Composite-bag-surface-scratch-prevention bag making method and system

A composite bag and composite film technology, applied in the method and bag making system, the composite bag bag making method and the bag making system, the field of preventing the surface scratching of the composite bag making bag, can solve the problems such as surface scratching, and achieve the purpose of preventing the surface scratching. The effect of reducing the damage, improving the utilization rate and reducing the cost of bag making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A method for preventing scratches on the surface of a compound bag making bag, comprising the steps of:

[0041] (1) Cover a layer of non-heat-sealable protective film 14 on the outer surface of the non-heat-sealable outer film of the composite film 2;

[0042] (2) Make the protective film 14 and the composite film 2 move synchronously, and go through the bag making process of the bag making machine together to obtain a composite bag.

[0043] A bag making system based on the above method, including:

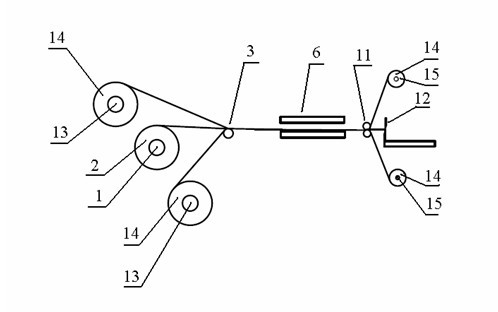

[0044] The composite film feeding mechanism 1, the first guiding mechanism 3, the heat sealing mechanism 6, the pulling roller 11 and the discharge device 12 arranged in sequence along the direction of travel of the composite film 2 are before the first guiding mechanism 3 and before the composite Protective film feeding mechanisms 13 are respectively provided above and below the film 2; in this embodiment, the first guiding mechanism 3 is provided with a guiding roller....

Embodiment 2

[0047] A method for preventing scratches on the surface of a compound bag making bag, comprising the steps of:

[0048] (1) Cover a layer of non-heat-sealable protective film 14 on the outer surface of the non-heat-sealable outer film of the composite film 2;

[0049] (2) Make the protective film 14 and the composite film 2 move synchronously, and jointly go through the bag making process of the bag making machine;

[0050] (3) Before the bag cutting step of the bag making machine, the protective film 14 is put away, and only the heat-sealed composite film 2 is cut to obtain a composite bag.

[0051] The bag making system based on the above method is as follows: figure 1 shown, including:

[0052] The composite film feeding mechanism 1, the first guiding mechanism 3, the heat sealing mechanism 6, the pulling roller 11 and the discharge device 12 arranged in sequence along the direction of travel of the composite film 2 are before the first guiding mechanism 3 and before the ...

Embodiment 3

[0055] A method for preventing scratches on the surface of a compound bag making bag, comprising the steps of:

[0056] (1) Cover a layer of non-heat-sealable protective film 14 on the outer surface of the non-heat-sealable outer film of the composite film 2;

[0057] (2) Make the protective film 14 and the composite film 2 move synchronously, and jointly go through the bag making process of the bag making machine;

[0058] (3) Before the bag cutting step of the bag making machine, the protective film 14 is put away, and only the heat-sealed composite film 2 is cut to obtain a composite bag.

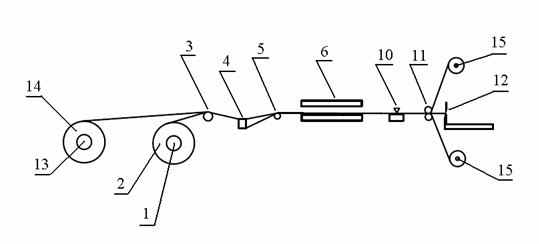

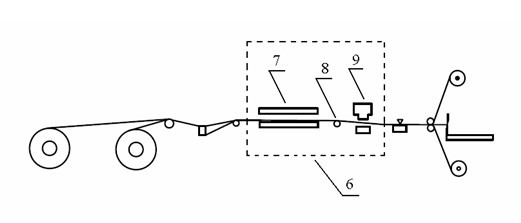

[0059] A bag making system based on the above method, including:

[0060] The composite film feeding mechanism 1, the first guide mechanism 3, the double folding mechanism 4, the heat sealing mechanism 6, the traction roller 11 and the discharge device 12 arranged in sequence along the direction of travel of the composite film 2 are arranged before the first guide mechanism 3 The pelli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com