Direct current wet-type electromagnet for valve

An electromagnet and wet-type technology, applied in the field of machinery, can solve the problems of reduced service life and use effect, high energy consumption and large iron loss, etc., achieve low thermal expansion coefficient, improve use performance, and reduce iron loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

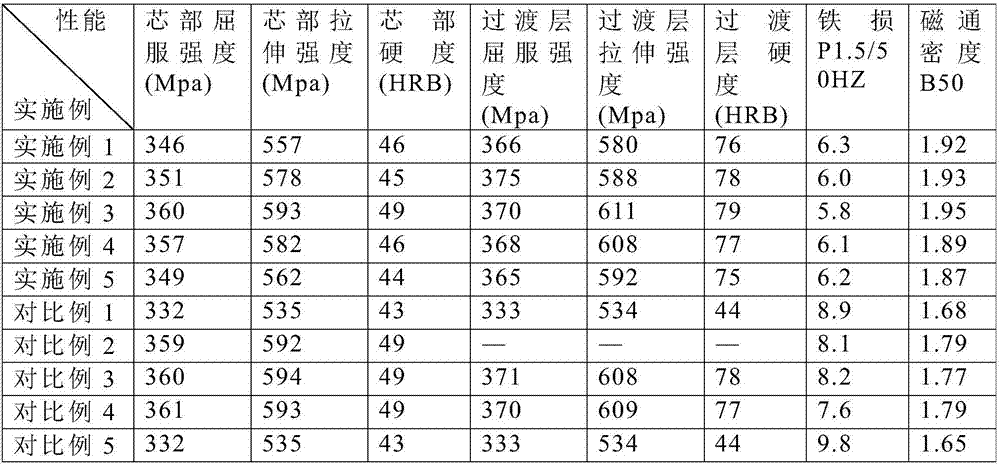

Examples

Embodiment 1

[0030]The electromagnet for a DC wet valve in this embodiment includes a coil, a guide sleeve, a fixed magnetic pole and an iron core. The iron core is made of a silicon steel sheet, and the silicon steel sheet includes a core, a transition layer, an auxiliary layer and an insulating and corrosion-resistant layer.

[0031] Wherein, the core is made of a silicon steel alloy comprising the following mass percentage components, 0.03%C, 3.5%Si, 1.1%Al, 0.3%Mn, 0.05%Cr, 0.5%Sn, 0.3%N, 0.06%Mo, 0.08% -0.16% Ga, 0.2-0.6% Ag, 0.005-0.01% Gd, the rest is iron and unavoidable impurities, N element is added in the form of ferrochromium nitride;

[0032] The transition layer is a silicon-steel alloy layer doped with 3.0% by mass of carbon fiber. The content of carbon fiber gradually increases from the interface between the core and the transition layer to the interface between the transition layer and the insulating and corrosion-resistant layer. The length of the carbon fiber is 0.1-0.8 ...

Embodiment 2

[0036] The electromagnet for a DC wet valve in this embodiment includes a coil, a guide sleeve, a fixed magnetic pole and an iron core. The iron core is made of a silicon steel sheet, and the silicon steel sheet includes a core, a transition layer, an auxiliary layer and an insulating and corrosion-resistant layer.

[0037] Wherein, the core is made of a silicon steel alloy comprising the following mass percentage components, 0.04%C, 4.3%Si, 1.7%Al, 0.4%Mn, 0.06%Cr, 0.7%Sn, 0.4%N, 0.07%Mo, 0.09% %Ga, 0.5%Ag, 0.007%Gd, the rest is iron and unavoidable impurities, and N element is added in the form of ferrochromium nitride;

[0038] The transition layer is a silicon-steel alloy layer doped with 4.0% by mass of carbon fiber. The content of carbon fiber gradually increases from the interface between the core and the transition layer to the interface between the transition layer and the insulating and corrosion-resistant layer. The length of the carbon fiber is 0.1-0.8 μm, the aspe...

Embodiment 3

[0042] The electromagnet for a DC wet valve in this embodiment includes a coil, a guide sleeve, a fixed magnetic pole and an iron core. The iron core is made of a silicon steel sheet, and the silicon steel sheet includes a core, a transition layer, an auxiliary layer and an insulating and corrosion-resistant layer.

[0043] Wherein, the core is made of a silicon steel alloy comprising the following mass percentage components, 0.04%C, 4.3%Si, 1.7%Al, 0.4%Mn, 0.06%Cr, 0.7%Sn, 0.4%N, 0.07%Mo, 0.09% %Ga, 0.5%Ag, 0.007%Gd, the rest is iron and unavoidable impurities, and N element is added in the form of ferrochromium nitride;

[0044] The transition layer is a silicon-steel alloy layer doped with 5.5% by mass of carbon fiber. The content of carbon fiber gradually increases from the interface between the core and the transition layer to the interface between the transition layer and the insulating and corrosion-resistant layer. The length of the carbon fiber is 0.1-0.8 μm, the aspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com