PE film efficient blow molding production line

A production line and high-efficiency technology, applied in the field of PE film high-efficiency blow molding production line, can solve problems such as low processing efficiency, and achieve the effect of improving processing quality, not easy to wrinkle, and improving feeding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in further detail below in conjunction with the accompanying drawings.

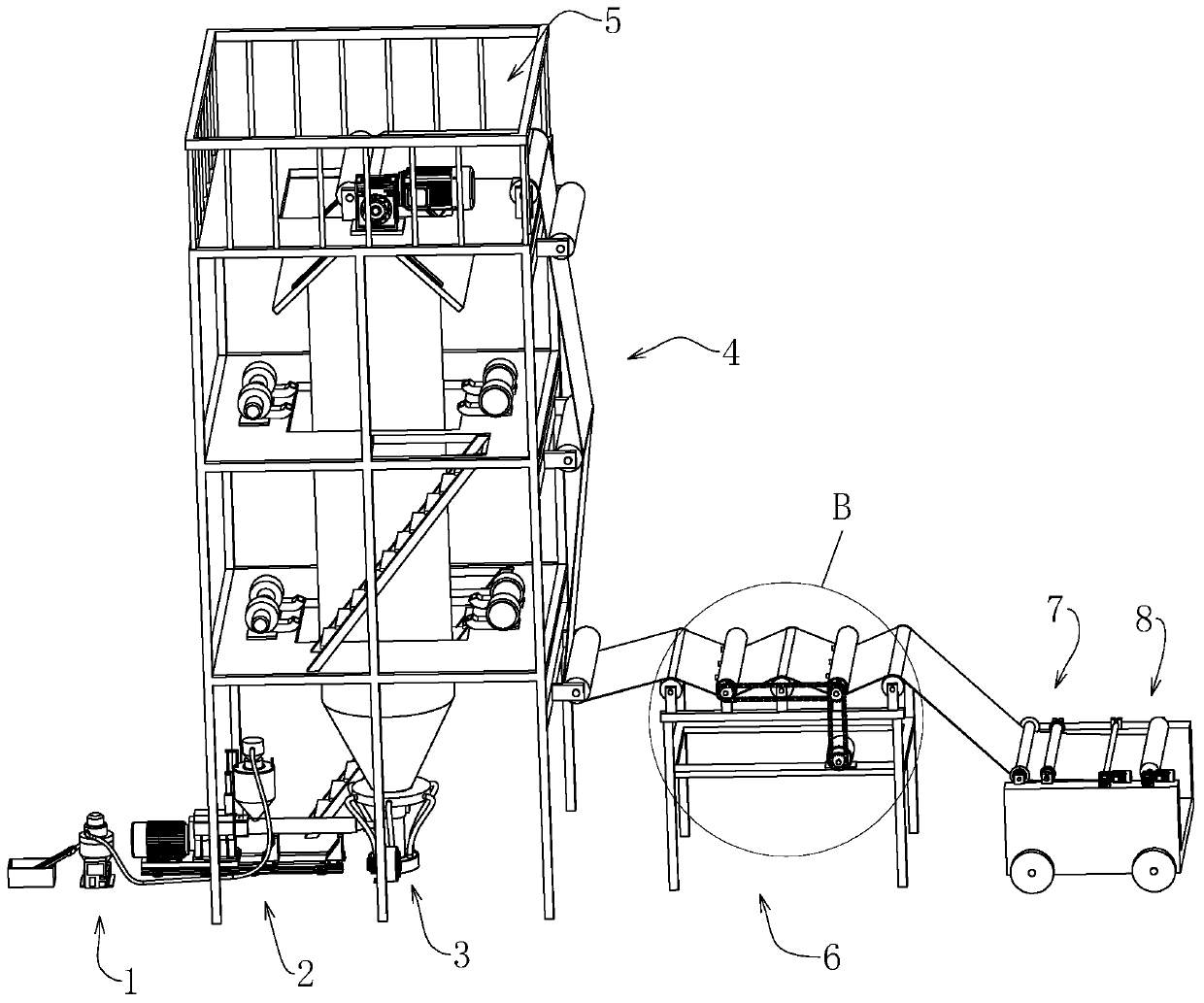

[0048] refer to figure 1 , is a PE film high-efficiency blow molding production line disclosed by the present invention, comprising a suction device 1, an extrusion device 2 is provided on one side of the suction device 1, and a blowing device is provided on the side of the extrusion device 2 away from the suction device 1. Molding device 3, a cooling device 4 is provided above the blow molding device 3, an extruding device 5 is arranged on the upper end of the cooling device 4, and a punching device 6 is provided on the side of the blow molding device 3 away from the extruding device 2, and the punching device 6 The edge trimming device 7 is provided on the side away from the blow molding device 3 , and the material receiving device 8 is provided on the side of the edge trimming device 7 away from the punching device 6 .

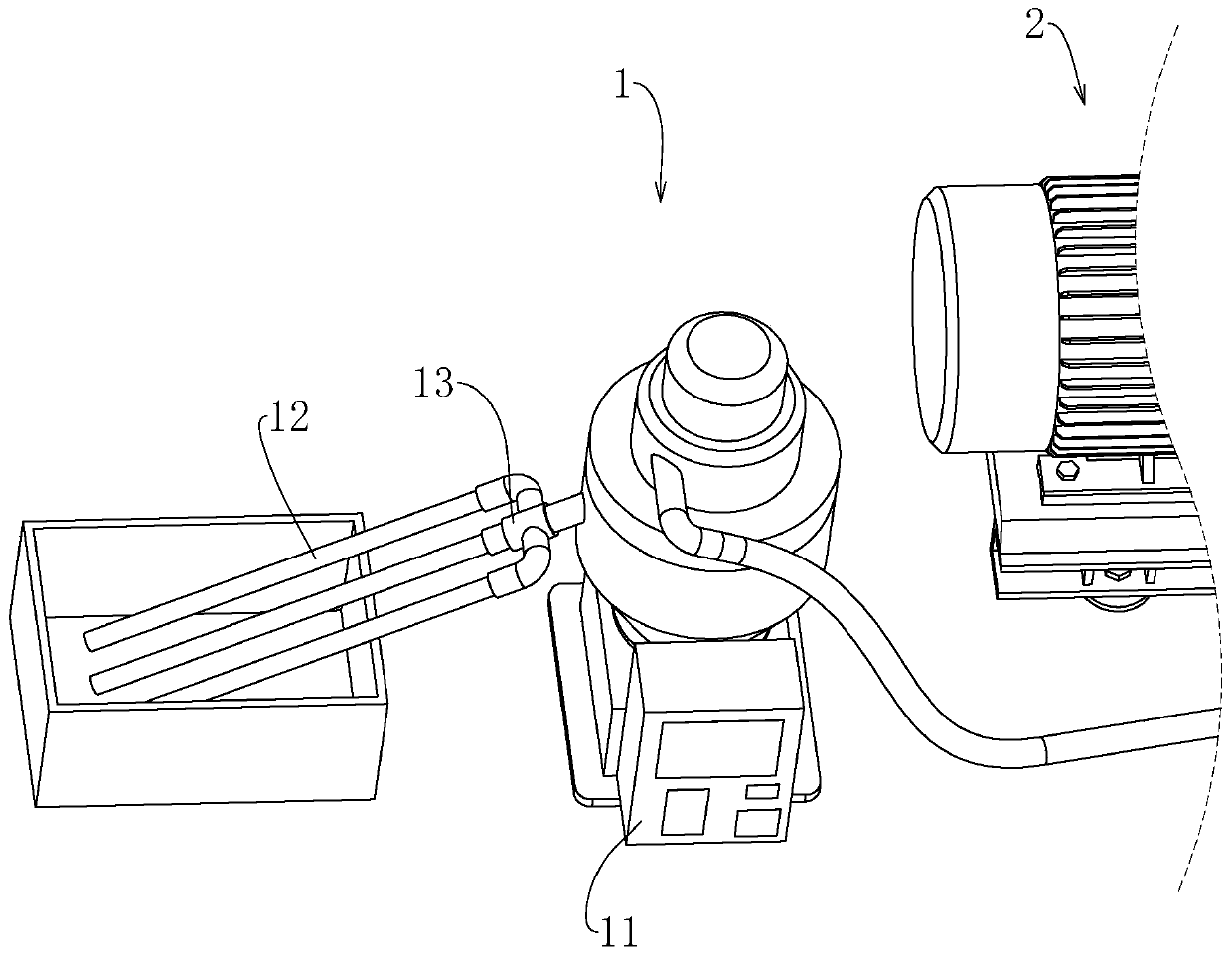

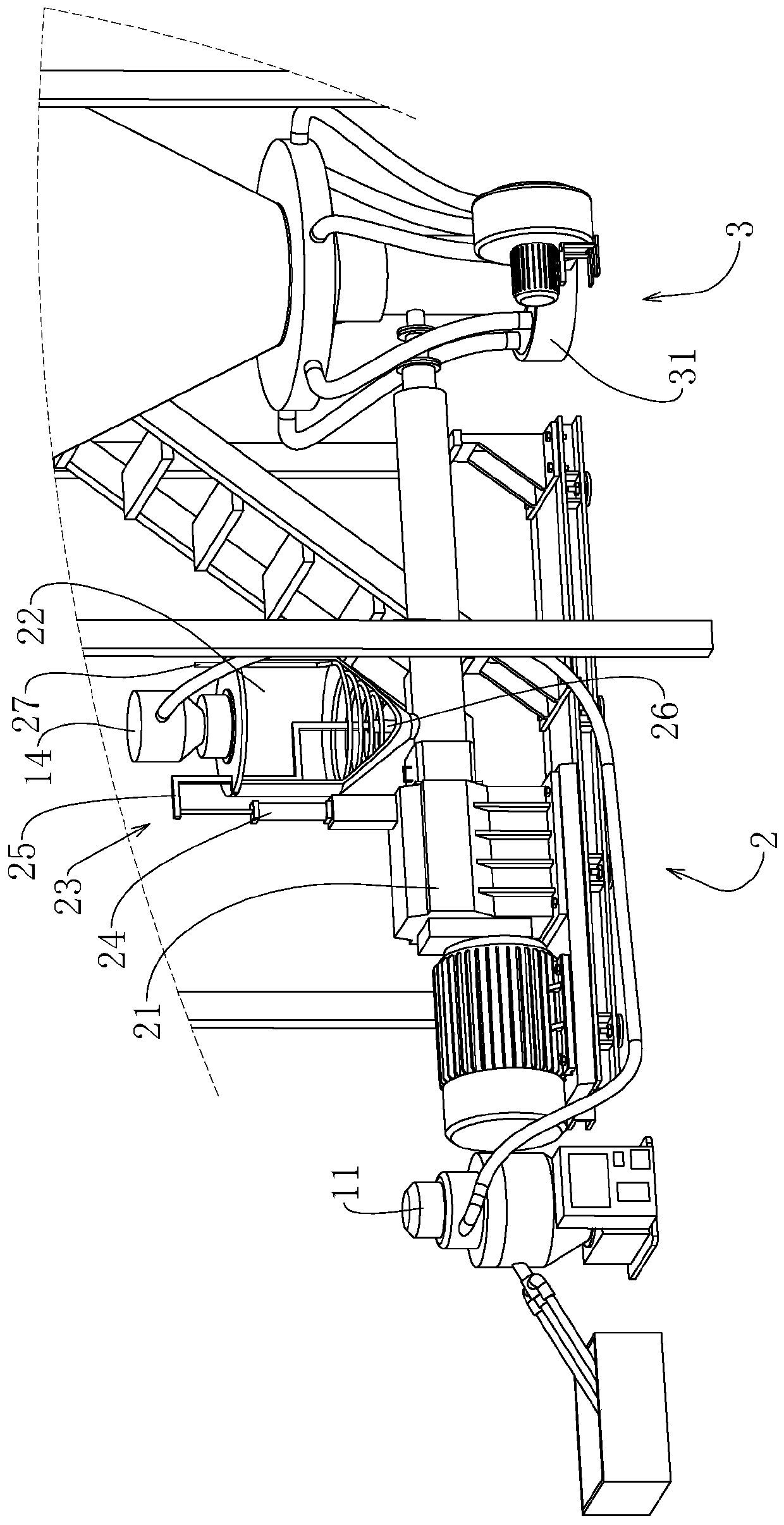

[0049] refer to figure 2 , The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com