Large-size book production method

A production method and large-size technology, applied in the production field of large-size books, can solve the problems of easy misalignment, reduce production efficiency, increase production time, etc., and achieve the effect of ensuring the quality of binding, reducing production time and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

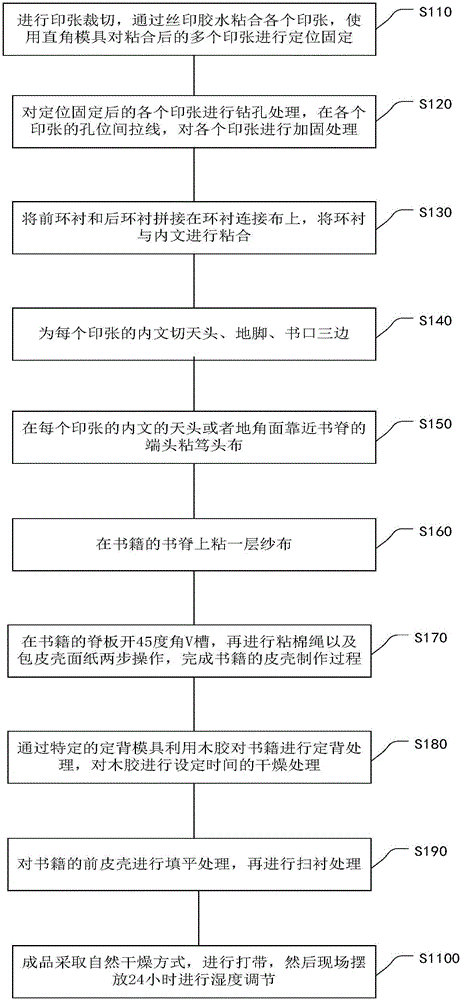

[0033] This embodiment provides a processing flow of a method for making a large-sized book such as figure 1 As shown, the following processing steps are included:

[0034] Step S110 , cutting the printed sheets, bonding each printed sheet with silk screen glue, and using a right-angle mold to position and fix the bonded multiple printed sheets.

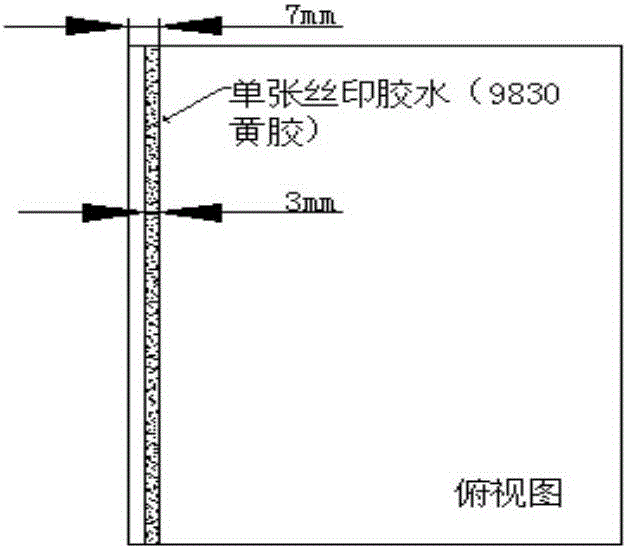

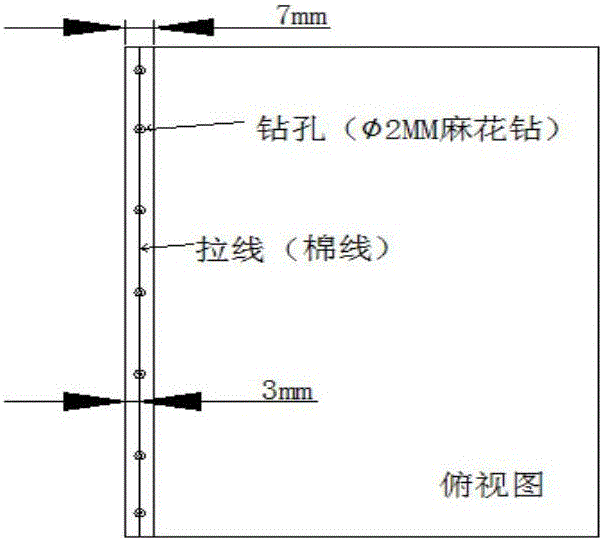

[0035] A schematic diagram of printing sheet cutting, gluing, and using a right-angle mold to position and fix printed sheets provided by the embodiment of the present invention is as follows figure 2 As shown, this step must be executed strictly in accordance with the following three aspects:

[0036] 1. Printed sheet cutting standard: After the printed sheet is cut, the size error range of each side is within ±0.05mm.

[0037] 2. Glue brushing: Use machine screen printing glue (too thick glue will cause paper deformation), the thickness of the glue is controlled within the range of 8-10μ, and each printed sheet is bonded by glue...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com