Sleeve vent folding and sewing integrated machine

An all-in-one machine and sewing machine technology, which is applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems of unguaranteed product quality, complicated operation process, high cost of garment making, etc., and achieve strong consistency of cost and quality, operation Convenience and good processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] According to the attached Figure 1 to Figure 6 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

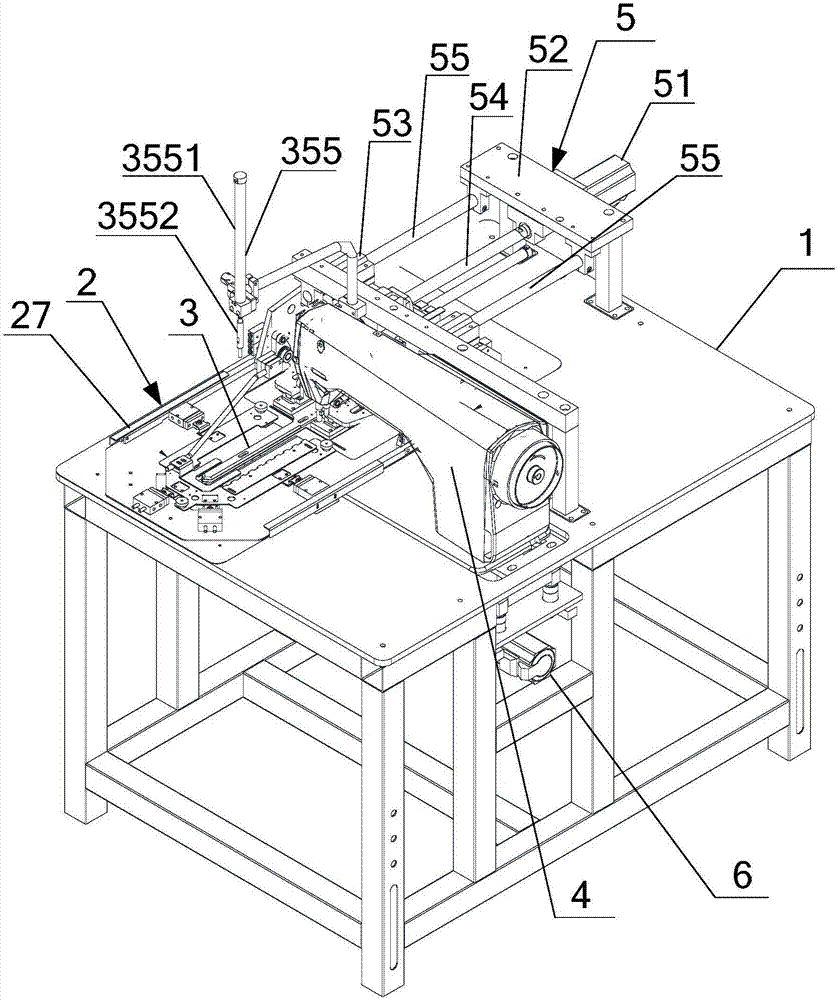

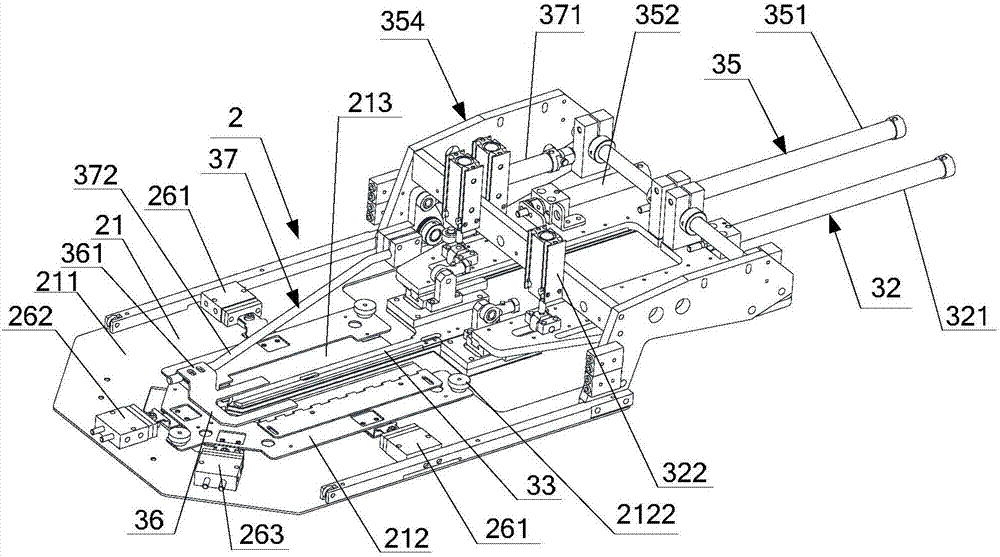

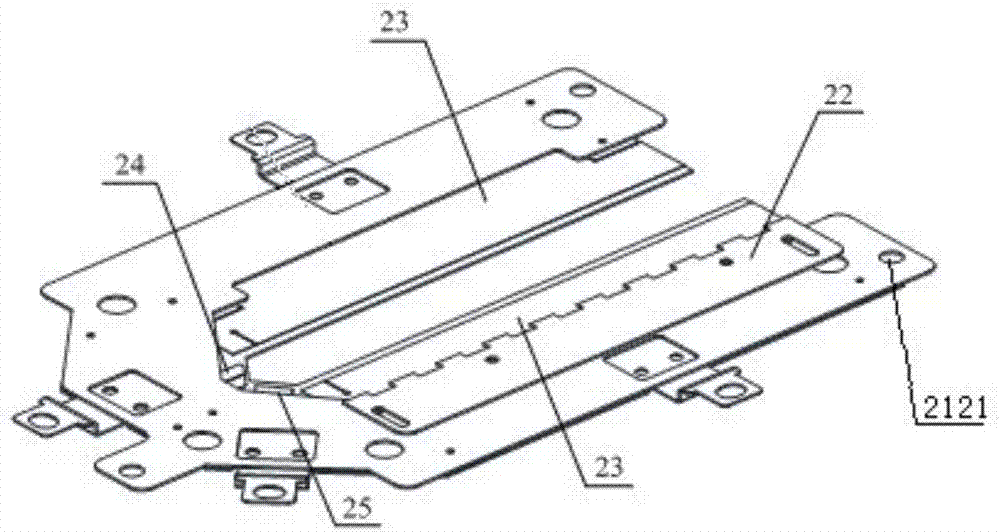

[0023] see figure 1 , an all-in-one machine for sleeve fork folding and sewing according to an embodiment of the present invention, comprising a frame 1, a folding mechanism 2, a positioning mechanism 3, a sewing machine 4, a first direction transmission mechanism 5 and a second direction transmission mechanism 6 The folding mechanism 2 is fixed on the frame 1 through the transmission mechanism 5 in the first direction and can reciprocate along the first direction; the sewing machine 4 is fixed on the frame 1 through the transmission mechanism 6 in the second direction and can move back and forth along the second direction. And the machine head of the sewing machine 4 is located above the folding mechanism 2, and the first direction is perpe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com