Flow battery capable of realizing sealing and battery stack

A liquid flow battery and side sealing technology, which is applied to fuel cells, regenerative fuel cells, circuits, etc., can solve the problems of complex sealing structure assembly, high manufacturing difficulty, and poor sealing effect of liquid flow batteries. The method is simple, novel, and sealed Good effect, convenient and quick adjustment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

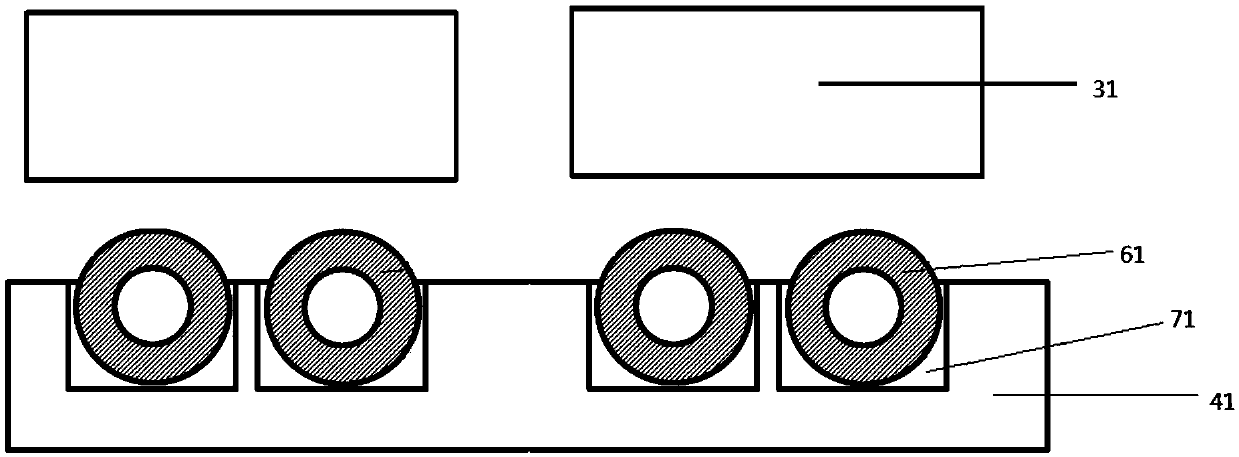

[0061] According to a preferred embodiment of the present invention, the cross-sectional diameter of the sealing ring 61 is larger than the width of the groove 71 ; the cross-sectional diameter of the opposite side sealing ring 62 is larger than the width of the groove 71 .

[0062] Further preferably, the cross-sectional diameter of the sealing ring 61 is 0.1-0.5 mm larger than the width of the groove 71 , preferably 0.2-0.4 mm. Further preferably, the cross-sectional diameter of the opposite side sealing ring 62 is 0.1-0.5 mm larger than the width of the opposite side groove 72 , preferably 0.2-0.4 mm. Adopting this preferred embodiment is more conducive to achieving better sealing, avoiding micro-leakage, and more conducive to improving the local gap-filling function of the flow battery.

[0063] The cross-sectional diameter mentioned in the present invention refers to the outer diameter of the ring when the cross-section of the sealing ring 61 and the opposite side sealing...

Embodiment 1

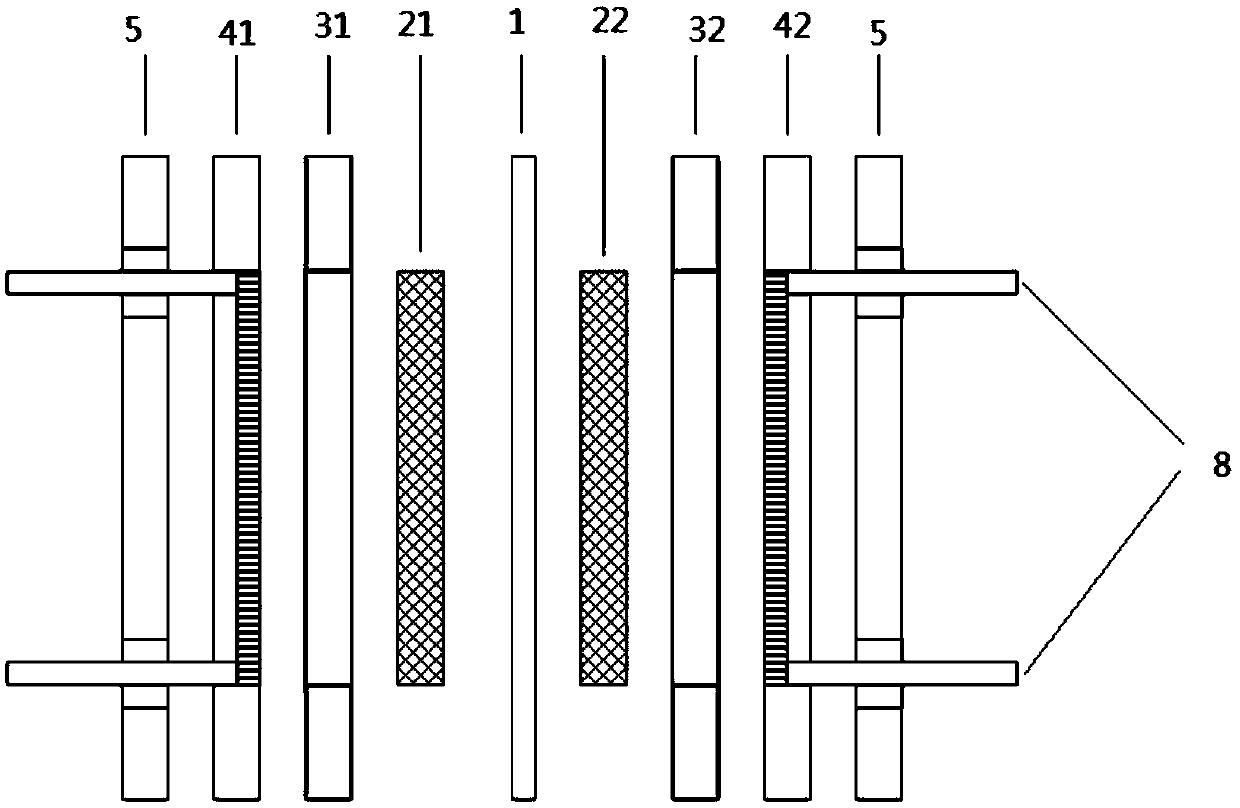

[0092] Flow battery such as figure 1 As shown, it includes: a diaphragm 1; one side of the diaphragm 1 is sequentially provided with an electrode 21 (porous carbon fiber felt, commercially available from SGL, the brand is KFD2.5EA, and the size is 200mm×200mm×2.5mm), a sealing gasket 31 and double Pole plate 41 (300mm×300mm×3mm, made of graphite); the opposite side electrode 22 (same as electrode 21), opposite side gasket 32 and opposite side bipolar plate 42 (same as bipolar plate) are arranged in sequence on the other side of diaphragm 1 41). Such as Figure 5 As shown, the flow battery also includes an electrolyte storage tank 81, an electrolyte inlet 91, an electrolyte outlet 101, an opposite electrolyte storage tank 82, an opposite electrolyte inlet 92, and an opposite electrolyte outlet 102; the electrolyte inlet 91 and the electrolyte outlet 101 make the electrolyte in the electrolyte storage tank 81 circulate between the electrolyte storage tank 81 and the electrod...

Embodiment 2

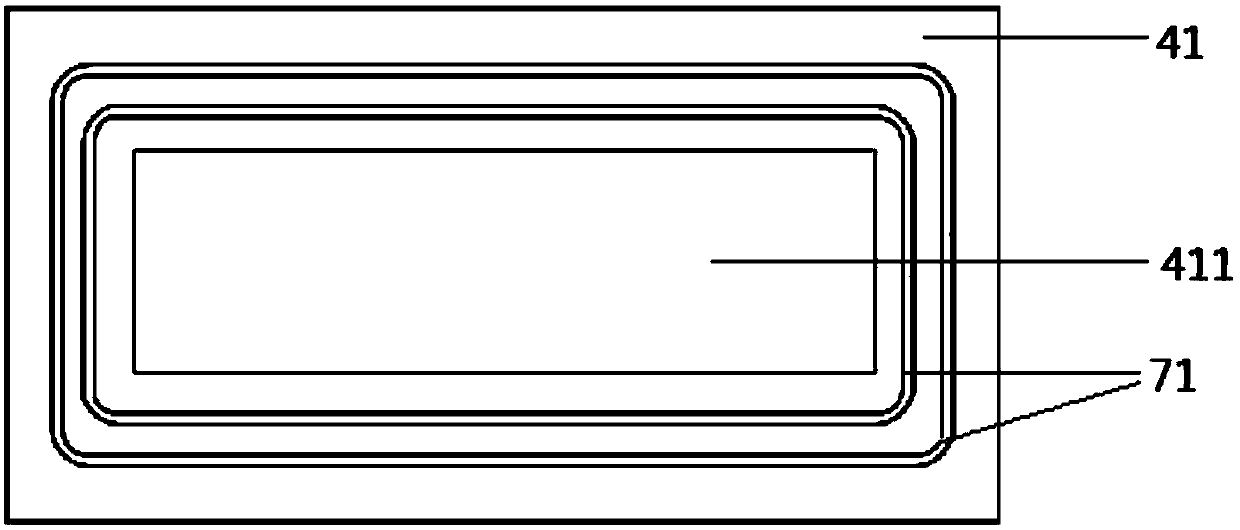

[0101] Assembling the flow battery according to Example 1, the difference is that a circle of grooves is provided on the bipolar plate 41 and the opposite bipolar plate 42, the grooves of the outer ring are reserved, and the grooves of the inner ring are not provided. The sealing ring of the inner ring is not provided, the width of the sealing gasket is 10mm, and the schematic diagram of the bipolar plate 42 on the opposite side is as follows Figure 6 , Figure 7 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com