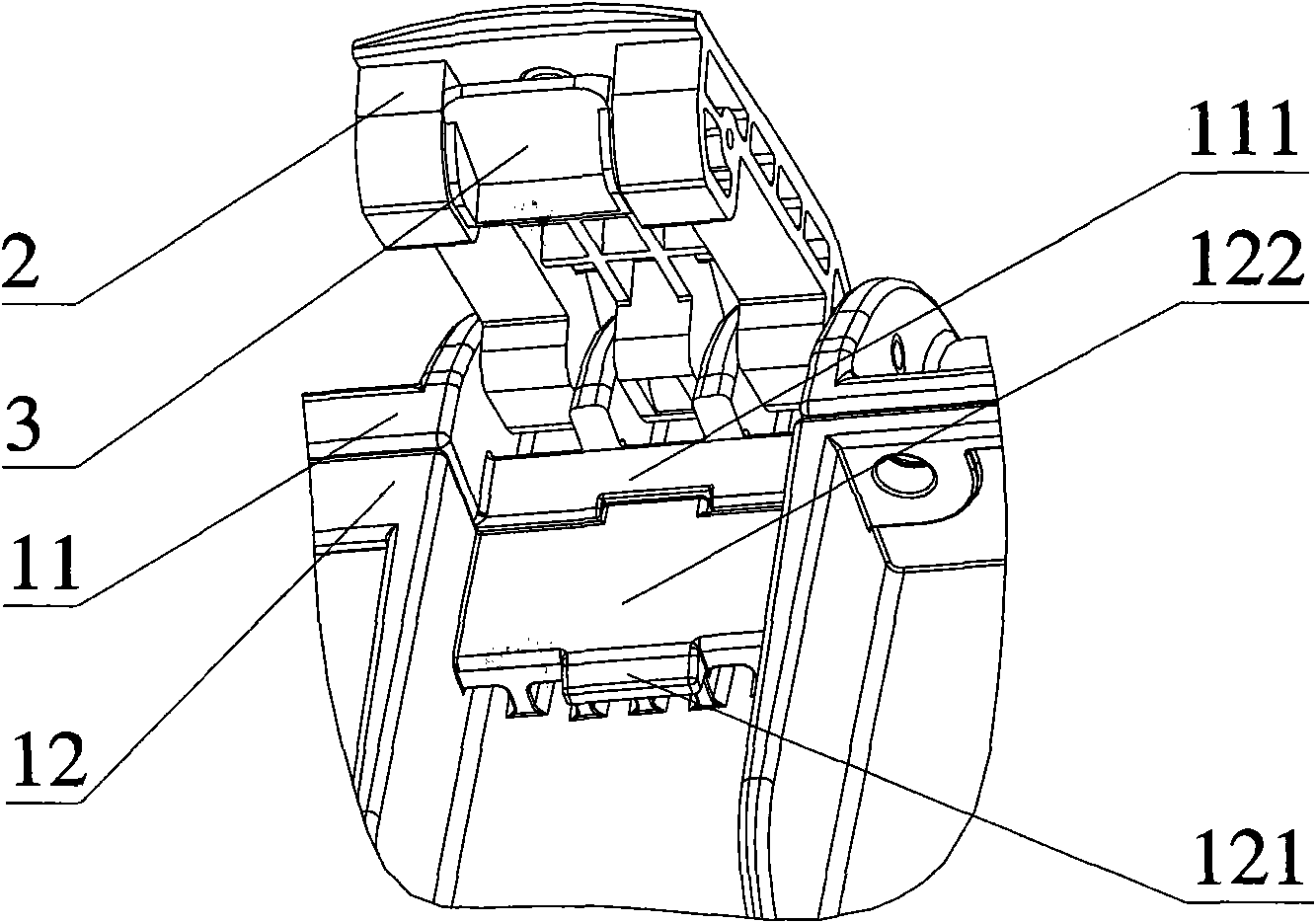

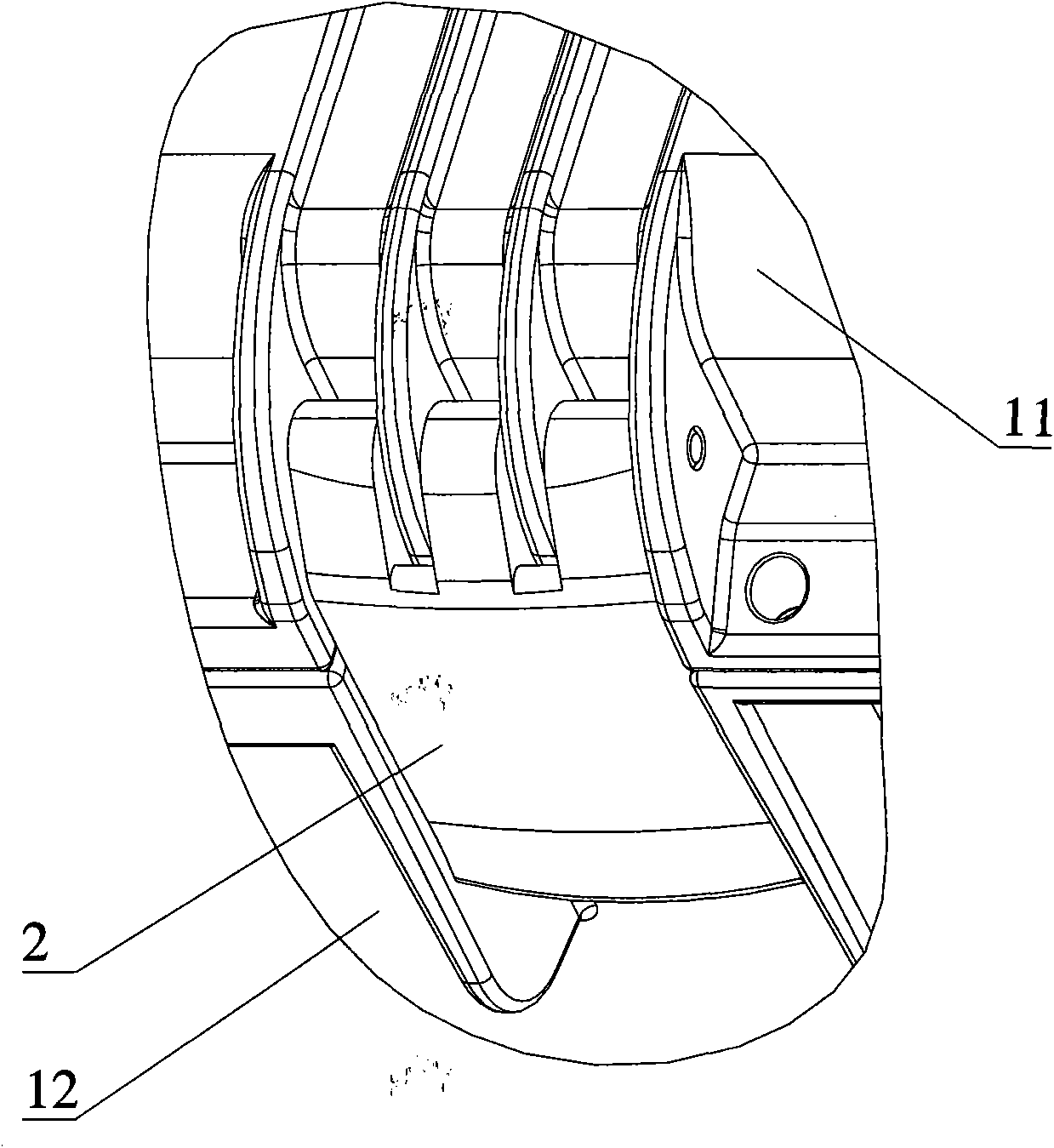

Connector holder, photoelectric converter provided with connector holder, optical connector fixing structure and method for assembling connector holder

ActiveCN101176024ARealize optical connectionEasy to disassembleCoupling light guidesEngineeringInput/output

The connector holder of the present invention fixes the optical connector assembled at the front end of the optical fiber on the optical module provided with the optical input and output terminals in such a manner that the optical fiber and the optical input and output terminals form an optical connection. This connector holder has a holding part that accommodates at least a part of the optical connector, and a cover part that is openably and closably attached to the holding part. The cover has a cover body and a pressing portion for pressing the optical connector against the optical module.

Owner:THE FUJIKURA CABLE WORKS LTD

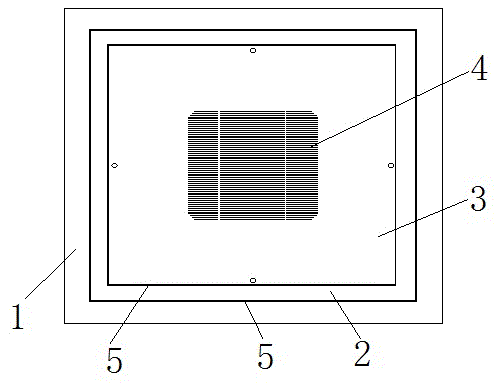

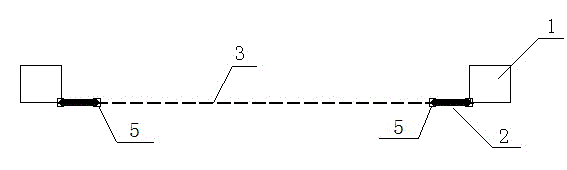

Electroforming metal film mesh plate for printing touch mesh spacing contacts

InactiveCN101555607AHigh hardnessExcellent brush resistanceElectroforming processesForme preparationYarnWire gauze

The invention discloses an electroforming metal film mesh plate for printing touch mesh spacing contacts; the invention is characterized by comprising an aluminium alloy section mesh frame, a nylon yarn mesh and a metal film; wherein, the metal film is formed by electroforming and provided with micro holes and a plurality of through holes; the nylon yarn mesh is stuck and connected with the aluminium alloy section mesh frame by solidified glue, and the periphery of the metal film is stuck and connected with the nylon yarn mesh by the solidified glue. The metal film mesh plate is made of nickel alloy material and overcomes the defects that photosensitive resistance material is easy to deform, break and the like; the surface of the mesh plate is high in rigidity and good in brushing resistance and dissolubility resistance; the electroforming metal film mesh plate is hard to misplace, and is higher in printing precision and circular degree, thus being capable of printing the touch mesh spacing contacts having the appearance circular degree of 99% and the diameter of 20mum.

Owner:昆山美微电子科技有限公司

Composite metal steel plate for solar battery pure subline printing

ActiveCN102744997ANo imprintThe overall thickness is thinScreen printersPlate printingSilver pasteSheet steel

The invention discloses a composite metal steel plate for solar battery pure subline printing. The composite metal steel plate comprises a single-layer metal film, wherein a plurality of sublines of a solar battery positive electrode are arranged on the single-layer metal film; and a plurality of the sublines are respectively of a strip shape and are uniformly distributed on the single-layer metal film. The composite metal steel plate for the solar battery pure subline printing in the invention can replace the original weaving silk screen plate printing, does not produce moulage on a printed object and meets super-elaborate requirement on printing; electrical performance of the solar battery positive electrode can be improved after silver paste printing so that the conversion efficiency of solar energy is improved; and the composite metal steel plate has the advantages of high hardness and good printing resistance and dissolve resistance, and has good application prospect.

Owner:昆山美微电子科技有限公司

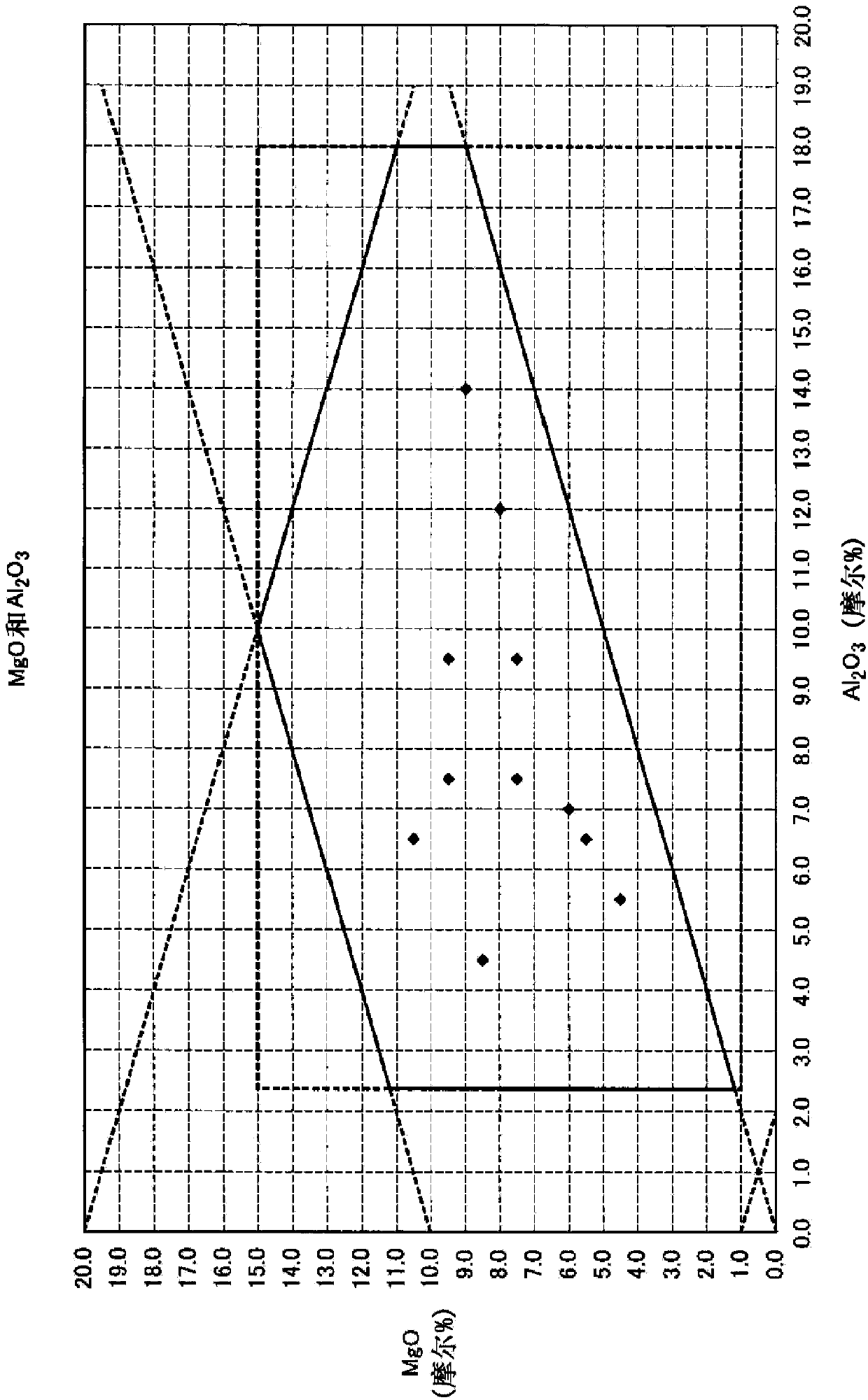

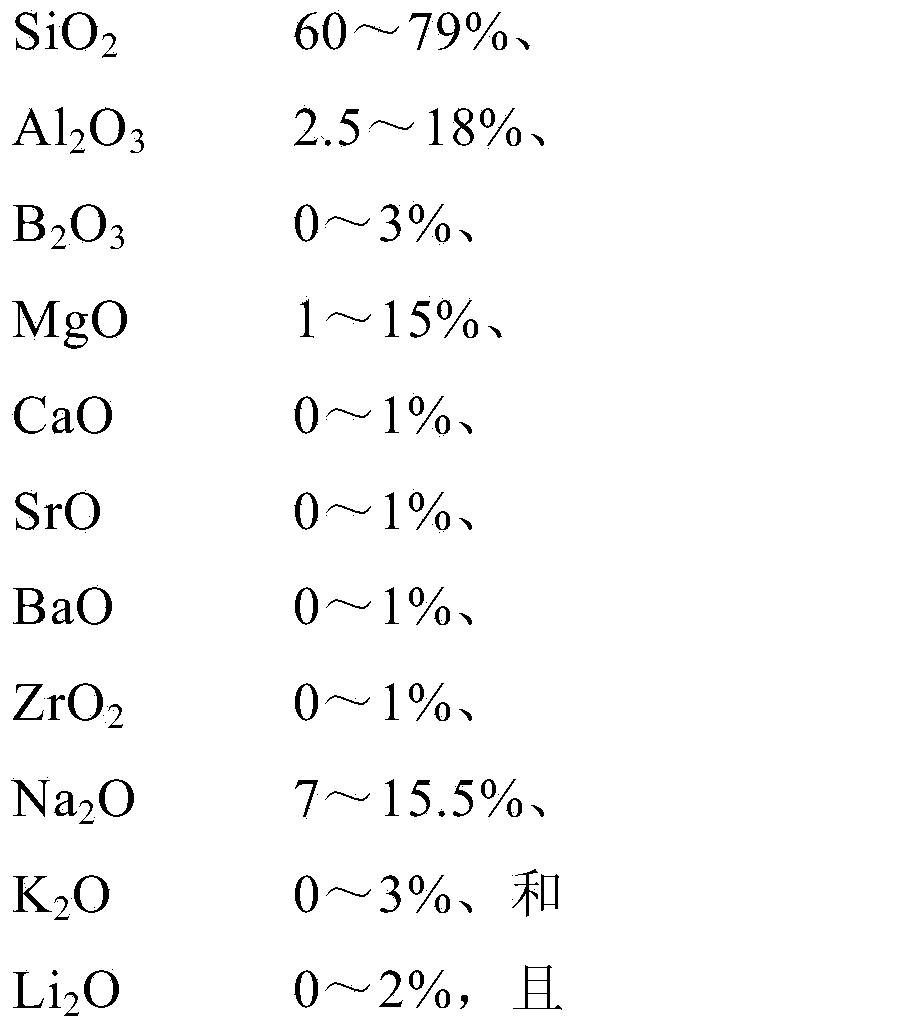

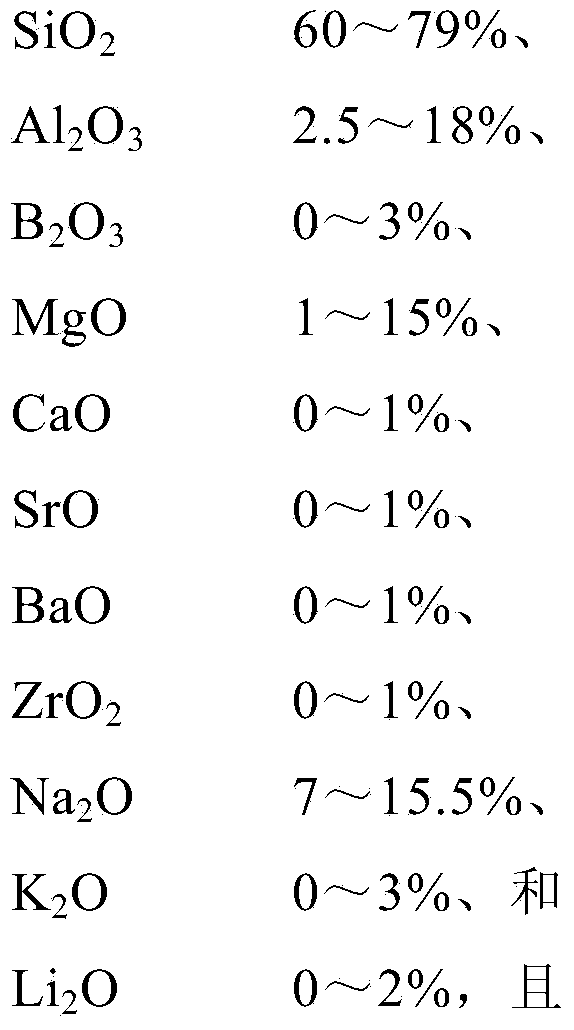

Glass substrate and method for producing same

The present invention provides a glass substrate having a high glass transition temperature, in which a compaction (C) is small in heat treatment at low temperature (150 to 300 DEG C). A glass substrate containing, in terms of mol% on the basis of the following oxides: from 60 to 79% of SiO 2 ; from 2.5 to 18% of Al 2 O 3 ; from 0 to 3% of B 2 O 3 ; from 1 to 15% of MgO; from 0 to 1% of CaO; from 0 to 1% of SrO; from 0 to 1% of BaO; from 0 to 1% of ZrO 2 ; from 7 to 15.5% of Na 2 O; from 0 to 3% of K 2 O; and from 0 to 2% of Li 2 O; wherein Na 2 O+K 2 O is from 7 to 15.5%, Na 2 O / (Na 2 O+K 2 O) is from 0.77 to 1, MgO+CaO+SrO+BaO is from 1 to 18%, MgO-0.5Al 2 O 3 is from 0 to 10, and MgO+0.5Al 2 O 3 is from 1 to 20, wherein the glass substrate has: a glass transition temperature of from 580 to 720 DEG C; an average coefficient of thermal expansion within a range of from 50 to 350 DEG C of from 6510 -7 to 8510 -7 / DEG C; a compaction (C) of 15 ppm or less; a glass surface devitrification temperature (T c ) of from 900 to 1,300 DEG C; a glass internal devitrification temperature (T d ) of from 900 to 1,300 DEG C; a temperature (T 4 ) at which a viscosity reaches 10 4 dPas of from 1,100 to 1,350 DEG C; a relationship (T 4 -T c ) between the temperature (T 4 ) at which a viscosity reaches 10 4 dPas and the glass surface devitrification temperature (T c ) of from -50 to 350 DEG C; and a relationship (T 4 -T d ) between the temperature (T 4 ) at which a viscosity reaches 10 4 dPas and the glass internal devitrification temperature (T d ) of from -50 to 350 DEG C.

Owner:AGC INC

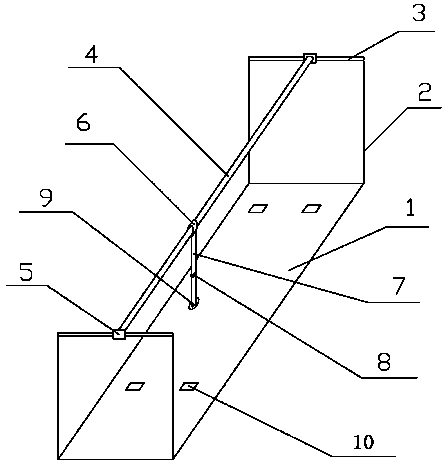

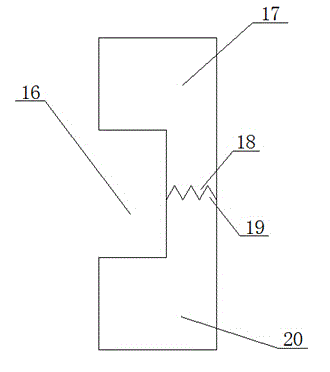

Locking device used for box body

ActiveCN102599709AImprove protectionEasy to unlockBuilding locksOther accessoriesEngineeringMechanical engineering

Owner:扬州哈登塑料技术有限公司

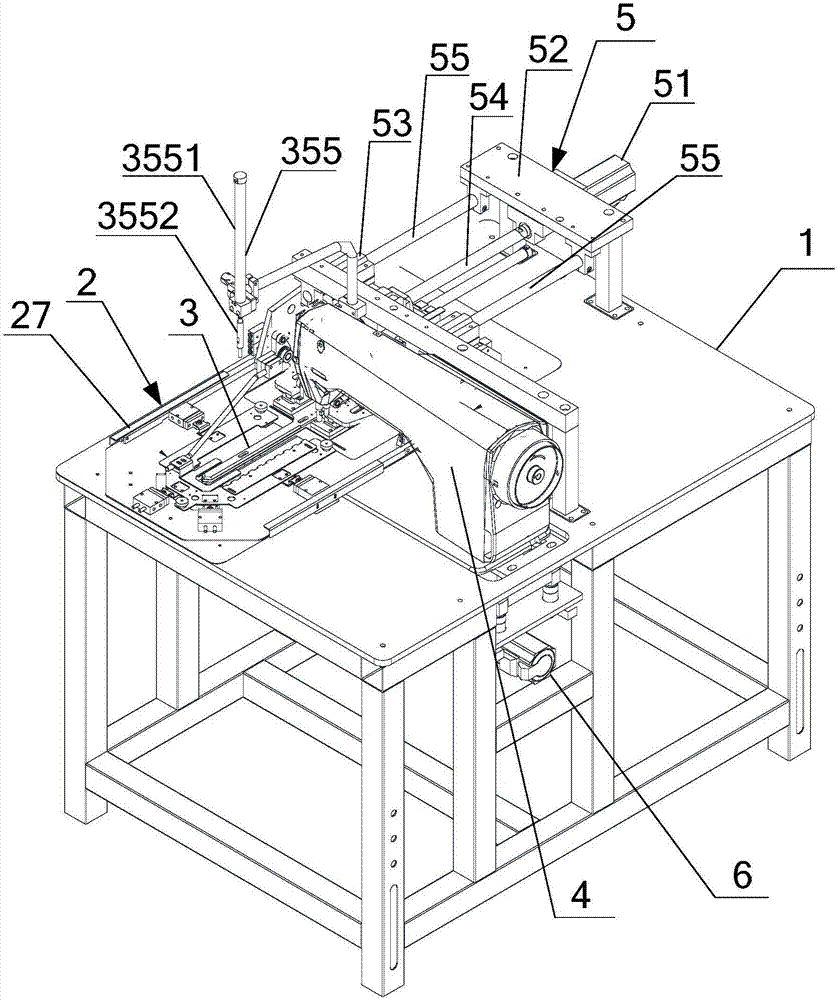

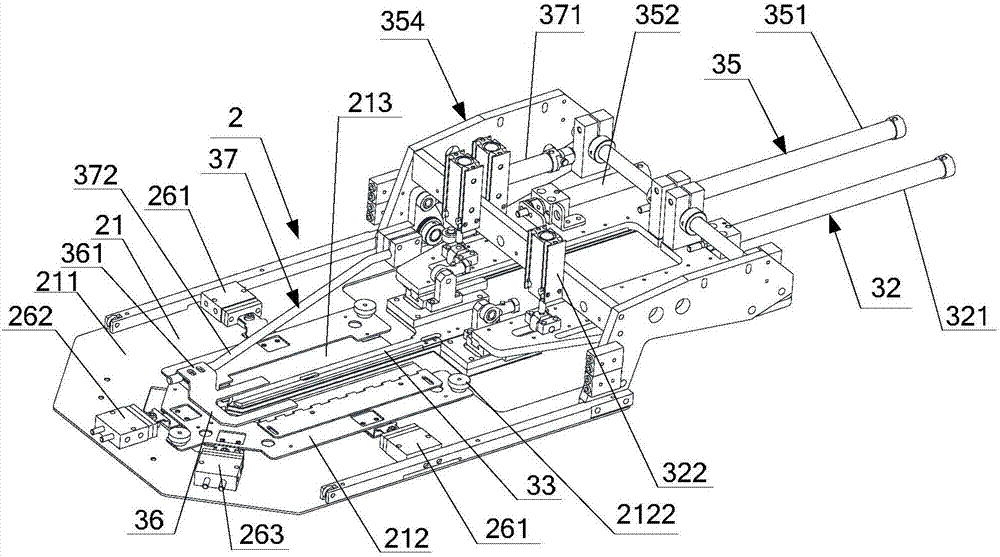

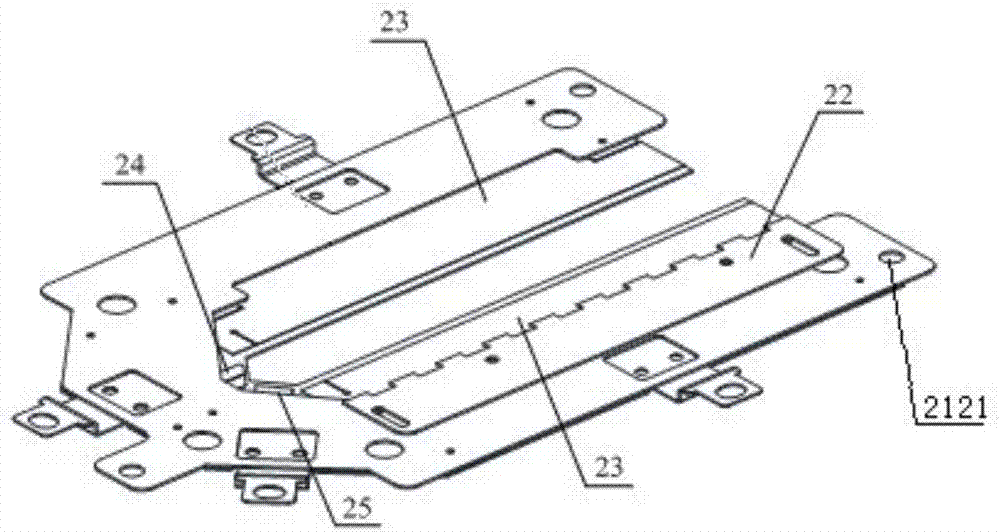

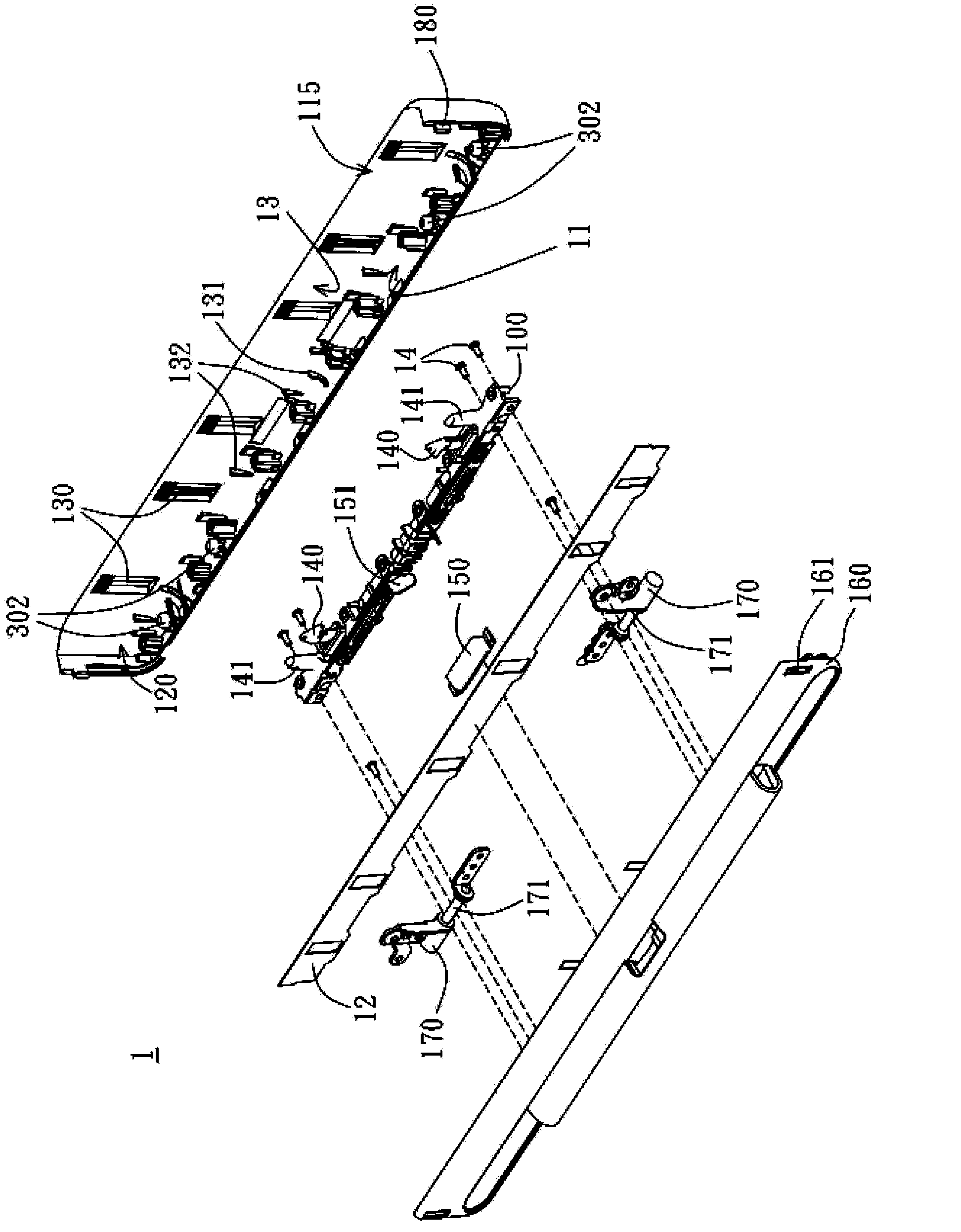

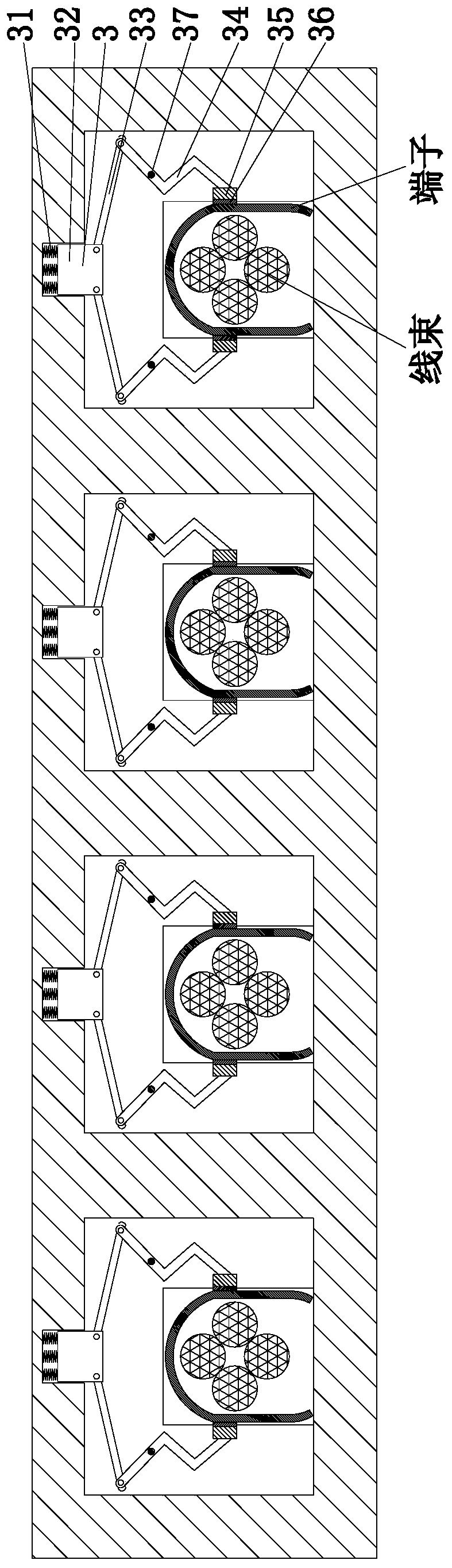

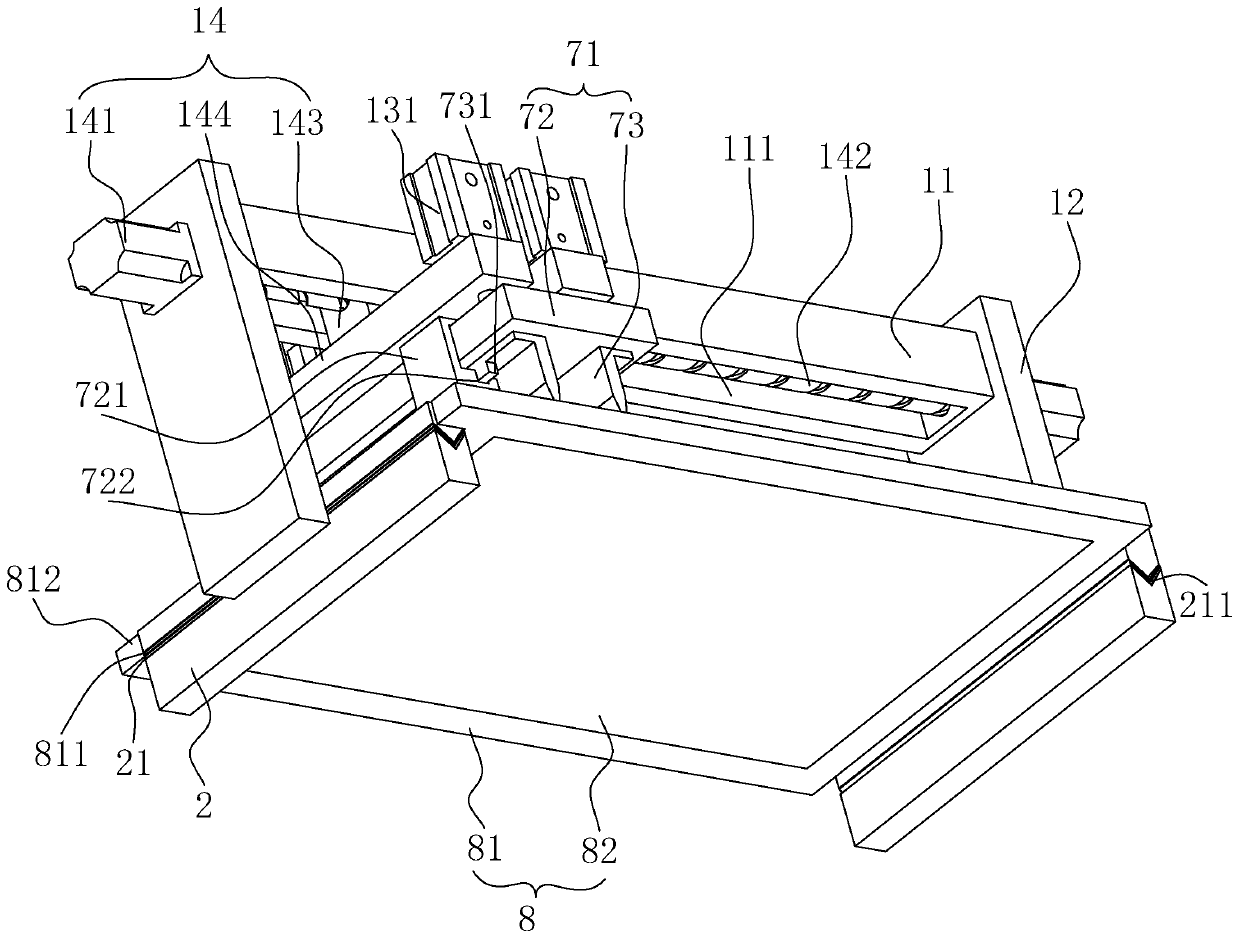

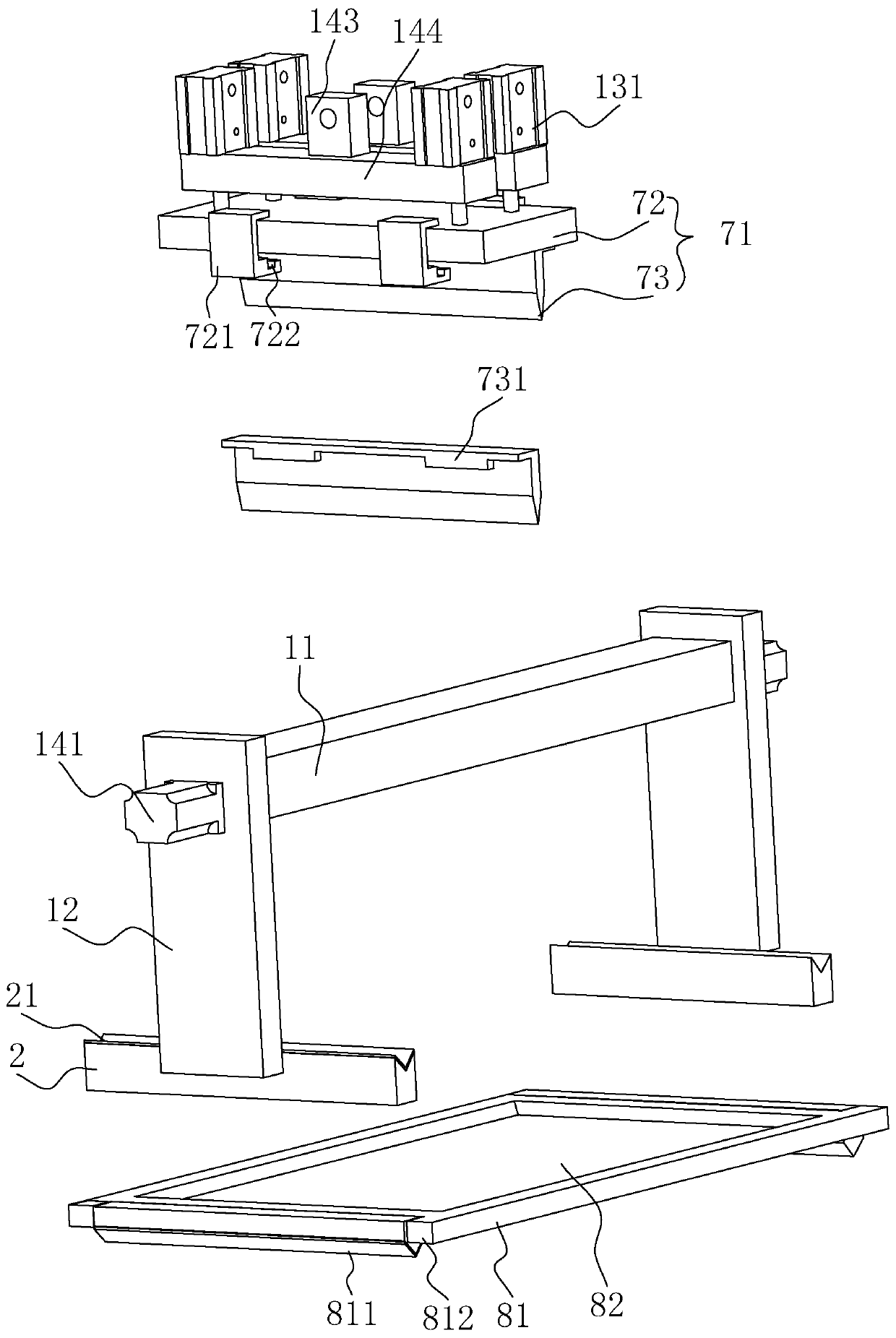

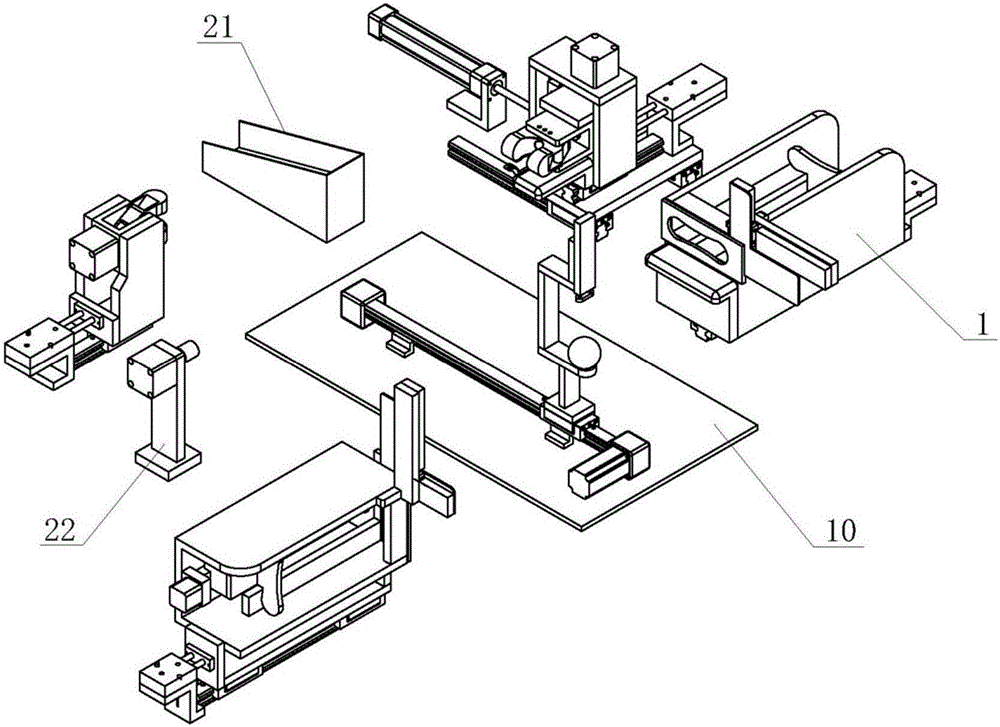

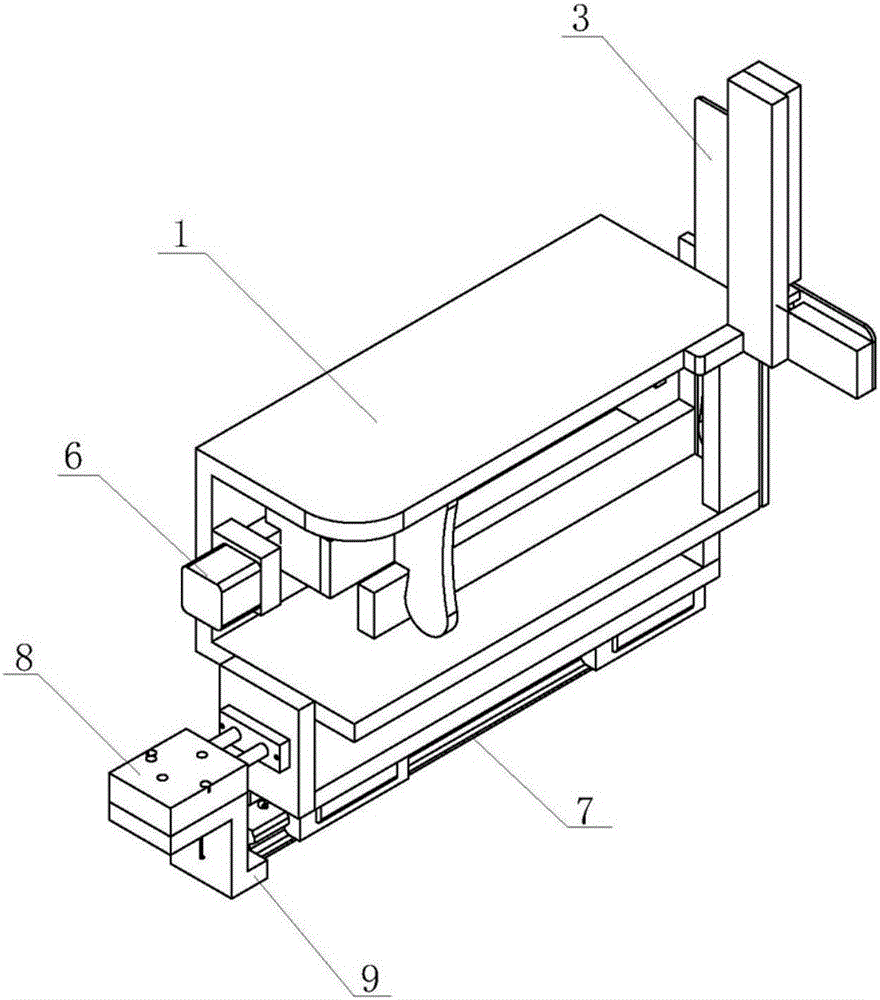

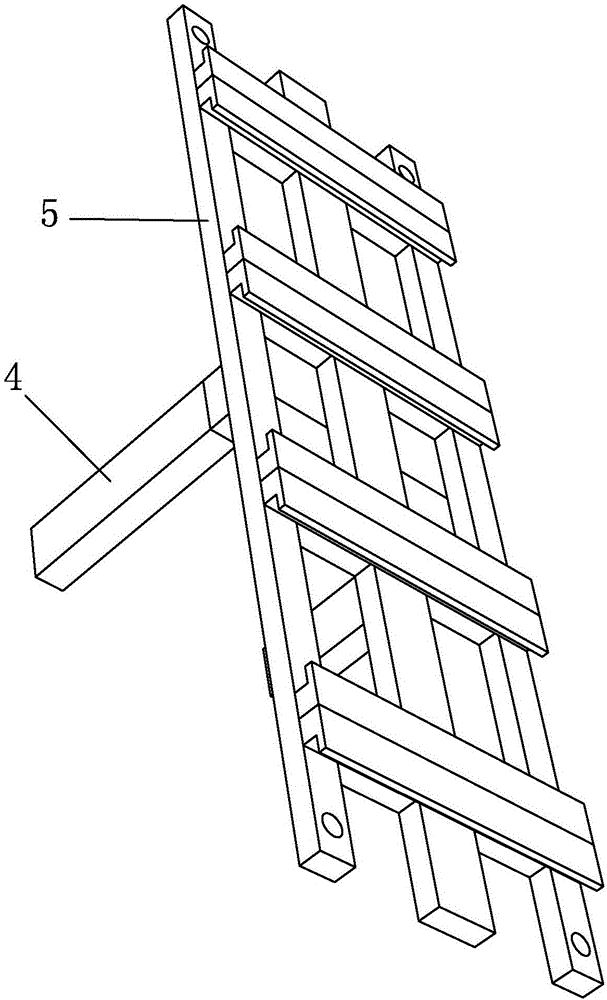

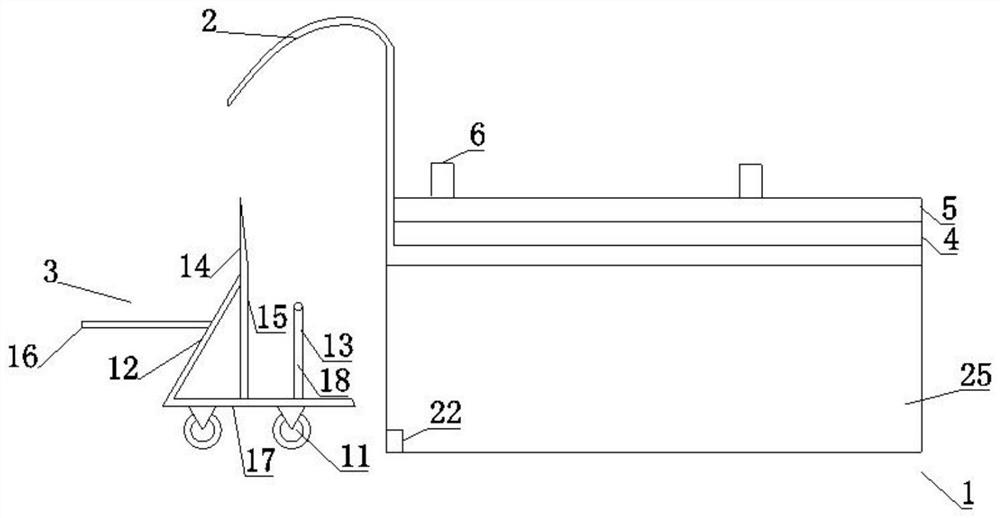

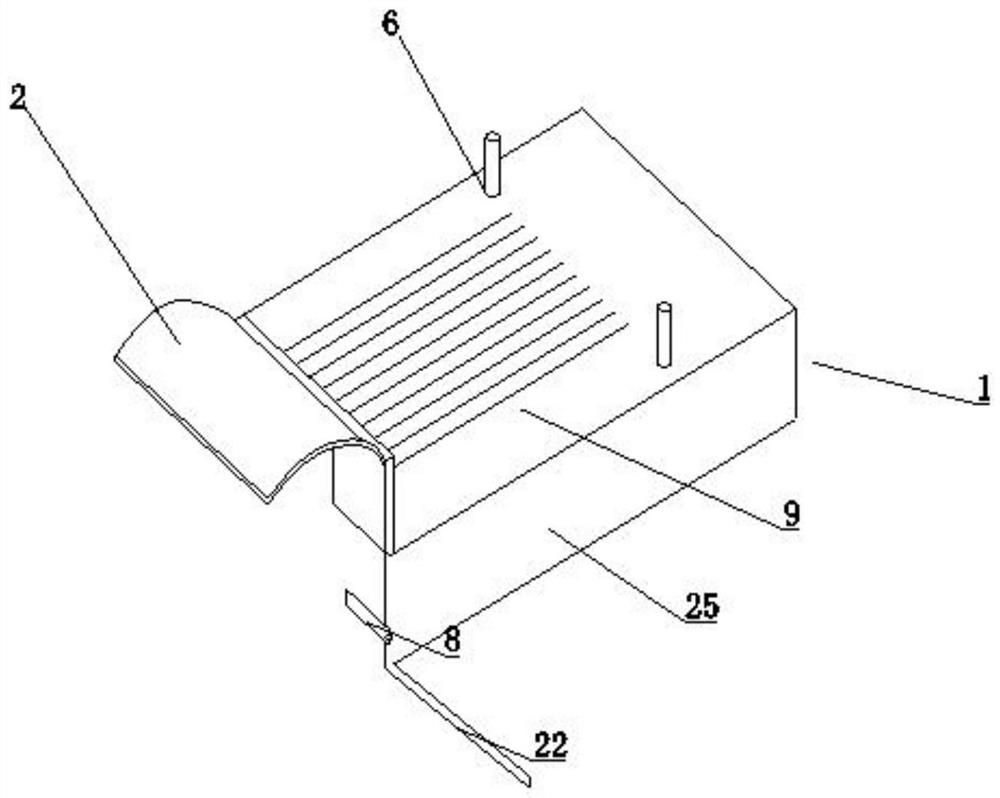

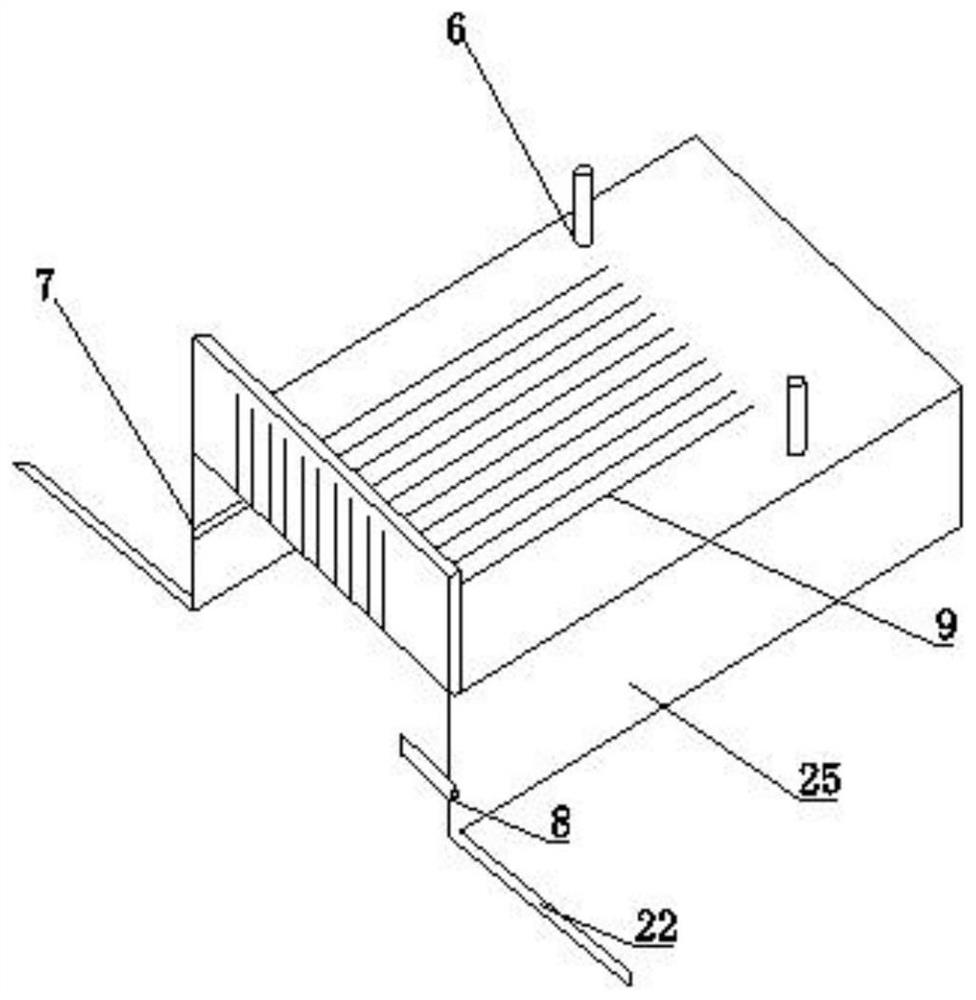

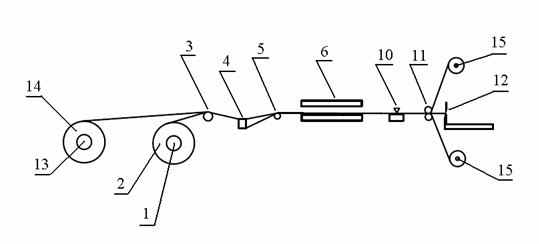

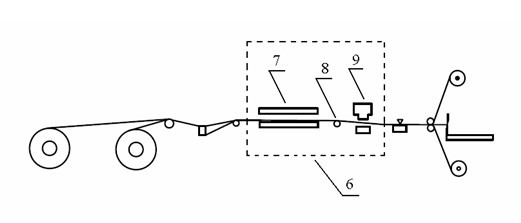

Sleeve vent folding and sewing integrated machine

ActiveCN107488946AEffective positioningAvoid deformationWork-feeding meansManufacturing computing systemsReciprocating motionEngineering

The invention provides a sleeve vent folding sewing integrated machine. The machine comprises a rack, a folding mechanism, a positioning mechanism, a sewing machine, a first direction transmission mechanism and a second direction transmission mechanism; the folding mechanism can be fixed onto the rack in a reciprocating motion mode in the first direction through the first direction transmission mechanism; the sewing machine can be fixed onto the rack in a reciprocating motion mode in the second direction through the second direction transmission mechanism, the machine head of the sewing machine is located above the folding mechanism, and the first direction is perpendicular to the second direction; the positioning mechanism is fixed to the folding mechanism. The sleeve vent folding sewing integrated machine can automatically conduct integrated folding and sewing on sleeve vents, and has the advantages that the machine is convenient to operate, high in processing efficiency, high in processing quality and high in universality and consistency of cost and quality.

Owner:SHANGHAI WEISHI MACHINERY

Expansion seat

InactiveCN103579847AAvoid collisionAvoid direct collisionCouplings bases/casesEngineeringMechanical engineering

Owner:PEGATRON

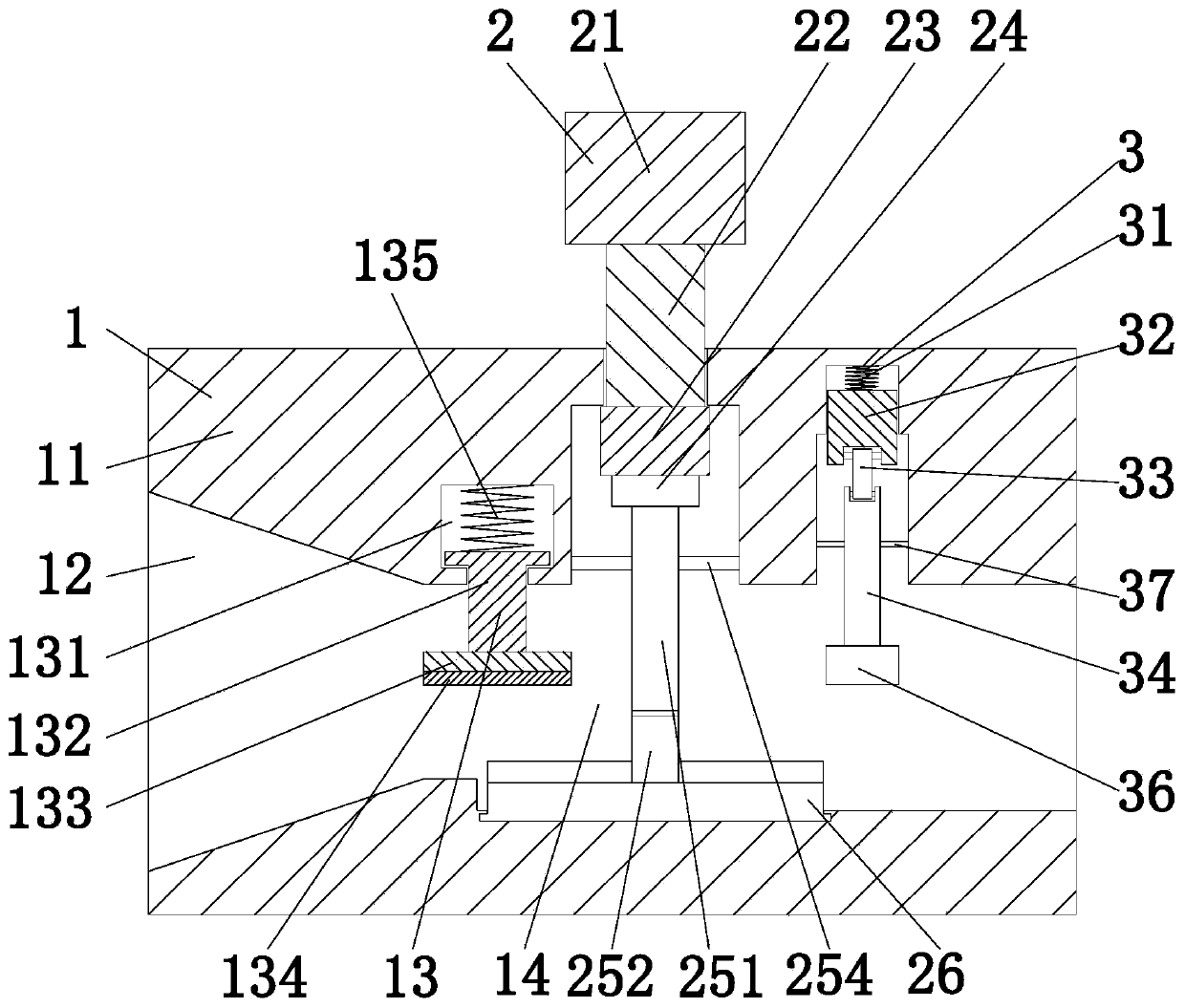

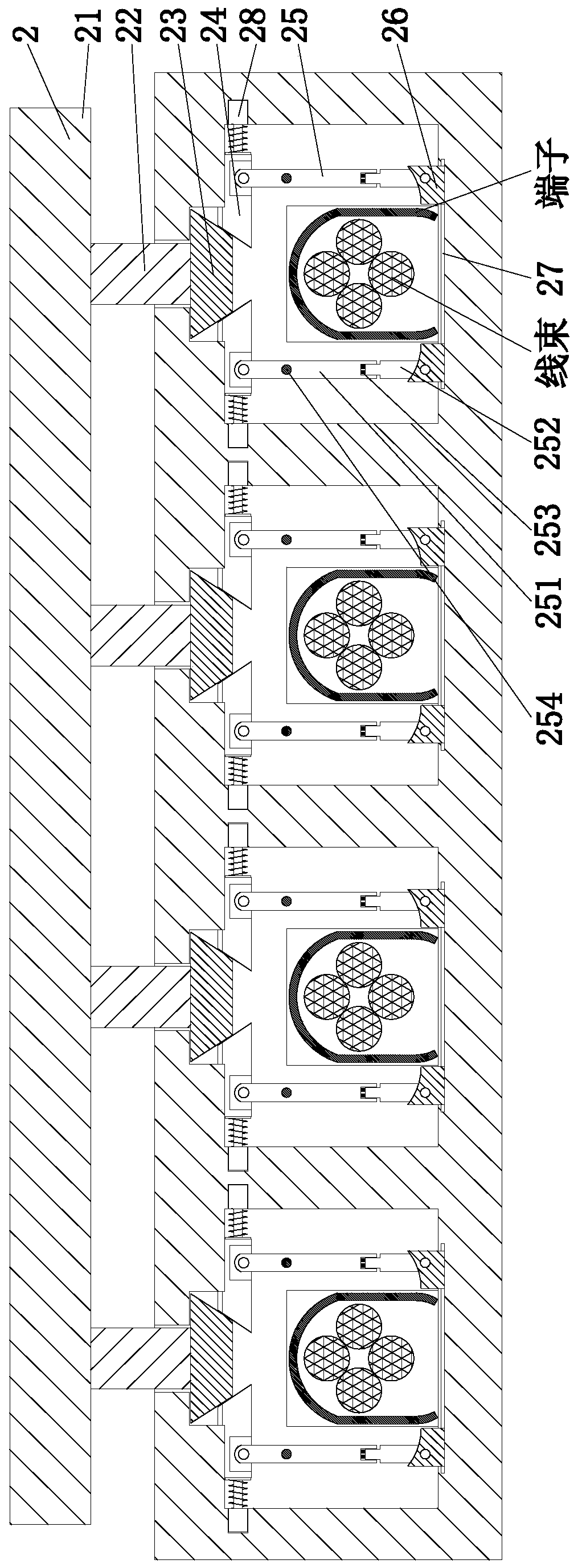

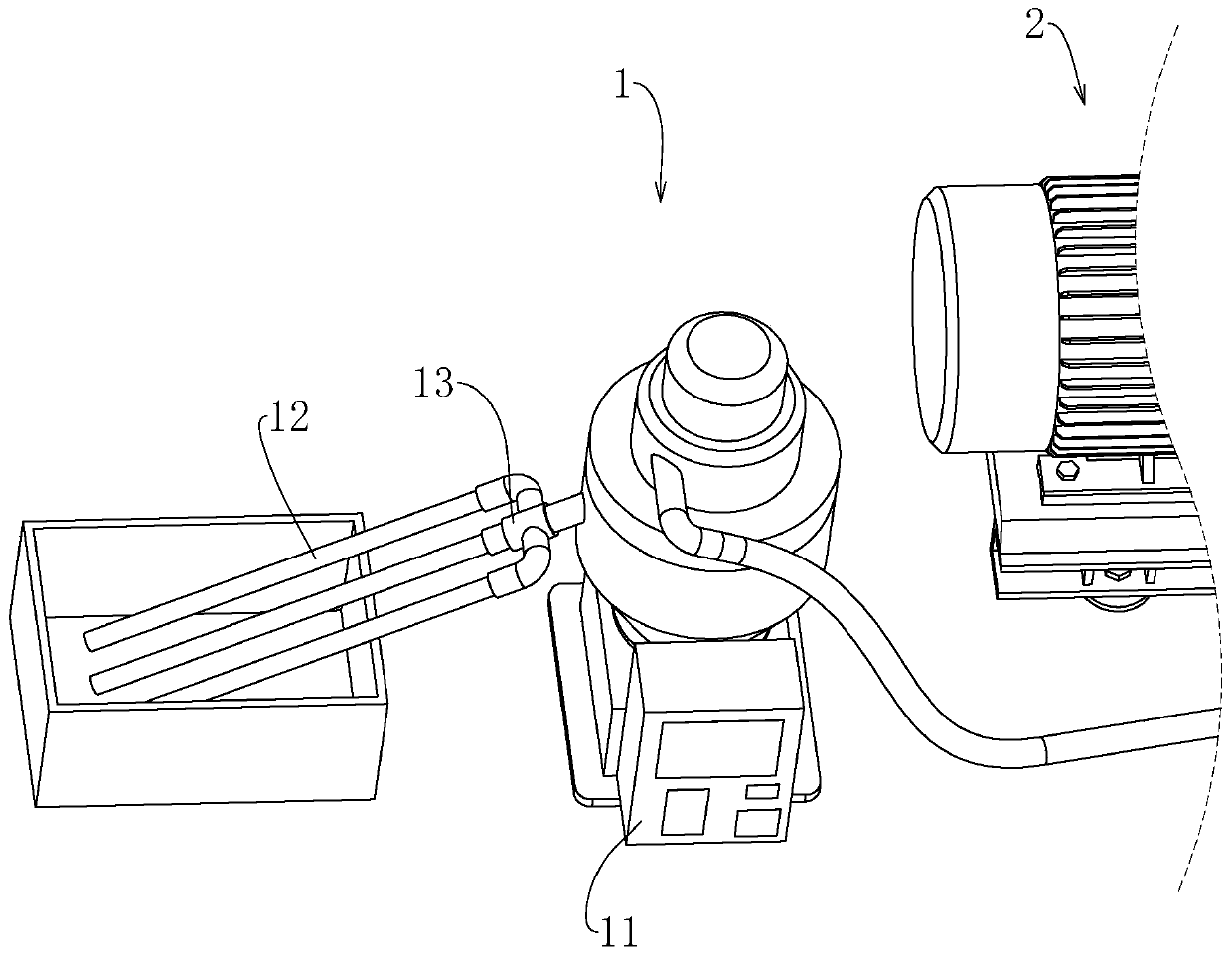

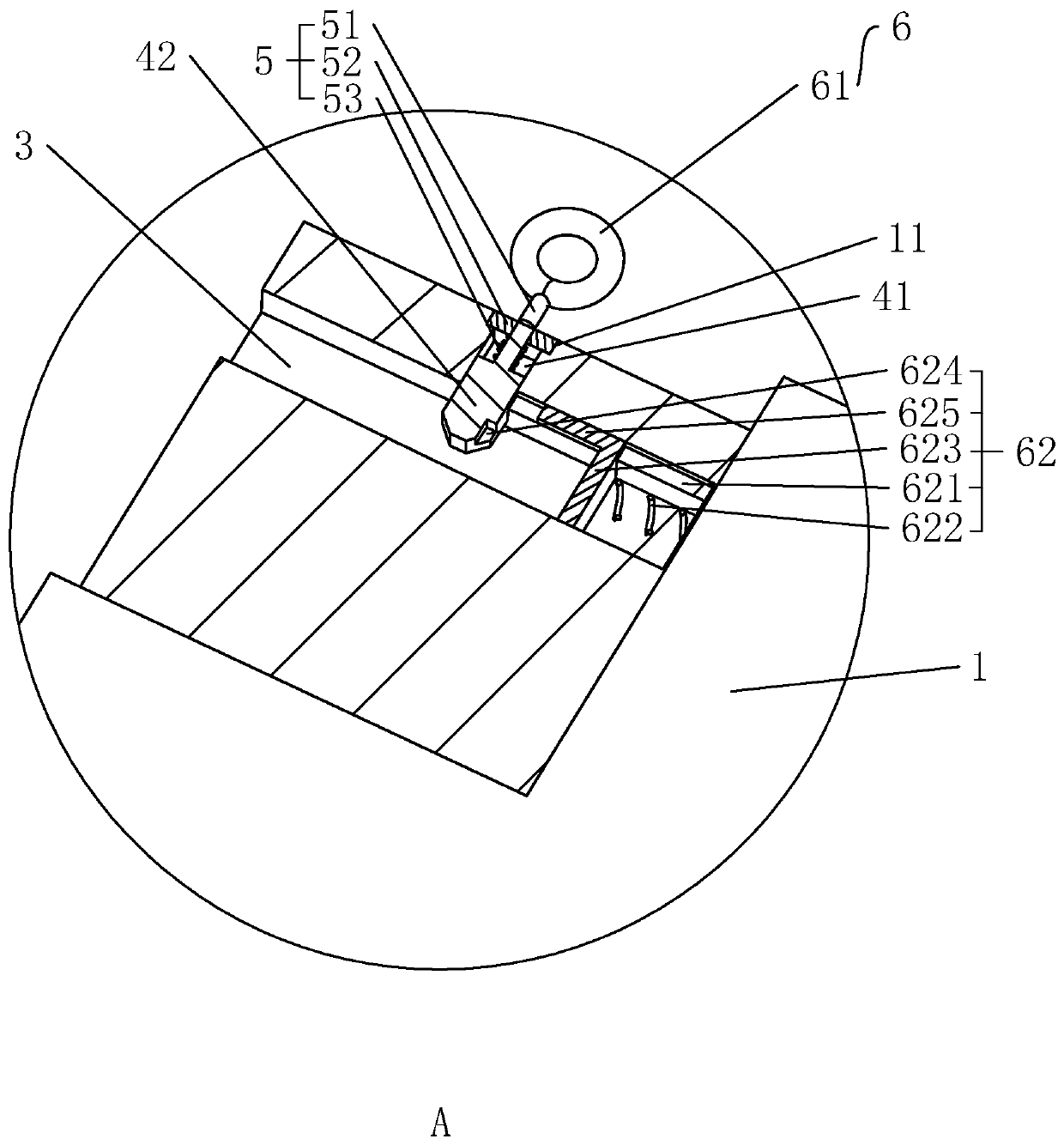

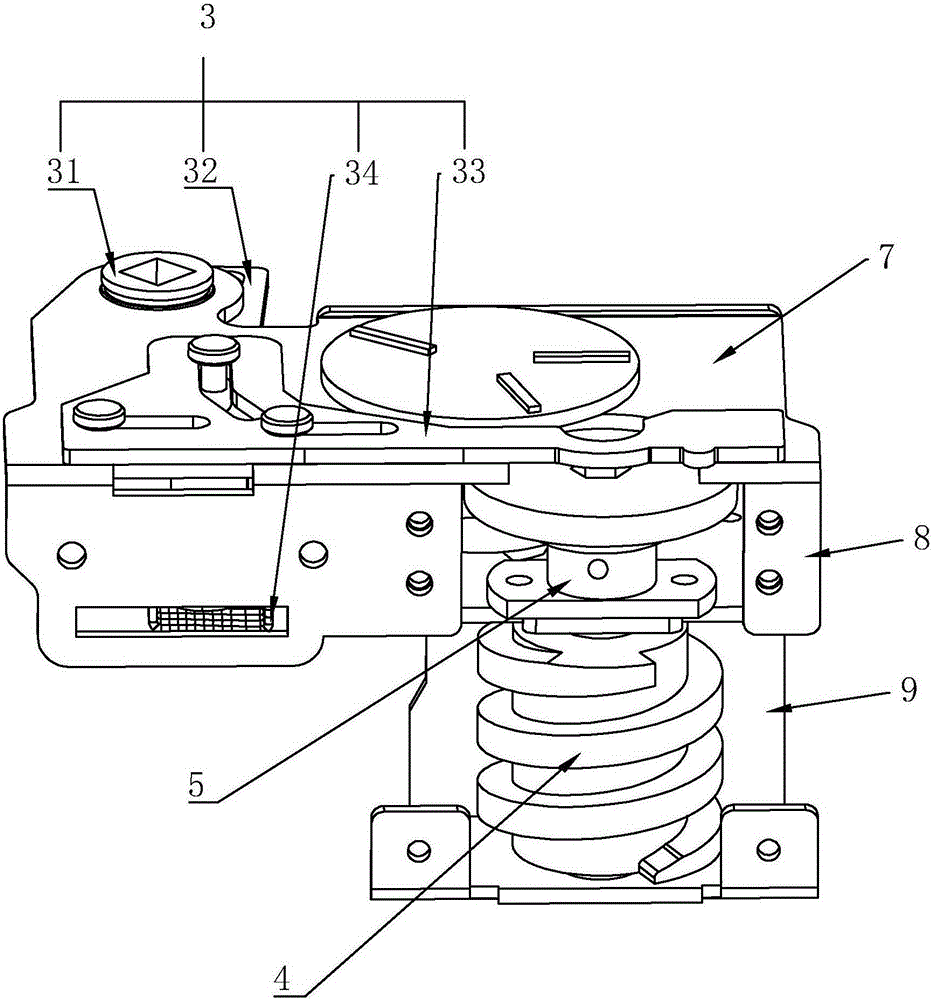

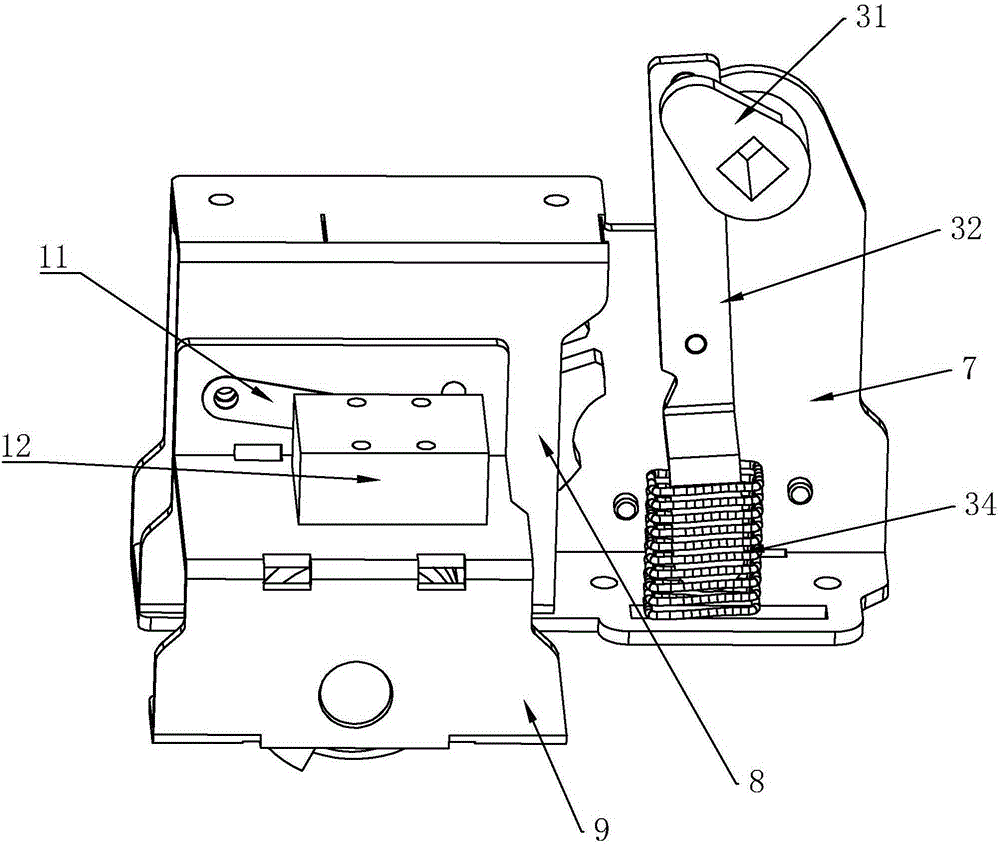

Handheld wire harness and terminal press-fitting tool

ActiveCN110783791AIncrease processing costReduce processing efficiencyLine/current collector detailsProcess engineeringElectrical and Electronics engineering

The invention relates to a handheld wire harness and terminal press-fitting tool, which comprises a wire harness device, a press-fitting device and a clamping device. The middle of the wire harness device is provided with the press-fitting device. The right side of the press-fitting device is provided with the clamping device. The handheld wire harness and terminal press-fitting tool can solve theproblem that existing handheld wire harness and terminal press-fitting tools mostly use a single wire hole for press-fitting, can process only one wire harness in one operation, and are low in wire harness and terminal press-fitting efficiency and large in manual labor workload, and can solve the problem that the handheld wire harness and terminal press-fitting tool lacks a stopping mechanism forthe wire harness and the terminal, which causes misalignment during the press-fitting of the wire harness and the terminal, press-fitting failure and a waste of terminal parts and thus causes an increase in processing cost and a decrease in processing efficiency.

Owner:惠州市金顺电子有限公司

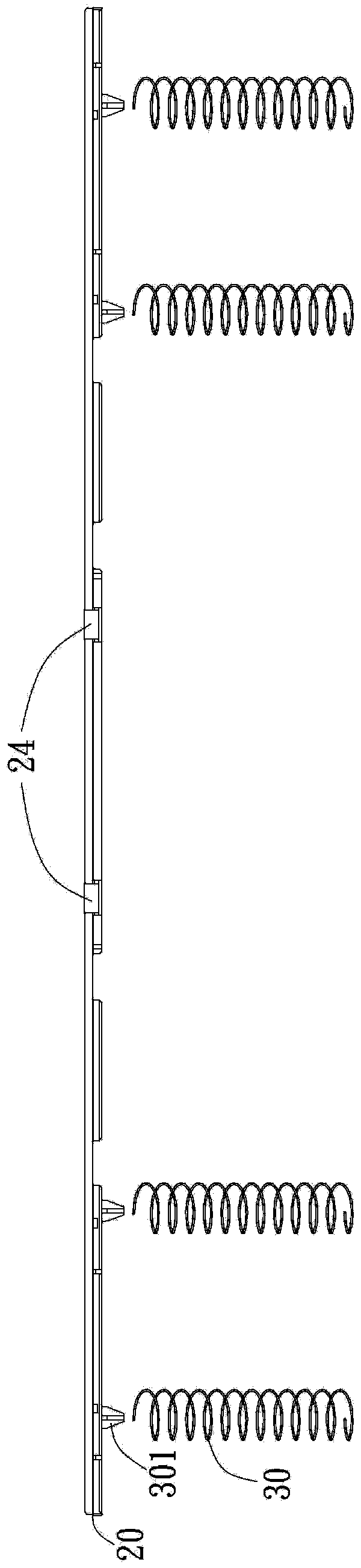

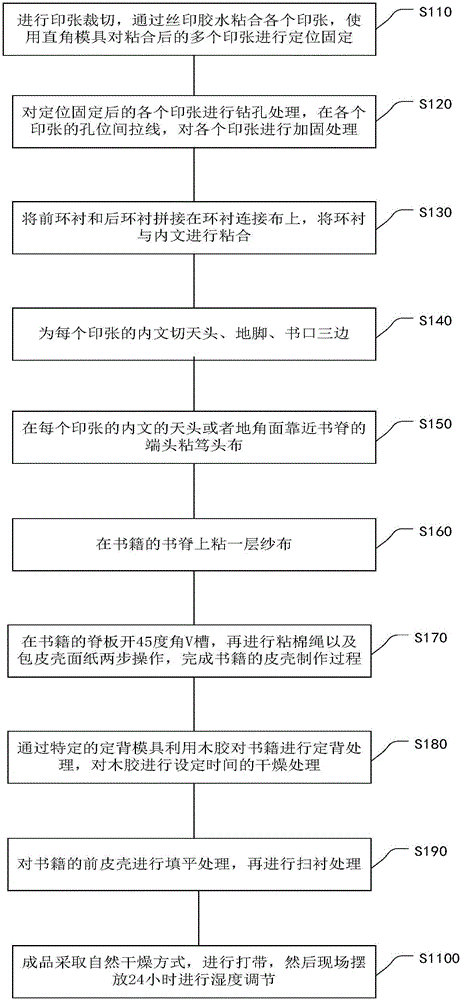

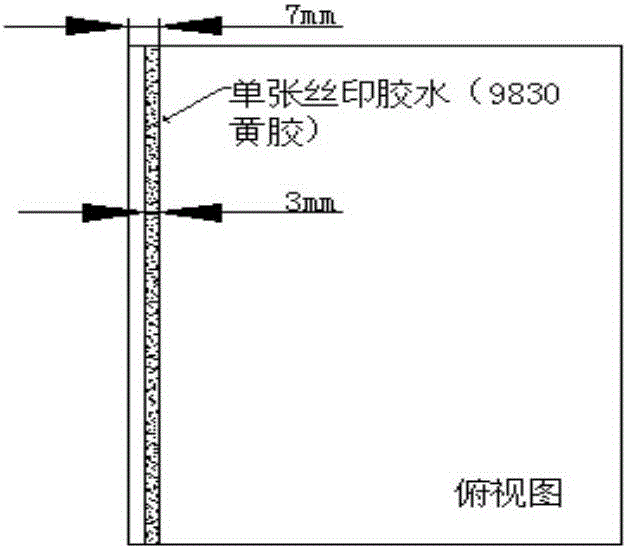

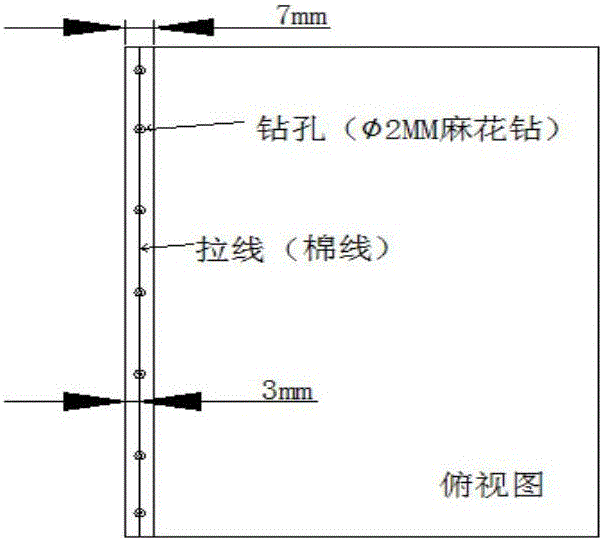

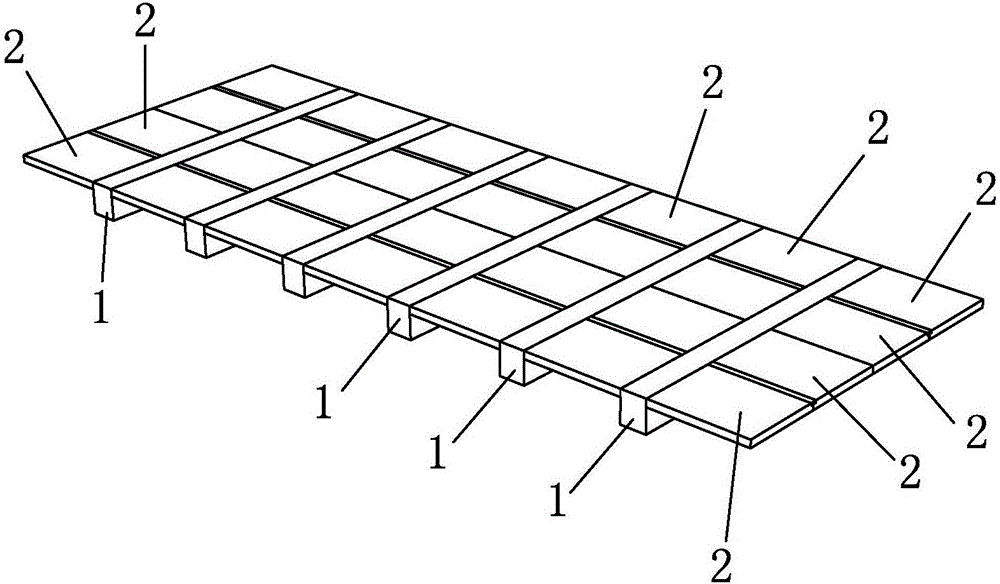

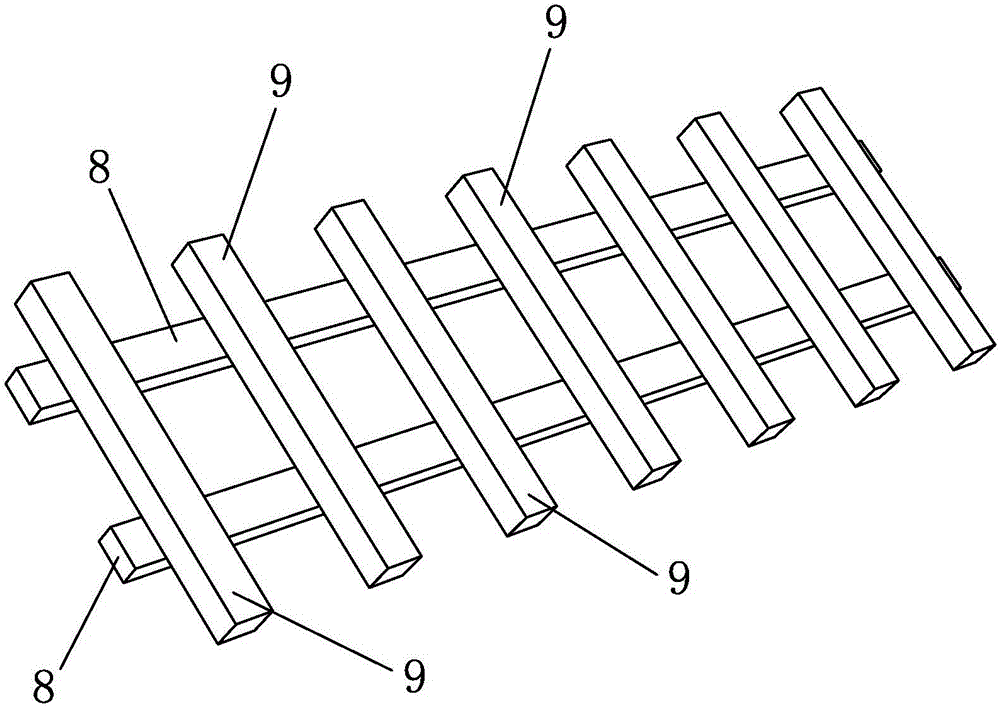

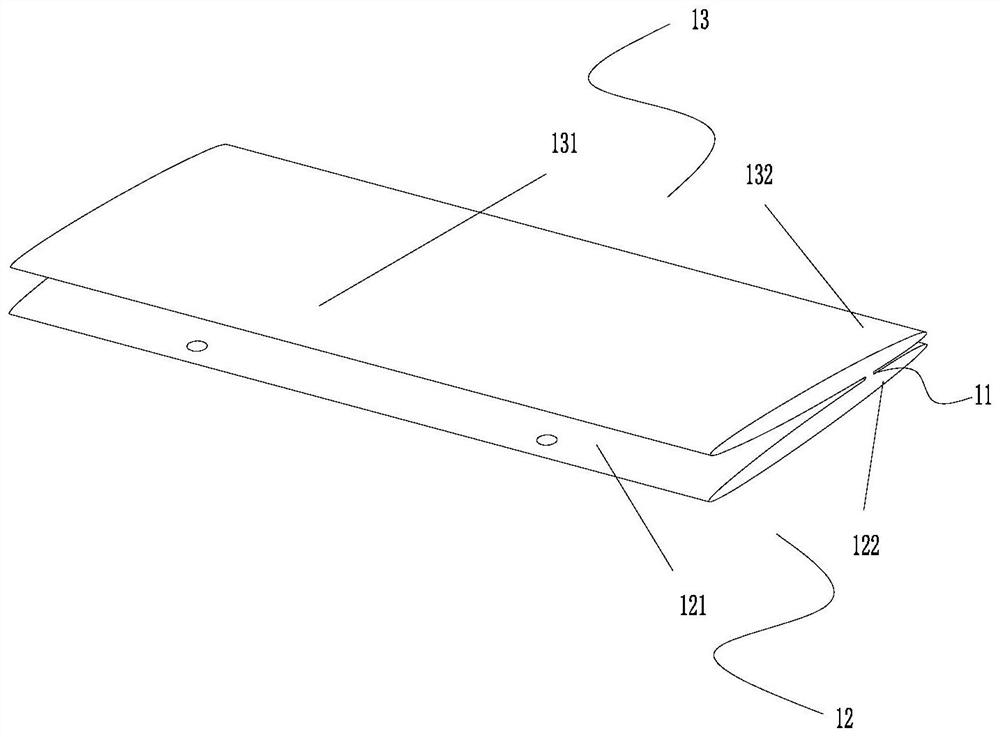

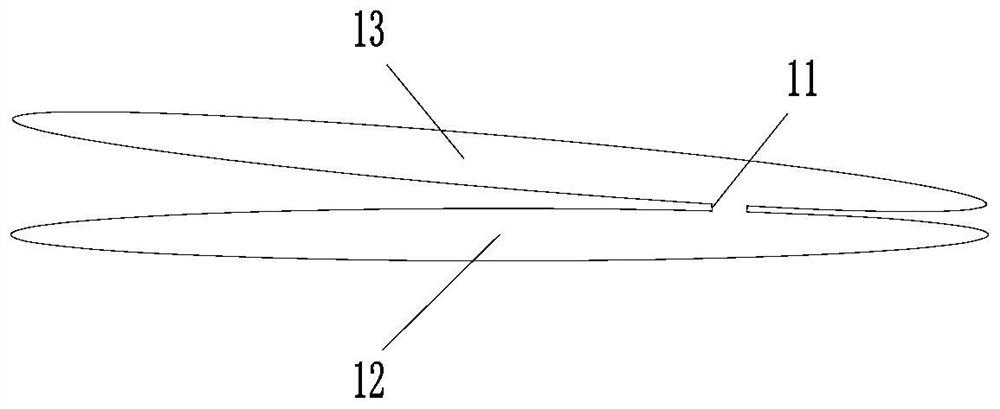

Large-size book production method

ActiveCN105128554ANot prone to misalignmentGuarantee the quality of bindingBook making processesSheet bindingEngineeringLarge size

The invention provides a large-size book production method. The method mainly comprises the following steps: papers of books are cut, glue is brushed at the edges of the papers, all the papers are bonded through the glue, and the multiple bonded papers are positioned and fixed by using a right-angled mold; and all the positioned and fixed papers are drilled, wires are pulled among holes of all the papers, and all the papers are reinforced. Front ring liners and back ring liners are spliced on ring liner connecting cloth; and then, the ring liners are bonded with contents. The right-angled mold is adopted to position, align and fix the multiple bonded papers, so that the papers are not easy to generate the dislocation, the book binding quality is guaranteed, the book beauty is increased, the book production time is shortened, and the book production efficiency is improved. The method can break through the limitation of 787*544 mm size of traditional books to realize the production of books with a larger size.

Owner:北京市文化科技融资租赁股份有限公司

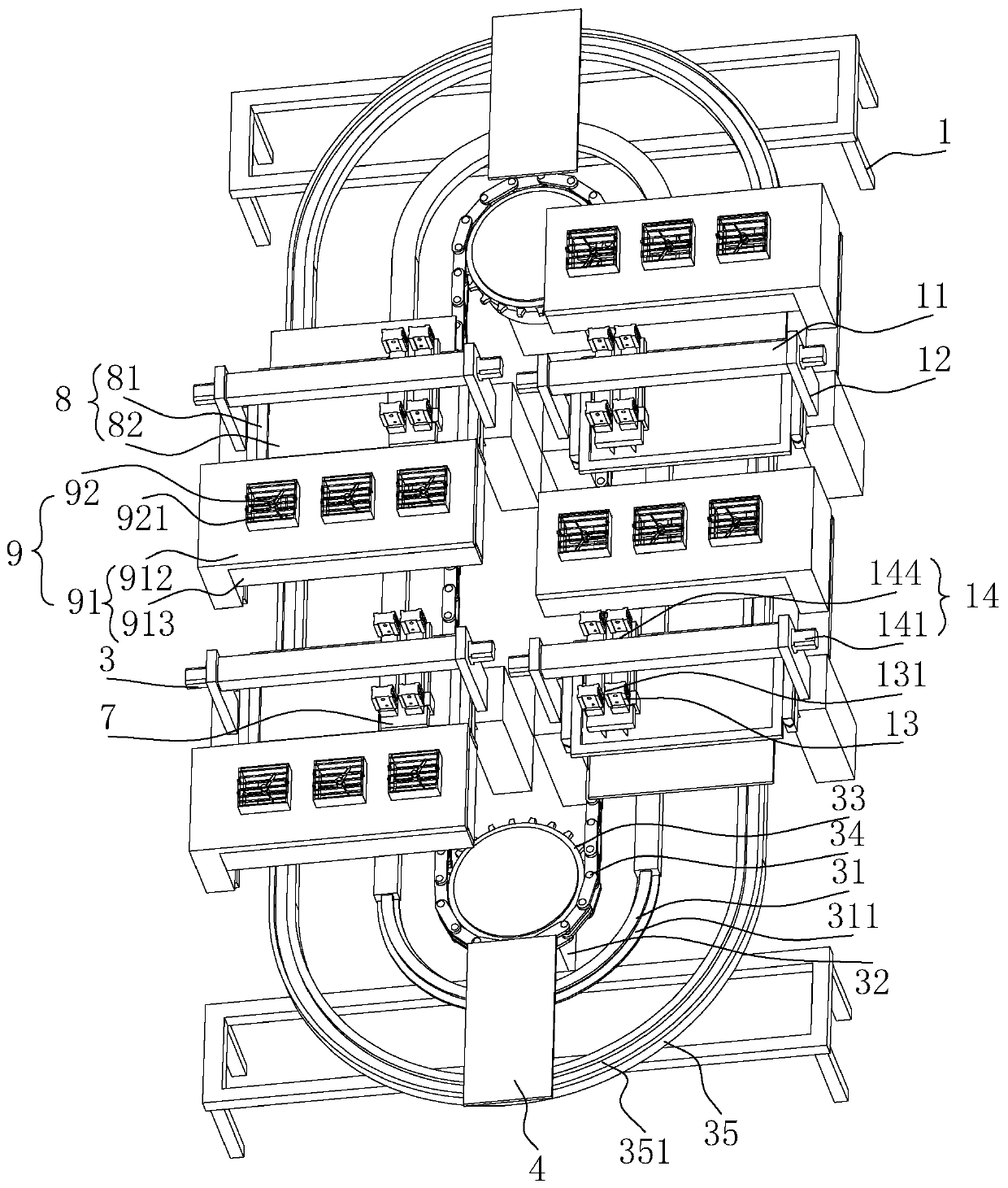

Automatic oval printing machine

ActiveCN111251704AEasy to installEasy to disassembleScreen printersScreen printingScreen printingTextile printer

The invention relates to the technical field of printing machines, in particular to an automatic oval printing machine. The automatic oval printing machine comprises a rack, a main transmission systemand a printing device, wherein a cross beam arm is arranged on the rack, the printing device comprises a scraper and a screen printing plate, the scraper is installed on the cross beam arm, the crossbeam arm is provided with a longitudinal driving mechanism used for driving the scraper to ascend and descend on the screen printing plate, the cross beam arm is provided with a transverse driving mechanism used for driving the scraper to reciprocate on the upper surface of the screen printing plate, the main transmission system comprises an annular track and a printing platen, the annular trackis installed on the rack, the printing platen is connected with the annular track in a sliding mode through a transmission assembly, and the printing platen is located below the screen printing platewhen passing through the printing device. The automatic oval printing machine has the effects of being uniform in pigment printing and firm in coloring during printing.

Owner:东莞威冠服饰工艺有限公司

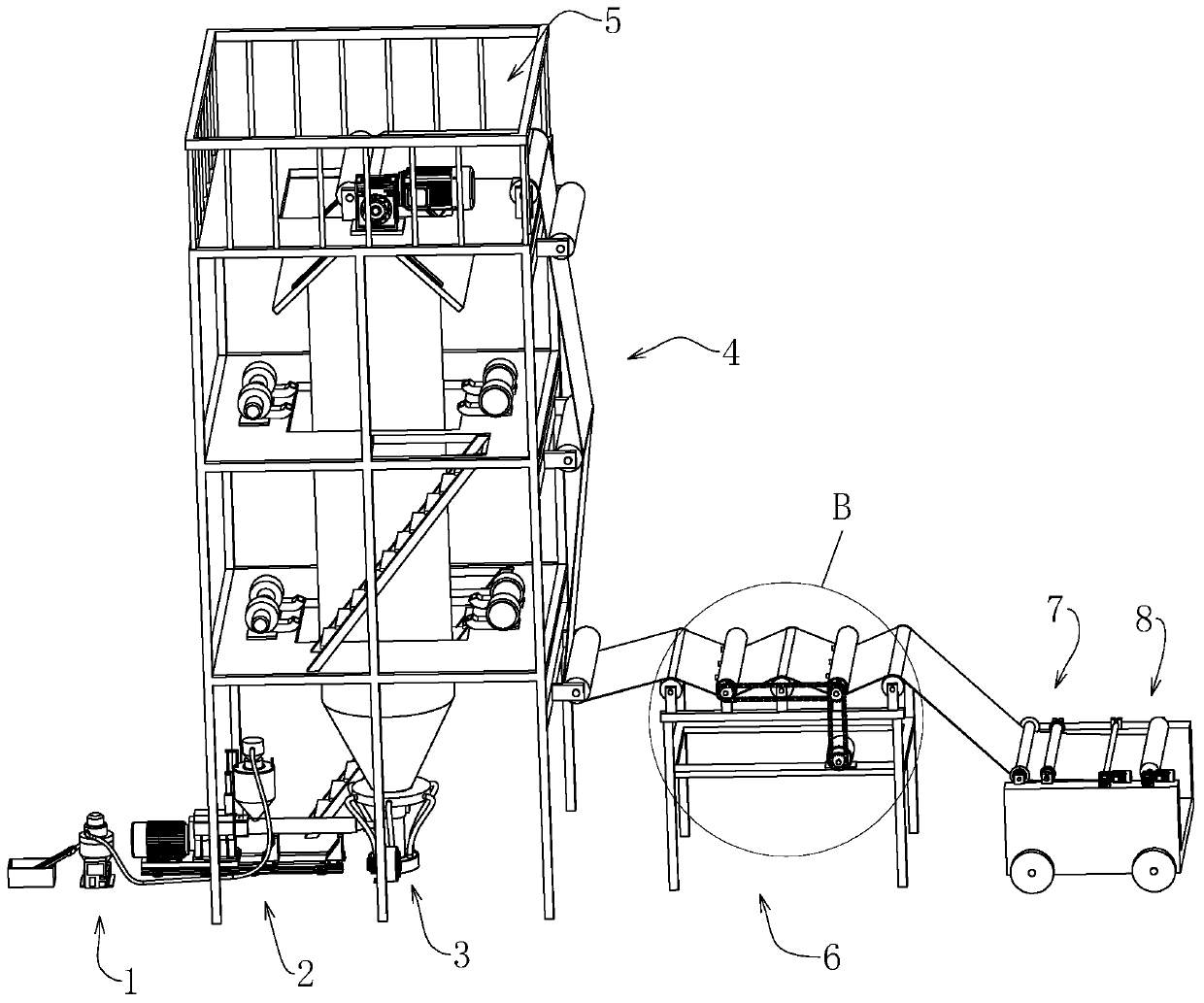

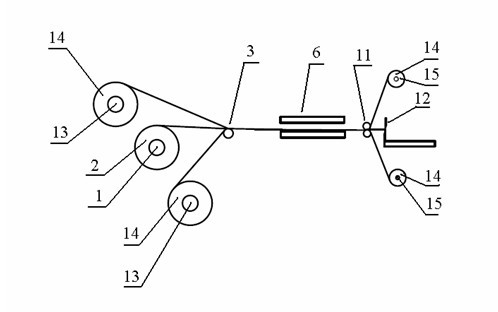

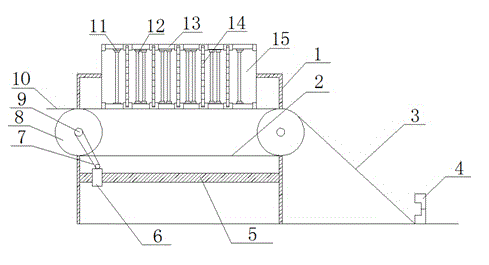

Full-automatic tennis felt wrapping machine

The invention provides an efficient and quick full-automatic tennis felt wrapping machine. Aiming at the defects of existing automatic tennis felt wrapping equipment, the invention provides the efficient and quick full-automatic tennis felt wrapping machine which can integrate felt separation and felt wrapping. The machine comprises a machine body, a felt separating device, a felt wrapping device and a conveying device, wherein the felt separating device, the felt wrapping device and the conveying device are all arranged on the machine body; the felt separating device and the felt wrapping device are arranged at two sides of the conveying device; the felt separating device comprises a feeding box and a separating mechanism; tennis felt formed by cutting is arranged in the feeding box; the separating mechanism comprises a separating needle and a power mechanism I; the separating needle is arranged at one end of the feeding box and moves under the action of the power mechanism I to separate the tennis felt at the outermost layer in the feeding box; a tennis liner with an outer layer coated with glue is arranged on the conveying device; and the conveying device sequentially conveys the tennis liner to the felt separating device and the felt wrapping device to operate.

Owner:金华市畅奔机械设备制造有限公司

Anti-seepage construction method for channel of accumulation waterlogging wet land

ActiveCN106544987AImprove construction efficiencyImprove integrityArtificial water canalsMarine site engineeringWater seepageComposite structure

The invention discloses an anti-seepage construction method for a channel of accumulation waterlogging wet land. The method comprises the first step of foundation treatment, the second step of channel bottom layer sand gravel cushion layer construction, the third step of channel bottom layer first building block construction, the fourth step of channel slope first building block construction, the fifth step of channel slope second building block construction, the sixth step of first building block construction area treatment and the seventh step of first building block construction area and second building block construction area flushing. First building blocks and second building blocks are adopted in the method for serving as a channel anti-seepage layer for construction, the single anti-seepage structure of the channel is converted into a composite structure, and the channel anti-seepage layer construction integrity and flatness are good; and the phenomena of water seepage and leakage of the channel are not likely to happen, the channel water conveying capability is improved, and the water conveying losses are reduced.

Owner:浙江景昌建设有限公司

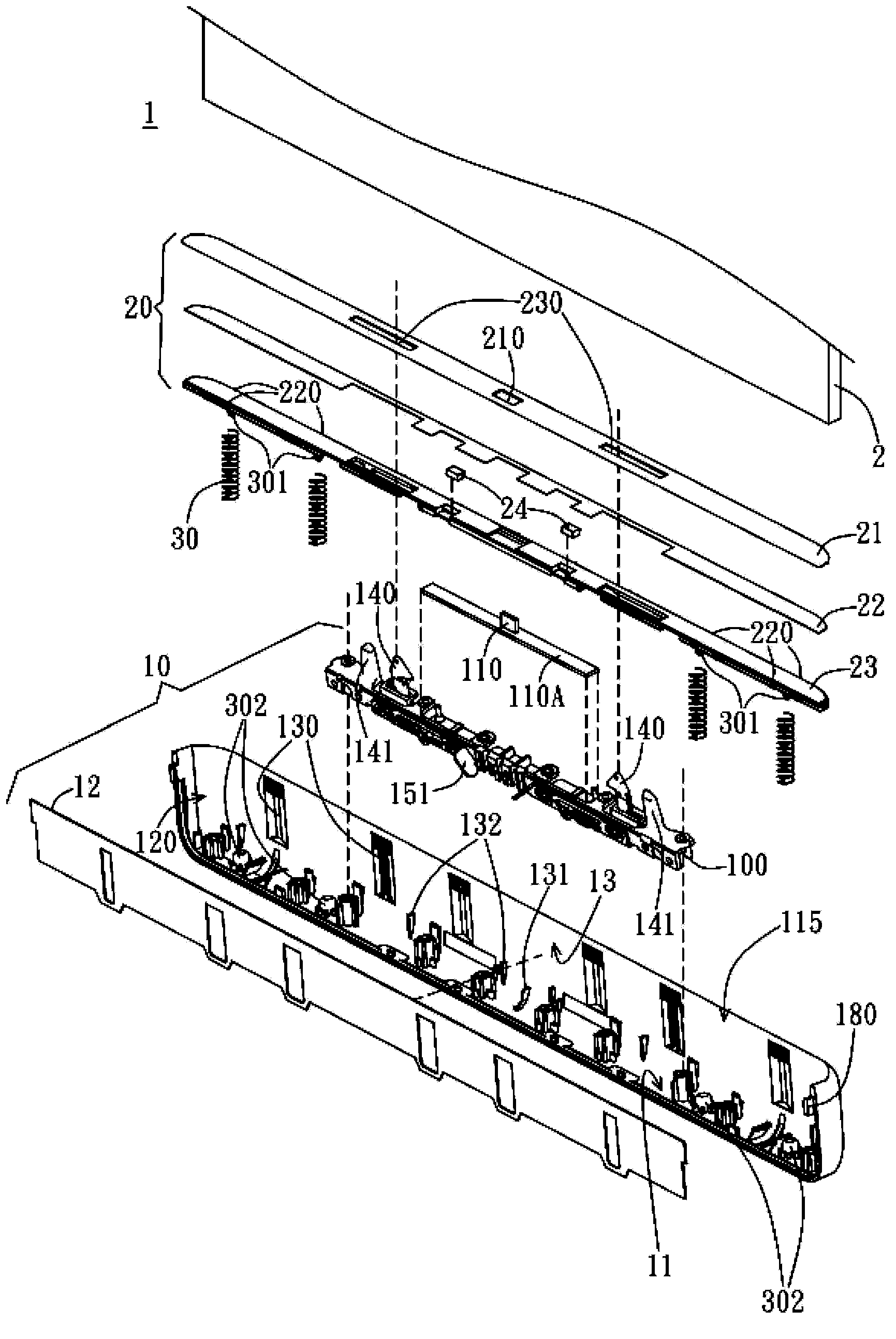

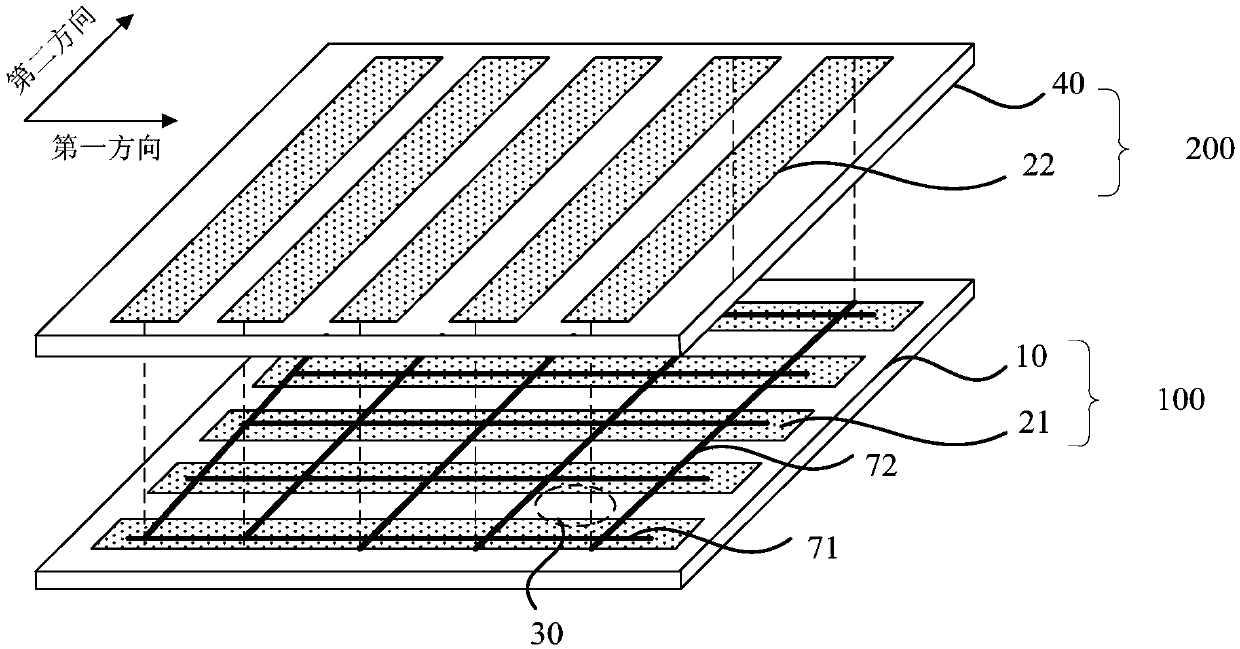

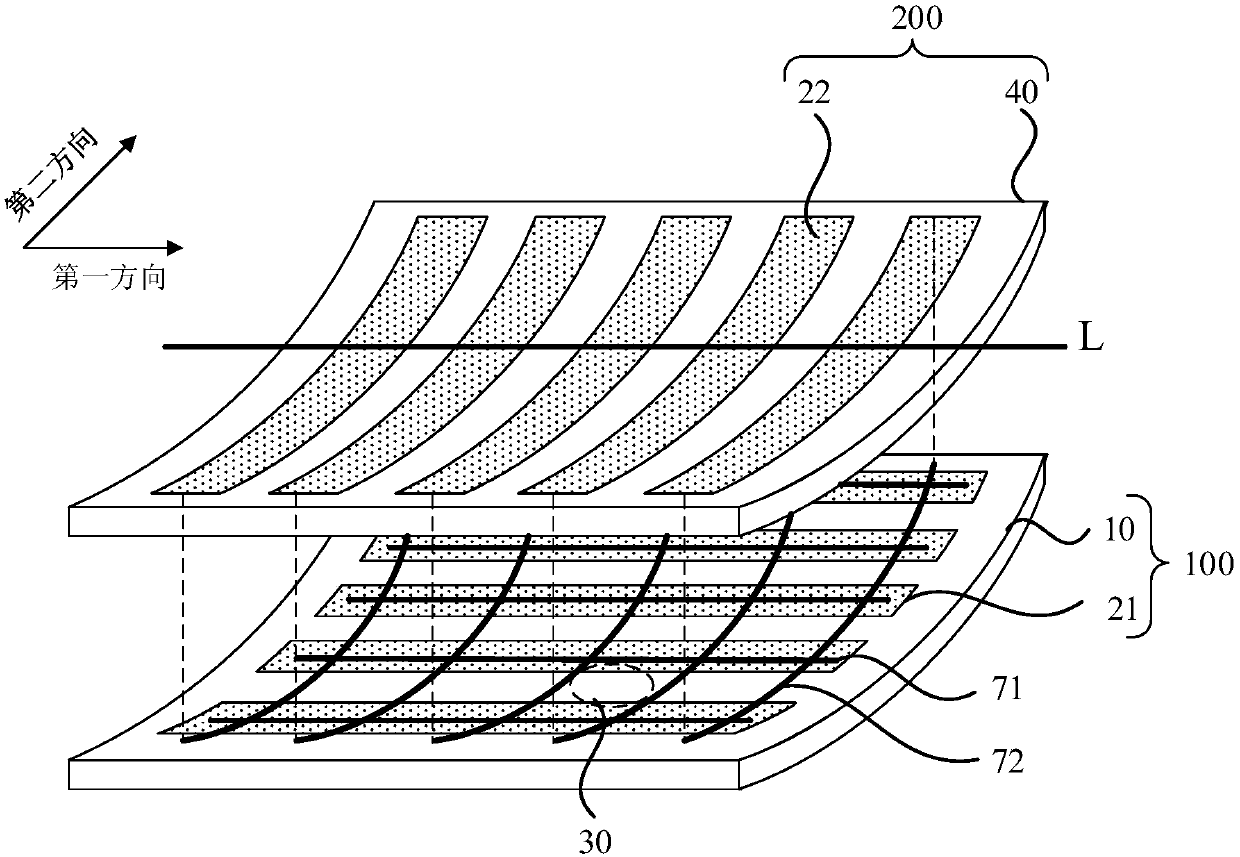

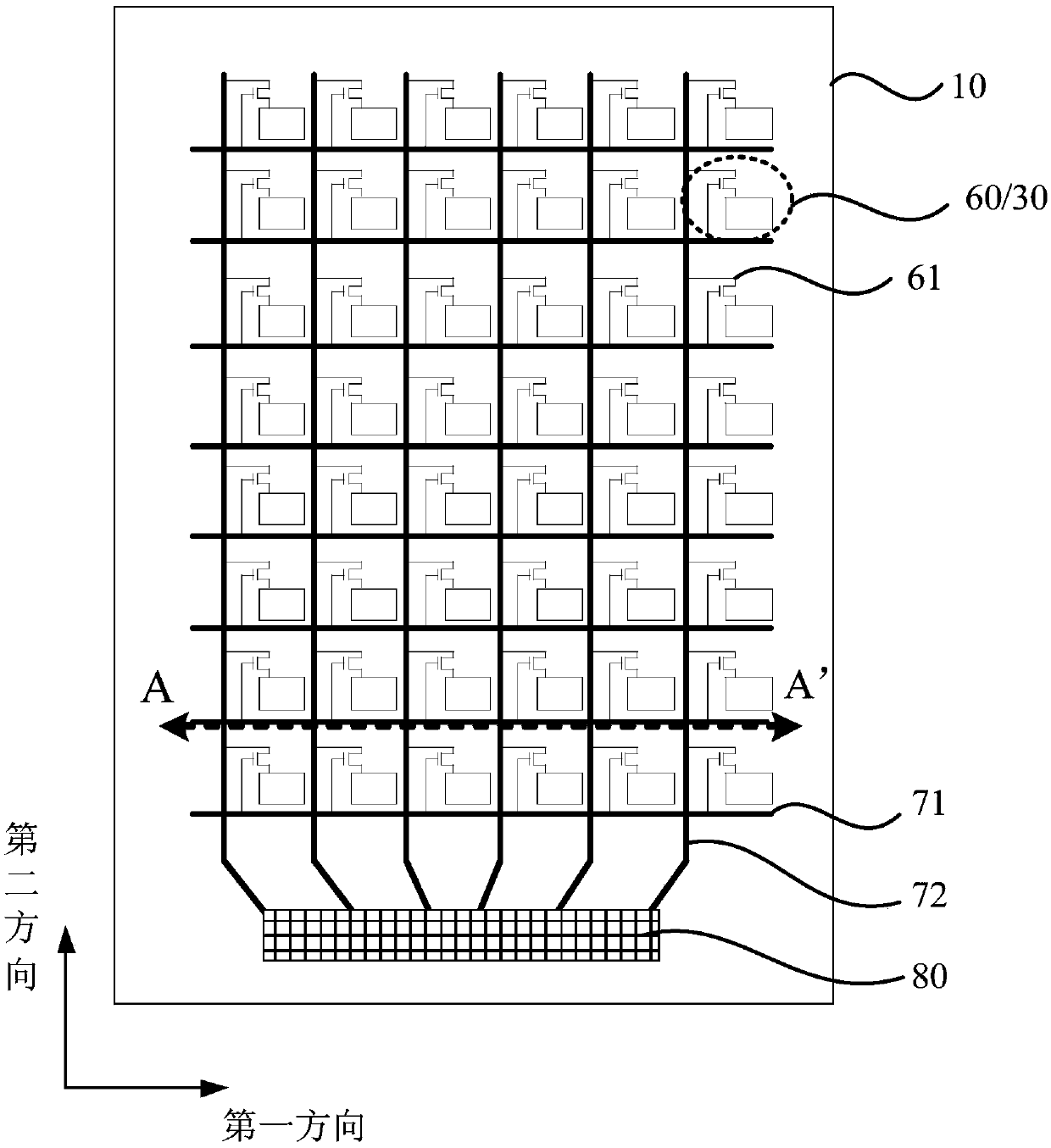

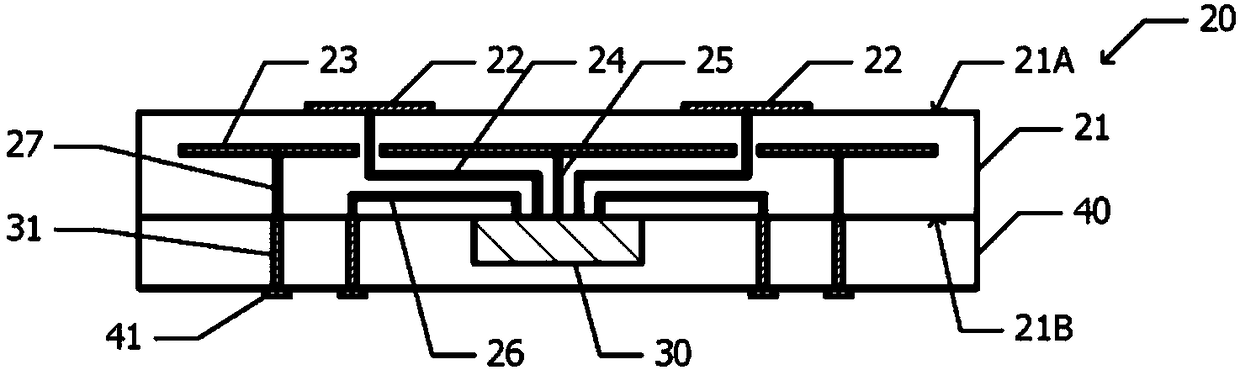

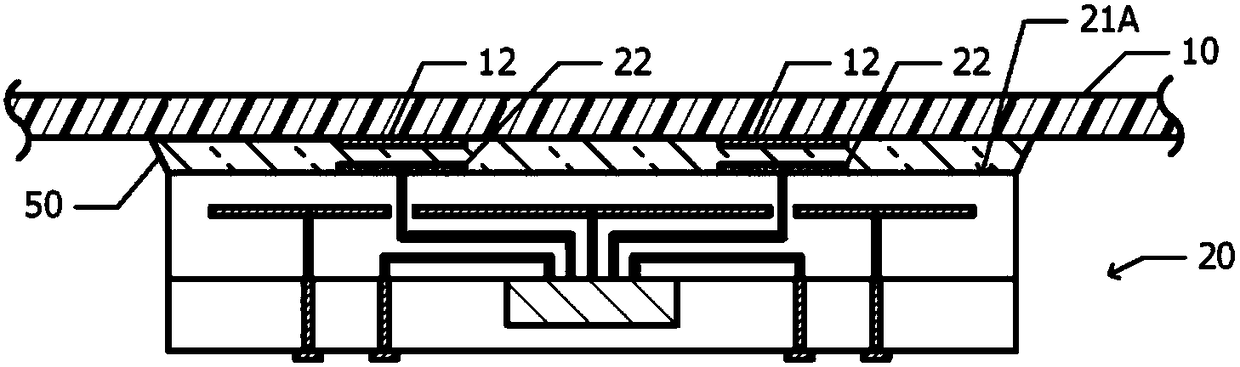

Curved display panel, display device and manufacturing method of curved display panel

InactiveCN108681141ASolve the problem of light leakageSolve color mixingNon-linear opticsColor filmDisplay device

The invention provides a curved display panel, a display device and a manufacturing method of the curved display panel. The curved display panel comprises an array substrate and a color film substratewhich are opposite, wherein the array substrate comprises a plurality of first signal lines and a plurality of second signal lines, the first signal lines are arranged in the second direction, and the second signal lines are arranged in the first direction. The array substrate further comprises a first substrate body and a plurality of array substrate shading strips, wherein the array substrate shading strips are located on the first substrate body, extend in the first direction and are arranged in the second direction. The color film substrate further comprises a second substrate body and aplurality of color film substrate shading strips, wherein the color film substrate shading strips are located on the second substrate body, extend in the second direction and are arranged in the firstdirection. The orthographic projection of the first signal lines on the first substrate body is located in the orthographic projection of the array substrate shading strips on the first substrate body, and the orthographic projection of the second signal lines on the first substrate body is located in the orthographic projection of the color film shading strips on the first substrate body. The problem of color mixture caused by dislocation of the curved display panel is solved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

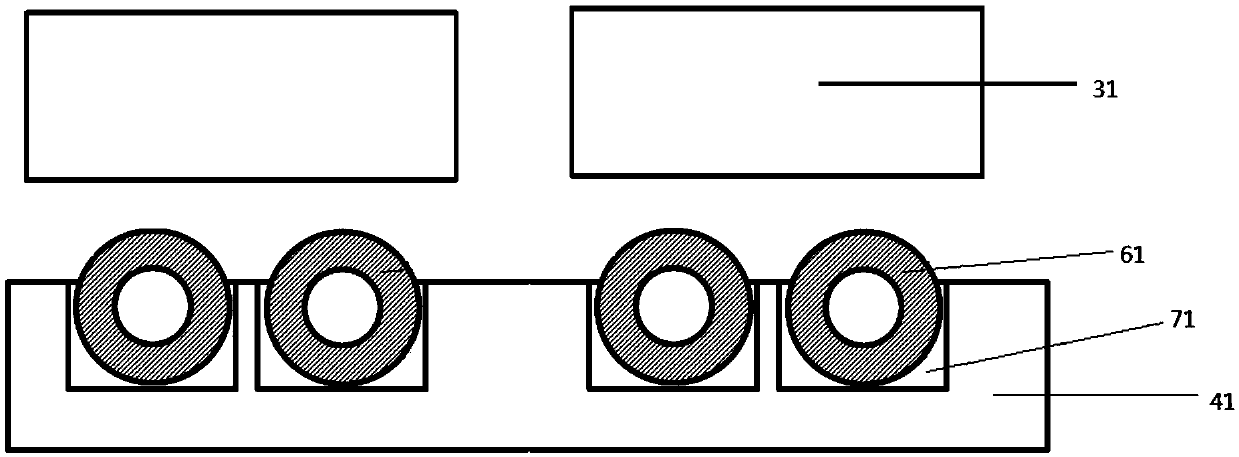

LED box assembly

PendingCN109118975AEliminate sheddingGuaranteed security propertiesIdentification meansLarge screenEngineering

The invention provides an LED box assembly, comprising a frame, wherein a connecting hole is arranged on the frame, and a first magnetic attractor is arranged at a first end of the connecting hole; the LED module provided with a second magnetic attractor, and the second magnetic attractor is inserted into the connection hole from the second end of the connection hole; an anti-detachment member fordefining the second magnetic attraction member within the connection hole. The invention eliminates the problem that the LED module may fall off due to the small magnetic force in front of the LED module, the safety property of the LED box assembly is ensured, and even when the magnetism of the first magnetic attracting member and the second magnetic attracting member is invalidated, the moving space of the LED module is very small, and the problems of falling off, dislocation or deformation are not easy to occur, which not only ensures the safety, but also ensures the display effect of the LED large screen.

Owner:LEYARD

Flame-proof large brick on back cut of roasting furnace chamber and method of manufacturing the same

The invention provides a roaster room back cup fire proof big brick, which is made of a dry material part and addition agents, wherein, the dry material part comprises: 32 to 37 weight portions of waste fire proof brick materials the grain diameter of which is 10-5mm, 22 to 26 weight portions of waste fire proof brick materials the grain diameter of which is 5-3mm, 8 to 12 weight portions of waste fire proof brick materials the grain diameter of which is less than 3mm and 28 to 33 weight portions of 180 head waste fire proof brick fine materials; the addition agents are water glass solution, sodium hexametahposphate, sodium fluosilicate and steel fibre; the invention adopts waste clay quality fire proof brick as main material to prepare the roaster room back cup fire proof big brick, is formed by direct moulding by adopting a vibration moulding mode during preparation, makes the fire proof big brick be a whole and do not easily have a dislocation even being impacted, basically does not need to be repaired, adopts waste materials as the main raw material, realizes resource recycling, changes waste into treasure, reduces environment pollution at the same time, reduces the labour intensity, and enhances the work efficiency.

Owner:MIANCHI BRANCH SANMENXIA TIANYUAN ALUMINUM

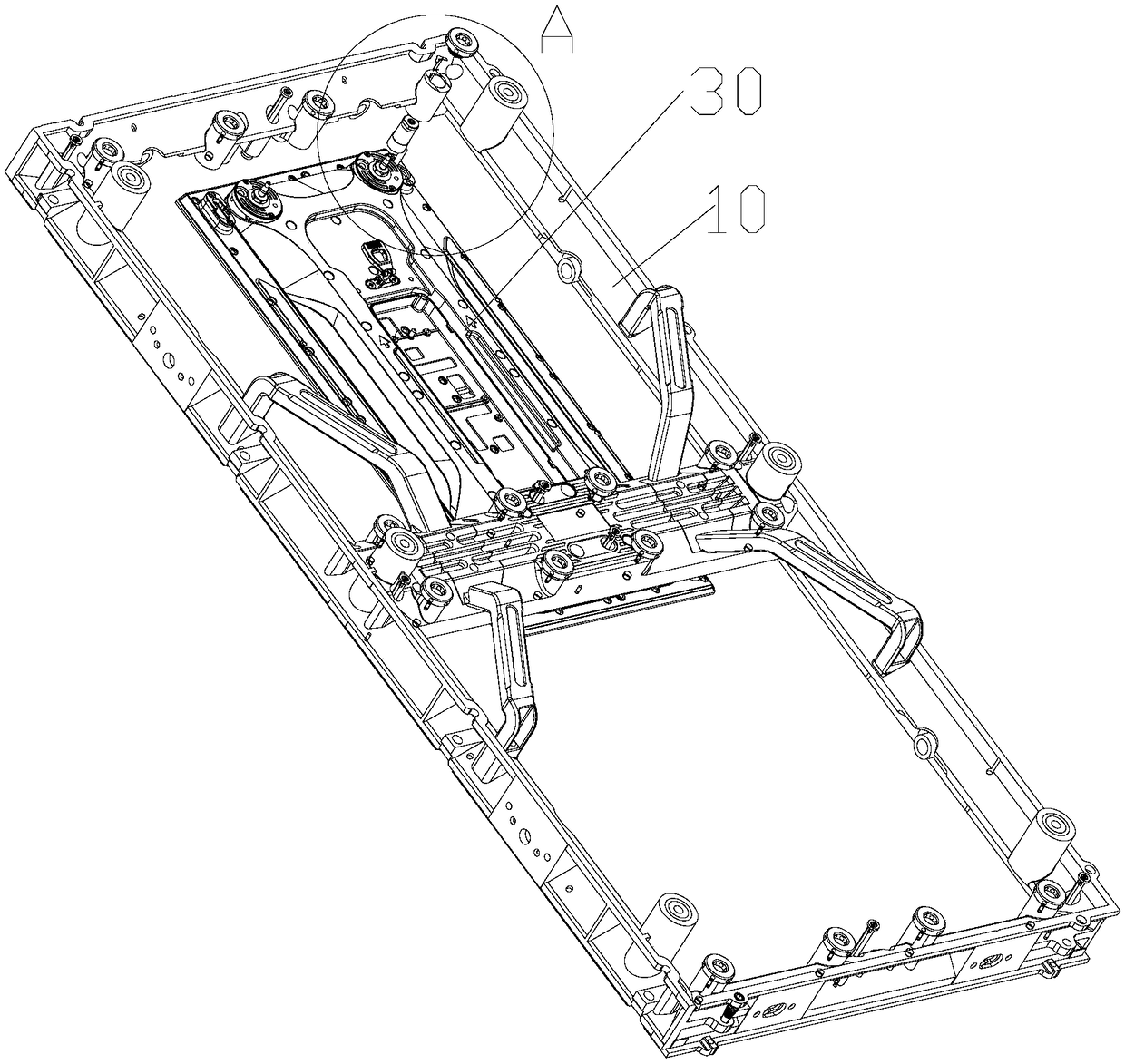

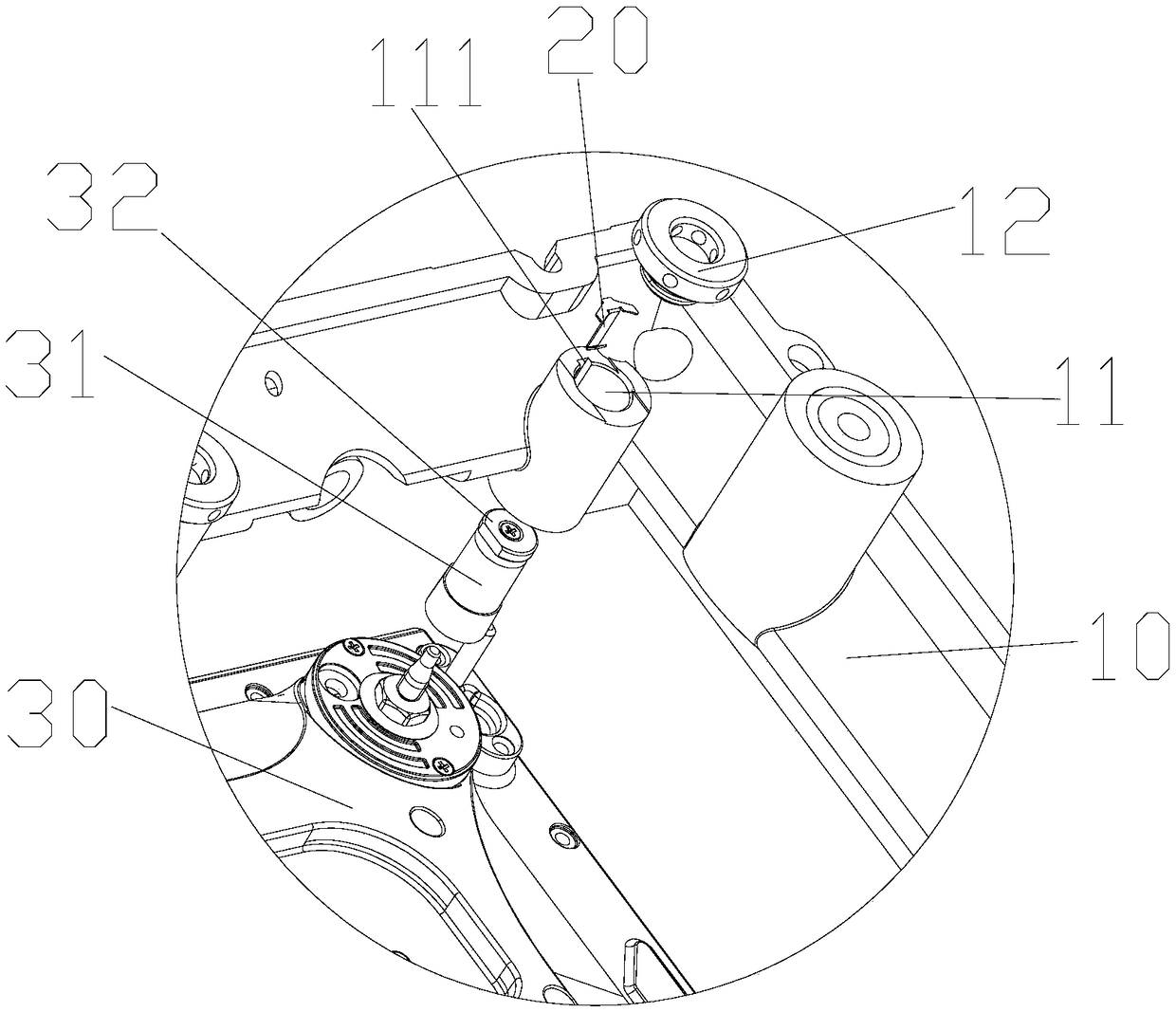

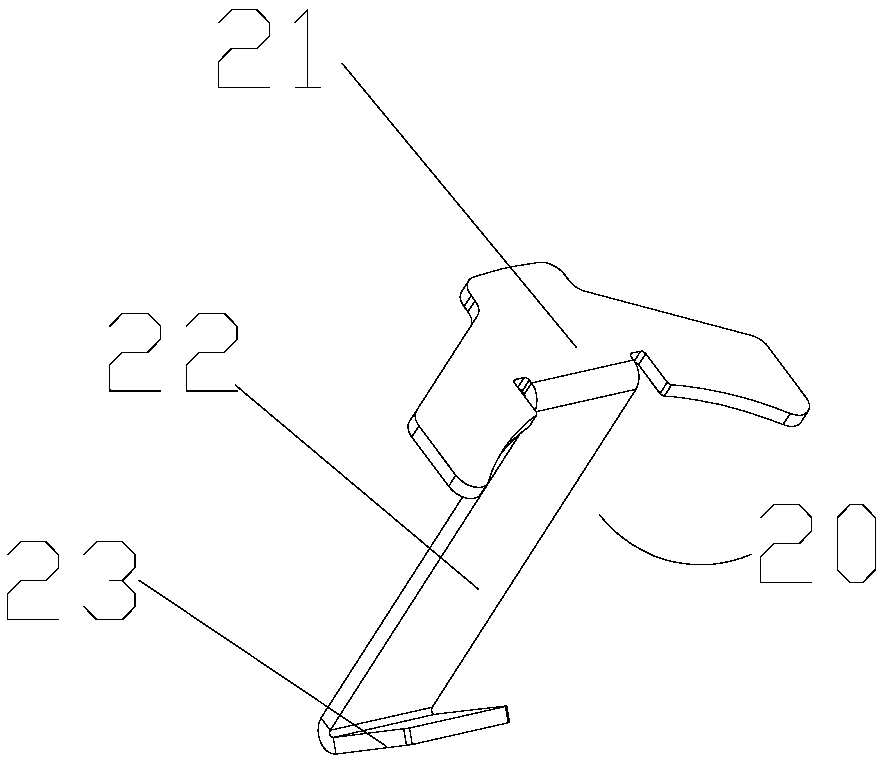

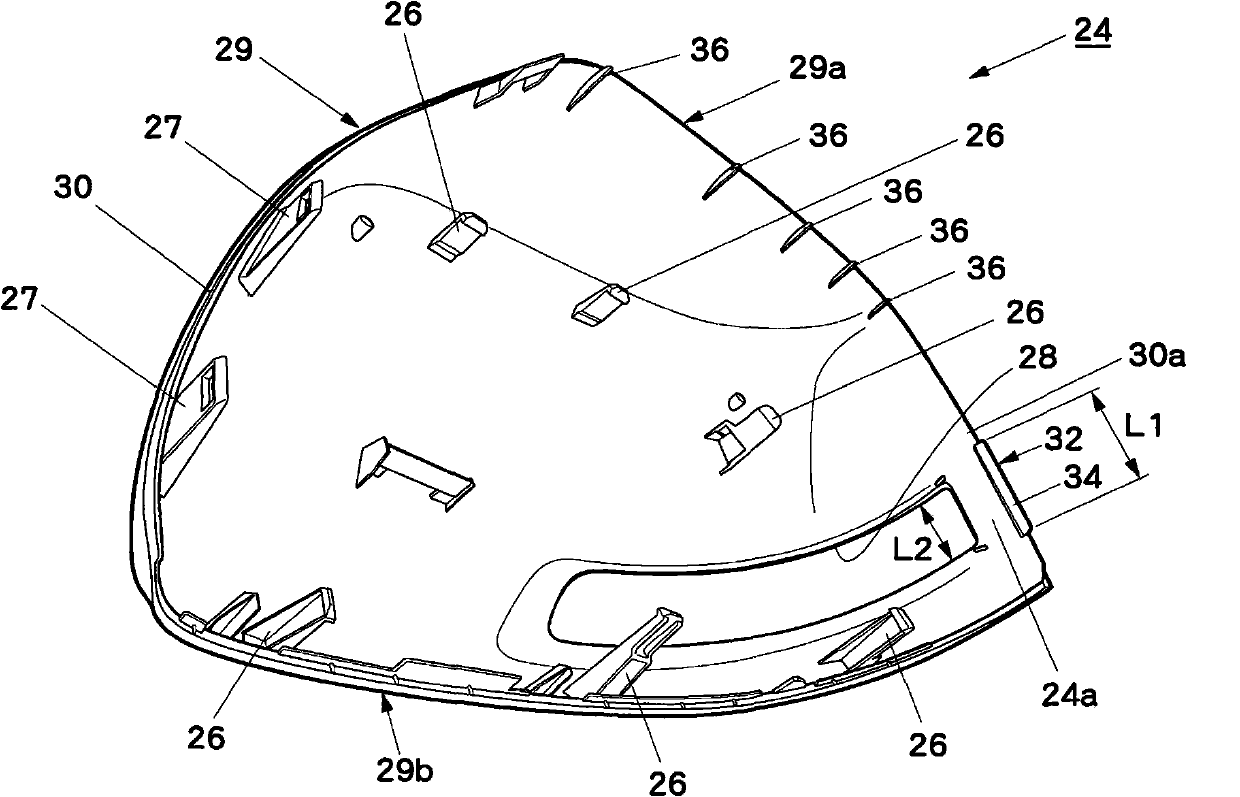

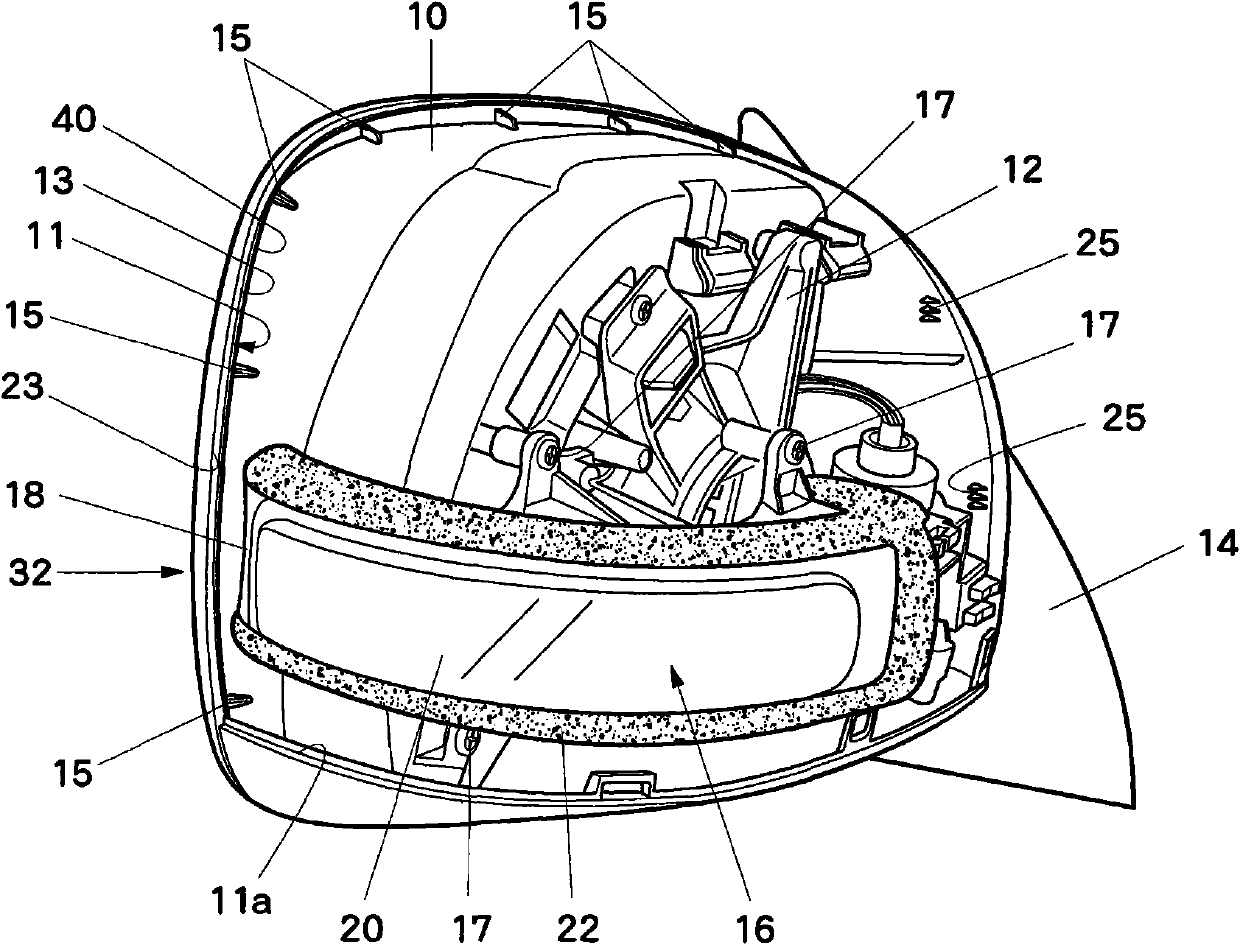

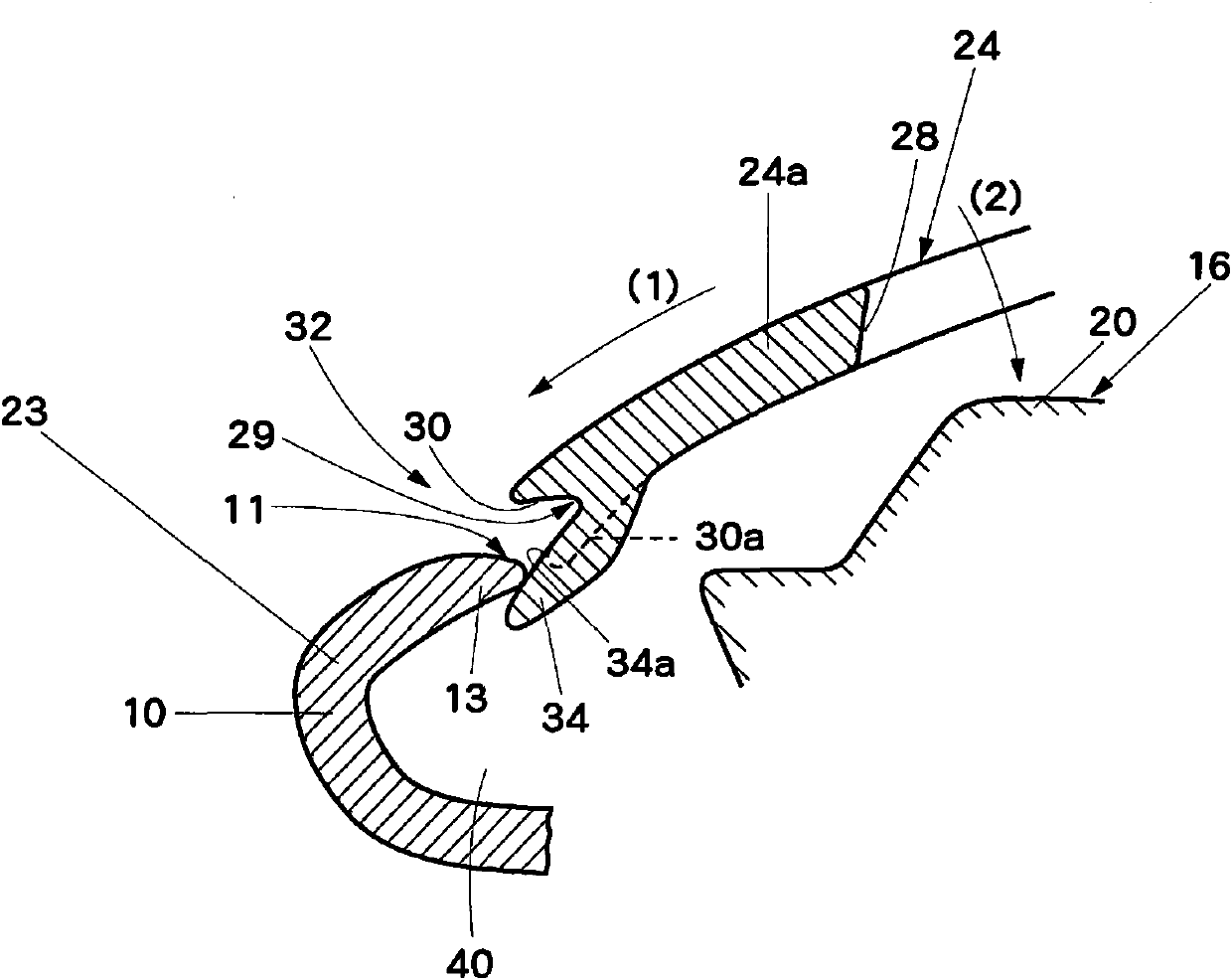

Outer mirror with turn lamp

ActiveCN102001312AChimerism is not easyNot prone to misalignmentOptical signallingOptical viewingEngineeringWing mirror

There is provided an outer mirror with turn lamp that facilitates assembling of a housing cover to a mirror housing and increases strength of the housing cover. A turn lamp assembly (16) is mounted to a mirror housing (10). A housing cover (24) is placed over and mounted to a partial area of the mirror housing (10). Thus, a lens (20) of the turn lamp assembly (16) is exposed through an opening (28) formed in an outer position of the housing cover (24). The mirror housing (10) and the housing cover (24) are connected to each other with a ridge (13) and a groove (30) in end surfaces (11, 29) and abutting against and fitting each other. On a wall (30a) on an inner side of the mirror that constitutes a part of the component of the groove (30) in the housing cover (24), at an assembling start position (32) in an outer position outside the opening, an assembling leading rib (34) is formed that protrudes in a direction abutting against the end surface (11) of the mirror housing (10).

Owner:MURAKAMI CORP

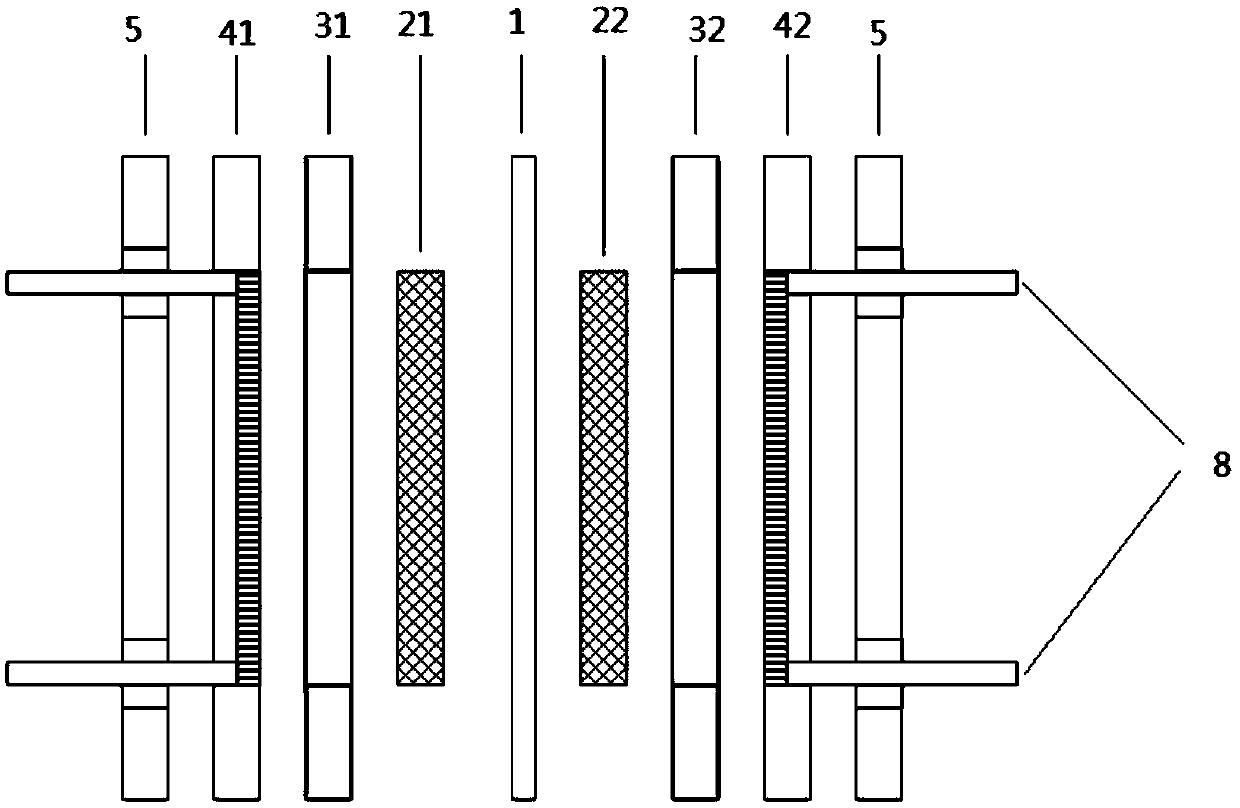

Flow battery capable of realizing sealing and battery stack

ActiveCN110970647AImprove assembly efficiencyWith guidanceRegenerative fuel cellsElectrical batteryStructural engineering

The invention relates to the field of flow batteries, and discloses a flow battery capable of realizing sealing and a battery stack. The flow battery comprises: a diaphragm; an electrode, a sealing gasket and a bipolar plate sequentially arranged on one side of the diaphragm; sealing rings; a current collecting area and grooves matched with the sealing rings arranged on the bipolar plate, whereinthe grooves are arranged at the outer portion of the current collecting area in a surrounding mode, the sealing rings are arranged in the grooves, and the sealing gasket covers the sealing rings; an opposite-side electrode, an opposite-side sealing gasket and an opposite-side bipolar plate arranged at the other side of the diaphragm; opposite-side sealing rings; an opposite-side flow collecting area and opposite-side grooves matched with the opposite-side sealing rings arranged at the opposite side bipolar plate, wherein the opposite-side grooves are arranged at the outer portion of the opposite-side flow collecting area in a surrounding mode, the opposite-side sealing rings are arranged in the opposite-side grooves, and the opposite-side sealing gasket covers the opposite-side sealing rings; and fastening parts used for pressing the flow battery, so that the sealing rings and the opposite-side sealing rings deform to realize sealing. The flow battery provided by the invention can realize better sealing, and is simple to assemble and low in manufacturing difficulty.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

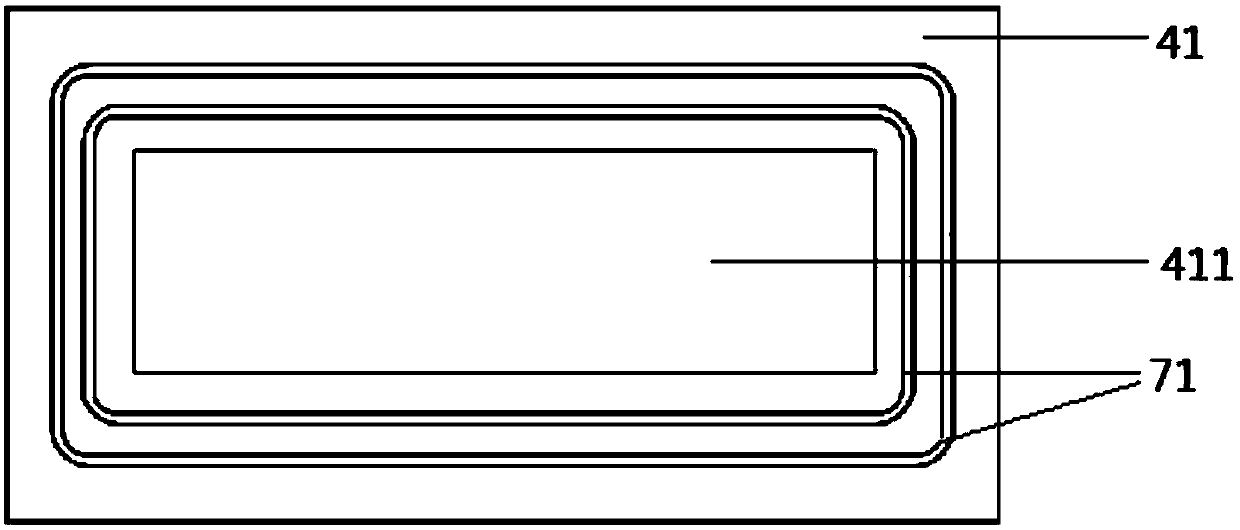

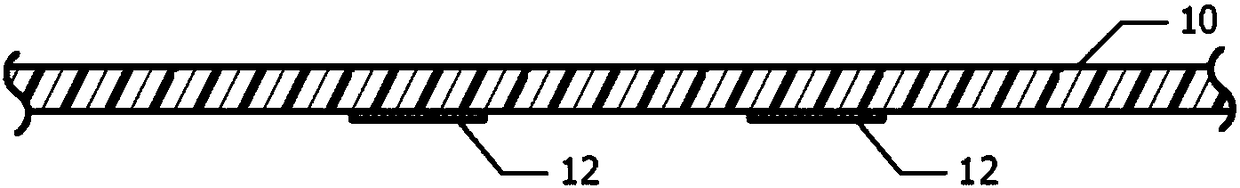

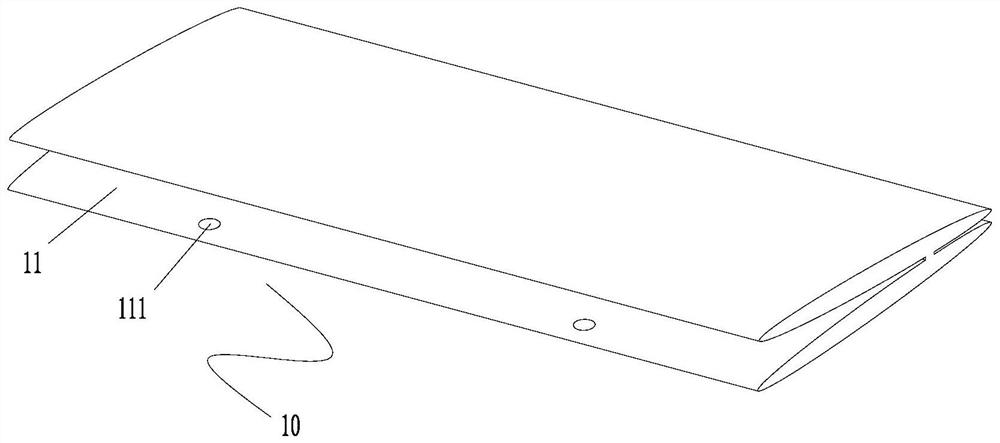

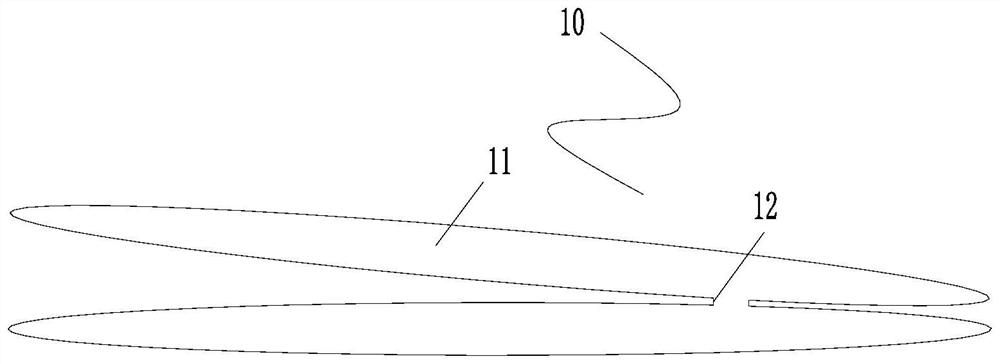

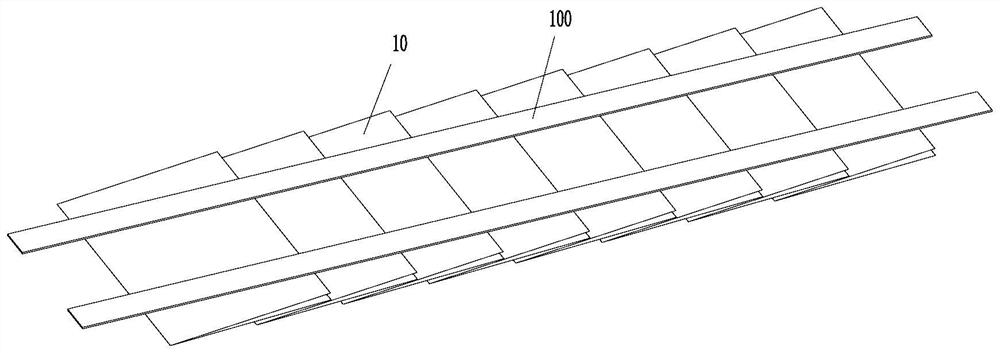

Antenna device and method for manufacturing antenna device

ActiveCN108376833ARealize thinner and lighterNot prone to misalignmentParticular array feeding systemsRadiating elements structural formsElectromagnetic couplingDielectric substrate

The invention provides an antenna device, which is suitable for thinning and lightening an apparatus and is not liable to cause staggering between a power supply component and a passive component. Anantenna module includes a dielectric substrate and a feed element provided on the dielectric substrate. A radome formed from a dielectric is disposed so as to oppose the antenna module in a radiationdirection of the feed element. A parasitic element is provided at a position on the radome at which the electromagnetic coupling with the feed element is achieved. The antenna module is bonded to theradome by an adhesive layer disposed between the antenna module and the radome.

Owner:MURATA MFG CO LTD

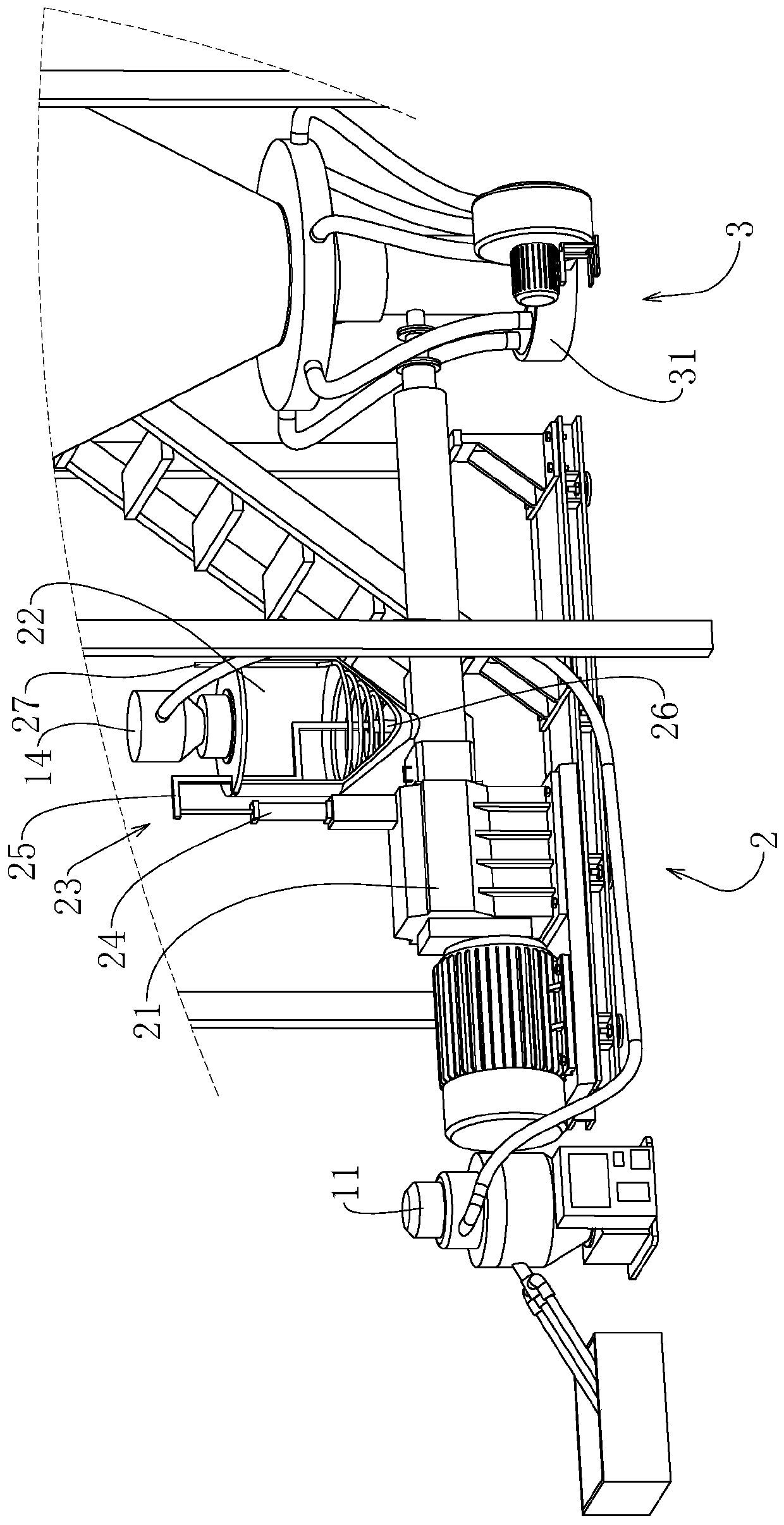

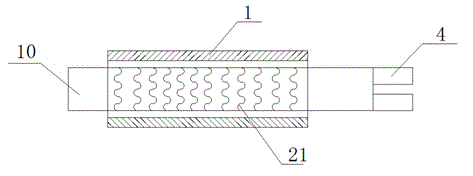

PE film efficient blow molding production line

The invention relates to a PE film efficient blow molding production line. The production line comprises a material suction device, an extrusion device, a blow molding device, a cooling device, an extrusion device, a punching device, an edge cutting device and a material collecting device, wherein the material suction device comprises a material suction machine, the material suction end of the material suction machine is connected with a plurality of material suction pipes, the extrusion device comprises an extruder body, the blow molding device comprises a blow molding machine body, the cooling device comprises a support and a plurality of cooling air outlet pipes located in the support, the extrusion device comprises a herringbone plate located at the upper end of the support and a mainpressing roller and an auxiliary pressing roller which have a cooling effect, the punching device comprises a first punching roller and a second punching roller, the first punching roller and the second punching roller are each provided with a plurality of annular roller cutters, the edge cutting device and the material collecting device are located in a movable rack, and the material collecting device comprises a first material collecting roller and a second material collecting roller. According to the PE film efficient blow molding production line, a PE film is punched and trimmed from production to winding, and the production line has the effects of being high in machining efficiency, high in production efficiency, saving in cost and low in labor intensity.

Owner:苏州惠国塑料制品有限公司

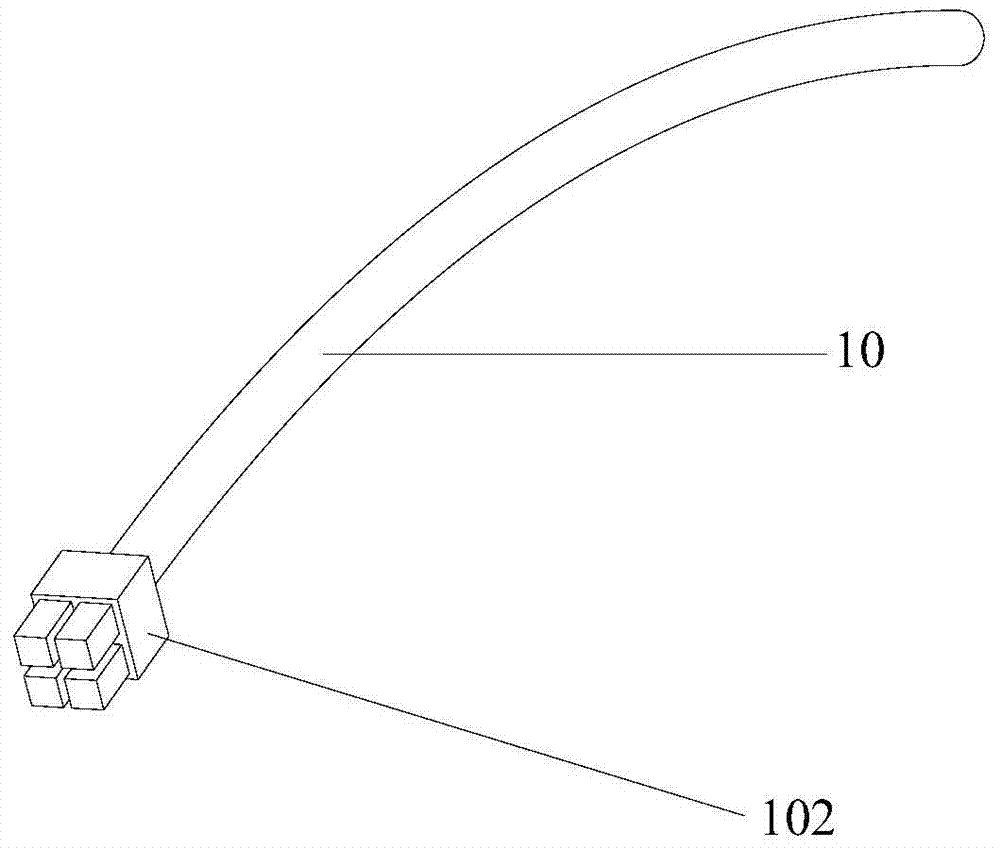

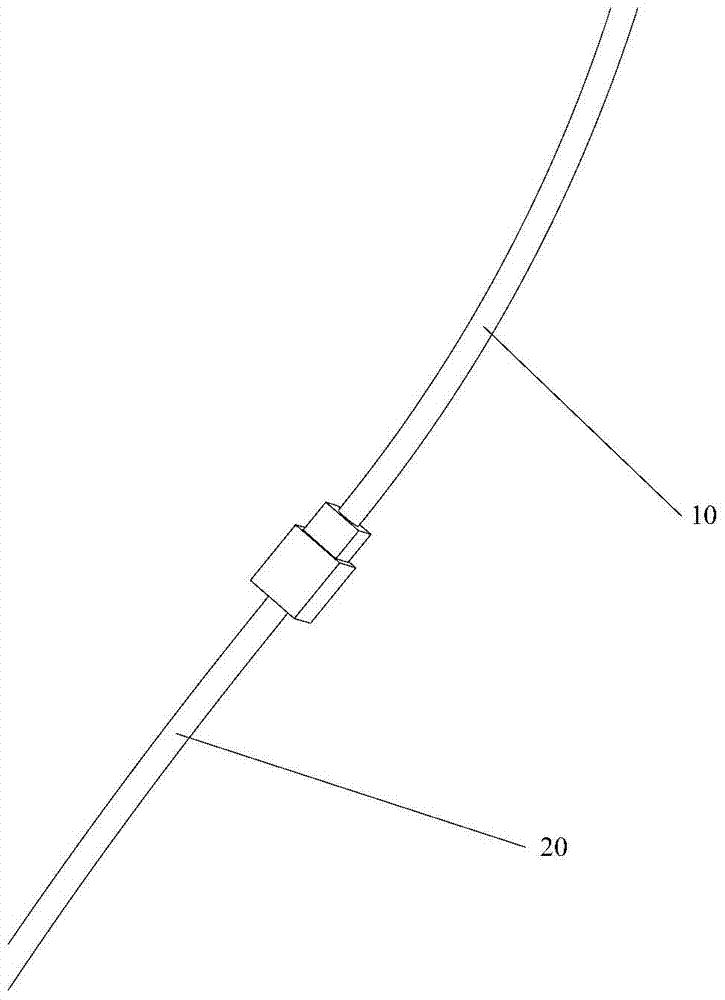

Wire Harness Protective Structure and Wire Harness

InactiveCN104466498BSimplified installation stepsEnsure consistencyCouplings bases/casesConnection insulationEngineeringMechanical engineering

The invention provides a wire harness protecting structure which is used for protecting a plugging terminal of a wire harness. The wire harness protecting structure comprises a cavity for containing the plugging terminal, wherein a containing structure recessed towards the inside of the cavity is arranged at the first end of the cavity and allows the wire harness to pass through, the cavity can be turned with the containing structure as the center, the inner wall of the cavity is changed into the outer wall of the cavity after turning, and the plugging terminal is wrapped in the cavity. Accordingly, the invention further provides the wire harness. Through the technical scheme, on one hand, the installation steps of the wire harness protecting structure can be effectively simplified, then the operation convenience and production efficiency are improved, and meanwhile the overall machine consistency of the wire harness protection structure is ensured; on the other hand, the protecting structure does not need to be fixed through additional material, and meanwhile the production cost is reduced.

Owner:崔祺

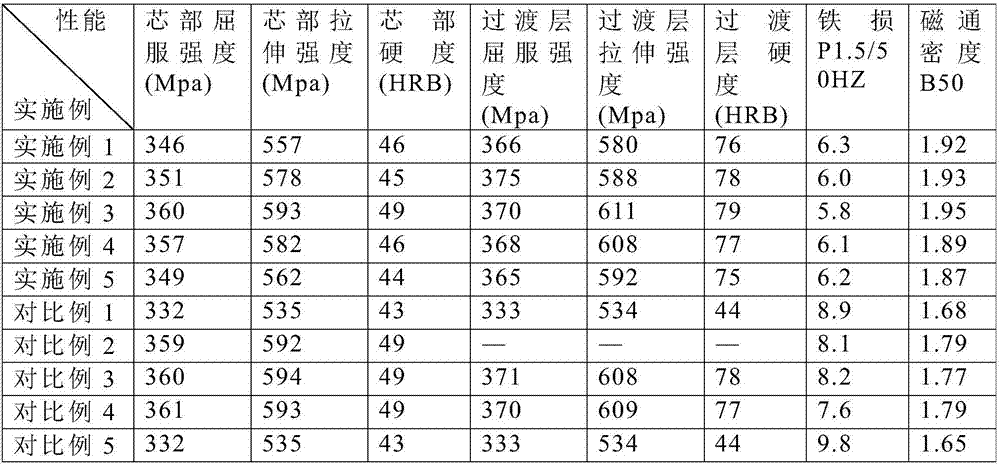

Direct current wet-type electromagnet for valve

InactiveCN108010653AImproves strength and wear resistanceImprove performanceStarch dervative coatingsInorganic material magnetismCorrosion resistantVALVE PORT

The invention relates to a direct current wet-type electromagnet for a valve, and belongs to the technical field of machinery. The direct current wet-type electromagnet for the valve comprises a coil,a guide sleeve, a fixed magnetic pole and an iron core. The iron core is made of silicon steel sheets, and each silicon steel sheet comprises a core part, a transition layer and an insulative corrosion-resistant layer. Each core part is made from silicon steel alloy prepared from, by mass, 0.03-0.05% of C, 3.5-5.5% of Si, 1.1-2.3% of Al, 0.3-0.5% of Mn, 0.05-0.07% of Cr, 0.5-0.8% of Sn, 0.3-0.5%of N, 0.06-0.08% of Mo, 0.08-0.16% of Ga, 0.2-0.6% of Ag, 0.005-0.01% of Gd and the balance iron and inevitable impurities. The direct current wet-type electromagnet for the valve has the advantages of being little in iron loss, resistant to corrosion and long in service life.

Owner:NINGBO YAOFENG HYDRAULIC ELECTRICS

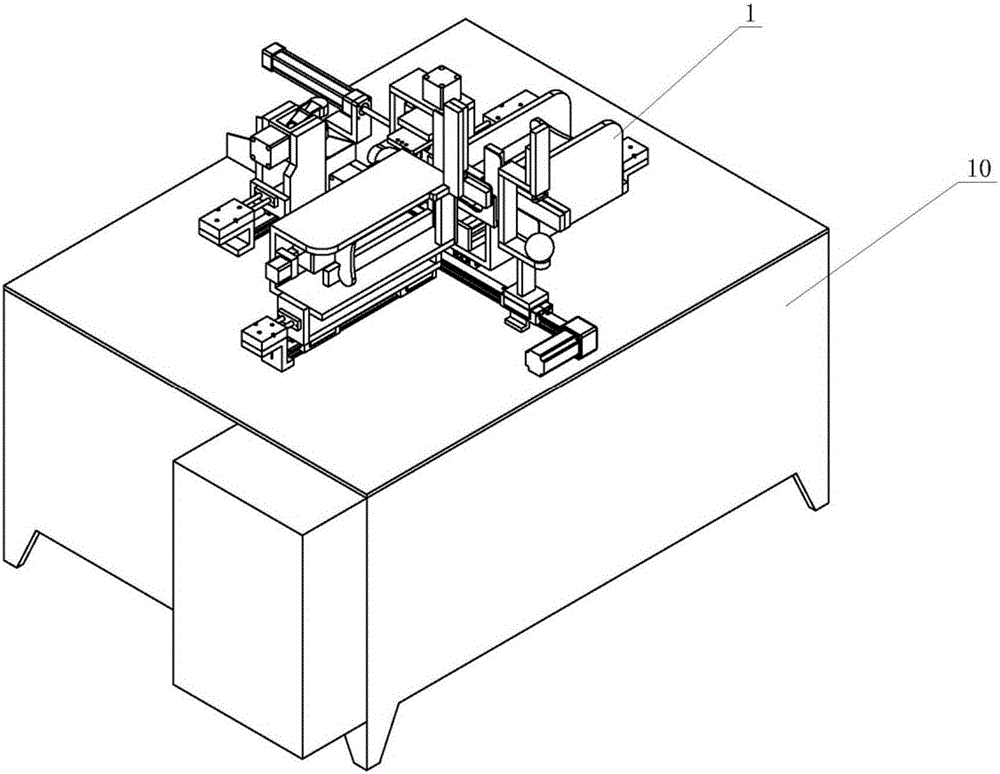

SMD IC welding and fixing device

ActiveCN103639565ANot prone to misalignmentGuaranteed yieldWelding/cutting auxillary devicesAuxillary welding devicesHand heldEngineering

The invention discloses an SMD IC welding and fixing device which comprises a base, two supports, a beam and a fixing piece. The two supports are oppositely arranged on the two ends of the base in parallel and are perpendicular to the base. The two ends of the beam are connected with the two supports respectively. The upper end of the fixing piece is connected with the beam and moves along the beam, the lower end of the fixing piece is opposite to the base, and the fixing piece is used for fixing the IC to a bonding pad of a PCB during SMD IC welding. Before welding, the SMD IC is fixed to the bonding pad of the PCB, the IC does not need to be fixed with human hands, one hand holds tin wires, the other hand holds an electric soldering iron to conduct welding, displacement cannot occur easily, welding can be achieved at a time even though an SMD IC has the very small lead pin pitch, and the yield is ensured.

Owner:JIANGSU SHENGLI DETECTION INSTR CO LTD

Method for cutting textile sample by using textile sample cutting machine

PendingCN114112592ASqueeze flatNot prone to misalignmentPreparing sample for investigationWoven fabricEngineering

The invention discloses a method for tailoring a textile sample by using a textile sample tailoring machine, which comprises the following basic steps: flatly laying a textile to be tailored on a middle layer, stacking an upper pressing disc, pushing a push rod, pushing a blade on an arrayed combined knife rest into an L-shaped hollow groove, and tailoring the textile for the first time; after finishing, turning and flatly laying the textile cut for the first time on the middle layer, and then stacking the textile on an upper pressing disc; the push rod is pushed to push the blades on the arrayed combined knife rest into the L-shaped hollowed-out groove, secondary cutting of the textile is carried out, and cutting of the textile sample is completed; the arrangement type combined knife rest cuts samples into textile sample fragments with the uniform size through a groove-shaped path formed in the bottom layer operation table. The textile sample cutting device not only can cut out sample fragments with uniform sizes, but also can extrude textile samples to be flat, is suitable for materials with different softness, hardness, thickness, thickness and the like, improves the cutting precision and the sample edge uniformity, remarkably reduces the working intensity, and improves the labor efficiency.

Owner:SUZHOU UNIV

Prolate glass sealed surface mounting diode and packaging tape thereof

ActiveCN101621042ANot easy to rollOt easy to slideSemiconductor/solid-state device detailsSolid-state devicesCross connectionSurface mounting

The invention discloses a prolate glass sealed surface mounting diode comprising a glass body and cylindrical electrodes at both ends of the glass body, wherein the glass body is a rectangular cylinder, and the diameter size of each electrode is between the length and the width of the rectangular cross section of the glass body. A packaging tape used by matching with the prolate glass sealed surface mounting diode comprises a tape body and a plurality of containing parts, wherein the containing parts are distributed on the tape body and are used for containing the diode, each containing part is provided with an inner cavity in the shape of the rectangular cylinder, and the width of the cross section of the inner cavity is greater than the diameter of the diode electrode and smaller than the length of the cross section of the glass body of the diode. The diode can not roll in the containing parts of the packaging tape, and can not easily roll or slide on a flat plate, thereby reducing the problems of poor cross connection and the like caused by deviation generated when the diode is mounted on a circuit board.

Owner:SIYANG GRANDE ELECTRONICS CO LTD

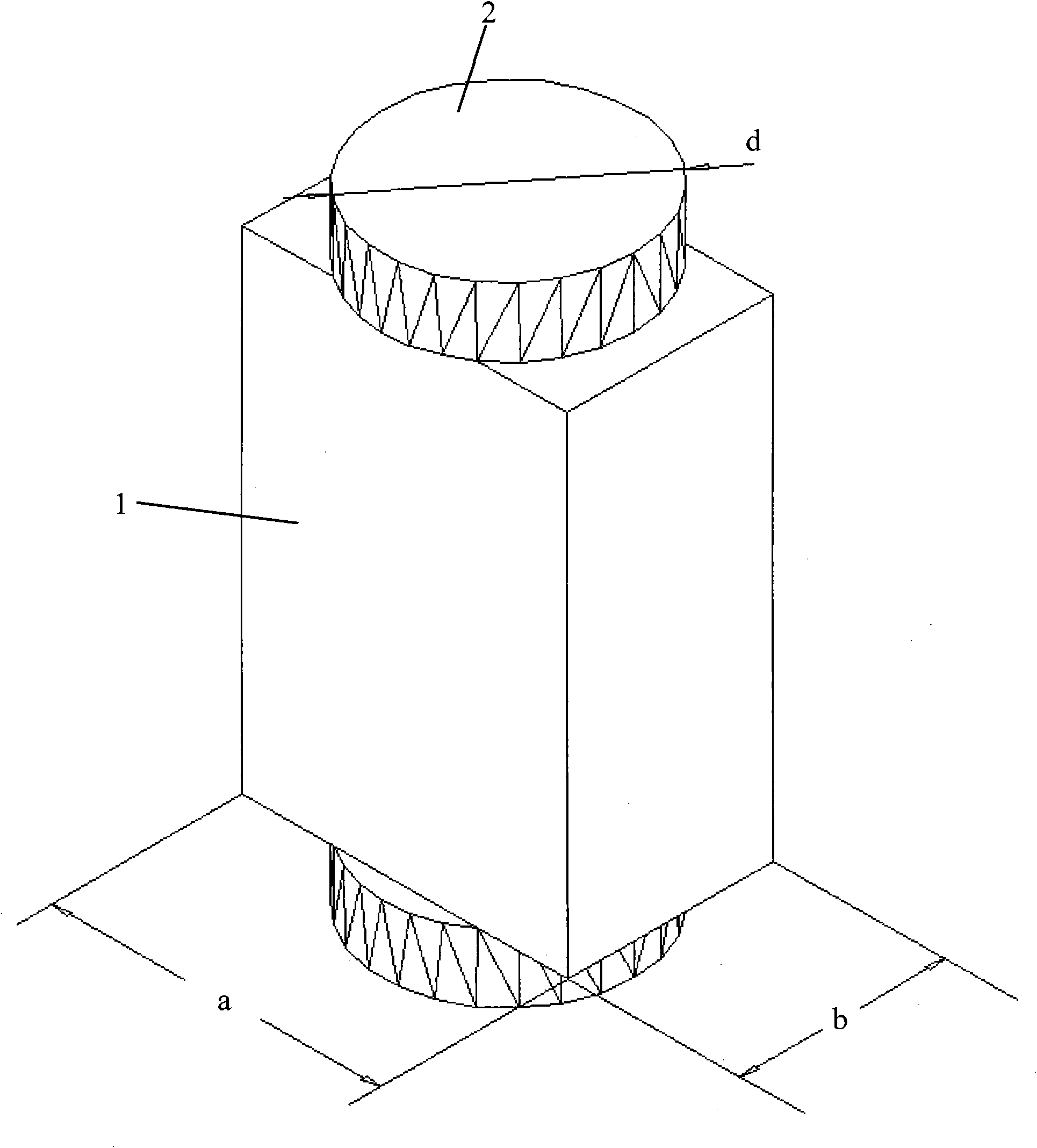

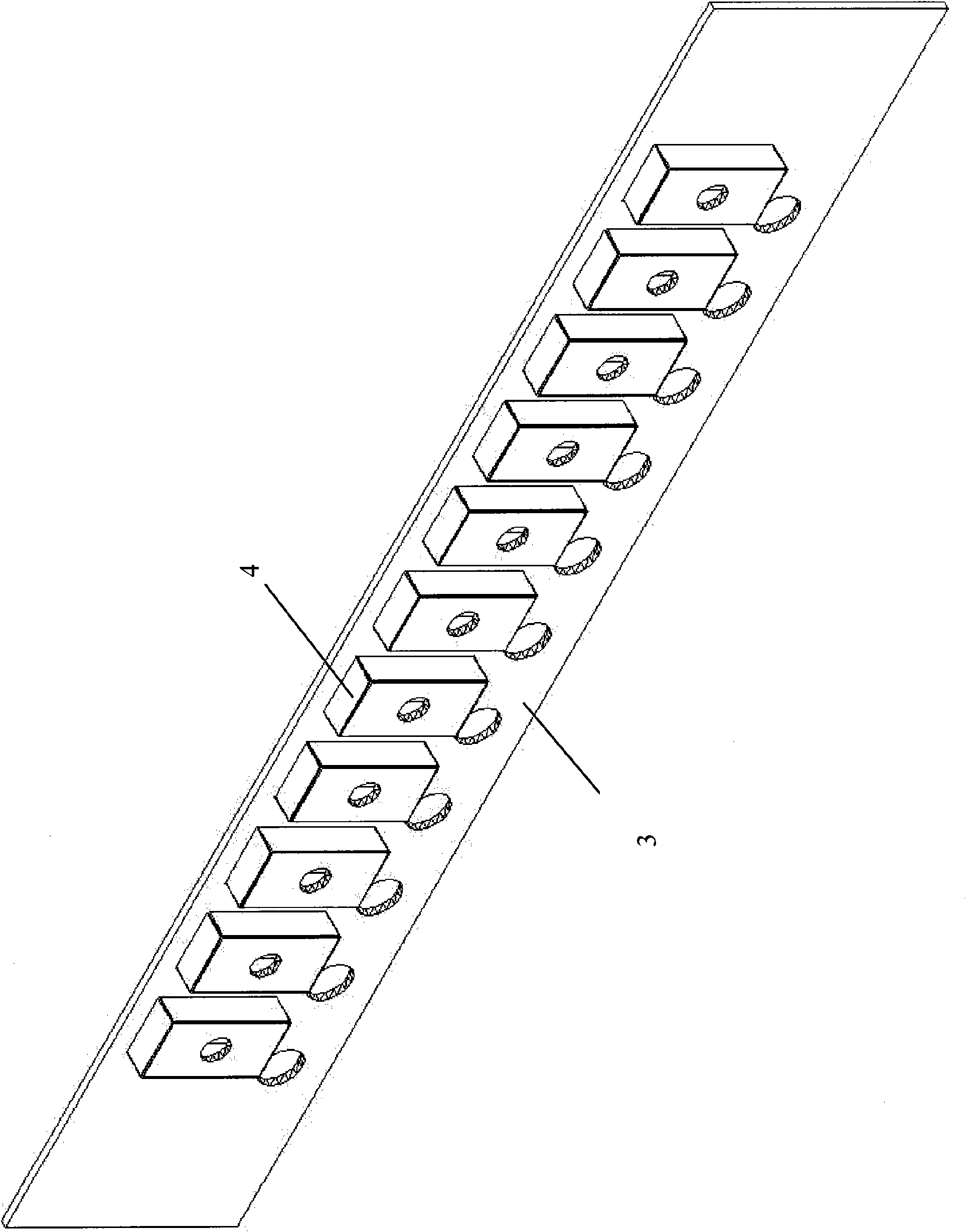

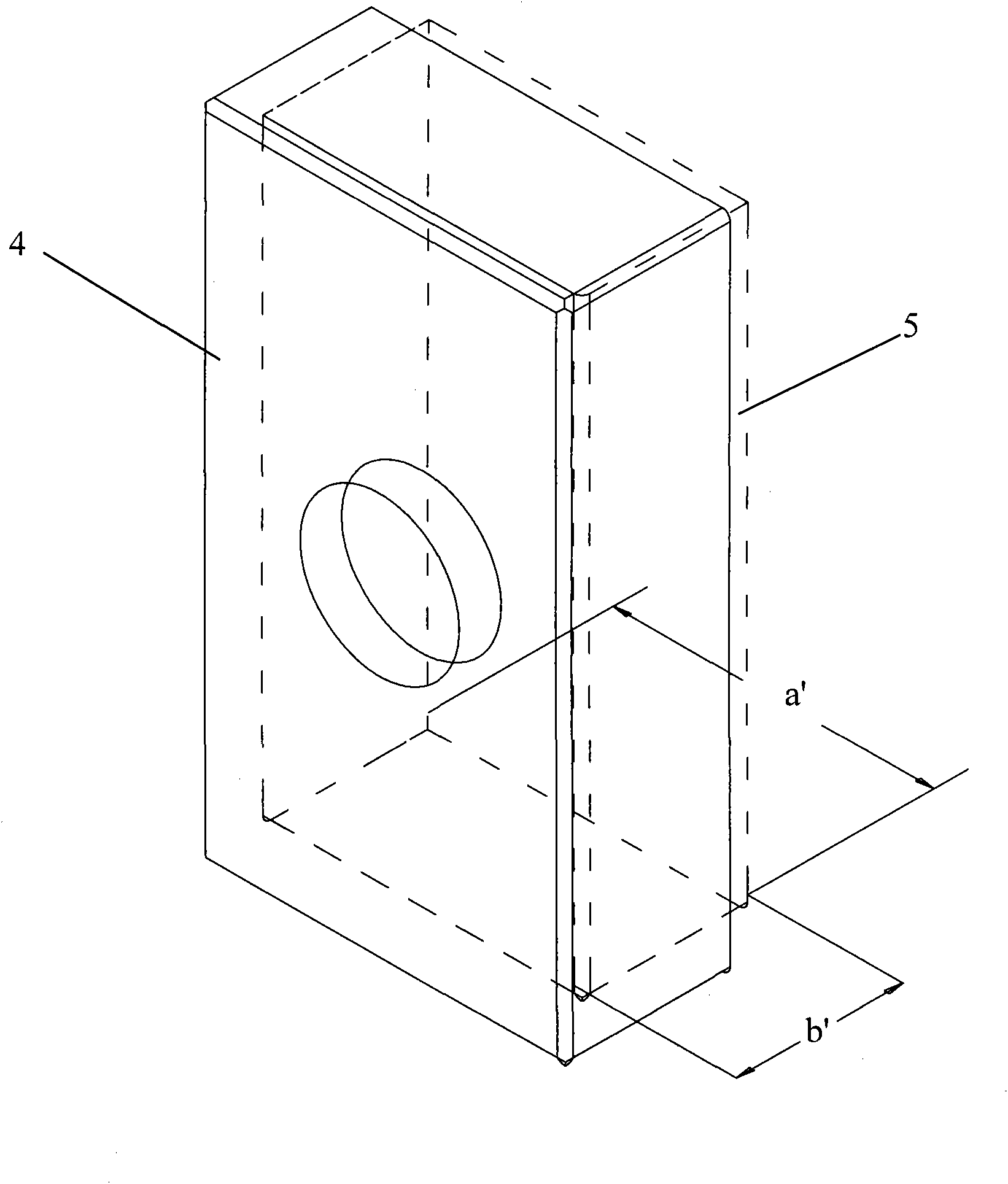

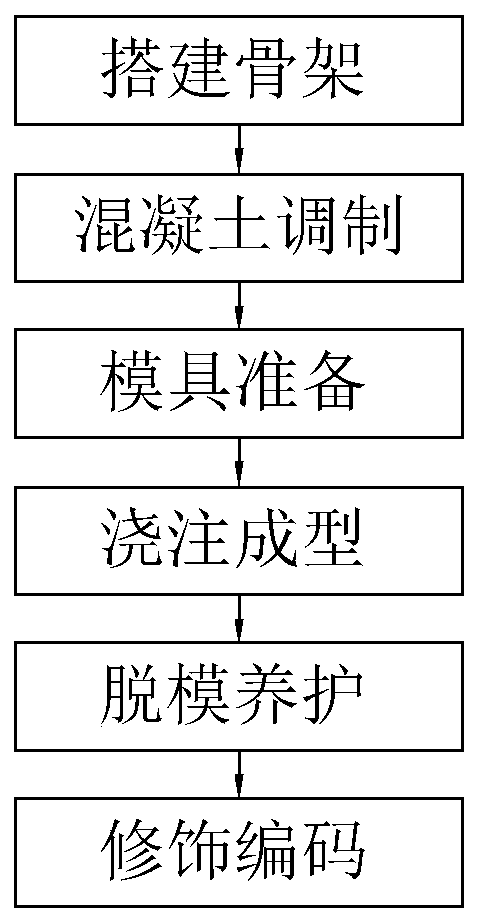

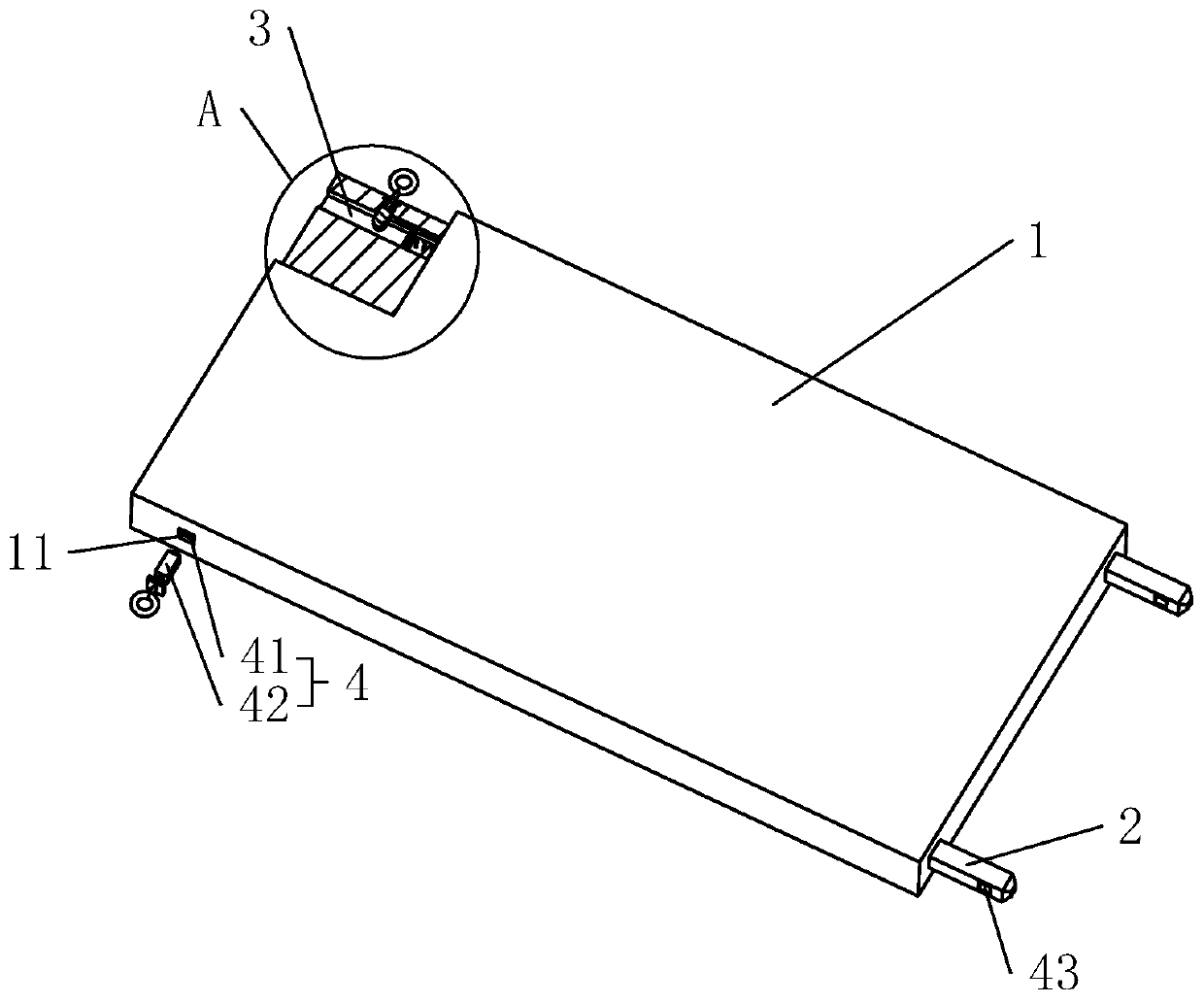

Production technology and product of prefabricated bridge slab

ActiveCN109732771AWon't breakAvoid damageCeramic shaping apparatusBridge structural detailsBrickCoal

The invention discloses a production technology and a product of a prefabricated bridge slab, and relates to building technology in order to solve the problem of damage to the environment due to adoption of bricks for construction. The production technology comprises steps as follows: building of a framework; concrete mixing; die preparation; casting formation; demoulding maintenance; modifying and coding. The production technology and the product of the prefabricated bridge slab have advantages and effects as follows: clay is not needed in the production process of the technology, damage to fields cannot be caused, a coal firing mode is also not needed for solidifying formation of the bridge slab, so that compared with clay and bricks, damage to the fields and atmosphere can be reduced, and purpose of energy conservation and emission reduction are achieved.

Owner:浙江大经住工科技有限公司

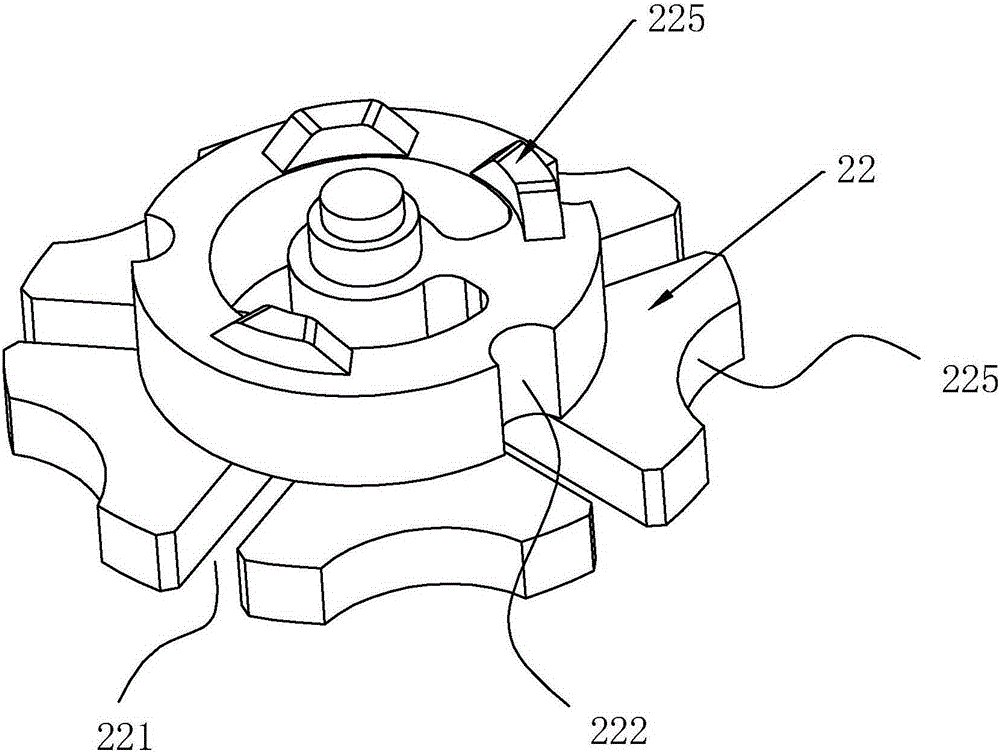

Drawer push-in interlocking mechanism

ActiveCN105244793AIncreasing the thicknessGuaranteed uptimeSwitchgear with withdrawable carriageDrive wheelGear drive

The present invention discloses a drawer push-in interlocking mechanism. The drawer push-in interlocking mechanism comprises a turbine, a drive unit configured to drive the rotation of the turbine. The drive unit comprises a star wheel, a driven wheel and an elastic locating piece configured to be fixed when the star wheel is in connection, experiment or separation states. The driven wheel is provided with a plurality of driving slots. The end face of the star wheel, with respect to the driven wheel, is provided with a driving lever configured to shift into the driving slots so as to drive the rotation of the driven wheel. According to the invention, the drives of the star wheel and the driven wheel take the place of the gear drive, and the drawer push-in interlocking mechanism has low cost, easy assembling and stable pushing.

Owner:ZHEJIANG JINLU ELECTRICAL

Airbag assembly, mattress and bed

PendingCN114176361AWith stableNot prone to misalignmentFluid mattressesAirbagManufacturing engineering

The invention relates to an air bag assembly, a mattress and a bed, the air bag assembly comprises an air bag clamping part, the air bag clamping part comprises a plurality of air bags, each air bag comprises a connecting part and a plurality of sub-air bags, the sub-air bags are stacked, the connecting parts are arranged between the adjacent sub-air bags so as to communicate the sub-air bags, and the connecting parts are connected with the sub-air bags; the connecting part is arranged between the first side of the airbag and the second side of the airbag; the adjacent air bags are clamped and matched in an overlapped mode so that the air bag assembly can extend in the direction from the first sides of the air bags to the second sides of the air bags. According to the technical scheme, the problems that in the prior art, when an air bag assembly is pushed and stroked, the continuity is poor, and the blocking feeling is generated are effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

Composite-bag-surface-scratch-prevention bag making method and system

ActiveCN102689455AAvoid surface scratchesIncrease profitBox making operationsPaper-makingHeat sealerThin membrane

The invention relates to a composite-bag-surface-scratch-prevention bag making method and system. The method comprises the following steps of: (1) covering a layer of non-heat-sealing type protective film on the external surface of a non-heat-sealing type outer membrane of a composite membrane; and (2) synchronously moving the protective film and the composite membrane to be subjected to a bag making process of a bag making machine together, thereby obtaining composite bags. The system based on the method comprises a composite membrane feeding mechanism, a first guide mechanism, a heat sealing mechanism, a traction roller and a discharging device which are sequentially arranged along the advancing direction of the composite membrane; a protective film feeding mechanism is arranged in front of the first guide mechanism; the protective film delivered by the protective film feeding mechanism covers on the external surface of the non-heat-sealing type outer membrane of the composite membrane; and the protective film and the composite membrane synchronously enter the first guide mechanism. During the process of bag making, only the protective film is scratched by a plurality of guide rollers and the traction roller of the bag making machine, and the surface of the composite membrane is not scratched, so that the problem that scratches exist on the surfaces of the composite bags is solved.

Owner:ZHEJIANG GOLDSTONE PACKING

Ultraviolet sterilization and packaging integrated device for sanitary towels

InactiveCN105752388AWide range of sterilizationImprove the bactericidal effectPaper article packagingPackage sterilisationFixed frameUltraviolet

The invention discloses an ultraviolet sterilization and packaging integrated device for sanitary towels. The ultraviolet sterilization and packaging integrated device comprises a fixing frame, ultraviolet sterilization devices and packaging devices, wherein the ultraviolet sterilization devices are fixed on the fixing frame, lamp shades, ultraviolet sterilization mechanisms and tubes are arranged inside the ultraviolet sterilization devices, the ultraviolet sterilization devices are arranged on two sides of a conveying belt, the conveying belt is connected with left and right transmission disks, rotating shafts are arranged in centers of the transmission disks and connected to power devices through belts, two ends of the fixing frame are fixedly connected by the aid of fixing support rods, the power devices are arranged on the left sides of the fixing support rods, the packaging devices are connected to the transmission disks through smooth plates, packaging ports are formed in left sides of the packaging devices, and each packaging device comprises an upper clamping block and a lower clamping block. The device is simple and reasonable in structure; the ultraviolet sterilization and packaging integrated device is adopted, so that the labor efficiency is improved, and the workload is reduced.

Owner:TIANJIN JUNFA SENDA SANITARY ARTICLES

Airbag assembly, mattress and bed

The invention relates to an air bag assembly, a mattress and a bed. The air bag assembly comprises a plurality of air bags, each air bag comprises a plurality of overlapped sub air bags and connecting parts, the connecting parts are arranged between the adjacent sub air bags to communicate the sub air bags, when the air bag assembly is horizontally placed, the projections of the adjacent air bags on a horizontal plane have overlapped parts, and the air bag assembly extends from the first sides of the air bags to the second sides of the air bags; and objects are arranged at the bottom of the airbag assembly and connected with the sub air bags at the bottom. According to the technical scheme, the problem that in the prior art, an air bag assembly is prone to dislocation during use is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com