Full-automatic tennis felt wrapping machine

A fully automatic, tennis technology, applied in the direction of balls, sports accessories, etc., can solve the problems of easy offset, inaccurate felting position, unsatisfactory yield, etc., and achieve the effect of high product yield and accurate felting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The present invention will be further described through the embodiments below with reference to the accompanying drawings.

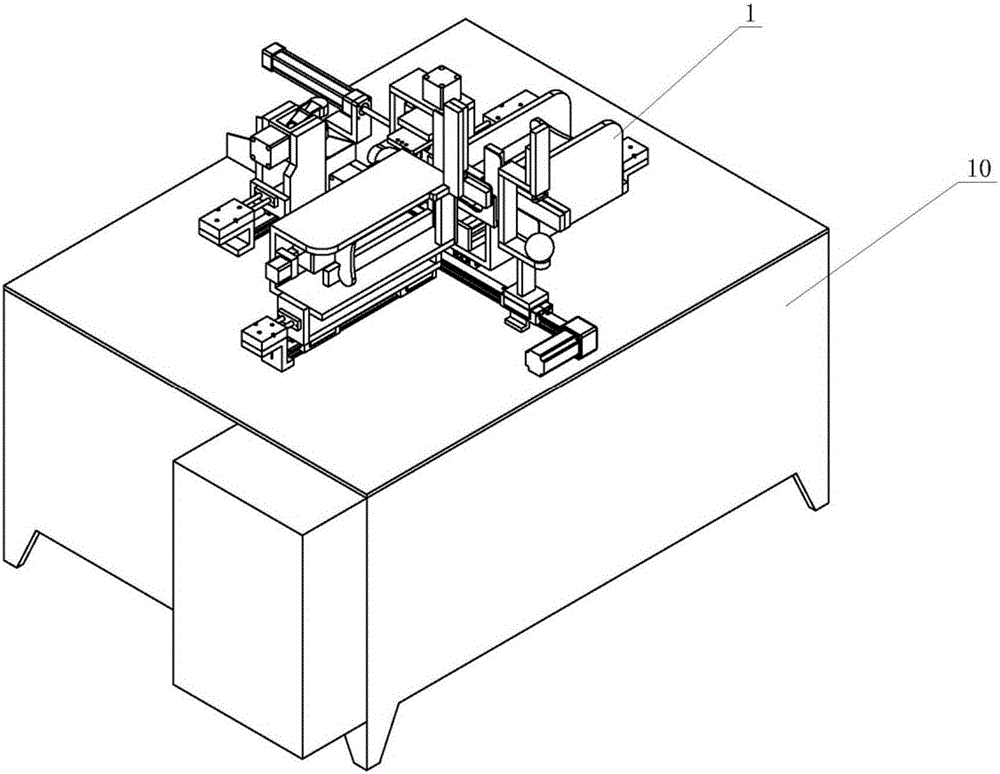

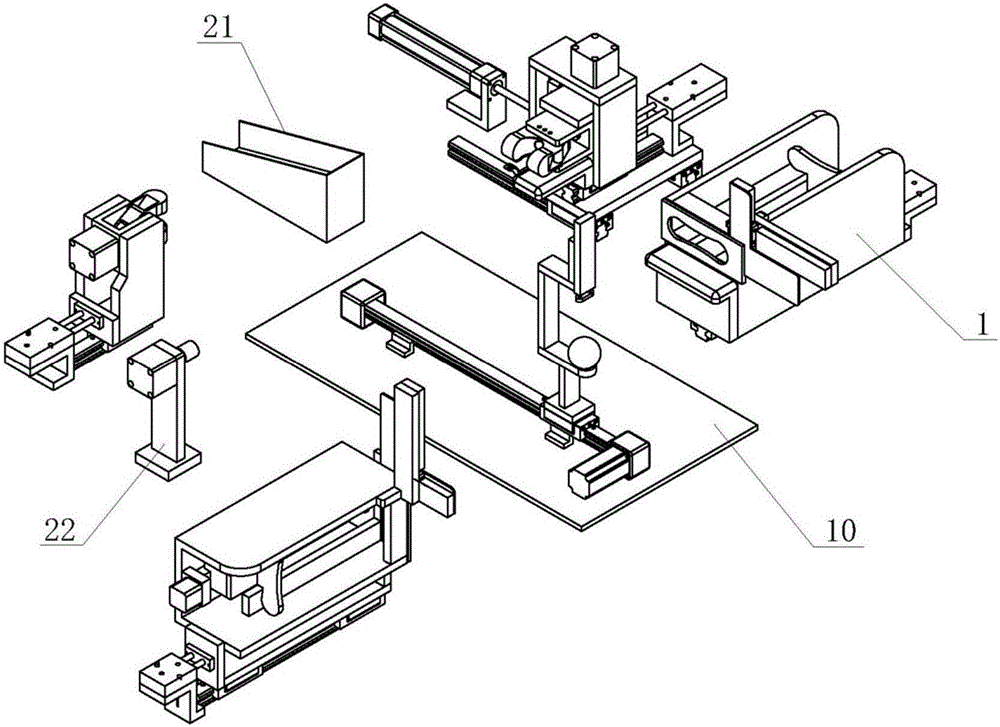

[0050] Refer to attached Figure 1-12 , a fully automatic tennis ball felting machine, which includes a body 10, a felt separating device, a felting device, a conveying device, a receiving tray 21 and an intelligent controller, wherein the felt separating device, the felting device The felt separation device and the felting device are arranged on both sides of the conveying device; the receiving tray 21 is fixed on the body 10, and the felted tennis balls are dropped to the receiving tray 21 through the felting device Collect in; Described intelligent controller is arranged on the body 10, is used for controlling the motion of felt separation device, packing device and conveying device;

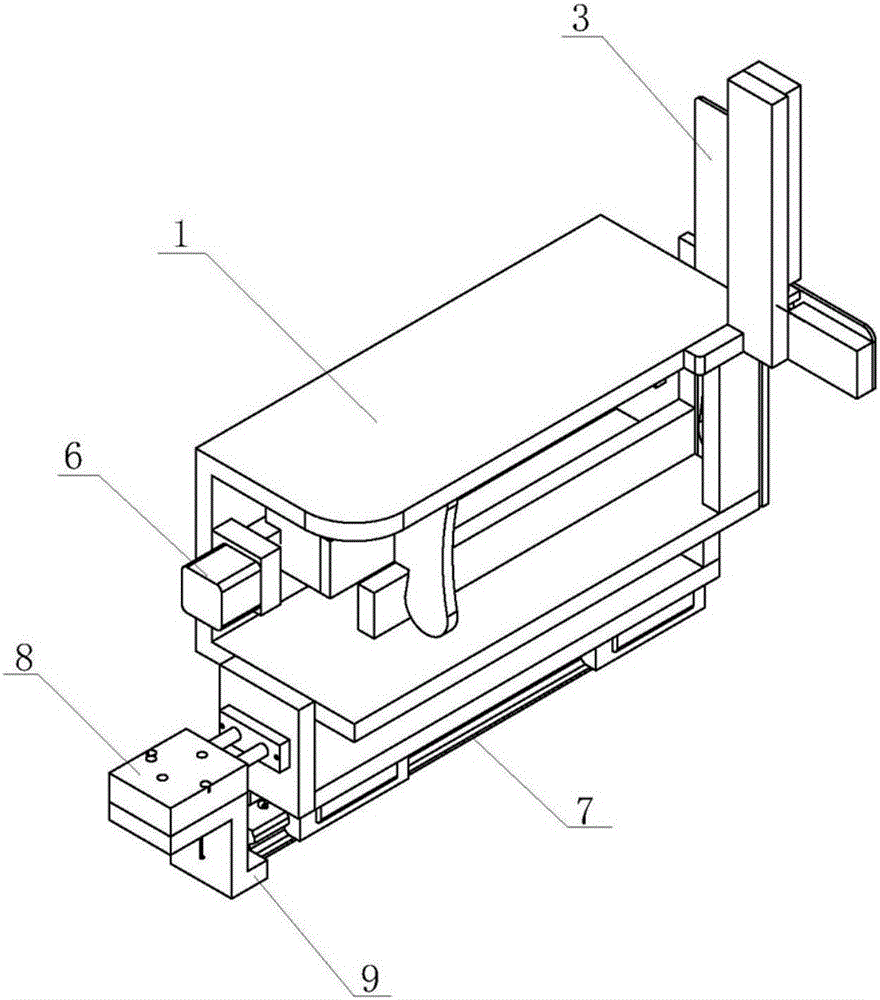

[0051] The felt separation device is symmetrically arranged on both sides of the conveying device respectively. The felt separation device includes a feeding bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com