Anti-seepage construction method for channel of accumulation waterlogging wet land

A construction method and channel technology, applied in sea area engineering, artificial waterways, water conservancy projects, etc., can solve problems such as large water loss, single anti-seepage structure, and reduced water delivery capacity of channels, so as to maintain integrity and smoothness, The structure is stable and firm, and the effect of improving construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

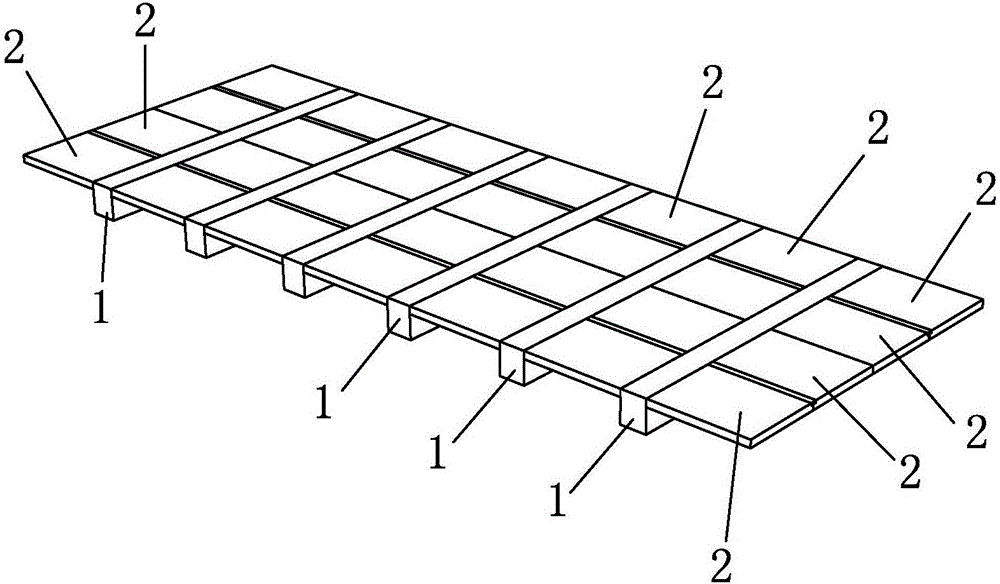

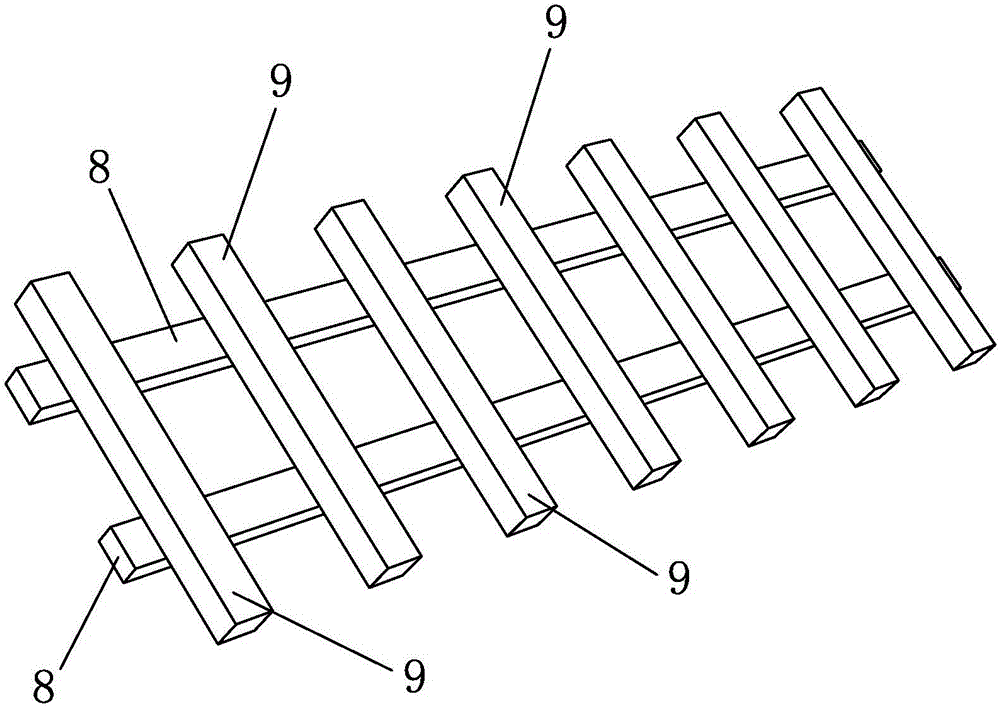

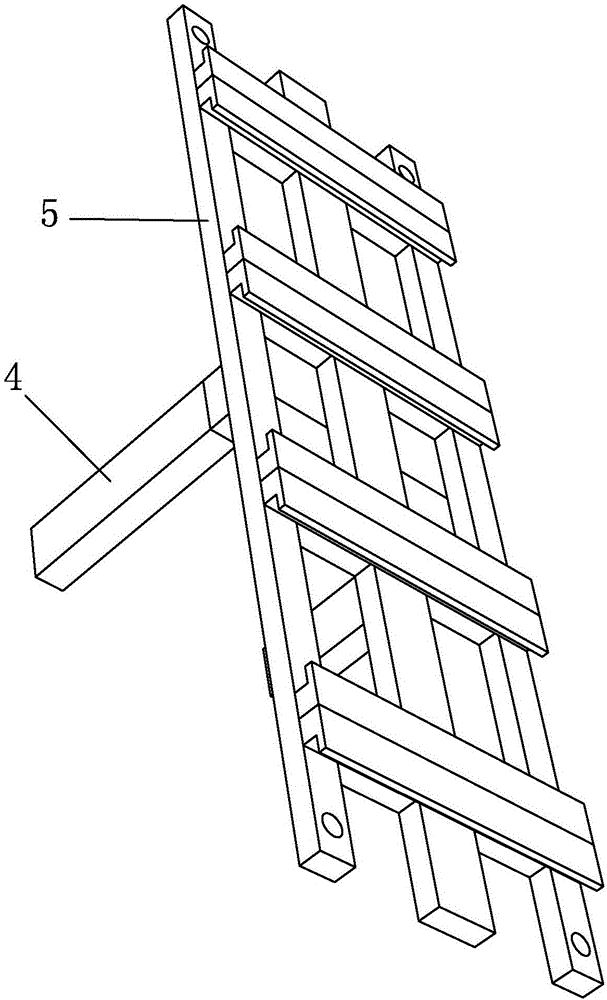

[0028] Such as Figure 1 to Figure 6 Shown, be the channel seepage prevention construction method of a kind of flood storage wetland of the present invention, comprise the steps:

[0029] (a) Foundation treatment: Stake out the channel according to the design drawings, release the bottom line of the channel and the mouth line of the channel, and then carry out excavation with the cooperation of machinery and manpower. Before excavation, the foundation is naturally air-dried. Then excavate in layers along the slope from top to bottom, remove the weeds, silt, tree roots, and organic humus on the side of the channel, and backfill the loosened parts of the excavation. The combination of mechanical and manual compaction is then used. The thickness of each layer of soil in the process of mechanical compaction is not greater than 20cm, and the thickness of each layer of soil in the process of manual compaction is not greater than 20cm. Then drain the accumulated water and reduce its...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com