Antenna device and method for manufacturing antenna device

A technology of antenna device and radome, which is applied in the direction of antenna, antenna coupling, electrical short antenna, etc., and can solve the problems of thinning and thinning wireless devices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

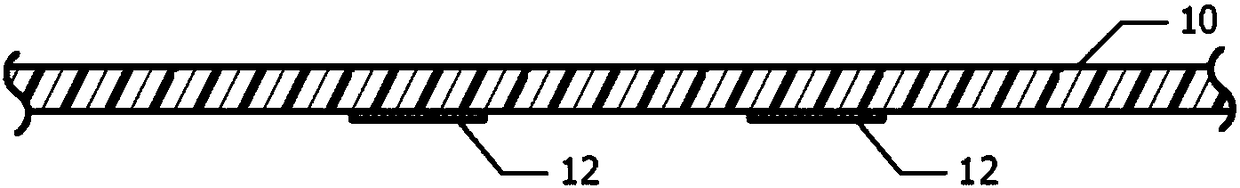

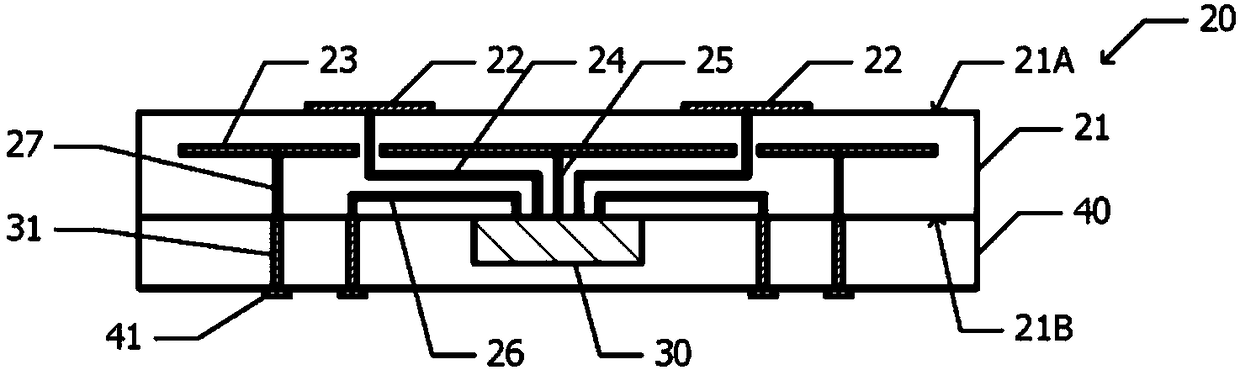

[0041] Reference Figure 1A to Figure 1D The drawings illustrate the antenna device of the first embodiment.

[0042] Figure 1A It is a partial cross-sectional view of the radome 10 and the passive element 12 used in the antenna device of the first embodiment. The radome 10 is, for example, a plate-shaped member made of a dielectric. A plurality of passive elements 12 are provided on one surface (inner surface) of the radome 10.

[0043] Figure 1B It is a cross-sectional view of the antenna module 20 used in the antenna device of the first embodiment. A plurality of power feeding elements 22 are formed on one surface (first surface) 21A of the dielectric substrate 21. For example, a patch antenna is used as the power supply element 22. The high-frequency integrated circuit element 30 is mounted on the second surface 21B of the dielectric substrate 21 on the side opposite to the first surface 21A. A ground plane 23 is arranged on the inner layer of the dielectric substrate 21....

no. 2 example

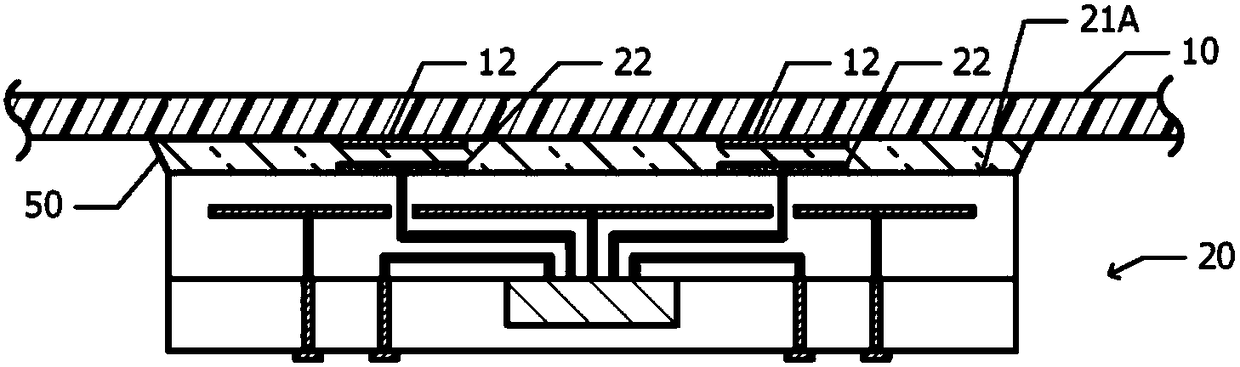

[0059] Next, the antenna device of the second embodiment will be described with reference to FIG. 3. Hereinafter, description of the configuration common to the antenna device of the first embodiment will be omitted.

[0060] Figure 3A It is a cross-sectional view of the antenna module 20 used in the antenna device of the second embodiment. In the first embodiment, in the stage before bonding with the radome 10, such as Figure 1B As shown, the power supply element 22 of the antenna module 20 is exposed. In the second embodiment, the first surface 21A of the dielectric substrate 21 and the power supply element 22 are covered by the dielectric layer 28. In this way, the power feeding element 22 is not arranged on the surface of the antenna module 20 but on the inner layer.

[0061] Figure 3B It is a cross-sectional view of the antenna device of the second embodiment. An adhesive layer 50 is arranged between the dielectric layer 28 of the antenna module 20 and the radome 10. As...

no. 3 example

[0065] Next, refer to Figure 4A with Figure 4B The antenna device of the third embodiment will be described. Hereinafter, description of the configuration common to the antenna device of the first embodiment will be omitted.

[0066] Figure 4A It is a cross-sectional view of the antenna device of the third embodiment. In the third embodiment, the convex portion 11 is provided on the inner surface of the radome 10. The antenna module 20 is in contact with the side surface (step surface) 11A of the convex portion 11.

[0067] Figure 4B It is a top view of the antenna device of the third embodiment. Figure 4B The one-dot chain line 4A-4A is equivalent to Figure 4A Cutaway view. The antenna module 20 has a substantially rectangular planar shape. The convex portions 11 provided on the inner surface of the radome 10 are arranged at positions corresponding to the four corners of the antenna module 20. The four corners of the antenna module 20 are chamfered to match the step surf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com