An OLED panel and a display device

A panel and thin film packaging technology, applied in electrical components, diodes, electrical solid devices, etc., can solve problems such as unfavorable outdoor visual functions, achieve outdoor visual functions, increase the brightness attenuation angle of a large viewing angle, and reduce the thickness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

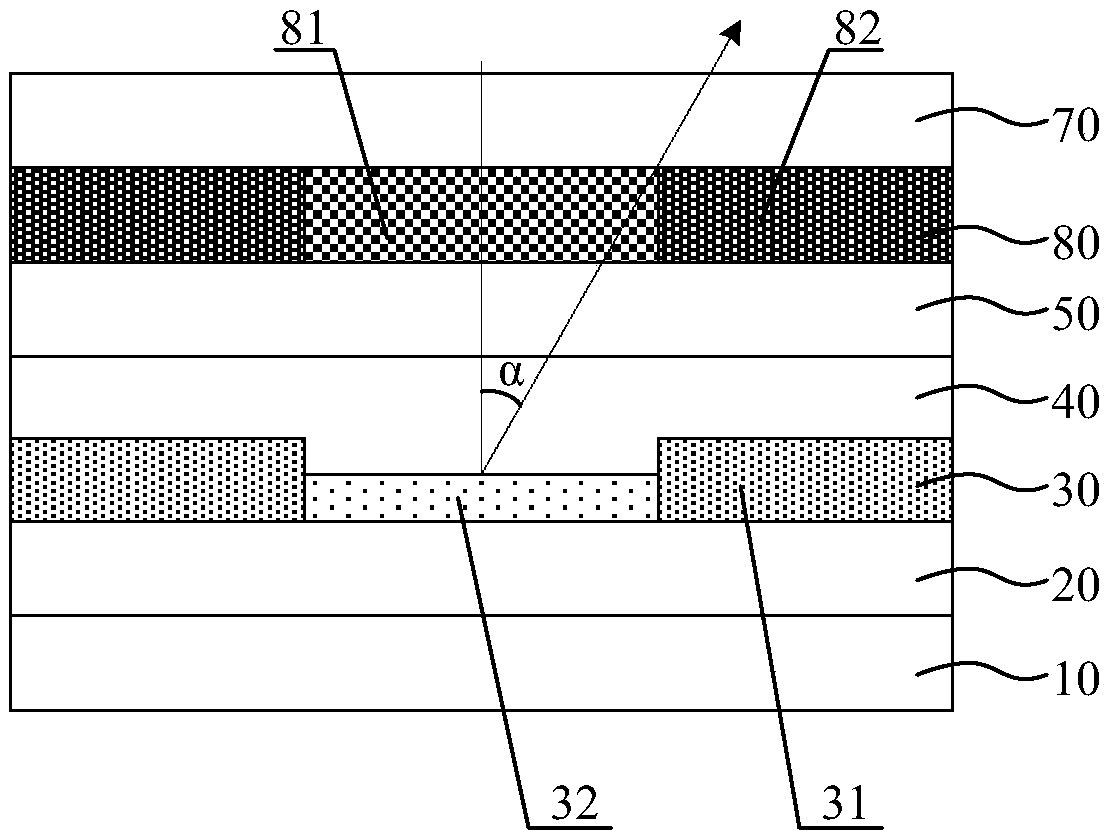

[0043] Image 6 It is a schematic structural diagram of an OLED panel according to the first embodiment of the present invention. from Image 6 It can be seen from the figure that the OLED panel of this embodiment includes a substrate 10 , a TFT array layer 20 , an organic light emitting layer 30 and a color filter layer 80 . Wherein, the TFT array layer 20 is disposed on the substrate 10 , and the organic light emitting layer 30 is disposed on the TFT array layer 20 . The organic light emitting layer 30 includes an OLED pixel 32 and a pixel defining layer 31 defining an area of the OLED pixel 32 . The color filter layer 80 is disposed on the organic light emitting layer 30 , and the color filter layer 80 includes a color filter 81 disposed on the OLED pixels 32 , and the color filter 81 is arranged in a one-to-one correspondence with the OLED pixels 32 .

[0044] The color filter 81 is disposed on the OLED pixel 32 , so that the light emitted by the OLED pixel 32 is emit...

no. 2 example

[0054] Figure 7 It is a schematic structural diagram of an OLED panel according to the second embodiment of the present invention. Different from the first embodiment, in this embodiment, if Figure 7 As shown, the OLED panel further includes a protective film layer 90 located between the organic light emitting layer 30 and the color filter layer 80 . The protective film layer 90 can further protect the OLED pixel 32 and the cathode of the OLED pixel 32, and further improve the water and oxygen barrier performance of the OLED panel.

[0055] The material of the protective film layer 90 includes at least one of silicon nitride and silicon oxide. In a specific implementation, the material of the protective film layer 90 may be silicon nitride, silicon oxide or a mixture of silicon nitride and silicon oxide. After the organic light emitting layer 30 is formed, the protective film layer 90 may be formed on the organic light emitting layer 30 by evaporation. The thickness of t...

no. 3 example

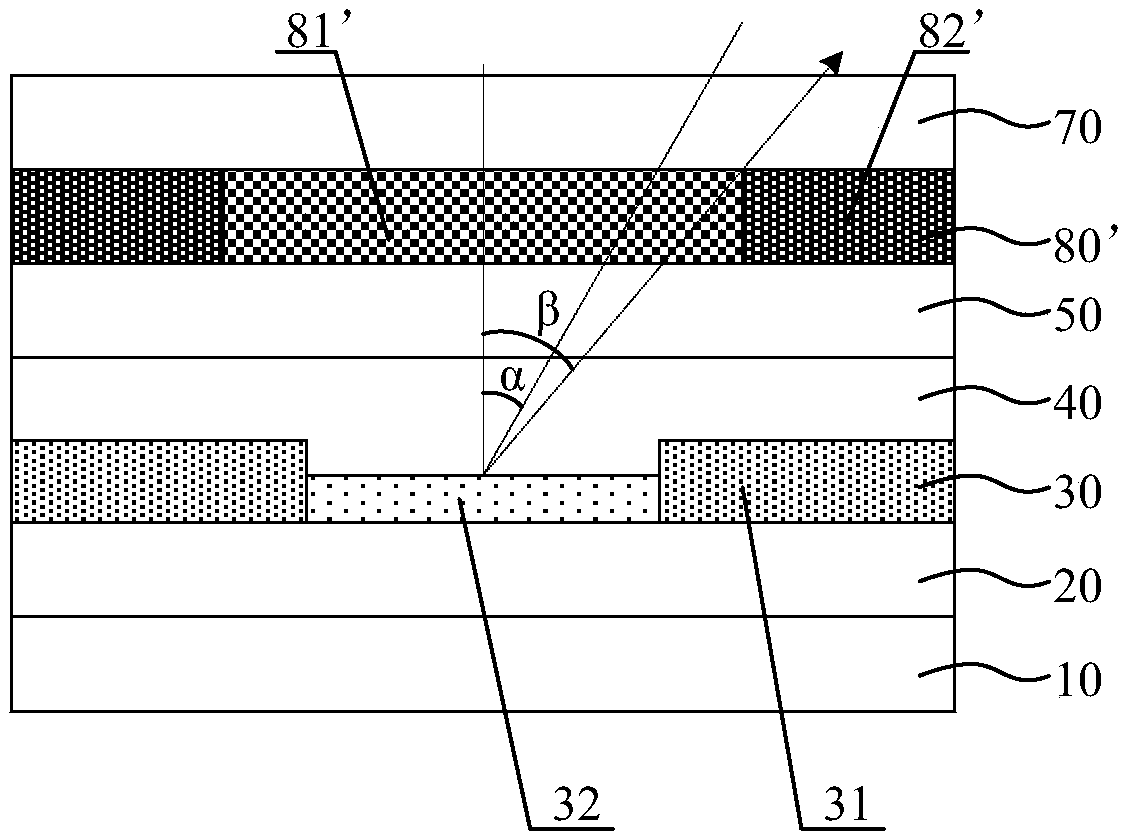

[0057] Figure 8 It is a schematic structural diagram of an OLED panel according to a third embodiment of the present invention. from Figure 8 It can be seen from the figure that the OLED panel of this embodiment includes a substrate 10 , a TFT array layer 20 , an organic light emitting layer 30 and a color filter layer 80 . Wherein, the TFT array layer 20 is disposed on the substrate 10 , and the organic light emitting layer 30 is disposed on the TFT array layer 20 . The organic light emitting layer 30 includes an OLED pixel 32 and a pixel defining layer 31 defining an area of the OLED pixel 32 . The color filter layer 80 is disposed on the organic light emitting layer 30 . Different from the first embodiment, in this embodiment, the color filter layer 80 includes a color filter 81 disposed on the OLED pixel 32 .

[0058] In addition, in this embodiment, the material of the pixel defining layer 31 is a black opaque material, such as black resin material, etc., so that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com